文章编号:1004-0609(2016)-12-2479-09

超声冲击对MB8镁合金焊接接头表层组织及力学性能的影响

魏 康,何柏林,于影霞

(华东交通大学 机电工程学院,南昌 330013)

摘 要:采用HJ-III型超声冲击机对MB8镁合金焊接接头焊趾进行表面处理,就不同冲击工艺参数对焊接接头表层组织及力学性能进行测试。结果表明: 经过超声冲击处理后,接头焊趾及其附近区域表层组织内的原始粗晶转变为晶界清晰、随机取向的纳米晶粒;焊趾处的应力集中系数得到有效降低,表层硬度及其抗拉强度得到提高;超声冲击前后接头拉伸试样均断于焊趾,接头的拉伸断裂机制为准解理断裂。冲击电流为1.2 A、冲击时间为6 min时,与未超声冲击试样相比,MB8镁合金接头的应力集中系数降低12.04%,焊趾表层最大硬度值提高63.2%,抗拉强度提高33.2%,接头表层金属晶粒细化以及焊趾处应力集中程度的降低是提高MB8镁合金焊接接头力学性能的主要原因。

关键词:超声冲击;焊接接头;表层组织;抗拉强度;晶粒细化

中图分类号:TG146 文献标志码:A

镁合金具有密度小、比强度和比刚度高、阻尼减震性能好、易于切削加工等优点,广泛应用在汽车、航空航天、电子通讯等工业领域,逐步成为继钢铁、铝合金之后的21世纪新型金属结构材料[1-3]。目前,大多数镁合金产品主要通过铸造和锻压的方法制成,这极大制约了镁合金的应用范围。通过焊接工艺实现大型复杂镁合金构件的制备能有效扩大镁合金在工程领域的应用[4-5]。但是,由于镁合金化学性质活泼、熔点低、导热快等特点,镁合金焊接接头焊缝组织的晶粒粗大,易形成氧化物及夹渣,同时,由于接头存在应力集中以及残余拉应力,这些因素均会降低镁合金焊接结构的力学性能(抗拉强度、疲劳强度),从而影响镁合金焊接结构的可靠性[6-8]。

为了改善镁合金焊接接头的组织和提高接头的力学性能,国内外的研究主要集中在优化镁合金材料的各种焊接工艺方法(如TIG焊、搅拌摩擦焊、激光焊等)。此外,采用表面强化技术(如超声冲击、激光熔修、TIG熔修、高能喷丸)对接头进行焊后处理,能有效细化接头表层组织,从而改善接头的力学性能[9-11]。超声冲击(Ultrasonic impact treatment, UIT)作为改善焊接接头性能的全新技术,可以有效降低接头应力集中程度,调整接头残余应力场,减小或消除表面微观缺陷,在提高钢铁材料、铝合金、钛合金焊接接头的耐腐蚀性、疲劳性能等方面得到深入的研究[12-16]。但关于超声冲击处理对MB8镁合金焊接接头组织性能的影响研究较少。本文作者对未超声冲击处理和不同工艺参数超声冲击处理MB8镁合金焊接接头的显微硬度、表层组织、冲击层厚度、应力集中系数以及拉伸性能进行了测试研究,同时,分析了超声冲击诱导接头焊趾表面晶粒细化机理以及超声冲击前后接头拉伸性能的改善效果。

1 实验

1.1 试验材料

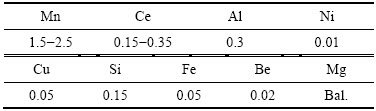

试验材料为MB8变形镁合金,该镁合金强度中等,且塑性较好,其化学成分(质量分数,%)和力学性能分别如表1和2所列。

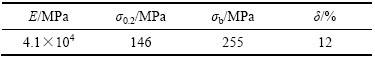

图1所示为MB8镁合金母材的金相组织。从图1中可以看出,MB8镁合金的晶粒分布较均匀,为细小的等轴晶,平均尺寸约为15~20 μm。

表1 MB8镁合金的化学成分

Table 1 Chemical composition of MB8 magnesium alloy (mass fraction, %)

