文章编号:1004-0609(2015)-09-2389-07

铝/黄铜异种金属TIG熔钎焊接头显微组织与力学性能

周 利1,李志勇1,赵洪运1,谢 宇1,黄永宪2,冯吉才1, 2

(1. 哈尔滨工业大学(威海) 山东省特种焊接重点实验室,威海 264209;

2. 哈尔滨工业大学 先进焊接与连接国家重点实验室,哈尔滨 150001)

摘 要:采用Zn-2%Al(质量分数)药芯焊丝对5052铝合金和H62黄铜进行TIG熔钎焊搭接试验,并对接头显微组织、界面层结构及力学性能进行分析。结果表明:Zn-2%Al药芯焊丝在黄铜母材表面润湿性良好,能够获得较好的铝/黄铜熔钎焊接头。在黄铜侧过渡区形成块状和条状的AlCu脆性金属间化合物相,同时在黄铜侧界面处形成Cu9Al4、CuZn金属间化合物层。随焊接热输入的增大,界面层厚度先增大后减小,接头拉伸载荷也是先增大后减小。焊缝中心区及界面层的显微硬度高于铝和黄铜母材的。接头拉伸时断于黄铜侧界面区,且断口为解理 断裂。

关键词:铝/黄铜异种金属;TIG熔钎焊;药芯焊丝;显微组织;力学性能

中图分类号: TG444 文献标志码:A

Microstructure and mechanical properties of Al/brass dissimilar metals TIG welding-brazing joint

ZHOU Li1, LI Zhi-yong1, ZHAO Hong-yun1, XIE Yu1, HUANG Yong-xian2, FENG Ji-cai1, 2

(1. Shandong Provincial Key Laboratory of Special Welding Technology,

Harbin Institute of Technology at Weihai, Weihai 264209, China;

2. State Key Laboratory of Advanced Welding and Joining, Harbin Institute of Technology, Harbin 150001, China)

Abstract: 5052 aluminum alloy and H62 brass dissimilar metals were welded by TIG welding-brazing lap using Zn-2%Al (mass fraction) flux-cored wire. Microstructure, interface layer structure and mechanical properties of the joint were studied. The results show that favorable welding-brazing joints are obtained due to the excellent wettability of molten Zn-2%Al on the surface of brass. The massive and strip AlCu intermetallic compounds (IMCS) form in the transition zone at the brass side, meanwhile, Cu9Al4 and CuZn intermetallic compound layers form at the interface. The interface layer thickness and tensile load of joint increase at first and then decrease with the increase of welding heat input. The micro-hardnesses of weld center and the interface layer are higher than those of aluminum and brass base metals. Tensile test results show that the joint fractures at interface layer of the brass side with cleavage fracture surface.

Key words: Al/brass dissimilar metals; TIG welding-brazing; flux-cored wire; microstructure; mechanical property

铜为稀缺金属,属于战略资源。铝合金的导电、导热性能与铜的接近;铝比铜轻,且在自然界中含量比铜丰富,价格也比铜便宜[1]。因此,采用铝/铜复合结构部分替代铜能够充分发挥两种材料的优势,达到成本和性能的平衡。铝/铜异种金属现阶段主要采用钎焊[2-5]、熔化焊[6]、压力焊[7-11]等方法进行连接。由于铜与铝的物理、化学性质差异较大并且冶金相容性差,采用传统熔化焊方法难以实现铝/铜异种金属的可靠连接[12]。压力焊和钎焊方法对接头的结构尺寸有限制,而且生产效率相对较低。近年来,熔钎焊方法成为异种难焊金属连接领域的研究热点,有望突破传统方法在接头质量、结构适应性等方面的不足。

熔钎焊利用异种金属熔点差异大的特点,在低熔点材料侧形成熔化焊接头,而在高熔点材料侧形成钎焊接头。董红刚等[13]采用Zn-15%Al(质量分数)实芯焊丝开展了铝/黄铜TIG熔钎焊搭接试验,结果表明部分柱状晶从界面层脱落进入焊缝,恶化了接头性能。界面层中的金属间化合物主要由CuZn5相组成。董鹏等[14]采用激光深熔钎焊方法对3 mm厚1060铝合金和T2紫铜进行对接,所得焊缝内晶粒较为细小,接头的抗拉强度可达到铝合金母材的94%以上,但焊缝内含有硬脆的Cu3Al2和CuAl2金属间化合物。SOLCHENBACH等[15]通过光斑环形摆动同时控制热输入实现了铝/铜异种金属的激光熔钎焊,焊后铝/铜界面处形成了厚度小于3.2 μm的均匀金属间化合物层。本文作者以TIG电弧作为热源、添加Zn-2%Al药芯焊丝进行铝/黄铜TIG熔钎焊搭接,并对接头显微组织和力学性能进行研究,为铝/黄铜异种金属的TIG熔钎焊工艺应用提供理论依据。

