搅拌摩擦挤压法制备纯镁线的耐磨耐蚀性能评价

来源期刊:中国有色金属学报(英文版)2015年第6期

论文作者:Mohammad SHARIFZADEH Mohammad ali ANSARI Morteza NARVAN Reza ABDI BEHNAGH Alireza ARAEE Mohammad Kazem BESHARATI GIVI

文章页码:1847 - 1855

Key words:friction stir extrusion; Mg wire; friction; wear; hardness; corrosion

摘 要:采用搅拌摩擦挤压法来将镁屑制成镁线。在搅拌摩擦挤压过程中,探头的旋转速率分别为150、250和355 r/min,切入速率固定为20 mm/min。研究对比试样和搅拌摩擦挤压试样的显微组织演化、摩擦磨损行为和耐腐蚀性能。通过光学显微镜和扫描电镜对样品的显微结构进行表征。力学性能的评价包括显微硬度和干滑动磨损测试。通过动电位极化测试对挤出试样的耐腐蚀性能进行表征。结果表明,挤出试样具有较好的表面质量,搅拌摩擦挤压过程有利于改善机械加工碎屑的硬度和耐磨性,同时,所得到的线条具有足够的耐腐蚀性。这些结果表明搅拌摩擦挤压法是一种将机械加工产生的镁屑转变成有用的镁线的有效方法。

Abstract: A solid-state process—friction stir extrusion (FSE) was applied to produce wires from Mg chips. The FSE process was performed using tool rotational speed of 150, 250 and 355 r/min at a constant plunge rate of 20 mm/min. The microstructural evolution, tribological behavior and corrosion resistance of the reference specimen and the friction stir extruded specimens were investigated. Microstructural characteristics of the specimens were investigated by optical microscopy (OM) and scanning electron microscopy (SEM). The evaluations of mechanical properties include microhardness and dry sliding wear test. The corrosion resistance of the extruded specimens was characterized by potentiodynamic polarization test. The results show that the extruded specimens possess good surface quality and the process is beneficial for the improvement of hardness and wear resistance of the first machined chips. The produced wires are also found to have adequate corrosion resistance. These results demonstrate that FSE is an effective strategy for converting the machined Mg chips into the usable wires.

Trans. Nonferrous Met. Soc. China 25(2015) 1847-1855

Mohammad SHARIFZADEH1, Mohammad ali ANSARI1, Morteza NARVAN1,

Reza ABDI BEHNAGH1,2, Alireza ARAEE1, Mohammad Kazem BESHARATI GIVI1

1. School of Mechanical Engineering, College of Engineering, University of Tehran, Tehran, Iran;

2. Faculty of Mechanical engineering, Urmia University of Technology, Urmia, Iran

Received 16 July 2014; accepted 6 May 2015

Abstract: A solid-state process—friction stir extrusion (FSE) was applied to produce wires from Mg chips. The FSE process was performed using tool rotational speed of 150, 250 and 355 r/min at a constant plunge rate of 20 mm/min. The microstructural evolution, tribological behavior and corrosion resistance of the reference specimen and the friction stir extruded specimens were investigated. Microstructural characteristics of the specimens were investigated by optical microscopy (OM) and scanning electron microscopy (SEM). The evaluations of mechanical properties include microhardness and dry sliding wear test. The corrosion resistance of the extruded specimens was characterized by potentiodynamic polarization test. The results show that the extruded specimens possess good surface quality and the process is beneficial for the improvement of hardness and wear resistance of the first machined chips. The produced wires are also found to have adequate corrosion resistance. These results demonstrate that FSE is an effective strategy for converting the machined Mg chips into the usable wires.