表2 MB8镁合金的力学性能

Table 2 Mechanical properties of MB8 magnesium alloy

图1 MB8镁合金母材金相组织

Fig. 1 Microstructure of MB8 magnesium alloy

1.2 接头形式及焊接工艺试验

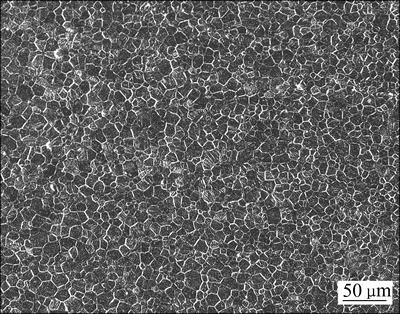

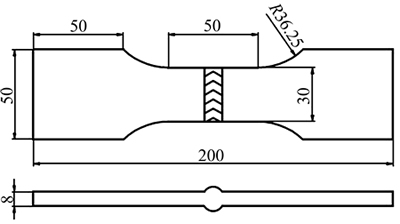

试验采用的接头形式为对接接头,试样的尺寸形状及其实物如图2和3所示。对接接头采用TIG焊将MB8变形镁合金板材焊接而成,焊丝采用的是直径为3 mm的MB3镁合金焊丝,采用MB3焊丝是为了避免在近焊缝区析出低熔点共晶体而产生裂纹。同时,为了保证焊接质量,焊前用丙酮清洗镁合金板材及焊丝表面,然后用纱布打磨,以充分去除其表面氧化膜。具体的焊接工艺参数如表3所列。

图2 对接接头的形状与尺寸

Fig. 2 Shapes and dimensions of butt joints (Unit: mm)

图3 对接接头实物图

Fig. 3 Physical map of butt welded joints

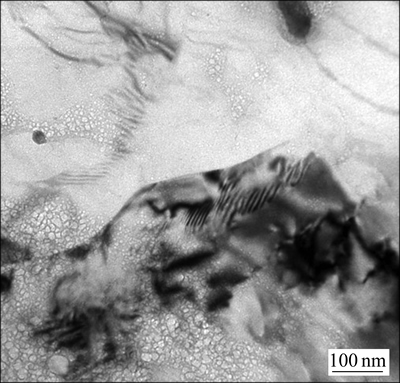

表3 对接接头焊接工艺参数

Table 3 Chemical composition of MB8 magnesium alloy

1.3 超声冲击试验

试验采用天津大学HJ-III型超声冲击设备,如图4所示。超声冲击试验主要工艺参数包括冲击能量(电流、振幅)、冲头直径和冲击时间等。本次试验中超声冲击机选用三冲头,冲头直径为3 mm、冲击电流为1.2 A,接头每道焊趾来回进行超声冲击处理。将相同接头形式的试样分为4组,每组3个试样,第一组不采用超声冲击处理,即0 min;其他3组试样依次超声冲击2 min、4 min和6 min。具体的冲击过程为:超声冲击枪垂直对准试样焊趾部位,同时冲击针沿焊缝方向排列,略施加少量的压力,使冲击过程基本在执行机构(冲击枪)自身质量的状态下进行。此外,冲击枪可在垂直于焊缝的方向做适当角度的摆动,以使焊趾区的几何外形为光滑圆弧过渡。

图4 HJ-III型超声冲击处理设备

Fig. 4 HJ-III type ultrasonic impact treatment equipment

1.4 金相组织及硬度试验

采用德国ZEISS公司生产的Axio Vert.A1型倒置万能金相显微镜对冲击和未经超声冲击处理的MB8镁合金焊接接头金相组织进行观察分析。同时,借助JEM-2000透射电镜(TEM)对超声冲击处理后的接头焊趾区域的表面显微组织进行观察分析,探究超声冲击MB8镁合金焊接接头表面纳米化的机理。由于接头表面各区域的硬度不同,采用XHV-1000Z型显微硬度计测试超声冲击前后接头焊趾区表层的显微硬度,分析各区硬度变化趋势以及超声冲击对焊接接头表面硬化作用。硬度测试从焊缝中心向一侧母材区进行,每隔0.4 mm左右打一个点,试验所加载荷为0.1 N,保荷时间10 s。

