文章编号:1004-0609(2011)09-2163-05

Cu/Mo/Cu轧制复合界面的结合特性

张 兵1, 王快社1, 孙院军2, 王 莎3

(1. 西安建筑科技大学 冶金工程学院,西安710055;

2. 金堆城钼业股份有限公司,西安 710077;3. 西部金属材料股份有限公司,西安 710065)

摘 要:采用轧制方法制备Cu/Mo/Cu复合材料,利用金相显微镜、扫描电镜和电子拉伸机等研究Cu/Mo/Cu复合材料的界面结构、断裂特点和工艺参数对结合强度的影响。结果表明:轧制前经(750 ℃,8 min)热处理,道次变形量为55%,复合材料的界面结合紧密,最大剪切强度为77 MPa;钼层金属显微组织呈扁平纤维状,组织较为均匀,铜层金属的晶粒呈等轴状,由界面至表面晶粒逐渐增大,且分布很不均匀;复合机制为典型的裂口结合和机械啮合。

关键词:Cu/Mo/Cu复合材料;轧制;复合界面;结合特性

中图分类号:TG146.2 文献标志码:A

Bonding property of Cu/Mo/Cu cladding metal materials by hot rolling

ZHANG Bing1, WANG Kuai-she1, SUN Yuan-jun2, WANG Sha3

(1. College of Metallurgy Engineering, Xi’an University of Architecture & Technology, Xi’an 710055, China;

2. Jinduicheng Molybdenum Co., Ltd., Xi’an 710077, China;

3. Western Metal Materials Co., Ltd., Xi’an 710065, China)

Abstract: The Cu/Mo/Cu cladding metal materials were made by hot rolling. The interface structure, fracture characteristic and the effect of rolling process parameters on bond strength were studied by optical microscope, scanning electron microscope and electron-tensile tester. The results show that the bonding interface of composite materials is tight when deformation rate is 55% for a pass with heat-treatment at 750 ℃ for 8 min, the maximum value of shearing strength is 77 MPa. The micro-structure of Mo layer is compressed fibrous and uniform distribution. The micro-structure of Cu layer is isometric crystal. The grain size is increased from the interface to the surface, and unevenly distributed. The mechanism of bonding is typically split bonding and mechanical interlocking.

Key words:Cu/Mo/Cu cladding metal material; rolling; cladding interface; bonding property

Cu/Mo/Cu复合材料(CMC)主要应用在电子封装领域。铜具有高的导电和导热性能,钼具有低的热膨胀系数、高温强度等优点,因此,利用两者优异性能制备的复合材料具有高导电导热、可调的热膨胀系数和较好的高温性能等优点,备受电子工程师的青 睐[1-4]。特别是随着电子技术的高速发展,半导体集成电路的密度越来越高,体积愈来愈小,使电子封装技术向着高密度、大功率、小型化、高性能、高可靠性方向发展,该复合材料在HB-LED、多芯片组基板材料、热沉散热、雷达、航空航天等领域有着广泛的应用前景[5-6]。

目前,国内外生产Cu/Mo/Cu复合材料的方法主要有轧制、爆炸焊接与爆炸焊接+轧制组合法等[7-13]。相对而言,轧制方法具有成本低、效率高、设备少等优点,是一种极具潜力的大规模生产Cu/Mo/Cu复合材料的制备加工方法[8, 11]。轧制复合的关键是材料间的界面结合特性。由于Cu和Mo的物理和加工性能差异较大,且在固态互不相溶,在制备过程中既要保证复合界面有牢固的结合,又要保证钼板不开裂,因此,这一直是研究的难点[14-15]。本文作者研究在轧制条件下Cu和Mo的界面结合特性,分析Cu/Mo/Cu复合材料的断裂特点和界面结合的内在机理。

1 实验

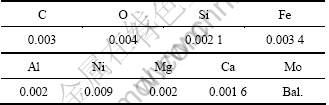

试验材料如下: Mo-1钼板,规格为125 mm×155 mm×3.0 mm; T2铜板,规格为150 mm×200 mm×3.0 mm。两者化学成分如表1和2所列。

表1 Mo-1钼板的化学成分

Table 1 Chemical compositions of molybdenum sheet Mo-1 (mass fraction, %)

表2 T2铜板化学成分

Table 2 Chemical compositions of copper sheet T2 (mass fraction, %)