Key words: friction stir extrusion; Mg wire; friction; wear; hardness; corrosion

1 Introduction

Mg and its alloys are widely used in automobile industry, aerospace and structural components because of their excellent specific strength, low density, great mechanical properties, good machinability, high specific stiffness, cold formability, good castability, and thermal conductivity [1]. Since Mg has great machinability, large quantities of Mg chips are produced at various machining processes. Recycling process of Mg involves traditional and non-traditional methods. In traditional recycling, large amounts of scraps and chips are re- melted consuming a large amount of energy. Due to the susceptibility of Mg to oxidation, and the consumption of a lot of energy and labor cost, this method is not affordable. In non-traditional recycling of Mg, proposed by CHINO et al [2], a direct approach without secondary operation is implemented [3]. By this method, Mg chips are compressed and the plastic deformation occurs during the consolidation process [4,5]. Non-traditional methods are more efficient than traditional ones in terms of air pollution (green recycling) and energy consumption. Furthermore, the specimens produced by solid-state recycling processes show high strength because of small grain size and homogeneous oxide dispersion. Some works on solid-state recycling of Mg alloys accompanied by AZ31 [1,3,5-7], AZ91 [4,8-10], ZK60 [11] and pure Mg [12], resulting in better mechanical properties and grain refinement compared with the primary ingot. The combination of solid-state recycling and friction stir welding was developed by friction stir extrusion (FSE) in The Welding Institute (TWI) in 1993 [13]. The FSE process follows the principles of the friction stir welding/processing (FSW-FSP), in which a rotating tool causes local softening of material through heat generated by friction and plastic work [14]. FSE is a solid-state material synthesizing process that produces extruded products by direct conversion of scraps into advanced bulk materials through mechanical and thermo-mechanical processing in a single step. Solid-state recycling eliminates the energy consumption pertinent to re-melting which is necessary in the conventional synthesis process. Different materials such as Mg, Al, Ti and steel have potentials to be used in this method [15-17]. Recently, TANG and REYNOLDS [17] have investigated the synthesis process of AA2050 and AA2195 Al by FSE. They indicated that the microstructure of the extruded wires consisted of fully equiaxed and recrystallized grains. They concluded that the limits on the process appeared to be related with the extrusion temperature [17]. Recently, the FSE process of AA7277 Al alloy chips has been studied by ABDI-BEHNAGH et al [18] experimentally. They showed the formation of various zones in the cross-section of the extruded wires, and the wire microstructure was characterized by equiaxed and recrystallized grains in the center of specimen. The tensile tests revealed that the mechanical properties of the extruded wire were comparable with the parent material in particular rotational speed.

Even though these investigations thoroughly demonstrate the potential of this process to emerge as an important recycling technique, however, not much is known about the wear and corrosion characteristics. As mentioned before, Mg offers a high potential for use as a lightweight structural material in transport applications such as automotive and motorbike. Since these may be subjected to serious environments, their corrosion behavior is a major concern. Mg is a naturally passive metal. Pitting corrosion will occur at free corrosion potential of Mg when exposed to chloride ions in a non-oxidizing medium [19]. It is generally observed that corrosion pits initiate at flaws adjacent to a fraction of the secondary phase particles such as Mg17Al12 as a result of the breakdown of passivity [19]. Moreover, Mg alloys have not traditionally been used for high performance applications due to their low hardness and wear resistance.

Therefore, researches in this direction are much needed to enhance the suitability of FSE for a wide range of industrial applications. Hence, the aim of this study is to investigate the corrosion and wear characteristics of the fully-consolidate Mg wires fabricated by FSE.