1.5 焊接接头应力集中系数的有限元计算

焊接结构的失效往往发生于应力集中现象严重的接头焊趾或焊根处,应力集中系数可以反映接头焊趾处的应力集中程度。超声冲击技术可以改善焊趾区域的表面形貌,使焊趾处平滑过渡,从而降低应力集中。本文作者根据超声冲击前后焊接接头的实际外形轮廓建立模型,采用有限元软件ABAQUS进行应力分析,选用六面体二次单元C3D20进行网格划分,在焊趾区域局部网格细化,材料的弹性模量E=41000 MPa,泊松比μ=0.34。模型的边界条件为:接头左端完全固定,右端施加60 MPa的均匀拉伸载荷。

1.6 单向静载拉伸试验

采用日本SHIMADZU AG-X 250 kN型万能试验机在室温的条件下进行拉伸试验,拉伸速率为2 mm/min。借助JSM-6360LA扫描电镜(SEM)观察分析接头拉伸断口的微观形貌特征,从而探究MB8镁合金焊接接头的拉伸断裂机制。

2 结果与分析

2.1 焊接接头金相组织分析

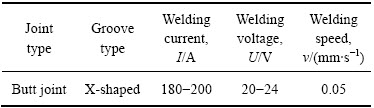

图5所示为MB8镁合金对接接头的金相组织。从图5(a)可以看出,焊缝金属(Weld metal, WM)为典型的铸造柱状晶组织。焊接过程中,由于焊接温度高于熔点,熔合线区域的液态金属在母材晶粒表面形核的同时,晶核以柱状晶的形态向焊缝中心长大。从图5(b)可以看出,热影响区(Heat affected zone, HAZ)的晶粒为不规则的等轴晶,它是由于变形晶粒在变形储存能的驱动下,发生再结晶,晶粒在晶界处重新形核长大而形成的。母材(Base metal, BM)晶粒尺寸比热影响区晶粒明显减小,两者之间有明显界限,界限处的晶粒在再结晶过程中容易软化,会降低晶界的致密程度,使得该区域在焊接残余拉应力的作用下容易萌生微裂纹,从而降低焊接接头的力学性能。

