J. Cent. South Univ. Technol. (2008) 15(s1): 406-410

DOI: 10.1007/s11771-008-389-9

Relationship between waxy crude viscosities and wax crystal microstructure

GAO Peng(高 鹏)1, 2, ZHANG Jin-jun(张劲军)1, HOU Lei(侯 磊)1, WANG Hai-feng(王海峰)1

(1. Beijing Key Laboratory of Urban Oil and Gas Distribution Technology,

China University of Petroleum (Beijing), Beijing 102249, China;

2. PetroChina Planning & Engineering Institute, Beijing 100083, China)

Abstract: It is important and profound to quantitatively study the relation between rheology and microstructure for development of the microstructural mechanism of crude oil rheology and even for the waxy crude oil pipelining. However, due to the high complexity and irregularity of wax crystal morphology, quantitative characterization is hard to achieve. This has hampered further study on the rheology—microstructure relationship. A new approach combined the fractal geometry and the stereology theory is presented for quantifying the intricate wax crystal morphology and structure. Based on the characterization, the effects of microstructures and oil composition on the waxy crude viscosities are analyzed quantitatively. It further validates the previous qualitative research and enriches understanding into the microstructural mechanism of waxy crude oil rheology.

Key words: waxy crude oil; apparent viscosity; wax crystal; morphology and structure; quantitative analysis

1 Introduction

Rheological data of waxy crude oil are critical to pipeline design and operation. Rheology of waxy crude oil relates not only to its components such as wax, resin and asphaltene, but also to the thermal and shear histories that the crude oil experienced. However, the composition, content, nature and morphology of wax in crude oils are the inherent factors that strongly impact the crude oil rheology. The wax crystal morphology and microstructure can be changed through physical or chemical methods, and thus the waxy crude rheological properties may be modified.

Many researchers[1-6] had discussed the relationship between the waxy crude apparent viscosity (viscosity for short hereinafter) and the wax crystal microstructure, or the cumulative precipitated wax amount, or the crude oil components and the composition. But because of the complex, diversifying and irregular morphology of wax crystals, these studies including the latest reports[6-8] could not characterize quantitatively and independently the wax crystal microstructures. There was also lack of reports on the relations between waxy crude viscosities and wax crystal morphology as well as oil composition.

In this study, the theory of fractal and stereology is used to independently quantify the wax crystal morphology and microstructure. On this basis, with the multiple cluster analysis and the multiple regression analysis, the effects of the wax crystal morphology and the composition of crude oils on waxy crude viscosities are quantitatively analyzed.

2 Experimental

2.1 Materials

Eight typical waxy crudes from different oilfields in China were selected as the test samples, with the labels of #1-#8. The contents of resin, asphaltene and wax in the eight oil samples are in the range of 3.19-22.27, 0.03-1.64 and 7.90-26.08 (mass fraction, %).

Viscosity measurements were conducted using a controlled-stress rheometer(HAAKE RS150H) with the coaxial cylinder test system Z41Ti equipped with a programmable thermal bath (HAAKE F8/C35). Wax crystals of the specimens were observed by a Nikon OPTIPHOT2-POL polarizing microscope, which was configured with a Linkam PE60 Peltier thermal stage in the temperature range from -20 to 90 ℃ with a control stability of ±0.1 ℃. Wax crystals were photographed with a CoolSNAP 3.3M digital CCD colour camera (Roper Scientific Inc., USA) connected to a computer.

2.2 Methods

The investigation proceeded as follows. Firstly, the oil specimen was preheated to a temperature, usually 80

℃, to completely melt all the existing wax. After keeping at this temperature for 25 min, the oil was cooled to the filling temperature at the cooling rate of 1.0 ℃/min and held isothermally for 15 min. Then the specimen was divided into two parts, one for rheological measurement and the other for optical microscopy examination.

To precisely explore the rheology—microstructure relations, the oil specimens should be sealed in a vessel and experienced the same thermal and shear history before the macro-property measurements and optical microscopy.

3 Results and discussion

3.1 Quantitative characterization of morphology and structure of wax crystals

Our previous work[9] reported the direct fractal approach based on micrograph analyses for characterizing the morphology and structure of wax crystals in crude oils. With this approach, the microstructure data can be obtained independently.

According to the viewpoint of the stereology researchers[10], the real wax crystal volume fractions and the apparent area fractions are the overall microstructure measurement parameters. The traditional stereology method, supplemented with the fractal approach, may better quantify morphology and microstructure of wax crystals in crude oils. This provides a basis for further study of the rheology-microstructure relations.

3.2 Cluster analyses of characterization parameters of microstructures of wax crystals and crude oil composition

With current test tools available,13 factors of wax crystal microstructures and oil composition affecting waxy crude oil viscosities were mainly investigated. These 13 factors are the average crude molecular mass (Mw), the average crude all-hydrocarbon carbon number (Noil), the average wax carbon number (Nwax), the asphaltene content (Ca), the resin content (Cr), the wax content (Cw), the viscous flow activation energy (Ea) and the pre-exponent factor (A) in the Arrhenius equation η0=Aexp[Ea/(RT)], the crude liquid phase viscosity (η0), the relative crude density (ρ4(t)), the real wax crystal volume fraction( ), the apparent wax crystal area fraction (F) and the average fractal dimension (Da).

