喷射沉积连续挤压制备2A12铝合金

来源期刊:中国有色金属学报2013年第4期

论文作者:尹建成 汪创伟 周静波 刘英莉 高鹏 李明瀚 钟毅

文章页码:957 - 963

关键词:快速凝固;连续挤压;喷射沉积;难成形材料;显微组织

Key words:rapid solidification; Conform; spray forming; difficult forming materials; microstructure

摘 要:采用自制的喷射沉积连续挤压设备,完成2A12铝合金的喷射沉积连续挤压试验,获得了d 7 mm的铝合金制品,并采用光学显微镜和扫描电镜对其显微组织进行分析。结果表明:在本试验条件下,该制品由帽状的粗晶层和细晶层交替堆垛而成,粗晶层的晶粒尺寸不大于30 μm,细晶层的晶粒尺寸在10 μm以下;该制品内仅有少量尺寸在3 μm以内的孔洞,相对密度可达99.1%。

Abstract: The spray forming Conform experiment of 2A12 aluminum alloy was accomplished by self-made spray forming Conform equipment. Ultimately, the Al alloy rod with diameter of 7 mm is obtained. The microstructure of the Al alloy rod was analyzed by optical microscopy (OM) and scanning electron microscopy (SEM). The results show that the alloy rod is composed of alternately hat-like coarse-grained layer with grain size under 30 μm and fine-grained layer with grain size under 10 μm. There are a little holes with size less than 3 μm, and the relative density of the product is 99.1%.

文章编号:1004-0609(2013)04-0957-07

汪创伟,尹建成,周静波,刘英莉,高 鹏,李明瀚,钟 毅

(昆明理工大学 材料科学与工程学院,昆明 650093)

摘 要:采用自制的喷射沉积连续挤压设备,完成2A12铝合金的喷射沉积连续挤压试验,获得了d 7 mm的铝合金制品,并采用光学显微镜和扫描电镜对其显微组织进行分析。结果表明:在本试验条件下,该制品由帽状的粗晶层和细晶层交替堆垛而成,粗晶层的晶粒尺寸不大于30 μm,细晶层的晶粒尺寸在10 μm以下;该制品内仅有少量尺寸在3 μm以内的孔洞,相对密度可达99.1%。

关键词:快速凝固;连续挤压;喷射沉积;难成形材料;显微组织

中图分类号:TG 146.2 文献标志码:A

WANG Chuang-wei, YIN Jian-cheng, ZHOU Jing-bo, LIU Ying-li, GAO Peng, LI Ming-han, ZHONG Yi

(Faculty of Materials Science and Engineering, Kunming University of Science and Technology,

Kunming 650093, China)

Abstract: The spray forming Conform experiment of 2A12 aluminum alloy was accomplished by self-made spray forming Conform equipment. Ultimately, the Al alloy rod with diameter of 7 mm is obtained. The microstructure of the Al alloy rod was analyzed by optical microscopy (OM) and scanning electron microscopy (SEM). The results show that the alloy rod is composed of alternately hat-like coarse-grained layer with grain size under 30 μm and fine-grained layer with grain size under 10 μm. There are a little holes with size less than 3 μm, and the relative density of the product is 99.1%.

Key words: rapid solidification; Conform; spray forming; difficult forming materials; microstructure

基金项目:国家自然科学基金资助项目(50874055);云南省自然科学基金资助项目(2007E0013Z)

收稿日期:2011-06-18;修订日期:2013-02-22

通信作者:尹建成,副教授,博士;电话:08715157895;E-mail: yjc_2002@126.com

喷射沉积技术(Spray forming)是英国Swansea大学的SINGER教授

喷射沉积技术的不足之处在于喷射沉积坯内往往存在孔隙,孔隙率可高达15%~20%,孔隙会降低材料的力学性能如强度、塑形、弹性模量、韧性,还会降低热导率和电导率[37]。为提高材料的使用性能,需采用挤压、热轧/冷轧、热等静压、楔形压制等致密化工艺来消除或减少/减小孔隙,并辅以热处理和/或锻造来优化组织,在此过程中易形成组织粗化和织构。另外,喷射沉积技术的成材率较低,主要归因于以下几个方面:某些液滴并未喷至坯料表面,冲击至坯料表面的液滴或粉末反弹,沉积坯头尾切除及切削或机加工损失等