1 实验

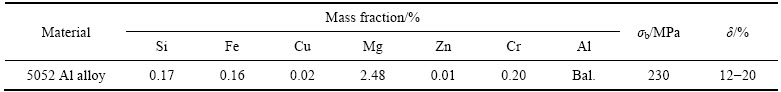

试验材料为200 mm×75 mm×2 mm尺寸的5052铝合金和200 mm×75 mm×1 mm尺寸的H62黄铜,其化学成分及力学性能分别如表1和2所列,填充材料选用直径1.6 mm的Zn-2%Al药芯焊丝。TIG熔钎焊搭接过程如图1所示,铝板在上、黄铜板在下,搭接宽度为10 mm。焊前先用钢丝刷擦拭待焊件表面及侧面氧化膜,然后用丙酮洗除打碎的氧化膜残渣及试件表面的油污及灰尘。焊接时令焊枪与板面成90°并偏向黄铜母材侧1 mm,钨极高度为5 mm,采用纯氩气保护。焊接工艺参数为:焊接速度2 mm/s、送丝速度0.8 m/min,焊接电流90~130 A。

沿垂直于焊接方向截取试样进行标准金相试样制备,使用凯勒试剂(3 mL HNO3+6 mL HCl+6 mL HF+150 mL H2O)腐蚀1~2 s后,采用GX51金相显微镜(Optical microscopy,OM)对接头显微组织进行观察,利用TESCAN VEGA3扫描电子显微镜(SEM)分析界面层组织并通过能谱(EDS)分析界面层物相。

沿着垂直于焊接方向加工尺寸为150 mm×10 mm的拉伸试样,在INSTRON 1186电子力学性能试验机上进行室温拉伸试验,加载速率为3 mm/min,拉伸性能采用3个拉伸试样的平均值表征。利用MICRO-586型显微硬度计对焊接接头截面显微硬度分布进行测试(加载载荷1.96 N,加载时间10 s,测试点间距0.2 mm)。

2 结果与分析

2.1 接头成形及显微组织

图2所示为不同焊接电流下所得接头表面形貌。当焊接电流为90A时,由于焊接热输入较小,熔化的焊丝及铝母材在黄铜母材表面的润湿铺展性不好,难以获得成形良好的接头。当焊接电流为100~120 A时,熔融材料在黄铜母材表面铺展较好。随着焊接电流的增大,焊接热输入提高,熔化的焊丝及铝母材在黄铜母材表面的润湿性越来越好,所得焊缝铺展面积逐渐增大。当焊接电流为130 A时,由于焊接热输入过大,黄铜母材熔化量过大,出现焊穿的现象,不能获得完整的熔钎焊接头。

表1 5052铝合金化学成分及力学性能

Table 1 Chemical compositions and mechanical properties of 5052 Al alloy

表2 H62黄铜化学成分及力学性能

Table 2 Chemical compositions and mechanical properties of H62 brass

图1 铝/黄铜TIG熔钎焊搭接示意图

Fig. 1 Schematic diagram of Al/Brass TIG lap welding–brazing

图2 不同焊接电流下所得焊缝表面形貌

Fig. 2 Surface appearances of joints obtained at different welding currents

图3所示为焊接电流100A时获得的典型铝/黄铜熔钎焊接头光学截面形貌及显微组织。图3(a)所示为接头截面形貌。由图3(a)可看出,焊缝中存在大小不一的气孔,这可能是由于Zn-2%Al药芯焊丝中主要成分Zn沸点较低,焊缝凝固过程中,蒸发的Zn来不及逸出形成气孔。由接头截面形貌可以看出,铝/黄铜TIG熔钎焊接头主要由3个区域组成:铝侧熔化焊区(I)、焊缝中心区(II)、黄铜侧类钎焊区(III)。铝侧熔化焊区呈现出熔化焊的组织特征(见图3(b)),凝固过程中熔融金属在铝母材上形核,并以柱状晶形式向焊缝中心区生长。柱状晶区域晶粒粗大,且存在较多缺陷,成为焊缝中的脆弱环节。在焊缝中心区(见图3(c))可以观察到大量的树枝晶组织。树枝晶组织的产生与冷却速度有关,冷却速度越大,越容易产生树枝晶组织。由于铝和黄铜都属于热导率较高的金属,焊缝冷却速度较快,促进了大量树枝晶的形成,可能会弱化焊缝的力学性能。焊缝组织主要由白色的β-Zn固溶体树枝晶组织、富锌相及黑色的α(Al)固溶体网状结构组成。由于铝母材熔化,铝原子进入焊缝中,导致越靠近铝母材侧,铝基固溶体的含量逐渐增大[13]。