试验方法如下:将经过完全退火、表面打磨处理和清洗后的Mo板和Cu板叠合在一起,用铆钉将4个角铆接,并将周边进行密封,防止加热时内表面氧化,在电阻炉中升温到650~800 ℃,保温5~10 min,然后取出在d 450 mm×550 mm二辊轧机上进行轧制,轧辊转速为2 m/s,道次变形量为50%~70%,并在每个阶段留取分析试样。使用PLOVER-MET型金相显微镜观察材料的金相组织,用WDW100-10t 型电子拉伸机在室温下对材料的力学性能进行测试,加载速度为1.0 mm/min,用东芝S-3400型扫描电镜对拉伸后的试样断口和剥离试样表面进行形貌观察。

2 结果与分析

2.1 轧制后复合板的界面结合特性

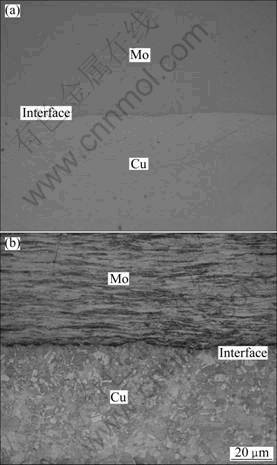

图1所示为轧制后Cu/Mo复合界面的光学显微照片。从图1可以看出,轧制后的复合界面较为平直,且结合紧密(见图1(a));钼层金属晶粒呈扁平纤维状,分布较为均匀;而铜层金属的晶粒呈等轴状,晶粒尺寸由复合界面至表层逐渐增大,分布极不均匀,局部有孪晶出现(见图1(b))。研究表明,由于铜和钼金属在力学性能方面的差异,在轧制复合变形时,铜板先于钼板变形;同时,又因为两种板材结合表面经过打磨后,表面粗糙度增加,摩擦因数增大,导致铜表面层金属在变形过程中受到较大摩擦剪切力的作用而破裂,新鲜金属在压应力作用下被挤出,并镶嵌在钼金属表面层的空隙中,因此,铜表面层金属的变形程度比内部的更为剧烈,晶粒在压应力和剪切应力的共同作用下被细化。轧制时变形温度为700 ℃(高于铜的再结晶温度),加上变形热的作用,Cu容易发生动态再结晶,所以晶粒为等轴状。

图1 轧制后Cu/Mo复合界面的光学显微照片

Fig.1 Optical microsgraphs of Cu/Mo interface after rolling: (a) Before corrosion; (b) After corrosion

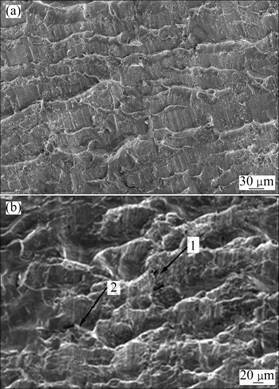

图2所示为复合界面剥离后的SEM像。从图2可以看出,钼表面呈层状断裂特点(见图2(a)),铜表面类似于层状起伏,但有明显的塑性变形,并存在硬化层碎裂形成的孔洞(见图2(b)中箭头1所指) 和剥离时金属表层被撕裂形成的裂缝(见图2(b)中箭头2所指)。研究表明,经打磨后的铜板表面形成硬化层,在轧制变形过程中,由于摩擦剪切应力和拉应力的共同作用,硬化层破碎,新鲜金属挤出并镶嵌到钼板表面的缝隙中,形成机械啮合。在剥离时,铜表面层金属发生一定的塑性变形。

图2 复合界面剥离后的SEM像

Fig.2 SEM images of cladding interface after peeling: (a) Stripping morphology of Mo surface; (b) Stripping morphology of Cu surface

2.2 Cu/Mo/Cu复合板的断裂特性

Cu/Mo/Cu复合材料的断裂特性对其使用性能影响很大,室温下拉伸断口的SEM像如图3所示。从图3(a)和(b)可以看出,Cu/Mo/Cu复合材料在拉伸过程中,两侧Cu发生了明显的颈缩现象,中间的Mo金属为分层断裂。在轧制变形过程中,由粉冶法制备的钼板坯的晶粒在受到剧烈变形被拉长的同时,大量的杂质和缺陷等汇聚到晶界处,形成细小的微裂纹,在拉伸过程中,微裂纹汇聚在一起沿层状晶界扩展,最终导致Mo金属的分层。在界面处,Mo/Cu表面结合紧密,说明在本研究采取的轧制工艺条件下,复合板界面结合良好。铜层断口形貌是明显的韧性断裂,靠近界面的区域比较平滑,呈纤维状(见图3(d)的上部),是裂纹的快速扩展区;而远离界面的区域是断裂的纤维区,有很多抛物线形状的韧窝,尺寸小,深度浅,是断裂裂纹的产生区(见图3(d)下部)。这表明经过塑性变形后,材料产生加工硬化,塑性下降。