图5 MB8镁合金对接接头的显微组织

Fig. 5 Microstructures of MB8 magnesium alloy butt joint

图6 冲击处理表面组织的TEM明场像

Fig. 6 TEM bright field image of surface with UIT

图7 对应选区电子衍射花斑

Fig. 7 Electron diffraction pattern of corresponding selected area

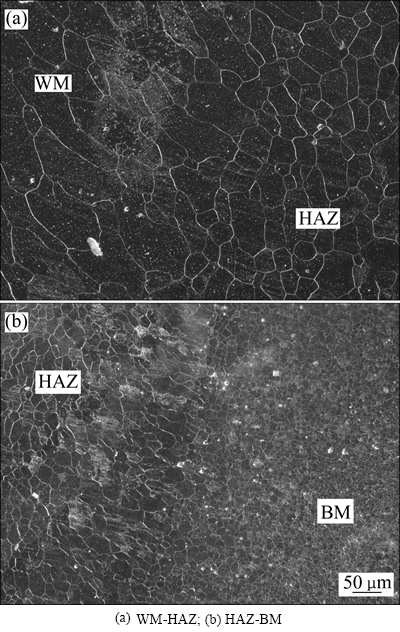

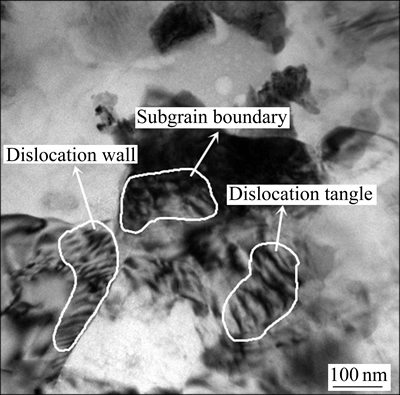

图6所示为超声冲击处理接头焊趾区域表面组织的高分辨透射电镜明场像,对应的选区电子衍射花样如图7所示(工艺参数:冲击电流1.2 A,冲击时间6 min)。从图6可知,经过超声冲击处理后,MB8镁合金焊接接头焊趾区域表面可以获得尺寸小于100 nm的纳米晶粒,其中较小的纳米晶尺寸为20~30 nm。同时,从图7可以看出,选区的电子衍射花样表现为连续的同心圆环,晶粒随机取向,这是典型的纳米晶衍射花样特征。图8所示为接头焊趾表面变形层内的位错缠结、位错墙以及亚晶的TEM像。由图8可知,在焊趾表面受到高频、高能量的外加载荷连续冲击初期,表层组织会产生剧烈的塑性变形,原始粗晶内形成大量的位错。随着冲击时间的增长,位错间的相互作用加强,大量位错杂乱无序的相互缠结,形成高密度的位错缠结和位错墙。然后,在晶粒内应变量大幅增加的情况下,大量位错湮灭和重排,位错的间距减小,位错缠结和位错墙转变为小角度亚晶界,形成晶粒细小的亚晶结构。最后,在动态再结晶的作用下,亚晶逐步演变成尺寸均匀、晶界清晰、随机取向的纳米晶组织。需要注意的是:这些阶段在MB8镁合金焊接接头晶粒纳米化的过程中并不是相互独立存在的,形成亚晶的同时往往伴随位错的湮灭和重生,位错运动始终存在于整个塑性变形过程中。

图8 冲击处理后表层组织内部位错缠结、位错墙、亚晶的TEM像

Fig. 8 TEM image of dislocation tangle, wall and sub-grain of surface after UIT

经超声冲击处理后,MB8镁合金焊接接头焊趾表面变形层为具有一定厚度的纳米晶层,晶粒得到细化,晶界数目显著增多,晶界在晶粒内所占的体积比也增大,位错运动会受到晶界更大的阻碍。只有突破晶界的阻碍作用,激发相邻晶粒内的位错源开动,滑移才能产生,而细晶粒要实现相邻晶粒发生塑性变形则需要增大外加应力。因此,晶粒细化可以降低位错能动性,提高金属材料的微观塑性变形抗力,即提高金属材料的屈服强度。

2.2 表面冲击层厚度分析

试验采用不同超声冲击工艺参数处理镁合金焊接接头焊趾区域,其对应的表面变形层厚度如图9所示,图9中红色箭头代表塑性变形层的界线。由图9可知,在相同冲击电流的情况下,冲击后的接头焊趾表面均产生严重的塑性变形,但变形量和变形层的厚度随冲击时间的增加呈梯度变化。冲击时间为2、4、6 min的情况下,对应的冲击层厚度依次约为50、110、130 μm。冲击时间越长意味着输入的能量越多,表层金属产生的塑性变形越剧烈,相对应的冲击层也越深。从图9还可以看出,焊趾表面存在变形量厚薄不均匀的现象,这是由于超声冲击处理过程中,有的晶粒容易产生滑移而优先发生塑性变形,而且变形会受应变速率、温度、层错能以及晶界等因素的影响,导致晶粒的塑性变形呈不均匀性。同时,由于光学显微镜的限制,表层变形区域内的晶粒细化程度需要借助透射电镜观察分析。

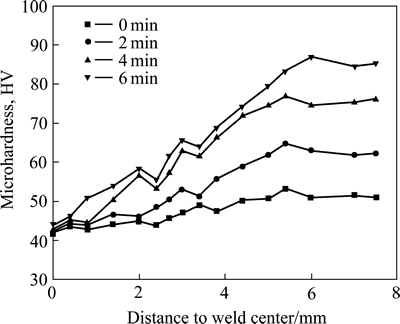

2.3 显微硬度测试结果及分析

为了研究超声冲击对MB8镁合金焊接接头表面硬化作用,对原始焊态以及不同冲击参数下的接头各区域的表面显微硬度进行测定,根据所得试验数据,绘制接头表面硬度分布图,如图10所示。由图10可知,由于原始焊态接头的焊缝及热影响区晶粒尺寸大于母材晶粒的,显微硬度值均低于母材,母材区最大硬度值为53.2 HV。经过超声冲击处理后,镁合金焊接接头焊趾区(主要是热影响区和母材)的表层硬度有了大幅度的提高,随着冲击时间的增加,硬度变化呈递增的趋势。冲击时间为2、4和6 min时,对应的接头焊趾表层最大硬度依次为64.7 HV、76.9 HV和86.8 HV,比原始焊态的最大硬度分别提高了21.6%、44.5%和63.2%。这是由于接头焊趾区表面经超声冲击处理后,产生明显的塑性变形层,可获得尺寸远小于原始粗晶的纳米晶粒,硬度增加是加工硬化和细晶强化的共同作用。