图3 焊接电流100 A下所得接头光学截面形貌及显微组织

Fig. 3 Cross-sectional OM morphology and microstructures of joint obtained at welding current of 100 A

图4所示为不同电流下所得接头中黄铜侧类钎焊区显微组织,其中又可细分为:焊缝区、过渡区、和界面层3个区域。焊接过程中,黄铜母材会向液态焊缝金属中溶解,同时可能存在黄铜母材少量熔化进入焊缝中;液态焊缝金属中的Zn原子和Al原子会向黄铜母材中扩散,因而主要元素Al、Cu和Zn可能在界面附近形成块状或层状金属间化合物相,这会使接头脆性增大,强度显著下降。焊接电流为100 A时界面层厚度在8 μm左右,焊接电流增大到110 A时界面层厚度在10 μm左右,焊接电流继续增加到120 A时界面层厚度在5 μm左右。随焊接热输入的增大,界面层厚度先增大后减小,这可能是由于随着焊接热输入的提高导致黄铜母材部分熔化,从而对界面处溶解和扩散过程产生了影响。董鹏等[16]对3 mm厚1060铝合金和T2紫铜进行激光深熔钎焊时,发现接头界面层厚度在垂直方向上均匀分布,约为25 μm。热输入继续增大,导致黄铜部分熔化得到深熔钎焊-熔焊接头时,由于在界面垂直方向存在较大的温度差以及熔池流动的影响,金属间化合物层厚度分布不均匀,在10~25 μm之间。可见随着焊接电流的增大,界面层的尺寸并非线性增加。

图4 不同焊接电流下所得接头黄铜侧类钎焊区显微组织

Fig. 4 Microstructures of brazing area of brass side in the joints obtained at different welding currents

采用SEM对焊接电流100 A时获得的铝/黄铜熔钎焊接头黄铜侧界面层组织和物相进行分析。图5所示为黄铜侧界面层SEM像。由图5可以看出,界面由3层组成。Ⅰ层位于界面层靠近焊缝一侧,呈笋状向焊缝中心方向生长;Ⅱ层位于界面层中心位置,其厚度较小且不均匀;Ⅲ层位于界面层中靠近黄铜母材的一层,与黄铜母材界面呈现出一个细长的曲线,颜色衬度与黄铜母材的接近。

图5 焊接电流100 A下所得接头黄铜侧界面层SEM像

Fig. 5 SEM image of interface layer in joint obtained at welding current of 100 A

对图5中黄铜侧界面层不同位置进行EDS分析,结果如表3所列。根据A点EDS分析结果可以推断界面层中的Ⅰ层为AlCu相,其中固溶了一定量的Zn原子,并呈笋状向焊缝中心方向生长。张旭超[17]采用Zn-15%Al实芯焊丝对铝/铜异种金属进行TIG熔钎焊时,在界面层处也有AlCu相生成。Al原子通过界面层向黄铜母材中扩散,形成了Ⅱ层,由B点EDS分析结果可推断Ⅱ层主要由Cu9Al4相构成。焊缝中Zn元素含量较高,黄铜母材中也含有一定比例的Zn元素,故焊缝与母材Zn元素浓度梯度相关减小,Zn原子的扩散速度也相对较小。焊接过程中由于黄铜母材中的Cu原子向焊缝中溶解,导致母材中部分区域Cu元素含量下降,最终形成了厚度较大的Ⅲ层,根据C点EDS结果可以判断Ⅲ层主要由CuZn相构成。

表3 图5所示位置EDS分析结果

Table 3 EDS analysis of positions shown in Fig. 5

2.2 接头力学性能

图6所示为焊接电流100 A时获得的典型铝/黄铜熔钎焊接头不同方向显微硬度分布图。图6中线1和线2分别为水平方向和垂直方向显微硬度测试示意线。水平方向硬度分布表明铝母材硬度较低,焊缝中心区硬度较高。这可能是由于焊缝中心区域组织为细小的树枝状组织,且在焊接过程铝和黄铜溶解扩散进入焊缝。垂直方向硬度分布表明黄铜母材硬度较低,界面处由于在焊接过程中分别形成了硬度较高的金属间化合物层,因而其硬度高于焊缝中心区域及黄铜母材的硬度。