连续挤压技术(Conform)是英国原子能局(UKAEA)斯普林菲尔德研究所的GREEN教授在1971年提出的,该技术具有诸多优点:能耗低,可比常规挤压降低能耗30%以上;坯料不需预热,减少了工序和设备投资;可实现真正意义上的连续生产,不仅可提高劳动生产率,缩短生产周期,大幅度减少了挤压压余、切头尾等几何废料,成品率高(可达95%以上),而且大大提高了制品沿长度方向组织和性能的均匀性;设备紧凑,占地面积小

在Spray rolling技术的启发下,课题组提出将喷射沉积和连续挤压两种先进技术结合在一起的构想,形成喷射沉积连续挤压新技术(Spray forming Conform)。其工作原理如下:合金熔炼后,合金液从导流管流出,经过喷嘴时,在高速气流的作用下,雾化为小液滴并快速凝固,在流型控制器的限制下,小液滴飞向连续挤压机的挤压轮槽并沉积在轮槽内,成为连续挤压的坯料,挤压轮起沉积底托的作用。坯料随挤压轮旋转,至堵头处受阻而转入模腔,在模具作用下形成制品见图1。

图1 喷射沉积连续挤压原理图

Fig. 1 Schematic diagram of spray forming Conform: 1—Honeycomb duct![]() ; 2—Rollers for area control; 3—Variable- frequency motor; 4—Guide roller; 5—Extrusion wheel; 6—Chamber and die assembly; 7—Fixed shoe; 8—Clamping apparatus

; 2—Rollers for area control; 3—Variable- frequency motor; 4—Guide roller; 5—Extrusion wheel; 6—Chamber and die assembly; 7—Fixed shoe; 8—Clamping apparatus

Spray forming Conform技术除具有喷射沉积和连续挤压两种先进技术的优点之外,还有以下优点:一是制品致密度高,形成制品前喷射沉积坯需依次经历压实轮的轧制,连续挤压机挤压轮轮槽与模腔表面构成的“挤压筒”内的剧烈剪切,堵头处的镦粗,从挤压轮轮槽转90°进入进料孔时的类似ECAP过程,模腔内的高静水压力(可达800~1 000 MPa),上述过程均有利于孔隙的闭合。二是组织及析出相更加均匀、细小,主要归因于以下几个方面:1) 水冷挤压轮轮槽内的沉积坯可以很薄,不仅进一步提高了冷却速率,细化晶粒,而且坯料整个横截面内各处的冷却速度差异较小,晶粒尺寸更均匀一致;2) 沉积坯内的显微组织在挤压轮轮槽内、转入进料孔时、以及在模腔内都将受到剧烈的剪切破碎,可进一步细化晶粒,使合金元素分布更均匀;3) 在挤压过程中,坯料呈半固态,其中的液相在随后凝固时类似于Castex,其凝固组织有望呈蔷薇状甚至球状。另外,固体颗粒(过喷粉末)的混入可增加形核位置,利于晶粒细化。三是成材率高,过喷粉末可在流型控制器作用下流入挤压轮轮槽成为制品,且压余、切头尾等几何废料很少。四是生产效率高,若合金液连续供给,则制品可连续生产。

Spray forming Conform技术本质上是将含有快速凝固组织的半固态浆料作为连续挤压的坯料,改变坯料中的固相分数便可调整坯料的变形抗力,故该技术可望覆盖现有连续挤压制品的所有规格,即截面 积≤13 000 mm2、宽度≤320 mm的管棒型线