图9 不同冲击参数下变形层的显微组织

Fig. 9 Microstructures of deformation layer under different impact parameters

图10 不同冲击参数下的焊接接头显微硬度分布

Fig. 10 Microhardness distribution of welded joints under different impact parameters

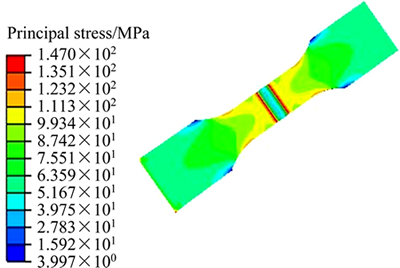

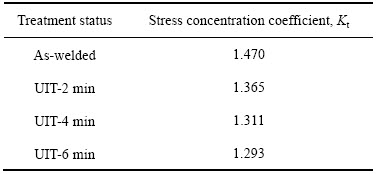

2.4 应力集中系数计算结果及分析

应力集中系数Kt的定义为焊趾处最大应力与所在截面的平均应力之比。图11所示为原始焊态接头试样(冲击0 min)的主应力云图,得到的应力集中系数Kt为1.470。

图11 焊接接头主应力云图

Fig. 11 Principal stress contours of welded joint

采用相同的网格单元及同样的加载情况下,其他冲击参数对应的接头Kt计算结果如表4所列(表4中Kt值为每组3个试样的计算结果平均值)。从图11和表4可以看出,应力主要集中在原始焊态接头焊趾处,经超声冲击处理后,应力集中系数Kt随着冲击时间的增加而不断减小。冲击时间为2、4和6 min时,对应的Kt降幅依次为7.14%、10.82%和12.04%。超声冲击技术通过增大接头焊趾过渡半径,可以有效减小应力集中系数,从而提高接头的力学性能。

表4 不同冲击参数下对应的接头应力集中系数

Table 4 Stress concentration coefficient of welded joints under different impact parameters

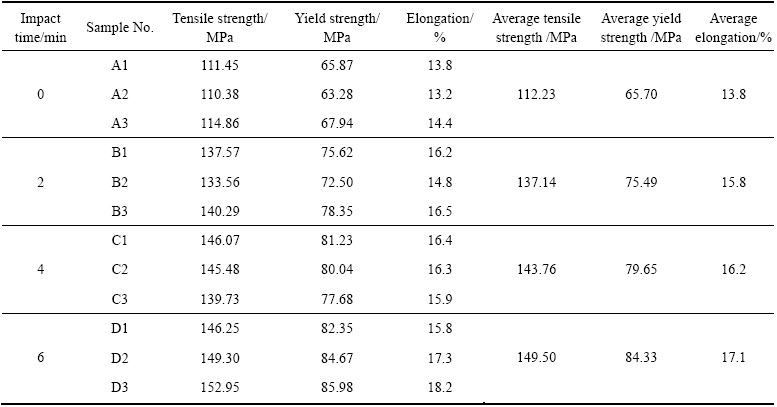

2.5 拉伸试验结果及分析

拉伸试验共分为4组,依次为未冲击、冲击2、4、6 min,每组3个试样,试验结果如表5所列。从表5中可以看出,超声冲击前后对接接头的最大抗拉强度不超过155 MPa,最大屈服强度不超过90 MPa,远低于MB8镁合金母材金属的,且拉伸试样均断裂在接头焊趾处,如图12所示。这是由于焊接接头焊趾处存在应力集中现象,焊缝区晶粒分布不均且尺寸较为粗大,同时,焊缝内存在焊接缺陷(如焊接气孔),导致焊接接头的力学性能往往低于母材的。