图3 拉伸断口的SEM像

Fig.3 SEM images of tensile fracture: (a) Macro side; (b) Photograph of fracture; (c) Zone 1 in Fig.3(b); (d) Zone 2 in Fig.3(b)

2.3 变形温度和变形量对剪切强度的影响

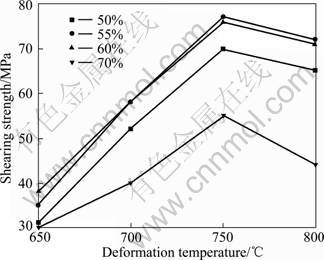

复合材料的重要表征性能就是界面结合强度。图4所示为不同轧制工艺条件下复合板的剪切强度。从图4可以看出,复合板的剪切强度分两个阶段:1) 在750 ℃以下,随变形量的增加和变形温度的升高,剪切强度增加;2) 在750 ℃以上时,剪切强度下降。当变形温度为750 ℃、变形量为55%时,剪切强度的最大值为77 MPa。这是因为:在较低温度进行轧制时,铜层金属在轧制压力作用下,虽然能够嵌入钼板凹坑,但难以达到整个表面的紧密结合,大部分为原子间的点结合和机械啮合。随着温度的升高和变形量的增加,铜的变形抗力下降,表面硬化层在剪切应力和压应力的作用下破碎,新鲜金属被挤出,充填在钼金属表面的凹坑中,增大了结合面积,从而使剪切强度增加;但温度过高时,板材表面易被氧化,从而使结合强度降低。同时,当变形量较大时,在铜金属层发生大变形所产生的拉应力作用下,钼板容易产生裂纹,导致剪切强度较低。此外,界面结合强度的大小还与材料表面的清洁程度、应力分布、硬化程度和保温温度、时间等因素有关。

图4 变形温度、变形量和剪切强度的关系图

Fig.4 Relational graph of temperature and deformation with shear strength

3 结论

1) 经750 ℃、保热8 min、道次变形量为55%的轧制后,Cu/Mo/Cu复合材料的界面结合紧密,且较为平直,最大剪切强度为77 MPa。钼金属层晶粒呈扁平纤维状,组织均匀;铜金属层的晶粒呈等轴状,由界面至表层逐渐增大,分布极不均匀,局部有孪晶出现。

2) 轧制后Cu/Mo/Cu复合材料的界面结合机理是铜表面硬化层破裂、新鲜金属挤出并镶嵌到钼板表面的缝隙中,形成机械啮合。

3) Cu/Mo/Cu复合材料的中间钼层金属易分层断裂,两侧铜层金属是明显的韧性断裂,对复合材料的抗拉强度有一定的影响。

REFERENCES

[1] ZWEBEN C. Metal-matrix composites for electronic packaging[J]. JOM, 1992, 44(7): 15-23.

[2] GERMAN R M, HENS K E, JOHNSON J L. Processing of thermal management materials for microelectronic applications [J]. Inter J Powder Metallurgy, 1994, 130(2): 205-215.

[3] 牟科强, 邝用庚. Mo-Cu材料的性能和应用[J]. 金属功能材料, 2002, 9(2): 26-29.

MU Ke-qiang, KUANG Yong-geng. The property and application of Mo-Cu composite[J]. Metallic Functional Materials, 2002, 9(2): 26-29.

[4] 张 兵, 袁守谦, 王训宏, 秦占先, 孙 健. 金属基电子封装复合材料的研究进展[J]. 稀有金属, 2006, 30(增刊): 90-95.

ZHANG Bing, YUAN Shou-qian, WANG Xun-hong, QIN Zhan-xian, SUN Jian. Development of metal matrix composite for electronic packaging[J]. Chinese Journal of Rare Metals, 2006, 30(Suppl): 90-95.

[5] 殷录桥, 李清华, 张建华. 提高大功率LED散热和出光封装材料的研究[J]. 半导体技术, 2008, 33(4): 281-285.