), the apparent wax crystal area fraction (F) and the average fractal dimension (Da).

But it is very difficult to correlate so many factors to the crude oil viscosities. At the same time quite complex connections exist among these factors. So, a few representative variables should be filtered from the 13 factors through a mathematic statistical method for the convenience of further study.

3.2.1 Cluster analysis method

The object of cluster analysis is to sort cases (things, events, etc) into groups, or clusters, so that the degree of association is strong between members of the same cluster and weak between members of different clusters. It can be divided into two types, R-type and Q-type. The R-type cluster analysis is to classify variables and the Q-type one is to do specimens. In this study, the R-type cluster analysis is used to sort the 13 factors.

3.2.2 Results of cluster analyses

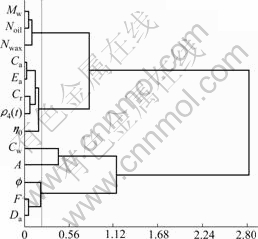

The cluster analyses that are classified with the dashed line are shown in Fig.1. According to the most strong relativities, the parameters, Mw, Noil and Nwax, are grouped as the first cluster; the other ones, η0, Ca, Ea, Cr and ρ4(t), are done as the second cluster; while Cw and A are done as the third cluster; and Da and F are done as the forth cluster; the real wax crystal volume fraction( ) is done as the fifth cluster because it is important in characterizing wax crystal microstructures of waxy crudes in stereology.

) is done as the fifth cluster because it is important in characterizing wax crystal microstructures of waxy crudes in stereology.

Fig.1 Cluster analysis spectrogram of parameters for describing wax crystal microstructures and oil composition

In consideration of the factor’s correlations and for convenience of obtaining the variable data, the average crude molecular mass, the crude liquid phase viscosity, the wax content, the average fractal dimension and the real volume fraction of wax crystals were selected from the above five clusters as representatives. In doing so, it could be achieved to characterize the features of the crude oil composition and the wax crystal microstructure with fewer parameters. It can greatly facilitate study on relationship between viscosities of crude oils and wax crystal microstructures along with the crude oil composition.

4 Correlations between crude oil viscosities and wax crystal microstructures and oil composition

For convenience of study, particularly designate the apparent viscosities at 20, 50 and 100 s-1 (η20, η50, η100), the consistency coefficient (K) and the flow behavior index (n) as the viscosity characteristic parameters.

4.1 Relations between viscosities and real wax crystal volume fraction

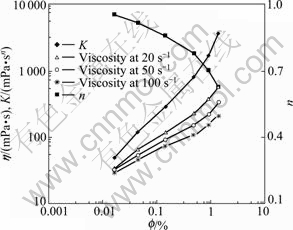

The relations between viscosities and real wax crystal volume fraction were investigated via experiments. It is found that the relations could be described approximately linearly in the double logarithmic coordinates. Taking Oil #2 as an example, the result is shown in Fig.2.

Fig.2 Relations between viscosities and real wax crystal volume fraction of Oil #2

4.2 Relations between viscosities and average wax crystal fractal dimension

The relations between viscosities and average wax crystal fractal dimension were studied via experiments. It is found that the relations could be described with the power law in double logarithmic coordinates. Taking Oil #2 as an example, the result is shown in Fig.3.

Fig.3 Relations between viscosities and average wax crystal fractal dimension of Oil #2

4.3 Relations between viscosities and oil composition

The crude oil liquid phase viscosity is the comprehensive characterization of the oil composition. The crude liquid phase viscosity—temperature relation conforms to the Arrhenius equation η0=Aexp[Ea/(RT)]. The parameter of A and Ea can be determined by experiments, and then are substituted into the Arrhenius equation for describing the crude oil liquid phase viscosity—temperature relation. In doing so, the data of the crude oil and liquid phase viscosities could be obtained. Analyses show that the relations between the crude viscosity parameters and liquid phase viscosity took on the power law by double logarithmic coordinates. Taking Oil #2 as the example, the result is shown in Fig.4.