Spray forming Conform技术的瓶颈在于喷射沉积区域较宽,而挤压轮槽较窄,实现二者的有效结合比较困难。课题组在控制喷射沉积坯的形状方面开展了较多工作。研究结果表明,在使用自行研制的流型控制器时,若选用合适的喷嘴和导流管,当过热度、雾化气体压力等参数选择恰当时,可获得较理想的细窄条状沉积坯[56]。

在上述研究的基础上课题组组建了喷射沉积连续挤压设备,本文作者首次采用该设备对2A12铝合金进行了喷射沉积连续挤压试验,获得了该铝合金的喷射沉积连续挤压制品,并对该制品进行了显微组织分析。

1 实验

试验用原料为2A12铝合金,其名义成分为Al-4.3Cu-1.5Mg(质量分数,%)。喷射沉积连续挤压设备是在JL350型连续挤压机上改造而成的,见图2。该设备主要包括熔炼部分、雾化部分和连续挤压3部分。熔炼部分是由SSF-60-H超音频感应加热设备改造而成的感应加热炉,其最大功率为60 kW,坩埚容铝量为6 kg;雾化部分主要包括四向塞式喷嘴,内孔尺寸为2 mm×10 mm的方形导流管和流型控制器

图2 喷射沉积连续挤压设备

Fig. 2 Equipment of spray forming Conform

参考课题组前期的研究结果,制定本文的工艺参数,具体数据列于表1。

表1 2A12铝合金喷射沉积连续挤压参数

Table 1 Process parameters of spray forming Conform of 2A12 aluminum alloy

将铝合金制品分别沿纵截面和横截面剖开,研磨抛光后用2 mL HCl+3 mL HNO3+5 mL HF+ 190 mL水溶液侵蚀,在XJP-6A显微镜下观察其显微组织。采用XL30-ESEM-TMP环境扫描电镜对金相试样表面进行观察,并对样品内的质点进行了能谱分析。密度测试采用排水法测量。

2 结果与讨论

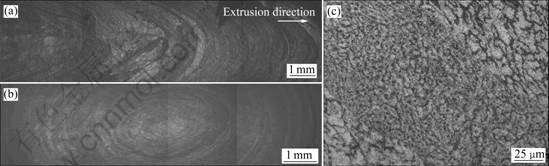

图3所示为喷射沉积连续挤压态2A12铝合金的显微组织。由图3(a)可见,喷射沉积连续挤压态2A12铝合金内组织沿轴向呈明暗相间的抛物线形条带状分布,抛物线顶点约在制品轴心处,顶点朝向挤出方向。

图3 喷射沉积连续挤压态2A12铝合金的显微组织

Fig. 3 Microstructures of as-spray forming Conform 2A12 Al alloy: (a) Longitudinal section; (b) Cross section; (c) Junction of light stripe and dark stripe

在制品横截面内有类似树木年轮状的图案,即由许多明暗相间的圆环构成,这些环的中心基本与制品的轴心重合,见图3(b)。较亮条带内的晶粒尺寸稍大,约20~30 μm,称之为粗晶层,较暗条带内的晶粒尺寸在10 μm以内,称其为细晶层,见图3(c)。此外,在光学显微镜下,样品内并未观察到孔隙。

由图1可知,在喷射沉积过程中,若挤压轮匀速旋转,则在挤压轮槽内可形成厚度较为均匀的带状沉积坯,本文实验条件下,带状沉积坯厚约2~3 mm。带状沉积坯随挤压轮槽旋转,至堵头处受阻,停留在堵头前方,随后的沉积坯同样也被塞在堵头前方。如此,堵头前的坯料便越来越厚。当沉积坯累积至足够厚度,坯料便可填满堵头前的轮槽(即连续挤压的“挤压筒”)。在后续坯料的推动下,堵头前方的坯料开始变形,坯料内的应力水平逐渐升高,轮槽侧壁对该部分坯料的摩擦力不断增大。当摩擦力达到一定程度后,堵头前方的坯料开始转入进料孔,继而在模具的作用下形成制品。在流动通道侧壁摩擦力的作用下,靠外侧的金属流动较慢,而中心区域流速较快,于是,原为近似平板的带状坯料便成了“帽状”。