图12 对接接头断裂位置

Fig. 12 Fracture position of butt joint

冲击处理后,MB8镁合金对接接头抗拉强度明显提高。当冲击时间分别为2、4和6 min时,接头的抗拉强度与未冲击的试样相比依次提高了22.2%、28.1%和33.2%;屈服强度依次提高了14.9%、21.2%和28.4%。随着冲击时间的增加,接头的抗拉强度逐渐上升,但增幅并不大。此外,冲击后焊接接头的平均伸长率均高于焊态试样和母材的,即塑性得到提高,且伸长率随着冲击时间的增加呈递增趋势。焊接接头经超声冲击处理后,焊趾几何外形变为光滑圆弧过渡,应力集中程度大幅降低;焊趾部位的应力分布更加均匀,焊接残余拉应力调整为有益的残余压应力。此外,焊趾表面会产生塑性变形层,组织由粗晶转变为纳米晶粒,这些因素都有利于提高焊接接头的力学性能。但是,冲击时间的不断增加也会导致接头表面完整性下降,即焊趾表面粗糙度不断增大且容易产生微观裂纹缺陷,这些不利因素与上述的有利因素相互竞争,使得接头抗拉强度的增幅明显下降。超声冲击后接头焊趾表面的最大冲击层厚度只有130 μm左右,拉伸试验过程中裂纹往往从内部缺陷处萌生,因此,仅仅依靠冲击表面并不能显著增加其抗拉强度。若只考虑涉及到的3个冲击工艺参数,提高镁合金焊接接头力学性能的最优冲击参数为1.2 A和6 min。

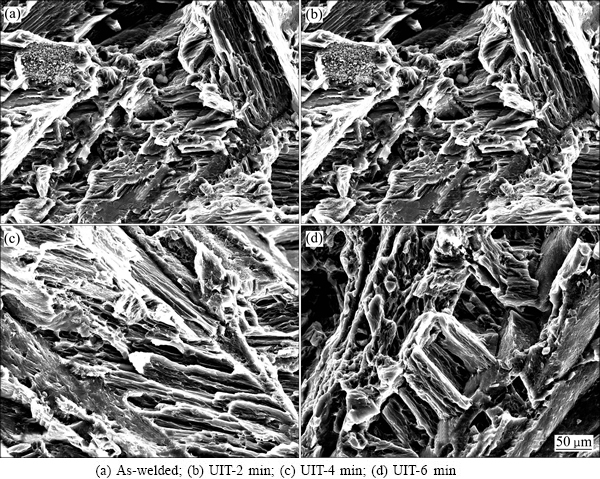

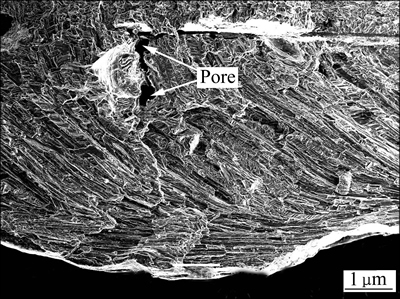

图13所示为MB8镁合金对接接头的拉伸断口形貌。由图13可看出,断口存在大量高密度短而弯曲的放射状撕裂棱,同时伴有解理台阶以及小刻面。局部撕裂棱上分布有尺寸较浅、大小均匀的等轴韧窝。因此,可以判断MB8镁合金焊接接头的拉伸断裂机制为介于解理断裂与韧性断裂之间的准解理断裂,超声冲击并不能改变接头的断裂机理,但可以增强其塑性和韧性。图14所示为焊缝断口的气孔形貌(白色箭头指的是气孔)。由图14可看出,拉伸过程中,气孔将作为应力集中源起作用,而成为裂纹萌生源,同时降低了接头横截面的受力面积,导致焊接接头的力学性能显著降低。

表5 不同冲击参数下对应的接头力学性能

Table 5 Mechanical properties of welded joints under different impact parameters

图13 不同冲击时间下接头的拉伸断口形貌

Fig. 13 Tensile fracture morphologies of joints at different impact time

图14 焊缝断口的气孔形貌

Fig. 14 Pore morphology of weld fracture surface

3 结论

1) 超声冲击处理使MB8镁合金焊接接头焊趾表层金属产生严重的塑性变形,冲击时间为2、4和6 min的情况下,对应的冲击层厚度依次约为50、110和130 μm;焊趾表面晶粒得到显著的细化,原始粗晶转变为晶界清晰、随机取向、尺寸小于100 nm的纳米晶粒。