图6 焊接电流为100 A时接头显微硬度分布

Fig. 6 Hardness distributions of joint obtained at welding current of 100 A

图7所示为不同焊接电流下所得接头拉伸试验结果,随焊接电流的增大,接头拉伸载荷先下降后升高。当焊接电流为120 A时,焊缝具有相对较高的拉伸性能,拉伸载荷为1917 N。这可能是由于焊接电流为120A时界面层的厚度最小。黄铜母材与焊缝之间界面层的厚度越大则接头力学性能相对越差。熔钎焊过程中可能可以通过控制高熔点母材的微量熔化,调节界面处元素浓度梯度,控制扩散和溶解过程,限制接头界面层的厚度,从而提高接头的力学性能。

图7 不同焊接电流下所得接头拉断载荷

Fig. 7 Tensile loads of joints obtained at different welding currents

图8 焊接电流为100 A时接头拉伸断口形貌

Fig. 8 Fracture appearance of tensile specimens in welding current of 100 A

图8所示为焊接电流100 A时获得的典型铝/黄铜熔钎焊接头拉伸断口形貌。由图8(a)可知,接头拉伸时断于黄铜侧界面区。图8(b)所示为接头断口黄铜侧SEM像。断口表面较为平坦,界面断口由许多大小相当于晶粒的解理刻面组成,裂纹跨过许多相互平行但高度不同的解理面,形成了解理台阶和河流花样,断口呈现解理断裂特征。焊接过程中在焊缝黄铜侧形成了金属间化合物层,另外过渡区内形成了尺寸较大的条状和块状脆性金属间化合物相。拉伸试验过程中,在外加载荷的作用下,作用应力尖端形成一次裂纹,随着外加应力持续作用发生撕裂,主裂纹向前扩展,次生裂纹向后扩展,裂纹连接使焊缝发生断裂。由于裂纹的快速扩展,断口处基本上不发生塑性变形,属于脆性断裂。

3 结论

1) 采用Zn-2%Al药芯焊丝作为填充材料,选择钨极高度h为5 mm(焊接电压U为18~20 V),焊接电流I为100~120 A,焊接速度v为2 mm/s,填丝速度vf为0.8 m/min,搭接宽度b为10 mm,偏移量O为1 mm(偏向铜侧为正),能够获得较好的铝/黄铜熔钎焊接头。当焊接电流为120 A时,熔融金属在黄铜母材表面的铺展较好,焊缝成形较好。

2) 熔钎焊接头分为3个区域:铝侧熔化焊区、焊缝中心区、黄铜侧类钎焊区。焊缝中存在大小不一的气孔。在黄铜侧过渡区中形成了块状和条状的AlCu脆性金属间化合物相,同时在黄铜侧界面处形成了Cu9Al4、CuZn金属间化合物层。随焊接热输入的增大,界面层厚度先增大后减小。

3) 黄铜侧界面层由于脆硬金属间化合物的形成,显微硬度高于铝和黄铜母材的。界面层厚度越大则接头力学性能相对越差,界面层厚度随焊接热输入的增大先增大后减小,导致接头拉伸载荷先减小后增大。当焊接电流为120 A时所得接头拉伸载荷最大,为1917 N。接头拉伸时断于黄铜侧界面区,断裂形式为解理断裂。

REFERENCES

[1] LACAZE J, TIERCE S, LAFONT M C, THEBAULTA Y,  , MANKOWSKIA G, BLANCA C, ROBIDOUB H, VAUMOUSSEB D, DALOZ D. Study of the microstructure resulting from brazed aluminium materials used in heat exchangers[J]. Materials Science and Engineering A, 2005, 413/414: 317-321.

, MANKOWSKIA G, BLANCA C, ROBIDOUB H, VAUMOUSSEB D, DALOZ D. Study of the microstructure resulting from brazed aluminium materials used in heat exchangers[J]. Materials Science and Engineering A, 2005, 413/414: 317-321.

[2] 张洪涛, 刘 多, 冯吉才, 胡乐亮. 铝/铜高频感应接触反应钎焊[J]. 焊接学报, 2012, 33(3): 89-92.

ZHANG Hong-tao, LIU Duo, FENG Ji-cai, HU Le-liang. Reactive contact brazing between aluminium alloy and copper by high frequency induction method[J]. Transactions of the China Welding Insitution, 2012, 33(3): 89-92.

[3] JI F, XUE S B, LOU J Y, LOU Y B, WANG S Q. Microstructure and properties of Cu/Al joints brazed with Zn-Al filler metals[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(2): 281-287.