YIN Lu-qiao, LI qing-hua, ZHANG Jian-hua. Research on packaging materials for improving LED heat dissipation and light extraction efficiency[J]. Semiconductor Technology, 2008, 33(4): 281-285.

[6] 张楼英, 李朝林. LED封装中的散热研究[J]. 电子与封装, 2009, 9(5): 1-4.

ZHANG Lou-ying, LI Chao-lin. Research on heat-release package of LED[J]. Electronics and Packaging, 2009, 9(5): 1-4.

[7] SINGH M, ASTHANA R, SHPARGEL T P. Brazing of carbon-carbon composites to Cu-clad molybdenum for thermal management applications[J]. Materials Science and Engineering A, 2007, 452/453: 699-704.

[8] 朱爱辉, 王快社, 张 兵. 电子封装用Cu/Mo/Cu复合材料的工艺研究[J]. 稀有金属快报, 2006, 25(7): 35-39.

ZHU Ai-hui, WANG Kuai-she, ZHANG Bing. Study on the process of Cu/Mo/Cu composite for electronic packaging[J]. Rare Metals Letters, 2006, 25(7): 35-39.

[9] 龚 深, 李 周, 肖 柱, 唐 宁. 爆炸焊接法制备金属复合材料的研究[J]. 材料导报, 2007, 21(11): 249-251.

GONG Shen, LI Zhou, XIAO Zhu, TANG Ning. Research on preparation of metallic composite with explosive welding[J]. Materials Review, 2007, 21(11): 249-251.

[10] 魏 伟, 史庆南. 铜/钢双金属板异步轧制复合原理研究[J]. 稀有金属, 2001, 25(4): 307-311.

WEI Wei, SHI Qing-nan. Bonding mechanism of Cu/Steel clad sheet in asymmetrical rolling of bimetal[J]. Chinese Journal of Rare Metal, 2001, 25(4): 307-311.

[11] 刘晓涛, 张廷安, 崔建忠. 层状金属复合材料生产工艺及其新进展[J]. 材料导报, 2002, 16(7): 41-44.

LIU Xiao-tao, ZHANG Ting-an, CUI Jian-zhong. Technology of clad metal production and its latest progress[J]. Materials Review, 2002, 16(7): 41-44.

[12] 刘 斌, 白培康, 程 军, 卜昭献. 钼/铜复合材料快速成型制备工艺研究[J]. 中北大学学报: 自然科学版, 2009, 30(1): 85-89.

LIU Bin, BAI Pei-kang, CHENG Jun, BU Zhao-xian. Study on rapid prototyping preparation process of molybdenum/copper composites[J]. Journal of North University of China: Natural Science Edition, 2009, 30(1): 85-89.

[13] 王 莎, 王快社, 张 兵, 郭 韡. 退火温度对Cu/Mo/Cu轧制复合板微观组织和力学性能的影响[J]. 稀有金属, 2010, 34(3): 447-450.

WANG Sha, WANG Kuai-she, ZHANG Bing, GUO Wei. Effect of annealing temperature on microstructure and mechanical properties of Cu/Mo/Cu laminates [J]. Chinese Journal of Rare Metals, 2010, 34(3): 447-450.

[14] 周 俊, 王志法, 崔大田, 吴化波. Cu/Mo/Cu电子封装材料中Mo的分层问题[J]. 中国钼业, 2007, 31(5): 54-56.

ZHOU Jun, WANG Zhi-fa, CUI Da-tian, WU Hua-bo. The delamination of molubdenum in Cu/Mo/Cu electronic material[J]. China Molybdenum Industry, 2007, 31(5): 54-56.

[15] 姜国圣, 王志法, 何 平, 王海山. 表面处理方式对铜钼铜复合材料界面结合效果的影响[J]. 稀有金属, 2005, 29(1): 6-10.

JIANG Guo-sheng, WANG Zhi-fa, HE Ping, WANG Hai-shan. Effect of processing of surface treatment on shear strength of interface of Cu/Mo/Cu composite[J]. Chinese Journal of Rare Metals, 2005, 29(1): 6-10.

(编辑 何学锋)

基金项目:陕西省“13115”科技创新重大专项资助项目(2008ZDKG-41);西安市工业应用发展研究项目(YF07052,CXY08006(4))

收稿日期:2010-08-25;修订日期:2011-02-15

通信作者:张 兵,高级工程师,博士;电话:029-82202322;E-mail:r.zhang1112@163.com