2) 超声冲击处理后,MB8镁合金焊接接头焊趾处应力集中系数得到有效降低,焊趾表层的硬度和抗拉强度得到显著提高,当冲击电流为1.2 A、冲击时间为6 min时,与未冲击的焊态试样相比,应力集中系数降低了12.04%,焊趾表层最大硬度值提高了63.2%,抗拉强度提高了33.2%。表层金属晶粒细化,以及焊趾处应力集中程度的降低是接头力学性能提高的主要原因。

3) 超声冲击前后MB8镁合金焊接接头的拉伸断口都存在大量放射状撕裂棱,同时,伴有解理台阶以及较浅的韧窝,其断裂方式为准解理断裂。超声冲击并不会影响接头的断裂机理。

REFERENCES

[1] 巫瑞智, 张景怀, 尹冬松. 先进镁合金制备与加工技术[M]. 北京: 科学出版社, 2012: 4-7.

WU Rui-zhi, ZHANG Jing-huai, YIN Dong-song. Preparation and processing technology of advanced magnesium alloy[M]. Beijing: Science Press, 2012: 4-7.

[2] 余 琨, 黎文献, 王日初, 马正青. 变形镁合金的研究、开发及应用[J]. 中国有色金属学报, 2003, 13(2): 277-288.

YU Kun, LI Wen-xian, WANG Ri-chu, MA Zheng-qing. Research, development and application of wrought magnesium alloys[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(2): 277-288.

[3] SAMEER K D, TARA S C, RAVINDRA K, SUMAN K N S. Magnesium and its alloys in automotive applications—A review[J]. American Journal of Materials Sciences and Technology, 2015, 4(1): 12-30.

[4] 冯吉才, 王亚荣, 张忠典. 镁合金焊接技术的研究现状及应用[J].中国有色金属学报, 2005, 15(2): 165-178.

FENG Ji-cai, WANG Ya-rong, ZHANG Zhong-dian. Status and expectation of research on welding of magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(2): 165-178.

[5] 彭 建, 朱 熹, 童小山, 潘复生. 复合助焊剂对AZ31镁合金TIG焊接头组织与性能的影响[J]. 中国有色金属学报, 2013, 23(11): 3141-3146.

PENG Jian, ZHU Xi, TONG Xiao-shan, PAN Fu-sheng. Effect of compound flux on microstructure and properties of TIG welded joints of AZ31 magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(11): 3141-3146.

[6] 黎文献. 镁及镁合金[M]. 长沙: 中南大学出版社, 2005: 383-390.

LI Wen-xian. Magnesium and magnesium alloy[M]. Changsha: Central South University Press, 2005: 383-390.

[7] 何柏林, 周尚谕. 镁合金焊接接头疲劳性能研究现状和发展趋势[J]. 热加工工艺, 2012, 41(15): 185-187.

HE Bo-lin, ZHOU Shang-yu. Study on research status and development trend of fatigue properties of Mg-alloy welded joint[J]. Hot Working Technology, 2012, 41(15): 185-187.

[8] 高 明, 曾晓雁, 唐海国. MB8镁合金CO2激光焊接工艺及接头性能[J]. 中国有色金属学报, 2011, 21(5): 939-944.

GAO Ming, ZENG Xiao-yan, TANG Hai-guo. Process characterization and joint mechanical properties of CO2 laser welding of MB8 magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(5): 939-944.

[9] 何柏林. 超声冲击对镁合金焊接接头疲劳性能的研究现状[J]. 华东交通大学学报, 2011, 28(3): 73-77.

HE Bo-lin. Researching status and developing trend of the effect of ultrasonic impact on fatigue properties of magnesium weld joints[J]. Journal of East China Jiaotong University, 2011, 28(3): 73-77.

[10] 李 正, 吴圣川, 徐道荣, 王文先. 激光熔修AZ31B镁合金焊趾区材料的疲劳性能[J]. 失效分析与预防, 2011, 6(4): 209-212.

LI Zheng, WU Sheng-chuan, XU Dao-rong, WANG Wen-xian. Investigation of fatigue property of welded toes on magnesium AZ31B alloy by laser dressing method[J]. Failure Analysis and Prevention, 2011, 6(4): 209-212.

[11] 张 兰. AZ31B镁合金焊接接头疲劳性能改善方法研究[D]. 太原: 太原理工大学, 2010: 31-39.