2 Experimental

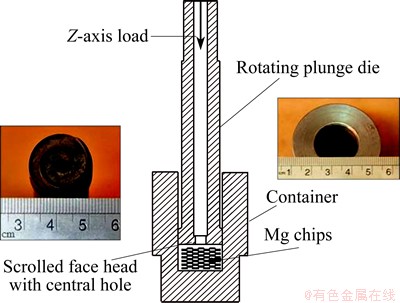

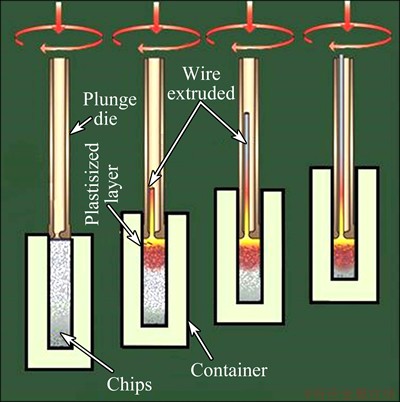

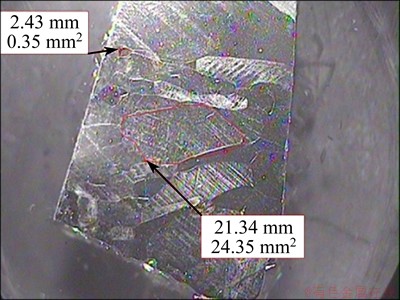

The clean and dry Mg chips used in this work was produced through machining Mg ingot without any lubricant fluid. The machining chip was prepared by a planning machine. The chip was 6-10 mm in length, 1-4 mm in width and about 0.2 mm in thickness. The chemical composition of the pure Mg ingot is <0.01% Al, 0.006% Cu, 0.03% Mn, 0.005% Zn, 0.005% Ca, <0.002% Sn and balanced Mg (mass fraction). The main components used in the process including a container and a rotating plunge die with scrolled face, which were made of H13 tool steel. The container cavity is 21 mm in diameter and 50 mm in height. The rotating plunge die has a 20 mm outer diameter with a 5 mm central hole which defines the diameter of the extruded wire. As shown in Fig. 1, the rotating plunge die has a scrolled face pattern with zero tilt angle. The scrolled face pattern is similar to the FSW tool shoulder design [17]. The container was fixed on the table of computer numerical control (CNC) milling machine. The rotating plunge die rotates in a clockwise direction and moves toward the container which is charged with Mg chips. The rotation and movement of the plunge die relative to the container cause the mixing and stirring of Mg chips, during which the contact and pressure between the rotating plunge die and Mg chips lead to the conversion of mechanical energy to thermal energy. The wire length is limited by the volume of the container. The extrusion axis is Z-axis of the machine, therefore, the extrusion force is equal to Z-force. Three rotational speeds of 180, 250 and 355 r/min under constant plunge rate of 120 mm/min were implemented. An infrared thermometer was used to monitor the temperature changes during the process. The temperature measurement is needed for the thermal analysis of the process. The schematic representation of the FSE process is shown in Fig. 2.

Fig. 1 Components used in FSE process

Fig. 2 Schematic representation of FSE process

The surface roughness (Ra) of the fabricated wires in the axial (extrusion) and traverse directions was performed using a WYKO NT1100 optical profiling system. Ra is used as a roughness parameter.

The microstructures of the FSE samples were investigated by optical microscopy (OM). The microstructures of the cross-sections of the wire were investigated perpendicular to the extrusion direction. The metal micro etch and specimen preparation for OM test were done based on ASTM E407-07 [20] and ASTM E3-11 [21], respectively. The polish was performed with a 1000 grit Al2O3 paper, and then with a 1 mm diamond paste. The final polish was done by colloidal silica with 40 nm in diameter. No scratch was observed on the polished surface. After polishing, the specimens were etched by acetic picral (5 mL acetic acid, 6 g picric acid, 10 mL water and 100 mL ethanol) at room temperature. The Vickers microhardness test was performed perpendicularly to the extrusion direction on the cross-section of the wires, with a load of 0.25 N holding for 15 s. The sliding wear behavior of the wire was evaluated with a reciprocating wear tester. The dry wear test was carried out at room temperature by applying a normal load of 20 N to the surface of the sample with hardened alloy steel (13 mm in diameter). Along the test, the sliding speed of the cylinder on the surface of the sample was 0.25 m/s for a total sliding distance of 1000 m.

The localized electrochemical measurement was performed on the cross-section of the samples in order to combine the microstructural analysis and the changes in corrosion susceptibility between the parent material and the FSE specimens. Potentiodynamic polarization is a test responsible for pitting, which can investigate the material behavior in various environments with different pH levels. It is a suitable and fast method to obtain potential pitting, corrosion rates and can give reproducible results. The electrochemical method used was Tafel polarization test. The samples were mechanically polished with a 1 μm diamond paste to a mirror finish. The electrochemical potentiodynamic measurement was performed in a three-electrode cell arrangement. A platinum mesh with the geometric area of about 20 cm2 was used as the counter electrode, while all potentials were measured with respect to a commercial saturated calomel electrode (SCE). The electrochemical experiment was carried out using a potentiostat/ galvanostat (Autolab 302N) run by PowerSuite software. The potentiodynamic curves were recorded at a scan rate of 0.3 mV/s in the potential range of -250 mV (vs OCP) to +700 mV (vs SCE).

3 Results and discussion

3.1 Thermal analysis

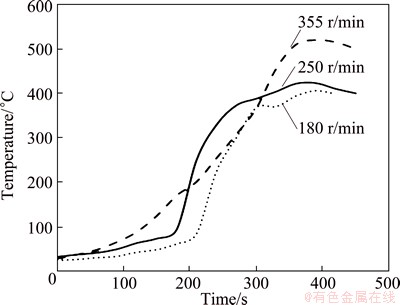

The temperature variation during the FSE process was monitored by an infrared thermometer pointed at the outer surface of the container. The purpose of this monitoring is to investigate the effect of temperature variation on the mechanical and metallurgical properties of the extruded wires. The temperature versus time curves of the FSE process during extrusion are shown in Fig. 3. The thermal energy in the FSE process is generated by the contact friction between the chips, and also the chips and die components by the insertion of vertical load and the die rotation. The amount of heat affects the average grain size and the surface quality of the produced wires. The temperature measurement indicates that the maximum temperature during the process is 0.8Tm with the rotation speed of 355 r/min, where Tm is the melting temperature.