Fig.4 Relations between viscosities and crude oil liquid phase viscosity of Oil #2

4.4 Stepwise regression analyses for relations between viscosities and wax crystal microstructure and oil composition

According to analyses of the single relations above, the expressions of the waxy crude oil viscosity— microstructure correlations are assumed as the following forms:

(1)

(1)

(2)

(2)

(3)

(3)

(4)

(4)

(5)

(5)

Take the logarithm to Eqns.(1)-(5) on both sides, and make them linearization. Then carry on the stepwise regression selection to each influencing factor at the confidence level of 95%. The effect of wax crystal volume fraction on crude viscosity had been qualitatively proved in Refs.[5-6]. According to the statistician’s viewpoints[11], to improve the goodness-of-fit of the models, directly choose  into the models firstly. As a result, at the confidence level of 95%, the variables significantly impacting on K, ln η20, ln η50, and ln η100 are lnη0, ln Da, ln Cw, ln Mw and ln

into the models firstly. As a result, at the confidence level of 95%, the variables significantly impacting on K, ln η20, ln η50, and ln η100 are lnη0, ln Da, ln Cw, ln Mw and ln in turn. The correlations are as follows:

in turn. The correlations are as follows:

(6)

(6)

(7)

(7)

(8)

(8)

(9)

(9)

For the rheological behavior index, n, at the confidence level of 95%, the variables significantly impacting on n are lnDa and lnCw in turn. The correlation is as follows:

(10)

(10)

4.5 Model test

4.5.1 Test using fitting specimen data (Oil #1-#7)

For Eqns.(6)-(10), the correlation deviation statistics are listed in Table 1. It is worth noting that this study selected 60% as relative deviation boundary point. This is mainly given to conveniently count large-deviation data points and to evaluate the results of the models. There is no other special significance.

4.5.2 Testing results using verifying sample data (Oil #8)

The forecasting performances of Eqns.(6)-(10) were verified with the sample data of Oil #8. The relative deviation results between the forecasting values of the models and the measurement values are listed in Table 2.

It can be seen from the model testing results above that the prediction values deviate from the measurement data quite largely. On one hand, for the data of Oil #7 and #8 the real wax volume fractions were substituted approximately with the real accumulated precipitated wax amounts due to lack of wax carbon distribution data; on the other hand insufficient data were one of the main reasons for the large relative deviation of the models. In following-up study, it is suggested that via this method a large number of experiments should be conducted in a targeted manner and sufficient data should be achieved in order to obtain more accurate micro-mechanism viscosity model for waxy crude oils.

5 Conclusions

Based on quantitative characterization of the morphology and microstructure of wax crystals, five representative parameters were selected from thirteen characterization variables of wax crystal microstructure and crude oil composition with the cluster analysis. Further, for temperatures below the wax appearance temperature correlations between the crude oil viscosity and the wax crystal microstructure as well as the oil composition were primarily built with use of the stepwise regression analysis. It makes better quantitative understanding of the waxy crude oil rheology— microstructure mechanism.

Table 1 Deviation statistics using fitting sample data (Oil #1-#7) for Eqns.(6)-(10)

Table 2 Deviation statistics using verifying sample data (Oil #8) for Eqns.(6)-(10)

References

[1] CAZAUX G, BARR? L, BRUCY F. Waxy crude cold start: Assessment through gel structural properties [C]// SPE 49213, SPE Annual Technical Conference and Exhibition. New Orleans, Louisiana, 1998.

[2] MAGRI N F, KALPAKCI B. Correlation of wax crystal morphology to oil type and inhibitor effectiveness by dynamic videomicroscopy and rheological data [C]// AIChE Spring Nat Mtg. Houston, 1999.

[3] XIA Hui-fang, ZHANG Jin-jun. Study on the influence of low rate shear on the low-temperature flow properties of the PPD-treated crude oil [J]. Oil & Gas Storage and Transportation, 2001, 20(2): 32-34. (in Chinese)

[4] PEDERSEN K S, R?NNINGSEN H P. Effect of precipitated wax on viscosities: A model for predicting non-newtonian viscosity of crude oils [J]. Energy & Fuels, 2000, 14: 43-51.

[5] LI Hong-ying, ZHANG Jin-jun. A generalized model for predicting non-Newtonian viscosity of waxy crudes as a function of temperature and precipitated wax [J]. Fuel, 2003, 82: 1387-1397.

[6] KAN? M, DJABOUROV M, VOLLE J L. Rheology and structure of waxy crude oils in quiescent and under shearing conditions [J]. Fuel, 2004, 83: 1591-1605.

[7] LOPES D A, SILVA J A, COUTINHO J A P. Dynamic rheological analysis of the gelation behavior of waxy crude oils [J]. Rheol Acta, 2004, 43: 433-441.

[8] VISINTIN R F G, LAPASIN R, VIGNATI E, DANRONA P, LOCKHART T P. Rheological behavior and structural interpretation of waxy crude oil gels [J]. Langmuir, 2005, 21: 6240-6249.

[9] GAO Peng, ZHANG Jin-jun. Direct image-based fractal characterization of morphology and structure of wax crystals in waxy crude oils [J]. Journal of Physics: Condensed Matter, 2006, 18: 11487-11506.

[10] RUSS J C, DEHOFF R T. Practical stereology (2nd ed) [M]. New York: Plenum Press, 1999.

[11] WU Ming-long. SPSS statistical applications of practice [M]. Beijing: China Railway Press, 2000. (in Chinese)

(Edited by YANG Bing)

Received date: 2008-06-25; Accepted date: 2008-08-05

Corresponding author: ZHANG Jin-jun, PhD; Professor; Tel: +86-10-89734627; E-mail: zhangjj@cup.edu.cn