粗细晶区的交替出现应与带状沉积坯横截面内的冷却速度不同有关。挤压轮温度较低,先沉积的坯料部分(即靠挤压轮槽底的部分)冷速很快,晶粒细小;随厚度的增加,随后沉积的坯料的沉积底托(即已沉积的坯料)的温度越来越高,冷却速度越来越慢,晶粒尺寸也越来越大。因此,带状坯料的晶粒尺寸在厚度方向由上而下逐渐减小。由于制品是由多层带状坯料叠加而成,故在两层层状坯料接触面处便出现了由细晶向粗晶的突变。本文作者选取的挤压轮转速较小,若将其提高一倍,则在同样的试验条件下,挤压轮槽内的喷射沉积带状坯料的厚度可减为原来的一半,带状坯料在厚度方向上的晶粒尺寸将会趋于一致,条带状图案或将消失。

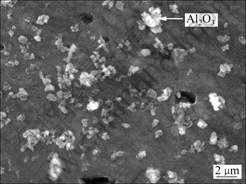

在扫描电镜下,可看到样品内有很多细小弥散的第二相质点,尺寸在2 μm以下,且分布均匀,见图4。能谱分析结果表明,质点中的主要元素为Al和O,应为Al2O3。本文试验的目的主要在于探索喷射沉积连续挤压技术的可行性,喷射沉积阶段并未采用惰性气氛保护,故氧化比较严重。然而值得注意的是氧化铝呈细小的近球状,弥散分布,其对高强铝合金的力学性能有何影响还有待检测。

由图4还可看出,在放大倍数较大时,样品内仍可观察到有孔隙存在,但其尺寸很小,最大孔隙也不超过3 μm,制品平均相对密度为99.1%。陈振华教授[22-23]采用楔形压制分别对喷射沉积耐热铝合金Al-Fe-V-Si和7075铝合金进行了致密化处理,当变形程度分别为50.4%和60%时,相对密度可达到99.3%和99.6%。可见,喷射沉积连续挤压态的铝合金与经致密化处理的喷射沉积材料的致密度相当,这将大大缩短高合金材料的加工流程。

MCHUGH等

图4 制品的SEM像

Fig. 4 SEM image of product

3 结论

1) 喷射沉积连续挤压技术是将喷射沉积和连续挤压两种先进技术进行有机结合后形成的一种快速凝固体材料连续成形新技术。在自行研制的喷射沉积连续挤压设备上,实现了2A12铝合金的喷射沉积连续挤压,获得相对密度高达99.1%的铝合金制品,与经致密化处理后的喷射沉积材料的相对密度相当。

2) 喷射沉积连续挤压制品由一层层“帽状”的粗晶层和细晶层交替堆垛而成,“帽顶”方向与挤出方向一致,其晶粒尺寸介于10~30 μm之间。

REFERENCES

[1] SINGER A R E. The principles of spray rolling of metals

[2] GRANT P S. Spray forming

[3] 马 力, 陈 伟, 翟 景, 郭安振, 秦占民. 喷射沉积铝合金材料研究现状与发展趋势

MA Li, CHEN Wei, ZHAI Jing, GUO An-zhen, QIN Zhan-min. Research status and development trend of spray-forming high property Al-alloys material[J]. Ordnance Material Science and Engineering, 2009, 32(2): 120-124.

[4] ZHANG G, LI Z, ZHANG Y, MI J, GRANT P S. Modeling the deposition dynamics of a twin-atomizer spray forming system[J]. Metallurgical and Materials Transactions B, 2010, 41(2): 303-307.