Fig. 3 Temperature variation vs time during FSE process

In the FSE process, the tool rotation results in the stirring of the material in the container which in turn increases the temperature of the metal. The increased temperature as a result of increasing rotational speed leads to the softening of the material and amends the plastic deformation and consequently eases the extrusion. However, excessive temperature rise paves the way for grain growth, leading to the aggravating of the mechanical properties of the specimen, and facilitating the formation of cracks [18]. On the other hand, insufficient temperature input results in the formation of voids, cold cracks, and twisting in the obtained wire [18]. So, a proper selection of the tool rotational speed as the input parameter is very important to obtain defect-free wires.

3.2 Microstructural analysis

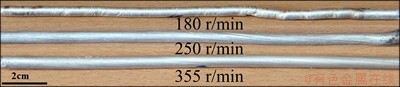

The surface appearances of the wires produced by the FSE process are shown in Fig. 4. Good and poor surface quality of wires are observed. The most important parameter affecting the process is the rotational speed [18]. Low rotational speed leads to insufficient heat generation during the process which increases the possibility of the extrusion defects. As shown in Fig. 4, there are twisting and cold tearing along with the wire surface at the rotational speed of 180 r/min. However, at the rotational speeds of 250 and 355 r/min, the entire lengths of the wires are with smooth surface and without any cracks. Moreover, the results show that the surface roughness is minimum at the rotational speed of 355 r/min, with the Ra values in the extrusion and traverse directions are 0.23 and 1.41 μm, respectively.

Fig. 4 Surface appearances of FSE samples

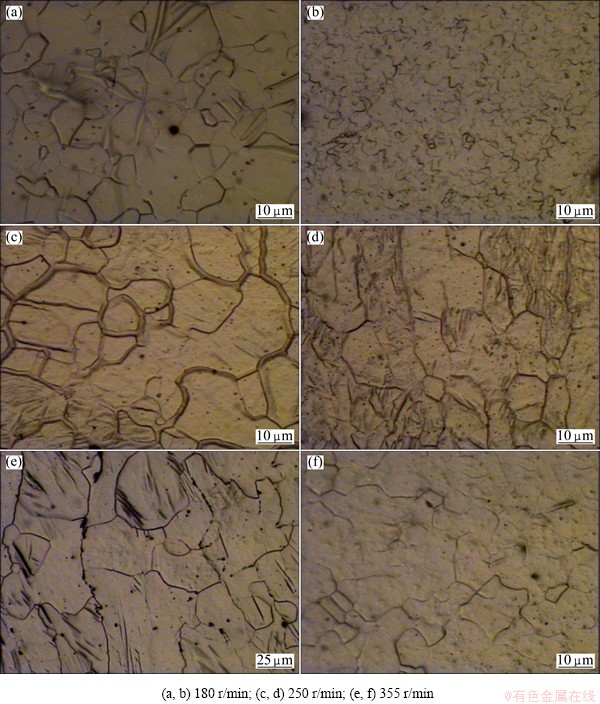

The optical image of the parent material is shown in Fig. 5. It is apparent that large grains are distributed in the parent material with the size of several millimeters, whereas the extruded specimens show relatively fine grains. The comparison of the microstructure views between the parent material and the wires in Figs. 5 and 6 proves that the grain refinement happens during the FSE process. In the FSE process, dynamic recrystallization that occurs during the deformation leads to the generation of fine grains. However, the average grain size is probably affected by the heat amount factor which is the direct result of the die rotation speed. The average grain size in the center of each specimen is shown in Table 1, which was measured by the mean linear intercept method. The average grain size in the FSE specimen ranges from 9 μm to 27 μm, which is much smaller than that of the base material (BM). Moreover, the two optical microscopy images for each sample show that the microstructure is not uniform along the wire. As shown in Fig. 6, in all specimens, the grains in the center are larger than those in the boundary of the wires. This may be attributed to the higher strain rate in the center regions.