[4] 李亚江, 吴会强, 陈茂爱, 杨 敏, 冯 涛. Cu/Al真空扩散焊接头显微组织分析[J]. 中国有色金属学报, 2001, 11(3): 424-427.

LI Ya-jiang, WU Hui-qiang, CHEN Mao-ai, YANG Min, FENG Tao. Microstructure analyses in vacuum diffusion welded joint of copper and aluminum[J]. The Chinese Journal of Nonferrous Metals, 2001, 11(3): 424-427.

[5] JI F, XUE S B. Growth behaviors of intermetallic compound layers in Cu/Al joints brazed with Zn-22Al and Zn-22Al-0.05Ce filler metals[J]. Materials & Design, 2013, 51: 907-915.

[6] LEE S J, NAKAMURA H, KAWAHITO Y, KATAYAMA S. Effect of welding speed on microstructural and mechanical properties of laser lap weld joints in dissimilar Al and Cu sheets[J]. Science and Technology of Welding and Joining, 2014, 19(2): 111-118.

[7] FIROUZDOR V, KOU S. Al-to-Cu friction stir lap welding [J]. Metallurgical and Materials Transactions A: Physical Metallurgy and Materials Science, 2012, 43(1): 303-315.

[8] LEE K S, YONG-NAM K. Solid-state bonding between Al and Cu by vacuum hot pressing[J]. Transactions of Nonferrous Metals Society of China, 2013, 23(2): 341-346.

[9] LI X W, ZHANG D T, QIU C, ZHANG W. Microstructure and mechanical properties of dissimilar pure copper/1350 aluminum alloy butt joints by friction stir welding[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(6): 1298-1306.

[10] AKINLABI E T, ANTHONY A, AKINLABI S A. Effects of processing parameters on corrosion properties of dissimilar friction stir welds of aluminum and copper[J]. Transactions of Nonferrous Metals Society of China, 2014, 24(5): 1323-1330.

[11] KUANG B B, SHEN Y F, CHEN W H, YAO X, XU H S, GAO J C, ZHANG J Q. The dissimilar friction stir lap welding of 1A99 Al to pure Cu using Zn as filler metal with “pinless” tool configuration[J]. Materials & Design, 2015, 68(5): 54-62.

[12] 毕应利. 铝-铜异种材料焊接工艺及其质量评价 [J]. 价值工程, 2015, 34(9): 69-71.

BI Ying-lin. Welding technology of aluminum-copper dissimilar material and its quality evaluation[J]. Value Engineering, 2015, 34(9): 69-71.

[13] 董红刚, 张旭超, 杨继承, 胡文金. 铝合金/黄铜异种金属电弧熔钎焊[J]. 中国机械工程, 2014, 25(8): 1122-1125.

DONG Hong-gang, ZHNEG Xu-chao, YANG Ji-cheng, HU Wen-jin. Arc-brazing of aluminum alloy to brass[J]. China Mechanical Engineering, 2014, 25(8): 1122-1125.

[14] 董 鹏, 陈凯华, 肖荣诗. 铝-铜异种金属激光深熔钎焊接头力学性能[J]. 中国激光, 2011, 38(6): 129-133.

DONG Peng, CHEN Kai-hua, XIAO Rong-shi. Mechanical properties of aluminum-copper joint by laser penetration brazing[J]. Chinese Journal of Lasers, 2011, 38(6): 129-133.

[15] Solchenbach T, Plapper P. Mechanical characteristics of laser braze-welded aluminum-copper connections[J]. Optics and Laser Technology, 2013, 54: 249-256.

[16] 董 鹏. 异种合金激光深熔钎焊机理与技术研究[D]. 北京:北京工业大学, 2011.

DONG Peng. Investigation on laser penetration brazing of dissimilar alloys[D]. Beijing: Beijing University of Technology, 2011.

[17] 张旭超. 铝合金/黄铜异种金属TIG熔钎焊温度场和流场的数值模拟[D]. 大连: 大连理工大学, 2013.

ZHANG Xu-chao. Numerical simulation of temperature field and fluid flow field during TIG fusion-brazing of aluminum alloy and brass[D]. Dalian: Dalian University of Technology, 2013.

(编辑 王 超)

基金项目:国家自然科学基金资助项目(51205084);教育部留学回国人员科研启动基金资助项目

收稿日期:2015-01-29;修订日期:2015-05-25

通信作者:周 利,副教授,博士;电话:0631-5687211;E-mail:zhouli@hitwh.edu.cn