[5] MI J, GRANT P S. Modelling the shape and thermal dynamics of Ni superalloy rings during spray forming Part 1: Shape modeling—Droplet deposition, splashing and redeposition[J]. Acta Materialia, 2008, 56(7): 1588-1596.

[6] MI J, GRANT P S. Modelling the shape and thermal dynamics of Ni superalloy rings during spray forming. Part 2: Thermal modeling—Heat flow and solidification[J]. Acta Materialia, 2008, 56(7): 1597-1608.

[7] MI J, GRANT P S, FRITSCHING U, BELKESSAM O, GARMENDIA I, LANDABEREA A. Multiphysics modelling of the spray forming process[J]. Materials Science and Engineering A, 2008, 477(1/2): 2-8.

[8] GRANT P S. Solidification in spray forming[J]. Metallurgical and Materials Transactions A, 2007, 38(7): 1520-1529.

[9] HOGG S C, PALMER I G, THOMAS L G, GRANT P S. Processing, microstructure and property aspects of a spraycast Al-Mg-Li-Zr alloy[J]. Acta Materialia, 2007, 55(6): 1885-1894.

[10] XU C, FURUKAWA M, HORITA Z J, LANGDON T G. Using ECAP to achieve grain refinement, precipitate fragmentation and high strain rate superplasticity in a spray-cast aluminum alloy[J]. Acta Materialia, 2003, 51: 6139-6149.

[11] XU C, FURUKAWA M, HORITA Z J, LANGDON T G. Influence of ECAP on precipitate distributions in a spray-cast aluminum alloy[J]. Acta Materialia, 2005, 53(3): 749-758.

[12] MARCO J S, GAO N, FURUKAWA M, HORITA Z J, XU C, LANGDON T G. Microstructural developments in a spray-cast Al-7034 alloy processed by equal-channel angular pressing[J]. Reviews on Advanced Materials Science, 2004, 7: 1-12.

[13] GAO N, STARINK M J, FURUKAWA M, HORITA Z J, XU C, LANGDON T G. Microstructural evolution in a spray-cast aluminum alloy during equal-channel angular pressing

[14] ZHANG Y Y, ZHANG, J S. Recrystallization in the particles interfacial region of the cold-sprayed aluminum coating: Strain-induced boundary migration[J]. Materials Letters, 2011, 65(12): 1856-1858.

[15] HOU L G, CUI C, ZHANG J S. Optimizing microstructures of hypereutectic Al-Si alloys with high Fe content via spray forming technique[J]. Materials Science and Engineering A, 2010, 527(23): 6400-6412.

[16] HUANG H J, CAI Y H, CUI H, HUANG J F, HE J P, ZHANG J S. Influence of Mn addition on microstructure and phase formation of spray-deposited Al-25Si-xFe-yMn alloy[J]. Materials Science and Engineering A, 2009, 502(1/2): 118-125.

[17] CAI Yuan-hua, LIANG Rui-guang, SU Zhan-pei, ZHANG Ji-shan. Microstructure of spray formed A1-Zn-Mg-Cu alloy with Mn addition[J]. Transactions of Nonferrous Metals Society of China, 2011, 21(1): 9-14.

[18] LI W, CHEN Z H, CHEN D, TENG J, FAN C. Low-cycle fatigue behavior of SiCp/Al-Si composites produced by spray deposition

[19] CHEN Z H, FAN C H, CHEN Z G, LI W, CHEN D. Densification of large-size spray- deposited Al-Mg alloy square preforms via a novel wedge pressing technology[J]. Materials Science and Engineering A, 2009, 506: 152-156.

[20] CHEN Z H, HE Y Q, YAN H G, CHEN Z G, YIN X J, CHEN G. Ambient temperature mechanical properties of Al-8.5Fe-1.3V- 1.7Si/SiCp composite[J]. Materials Science and Engineering A, 2007, 460/461: 180-185.