Fig. 5 Optical micrograph of Mg ingot

Fig. 6 Optical micrographs of wires produced at different rotational speeds

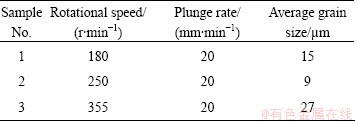

Table 1 Average grain size of FSE samples

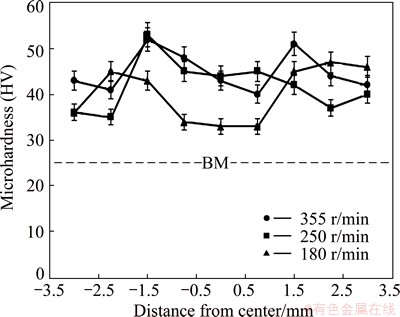

3.3 Hardness and wear performance

For the BM, the average hardness value is approximately HV 25. A fine-grained material (one that has small grains) is harder and stronger than the coarse- grained one, since the former has a greater total grain boundary area to impede the dislocation motion [22]. The Vickers microhardness profiles of the cross-section of the wires perpendicular to the extrusion direction are shown in Fig. 7. It can be seen that the hardness value along the diameter of the wire is higher than that of the BM. The relationship between the room-temperature hardness H and the average grain size D is represented by Hall–Petch equation [22]:

H=H0+kD-1/2 (1)

where D is the average grain diameter, H0 and k are the constants for a particular material.

Fig. 7 Microhardness profiles of BM and produced wires

It is suggested from Eq. (1) that the FSE specimens, when D is reduced to around or less than 5 μm, possess higher performance of the room-temperature hardness compared with the first machined chips.

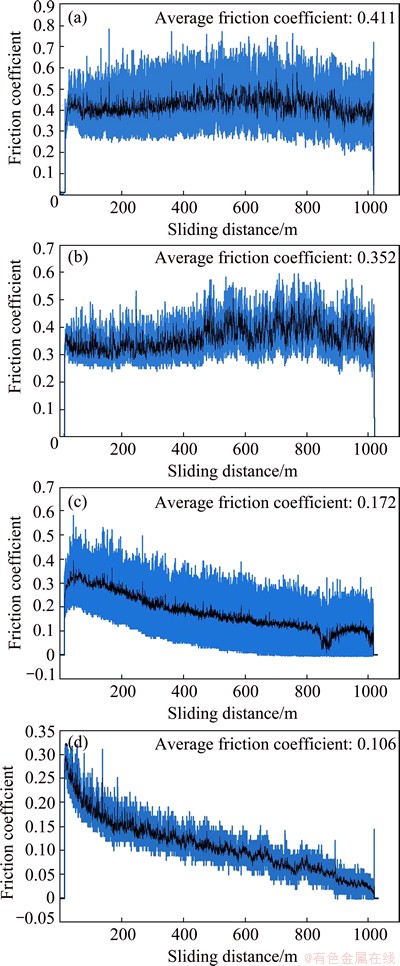

Figure 8 shows the variation of friction coefficient with sliding distance (SD) for the BM and the FSE samples. The average friction coefficient of the BM is found to be 0.411 as indicated by high fluctuations in the friction curves. The minimum value of friction coefficient is about 0.106 that is achieved at the rotational speed of 355 r/min, which is clearly much lower than that of the BM. From Fig. 8, it is found that the average friction coefficient of 180 r/min sample is significantly higher than those of 250 and 355 r/min samples. This result was not unexpected due to the lower hardness values of 180 r/min sample shown in Fig. 7.

Fig. 8 Variation of friction coefficient of BM (a) and wires produced at rotational speed of 180 r/min (b), 250 r/min (c) and 355 r/min (d)