ZHANG Lan. Study on the improving methods of fatigue property for AZ31B magnesium alloy welded joint[D]. Taiyuan: Taiyuan University of Technology, 2010: 31-39.

[12] 何柏林, 于影霞, 余皇皇, 江民华, 史建平. 超声冲击对转向架焊接十字接头表层组织及疲劳性能的影响[J].焊接学报, 2013, 34(8): 51-54.

HE Bo-lin, YU Ying-xia, YU Huang-huang, JIANG Min-hua, SHI Jian-ping. Effect of ultrasonic impact on the surface microstructure and fatigue properties of welded cross joint for train bogie[J]. Transactions of The China Welding Institution, 2013, 34(8): 51-54.

[13] 解瑞军, 邱小明, 陈芙蓉, 史志铭. 超声冲击实现7A52铝合金焊接接头表面纳米化[J]. 焊接学报, 2014, 35(12): 35-38.

XIE Rui-jun, QIU Xiao-ming, CHEN Fu-rong, SHI Zhi-ming. Surface nanocrystallization of 7A52 aluminum welded joint using ultrasonic impact treatment[J]. Transactions of The China Welding Institution, 2014, 35(12): 35-38.

[14] 黄丽婷, 陈明和, 谢兰生, 张长清. 超声冲击载荷对CP3钛合金焊接接头残余应力的影响[J]. 航空材料学报, 2014, 34(1): 52-55.

HUANG Li-ting, CHEN Ming-he, XIE Lan-sheng, ZHANG Chang-qing. Influence of ultrasonic impact load on residual stresses distribution of welded joints for CP3 titanium alloy[J]. Journal of Aeronautical Materials, 2014, 34(1): 52-55.

[15] BRIAN V, CAROLINE R B, ADOLFO B M, STANLEY T R. Fatigue behavior of welded coverplates treated with ultrasonic impact treatment and bolting[J]. Engineering Structures, 2012, 34: 163-172.

[16] BERG-POLLACK A, VOELLMECKE F J, SONSINO C M. Fatigue strength improvement by ultrasonic impact treatment of highly stressed spokes of cast aluminum wheels[J]. International Journal of Fatigue, 2011, 33: 513-518.

Effect of ultrasonic impact on surface microstructures and mechanical properties of MB8 magnesium alloy welded joint

WEI Kang, HE Bo-lin, YU Ying-xia

(College of Mechanical and Electrical Engineering, East China Jiaotong University, Nanchang 330013, China)

Abstract: Surface treatment was carried out on the weld toe of MB8 magnesium alloy welded joint with HJ-III type ultrasonic impact treatment equipment. The surface microstructures and mechanical properties of MB8 magnesium alloy welded joints treated by different impact parameters were investigated. The results indicate that, after ultrasonic impact treatment, the primary coarse grains in the surface layer of weld toe and adjacent area turn into randomly oriented nano-crystalline grains with explicit grain boundary. The stress concentration coefficients at weld toe reduce effectively. The surface hardness and tensile strength of joints improve. The joints before and after ultrasonic impact fracture at the weld toe with tensile failure mechanism of quasi-cleavage fracture. In the impact current of 1.2 A and impact time of 6 min, compared with untreated specimens, the stress concentration coefficients reduce by 12.04%, and the surface maximum hardness and tensile strength of treated welded joints increase by 63.2% and 33.2%, respectively. The grain refining of surface layers and the reduced stress concentration at weld toe are main factors which improve the mechanical properties of MB8 magnesium alloy welded joints.

Key words: ultrasonic impact; welded joint; surface microstructure; tensile strength; grain refining

Foundation item: Project(51265013) supported by the National Natural Science Foundation of China; Project (20151BAB206007) supported by the Natural Science Foundation of Jiangxi Province, China

Received date: 2015-09-08; Accepted date: 2016-03-15

Corresponding author: HE Bo-lin; Tel: +86-791-87046116; E-mail: hebolin@163.com

(编辑 李艳红)

基金项目: 国家自然科学基金资助项目(51265013);江西省自然科学基金项目资助项目(20151BAB206007)

收稿日期:2015-09-08;修订日期:2016-03-15

通信作者:何柏林,教授,博士;电话:0791-87046116;E-mail: hebolin@163.com