[21] ZHOU Tao, CHEN Ding, CHEN Zhen-hua. Microstructures and properties of rapidly solidified Mg-Zn-Ca alloys[J]. Transactions of Nonferrous Metals Society of China, 2008, 18(S1): s101-s106.

[22] 陈振华, 陈志钢, 陈 鼎, 贺毅强, 陈 刚. 大尺寸喷射沉积耐热铝合金管坯楔压致密化与力学性能

CHEN Zhen-hua, CHEN Zhi-gang, CHEN Ding, HE Yi-qiang, CHEN Gang. Densification and mechanical properties of spray deposited large scale heat-resistant aluminum alloy tubular performs during wedge pressing[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(8): 1383-1388.

[23] 何武强, 陈振华, 范才河, 王灿让, 陈 鼎. 大尺寸喷射沉积7075铝合金楔压致密化工艺

HE Wu-qiang, CHEN Zhen-hua, FAN Cai-he, WANG Can-rang, CHEN Ding. Densification technology of heavy gauge spray-deposited 7075 aluminum alloy in wedge pressing[J]. Journal of Plasticity Engineering, 2010, 17(5): 66-70.

[24] NING Z L, GUO S, CAO F Y, WANG G J, LI Z C, SUN J F. Microstructural evolution during extrusion and ECAP of a spray- deposited Al-Zn-Mg-Cu-Sc-Zr alloy[J]. Journal of Materials Science, 2010, 45: 3023-3029.

[25] 康福伟, 孙剑飞, 曹福洋, 李 周, 张国庆. 一种新型喷射成形高温合金热变形机制

KANG Fu-wei, SUN Jian-fei, CAO Fu-yang, LI Zhou, ZHANG Guo-qing. Hot deformation mechanisms of a new spray formed superalloy[J]. Rare Metal Materials and Engineering, 2010, 39(7): 1210-1214.

[26] 康福伟, 孙剑飞, 张国庆, 李 周, 沈 军. 喷射成形镍基高温合金热变形特性及微观组织变化

KANG Fu-wei, SUN Jian-fei, ZHANG Guo-qing, LI Zhou, SHEN Jun. Characteristics of hot compression deformation and microstructure evolution of spray formed nickel base superalloy

[27] CUI C S, FRITSCHING U, SCHULZ A, LI Q C. Mathematical modeling of spray forming process of tubular preforms part 2. heat transfer[J]. Acta Materialia, 2005, 53: 2775-2784.

[28] 马万太, 宋红媛, 张 豪, 张 捷. 往复式喷射成形管坯沉积特性及运动参数优化

MA Wan-tai, SONG Hong-yuan, ZHANG Hao, ZHANG Jie. Deposition behavior and movement parameters optimization for reciprocating spray forming tubular[J]. The Chinese Journal of Nonferrous Metals, 2007, 17(6): 878-884.

[29] 李振亮, 谢建新, 陈 伟, 翟 景, 任慧平, 王玉峰. 固溶处理对喷射沉积含镍高强Al-Zn-Mg-Cu合金组织和性能的影响

LI Zhen-1iang, XIE Jian-xin, CHEN Wei, ZHAI Jing, REN Hui-ping, WANG Yu-feng. Effects of solid-solution on microstructure and property of high strength spray deposited Al-Zn-Mg-Cu alloy modified by Ni[J]. The Chinese Journal of Nonferrous Metals, 2009, 19(12): 2099-2105.

[30] 李振亮, 陈 伟, 翟 景, 任慧平, 王玉峰. 喷射沉积含锆镍超高强铝合金的组织与性能研究

LI Zhen-liang, CHEN Wei, ZHAI Jing, REN Hui-ping, WANG Yu-feng. Property and structure of ultra-high strength spray deposited A1-Zn-Mg-Cu alloy modified by Ni and Zr[J]. Ordnance Material Science and Engineering, 2009, 32(3): 41-44.