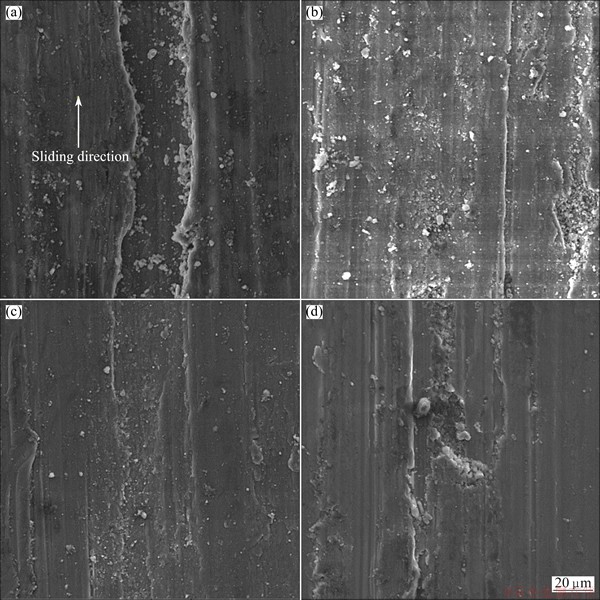

The SEM images of the worn surfaces of the BM and FSE samples are shown in Fig. 9. The existence of the deep ploughs in Fig. 9(a) shows the severe adhesive wear happened on the surface of the BM. When two sliding surfaces come into contact, normal and tangential loads are transmitted through the contact areas by ploughing and adhesive actions. From the SEM micrograph of the worn surfaces, it is found that the abrasive wear also happens in the BM. Although the metal-to-metal contact between the steel disk and the Mg surface is expected to occur adhesive wear, it seems that resulted in a combination of adhesive and abrasive wear. The adhesive wear transfers the removed material from the surface of the BM to the steel disk. These transferred materials might have been oxidized during the sliding and therefore the large metallic debris particles are produced [23]. The existence of these particles could result in abrasive wear and increase the wear rate of the parent material.

Albeit both the BM and FSE samples exhibit similar wear mechanisms, the present results indicate that the FSE wire surfaces have lower friction coefficient and smaller wear rate, which implies that the FSE samples have higher wear resistance than the BM. The fine equiaxed grains and the consequent hard surface of the FSE samples positively affect the wear resistance. As mentioned before, according to the Hall–Petch relationship, the reduction in the grain size will result in the hardening or strengthening of the metal, thereby in accordance with Archards law [24]:

V/L=KW/H (2)

where V is the wear volume, L is the sliding distance, K is the coefficient of wear, W is the normal load, and H is the hardness of the softer material in the two contacting metals. The H is valid to both the adhesive and abrasive wears, in other words, the higher the hardness, the lower the wear volume would be.

Increased hardness prevents the wires from the severe adhesive wear and consequently decreases the rate of wear.

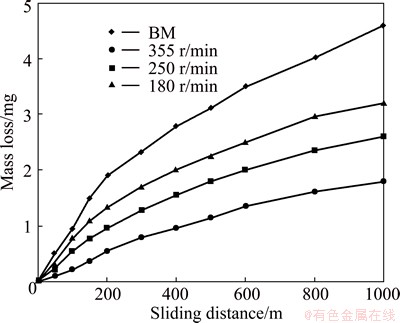

The wear mass loss versus the sliding distance is plotted for the BM and the fabricated wires (Fig. 10). As shown in Fig. 10, the mass loss increases with increasing the sliding distance, and the mass loss of the BM is much higher than that of the FSE specimens. Again, the effect of the FSE process on decreasing the wear mass loss of the machined chips can be attributed to the enhanced hardness and strength of the material against the plastic deformation by reducing the adhesion between the sliding disk and the metal.

Fig. 9 Typical worn surface morphologies of BM (a) and wires produced at rotational speed of 180 r/min (b), 250 r/min (c) and 355 r/min (d)

Fig. 10 Mass loss as function of sliding distance for BM and FSE samples

It can be concluded from these results that the wear resistance of the pure Mg chips significantly was enhanced by the friction stir extrusion due to the intensive grain refinement during the process.

3.4 Corrosion resistance

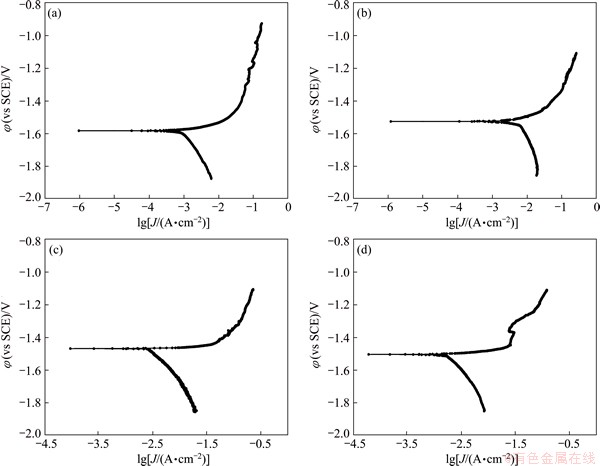

It can be seen from Fig. 11 that the corrosion potential (φcorr) smoothly differs from one FSE sample to another. The values are around -1.5 V (vs SCE), while the value for the BM is around -1.6 V. So, in almost all cases, the BM is more reactive than the FSE specimens. Therefore, the FSE specimens have better pitting resistance as compared with the as-received material.