[31] 张 勇, 张国庆, 李 周, 袁 华, 许文勇, 刘 娜, 高正江. 喷射成形高速钢内部组织研究

ZHANG Yong, ZHANG Guo-qing, LI Zhou, YUAN Hua, XU Wen-yong, LIU Na, GAO Zheng-jiang. Research on microstructure of high speed steel prepared by spray forming[J]. Journal of Aeronautical Materials, 2010, 30(5): 19-24.

[32] 史海生, 颜 飞, 樊俊飞, 乐海荣, 金冰忠, 彭 勇. 喷射成形技术在高合金工模具钢中的应用

SHI Hai-sheng, YAN Fei, FAN Jun-fei, LE Hai-rong, JIN Bing-zhong, PENG Yong. Application of spray forming technique in high alloy tool and mould steel[J]. Materials Science and Engineering of Powder Metallurgy, 2008, 13(3): 165-170.

[33] 左玉婷, 王 锋, 熊柏青, 张永安, 朱宝宏, 刘红伟, 李志辉. 喷射成形Al-9.97Zn-2.65Mg-1.94Cu-0.12%Zr合金均匀化过程中的组织演变

ZUO Yu-ting, WANG Feng, XIONG Bai-qing, ZHANG Yong-an, ZHU Bao-hong, LIU Hong-wei, LI Zhi-hui. Microstructural evolution of spray formed Al-9.97Zn-2.65Mg-1.94Cu- 0.12%Zr alloy during homogenization[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(5): 820-826.

[34] 王 锋, 熊柏青, 张永安, 朱宝宏, 刘红伟, 何小青. 双级时效处理对喷射沉积Al-Zn-Mg-Cu合金微观组织和力学性能的影响

WANG Feng, XIONG Bai-qing, ZHANG Yong-an, ZHU Bao-hong, LIU Hong-wei, HE Xiao-qing. Effect of two-step aging treatment on microstructure and mechanical properties of spray-deposited Al-10.8Zn-2.8Mg-1.9Cu alloy[J]. The Chinese Journal of Nonferrous Metals, 2007, 17(7): 1058-1062.

[35] LIU Dong-ming, ZHAO Jiu-zhou, LI Mu-sen. Modeling and experimental verification of tubular product formation during spray forming[J]. Transactions of Nonferrous Metals Society of China, 2009, 19: 661-667.

[36] XIANG Jin-zong, ZHANG Yin, FAN Wen-jun, WANG Ping, HE You-duo. Spray deposition behavior and numerical simulation of growth of tubular preform in spray forming process[J]. Journal of Iron and Steel Research, International, 2012, 19(2): 28-35.

[37] MCHUGH K M, UHLENWINKEL V, ELLENDT N. Density of spray-formed materials[C]// LAWCOCK R, LAWLEY A, MCGEEHAN P. Proceedings of the 2008 World Congress on Powder Metallurgy & Particulate Materials. Washington DC: Metal Powder Industries Federation, 2008: 51-65.

[38] YAO J L, MCHUGH K M, ZHOU Y Z, LAVERNIA E J. The selection of the spray deposition rate during the spray rolling process

[39] YAO J L, MCHUGH K M, ZHOU Y Z, LAVERNIA E J. The transient to steady-state transition during the spray-rolling process

[40] LI F X, LIU Y Z, LUO X. Numerical simulation of deposit shape evolution during the spray-rolling process

[41] 李凤仙, 刘允中, 刘尉俊. 喷射轧制技术的研究进展

LI Feng-xian, LIU Yun-zhong, LIU Wei-jun. Development of the technique of spray rolling

[42] 谢建新. 材料加工新技术与新工艺

XIE Jian-xin. Advanced processing technology of materials[M]. Beijing: Metallurgical Industry Press, 2006: 197-198.

[43] VENKATESWARLU K, GHOSH M, RAY A K, XU C, LANGDON T G. On the feasibility of using a continuous processing technique incorporating a limited strain imposed by ECAP

[44] XU C, SCHROEDER S, BERBON P B, LANGDON T G. Principles of ECAP–Conform as a continuous process for achieving grain refinement: Application to an aluminum alloy

[45] RAAB G J, VALIEV R Z, LOWE T C, ZHU Y T. Continuous processing of ultrafine grained Al by ECAP–Conform[J]. Materials Science and Engineering A, 2004, 382(1/2): 30-34.

[46] 周天国, 温景林, 陈彦博, 李英龙, 王顺成. 挤压比对6201铝合金半固态连续挤压成形组织和性能的影响

ZHOU Tian-guo, WEN Jing-lin, CHEN Yan-bo, LI Ying-long, WANG Shun-cheng. Effect of extrusion ratio on microstructures and properties of 6201 alloy wire produced by semisolid continuous extrusion[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(10): 1683-1688.

[47] 周天国, 温景林, 陈彦博. 连续半固态成形6201合金线材的组织和性能

ZHOU Tian-guo, WEN Jing-lin, CHEN Yan-bo. Microstructures and properties of 6201 alloy wires manufactured by continuous semisolid forming[J]. Chinese Journal of Materials Research, 2005, 19(3): 331-336.

[48] 管仁国, 赵占勇, 陈礼清, 王付兴. AZ31镁合金型材连续流变挤压成形过程的数值模拟

GUAN Ren-guo, ZHAO Zhan-yong, CHEN Li-qing, WANG Fu-xing. Numerical simulation of continuous rheo-extrusion process of AZ31 alloy[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(5): 923-929.

[49] 陈广霞, 彭大暑, 左铁镛, 肖景容. Conform连续挤压理论分析中的逐次单元法

CHEN Guang-xia, PENG Da-shu, ZUO Tie-yong, XIAO Jing-rong. The progressive element method of the Conform continuous extrusion[J]. Journal of Mechanical Strength, 1994, 16(1): 20-23.

[50] 储灿东, 彭颖红, 阮雪榆. 连续挤压成形过程的计算机仿真

CHU Can-dong, PENG Ying-hong, RUAN Xue-yu. Computer simulation of continuous extrusion forming process

[51] 储灿东, 彭颖红, 阮雪榆. 连续挤压成形过程仿真中的摩擦模型

CHU Can-dong, PENG Ying-hong, RUAN Xue-yu. Frictional model in computer simulation of continuous extrusion forming process[J]. Journal of Shanghai Jiaotong University, 2001, 35(7): 993-997.

[52] 隋 贤, 宋宝韫, 李 冰, 运新兵, 高 飞. H65黄铜合金连续挤压过程中的组织和性能演变特征

SUI Xian, SONG Bao-yun, LI Bing, YUN Xin-bing, GAO Fei. Characteristic of microstructure and properties evolution of H65 brass alloy during continuous extrusion process[J]. The Chinese Journal of Nonferrous Metals, 2009, 19(6): 1049-1054.

[53] 宋宝韫, 宋娜娜, 陈 莉. 宽铜母线连续挤压扩展成形挤压力的分析

SONG Bao-yun, SONG Na-na, CHEN Li. Analysis of continuous extrusion extending forming force for wide copper bus-bar[J]. Journal of Plasticity Engineering, 2011, 18(4): 6-10.

[54] 钟 毅. 连续挤压技术及其应用

ZHONG Yi. Continuous extrusion technology and its application[M]. Beijing: Metallurgical Industry Press, 2004: 25-26.

[55] HE Y L, GAO F, SONG B Y, FU R, WU G M, LI J, JIANG L. Grain refinement of magnesium alloys by CONFORM: A continuous severe plastic deformation route?

[56] 周静波. 喷射沉积连续挤压设备研发及实验研究

ZHOU Jing-bo. R & D and experimental study of spray deposition continuous extrusion equipment[D]. Kunming: Kunming University of Science and Technology, 2012: 17-34.