Fig. 11 Potentiodynamic polarization curves of BM (a) and wires produced at rotational speed of 180 r/min (b), 250 r/min (c) and 355 r/min (d)

The most important factors affecting the corrosion behavior of Mg alloys are the alloying elements, grain size, microstructural modification and heat treatment. It seems that in the FSE process of pure Mg, the grain size is the most important factor affecting the corrosion behavior. Friction stir extrusion as a solid-state process refines the microstructure, which is beneficial to the corrosion properties. For the FSE samples, since the structure and grain sizes are almost the same, there is a little difference between the corrosion resistances of them. As mentioned before, the first machined pure Mg chips exhibited very coarse grains with the size of several millimeters, whereas the extruded wires showed relatively fine grains (Fig. 6). The large grain may be the main reason of the poor corrosion behavior of the pure Mg. Many previous studies reported that the reduction of the grain size in Mg alloys can lead to a significantly reduced corrosion rate [25,26]. Moreover, the segregation of alloying elements and the impurities in the grain boundaries result in a more cathodic behavior of the grain boundaries compared with the center of the grains. In the fine grained Mg alloys, the anode and cathode are close to each other and distributed more uniformly, hence the corrosion behavior appears to be more homogeneous. The homogenous corrosion behavior is an important factor in the cardiovascular stent applications.

4 Conclusions

1) FSE is an energy efficient solid-state synthesis process that produces the extruded products by direct conversion of the scrap materials to the advanced nano-engineered bulk material in a single step.

2) The FSE of the machined pure Mg chips resulted in the fabrication of the wires with good surface quality and fine homogenous microstructure. The resulted microstructure lowered the friction coefficient and enhanced the wear resistance of the BM after extrusion.

3) The grain size and the evolution of microstructure are the factors affecting the corrosion behavior of the FSE samples. The fine grains may be the main reason of the improved corrosion resistance of the produced wires.

References

[1] ZHANG T, JI Z, WU S. Effect of extrusion ratio on mechanical and corrosion properties of AZ31B alloys prepared by a solid recycling process [J]. Materials and Design, 2011, 32: 2742-2748.

[2] CHINO Y, HOSHIKA T, MABUCHI M. Mechanical and corrosion properties of AZ31 magnesium alloy repeatedly recycled by hot extrusion [J]. Materials transactions, 2006, 4: 1040-1046.

[3] JI Z, WEN L, LI X. Mechanical properties and fracture behavior of Mg-2.4Nd-0.6Zn-0.6Zr alloys fabricated by solid recycling process [J]. Journal of Materials Processing Technology, 2009, 209: 2128-2134.

[4] YING Tao, ZHENG Ming-yi, HU Xiao-shi, WU Kun. Recycling of AZ91 Mg alloy through consolidation of machined chips by extrusion and ECAP [J]. Transactions of Nonferrous Metals Society of China, 2010, 20: s604-s607.

[5] WU Shu-yan, JI Ze-sheng, RONG Shou-fan, HU Mao-liang. Microstructure and mechanical properties of AZ31B magnesium alloy prepared by solid-state recycling process from chips [J]. Transactions of Nonferrous Metals Society of China, 2010, 20: 783-788.

[6] MORISADA Y, FUJII H, NAGAOKA T, FUKUSUMI M. MWCNTs/AZ31 surface composites fabricated by friction stir processing [J]. Materials Science and Engineering A, 2006, 419: 344-348.

[7] CHINO Y, K H, KISHIHARA R, SHIMOJIMA K, HOSOKAWA H, YAMADA Y, WEN C, IWASAKI H, MABUCHI M. Superplasticity and cavitation of recycled AZ31 magnesium alloy fabricated by solid recycling process [J]. Materials transactions, 2002, 43: 2437-2442.

[8] HU M, JI Z, CHEN X, ZHANG Z. Effect of chip size on mechanical property and microstructure of AZ91D magnesium alloy prepared by solid state recycling [J]. Materials Characterization, 2008, 59: 385-389.

[9] HU Mao-liang, JI Ze-sheng, CHEN Xiao-yu, WANG Qu-dong, DING Wen-jiang. Solid-state recycling of AZ91D magnesium alloy chips [J]. Transactions of Nonferrous Metals Society of China, 2012, 22: 68-73.

[10] MABUCHI M, KUBOTA K, HIGASHI K. New recycling process by extrusion for machined chips of AZ91 magnesium and mechanical properties of extruded bars [J]. Materials Transactions, 1995, 36: 1249-1254.

[11] NAKANISHI M, MABUCH M, SAITO N, NAKAMURA M, HIGASHI K. Tensile properties of the ZK60 magnesium alloy produced by hot extrusion of machined chip [J]. Journal of materials science letters, 1998, 17: 2003-2005.

[12] CHINO Y, HOSHIKA T, MABUCHI M. Enhanced corrosion properties of pure Mg and AZ31Mg alloy recycled by solid-state process [J]. Materials Science and Engineering A, 2006, 435: 275-281.

[13] THOMAS W M, NICHOLAS E D, JONES S B. Friction extrusion metal working: US, No.5262123 [P], 1993.

[14] MISHRA R S, MA Z Y. Friction stir welding and processing [J]. Materials Science and Engineering R, 2005, 50: 1-78.

[15] PELLEGRINO J L, MARGOLIS N, JUSTINIANO M, MILLER M. Energy use, loss and opportunities analysis [M]. Energetics, Incorporated and E3M, 2004: 169.

[16] DAS S K, GREEN J A S, GILBERT KAUFMAN J, EMADI D, MAHFOUD M. Aluminum recycling—An integrated, industry wide approach [J]. JOM, 2010, 62: 23-26.

[17] TANG W, REYNOLDS A. Production of wire via friction extrusion of aluminum alloy machining chips [J]. Journal of Materials Processing Technology, 2010, 210: 2231-2237.

[18] ABDI BEHNAGH R, MAHDAVINEJAD R, YAVARI A, ABDOLLAHI M, NARVAN M. Production of wire from AA7277 aluminum chips via friction-stir extrusion (FSE) [J]. Metallurgical and Materials Transactions B, 2014, 45: 1484-1489.

[19] SONG G, ATRENS A. Corrosion mechanisms of magnesium alloys [J]. Advance Engineering Materials, 1999, l: 11-33.

[20] ASTM Standard #E407-07. Standard test methods for microetching [S]. 2004.

[21] ASTM Standard #E3-11. Standard test methods for sample grounding and polishing [S]. 2004.

[22] CALLISTER W D, RETHWISCH D G. Fundamentals of materials science and engineering: An integrated approach [M]. John Wiley & Sons, 2012.

[23] CHEN H, ALPAS A T. Sliding wear map for the magnesium alloy Mg-9Al-0.9 Zn (AZ91) [J]. Wear, 2000, 246: 106-116.

[24] SUN H Q, SHI Y N, ZHANG M X. Wear behaviour of AZ91D magnesium alloy with a nanocrystalline surface layer [J]. Surface & Coatings Technology, 2008, 202: 2859-2864.

[25] BIRBILIS N, RALSTON K D, VIRTANEN S, FRASER H L, DAVIES C H J. Grain character influences on corrosion of ECAPed pure magnesium [J]. Corrosion Engineering, Science and Technology, 2010, 45: 224.

[26] ALVAREZ-LOPEZ M, PEREDA M D, DEL VALLE J A, FERNANDEZ-LORENZO M, GARCIA-ALONSO M C, RUANO O A, ESCUDERO M L. Corrosion behaviour of AZ31 magnesium alloy with different grain sizes in simulated biological fluids [J]. Acta Biomaterialia, 2010, 6: 1763-1771.

Mohammad SHARIFZADEH1, Mohammad ali ANSARI1, Morteza NARVAN1,

Reza ABDI BEHNAGH1,2, Alireza ARAEE1, Mohammad Kazem BESHARATI GIVI1

1. School of Mechanical Engineering, College of Engineering, University of Tehran, Tehran, Iran;

2. Faculty of Mechanical engineering, Urmia University of Technology, Urmia, Iran

摘 要:采用搅拌摩擦挤压法来将镁屑制成镁线。在搅拌摩擦挤压过程中,探头的旋转速率分别为150、250和355 r/min,切入速率固定为20 mm/min。研究对比试样和搅拌摩擦挤压试样的显微组织演化、摩擦磨损行为和耐腐蚀性能。通过光学显微镜和扫描电镜对样品的显微结构进行表征。力学性能的评价包括显微硬度和干滑动磨损测试。通过动电位极化测试对挤出试样的耐腐蚀性能进行表征。结果表明,挤出试样具有较好的表面质量,搅拌摩擦挤压过程有利于改善机械加工碎屑的硬度和耐磨性,同时,所得到的线条具有足够的耐腐蚀性。这些结果表明搅拌摩擦挤压法是一种将机械加工产生的镁屑转变成有用的镁线的有效方法。

关键词:搅拌摩擦挤压;Mg线;摩擦;磨损;硬度;腐蚀

(Edited by Mu-lan QIN)

Corresponding author: Reza ABDI BEHNAGH; Tel: +98-0443-3728180; Fax: +98-0443-1980251; E-mail: r.abdibehnagh@mee.uut.ac.ir

DOI: 10.1016/S1003-6326(15)63791-8