电火花线切割5083 Al合金的实验研究和参数优化

来源期刊:中国有色金属学报(英文版)2014年第2期

论文作者:G. SELVAKUMAR G. SORNALATHA S. SARKAR S. MITRA

文章页码:373 - 379

关键词:丝电火花加工;铝合金;Taguchi方法;附加模型;优化;Pareto优化

Key words:wire electrical discharge machining (WEDM); aluminum alloy; Taguchi method; additive model; optimization; Pareto optimization

摘 要:通过实验分析,优化电火花线切割5083 Al合金的工艺参数。基于Taguchi优化法,将脉宽、脉间、峰电流和线张力作为输入参数进行了系列实验。将表面粗糙度和切割速度作为响应,基于信噪比,测定了输入参数对响应的影响。通过Taguchi优化方法,得到了最大切割速度和最小表面粗糙度的最佳加工参数。再采用附加的模型预测可能的加工组合。最后,通过使用Pareto优化法,得到一个简明的工艺参数表。

Abstract: The experimental analysis presented aims at the selection of the most optimal machining parameter combination for wire electrical discharge machining (WEDM) of 5083 aluminum alloy. Based on the Taguchi experimental design (L9 orthogonal array) method, a series of experiments were performed by considering pulse-on time, pulse-off time, peak current and wire tension as input parameters. The surface roughness and cutting speed were considered responses. Based on the signal-to-noise (S/N) ratio, the influence of the input parameters on the responses was determined. The optimal machining parameters setting for the maximum cutting speed and minimum surface roughness were found using Taguchi methodology. Then, additive model was employed for prediction of all (34) possible machining combinations. Finally, a handy technology table has been reported using Pareto optimality approach.

Trans. Nonferrous Met. Soc. China 24(2014) 373-379

G. SELVAKUMAR1, G. SORNALATHA2, S. SARKAR3, S. MITRA3

1. Department of Mechanical Engineering, National Engineering College, K.R. Nagar 628503, Tamilnadu, India;

2. Mechanical Engineering Department, SCAD College of Engineering & Technology, Cheranmahadevi 627414, Tamilnadu, India;

3. Production Engineering Department, Jadavpur University, Kolkata 700032, India

Received 19 April 2013; accepted 11 July 2013

Abstract: The experimental analysis presented aims at the selection of the most optimal machining parameter combination for wire electrical discharge machining (WEDM) of 5083 aluminum alloy. Based on the Taguchi experimental design (L9 orthogonal array) method, a series of experiments were performed by considering pulse-on time, pulse-off time, peak current and wire tension as input parameters. The surface roughness and cutting speed were considered responses. Based on the signal-to-noise (S/N) ratio, the influence of the input parameters on the responses was determined. The optimal machining parameters setting for the maximum cutting speed and minimum surface roughness were found using Taguchi methodology. Then, additive model was employed for prediction of all (34) possible machining combinations. Finally, a handy technology table has been reported using Pareto optimality approach.

Key words: wire electrical discharge machining (WEDM); aluminum alloy; Taguchi method; additive model; optimization; Pareto optimization

1 Introduction

Wire electrical discharge machining (WEDM) is one of the most extended non-conventional machining processes used to produce complex shapes and profiles. It is a thermoelectric process in which workpiece material is eroded by a series of discrete sparks between the workpiece and a traveling wire electrode immersed in a liquid dielectric medium. These electrical discharges melt and vaporize minute a mount of the work material, which is then ejected and flushed away by the dielectric [1]. The movement of the wire is precisely monitored by a computer-numerically controlled (CNC) system. WEDM is widely used in aerospace, automobile, medical, tool and die manufacturing industries [2]. The selection of optimum machining parameters for obtaining higher cutting speed with specified surface finish and other accuracy features is a difficult job in WEDM owing to the presence of a large number of process variables and complicated stochastic process mechanism. Hence, an elaborate study is required for optimum parameter setting to achieve the maximum process criteria yield for different classes of engineering materials. A large amount of research work has been reported for different classes of engineering materials in the area of parametric optimization of WEDM.

HEWIDY et al [3] used response surface methodology (RSM) models for correlating the inter- relationships of various WEDM machining parameters of Inconel 601. PRASAD and GOPALAKRISHNA [4] employed the RSM modeling and optimized the responses by applying non-dominated sorting genetic algorithm. KURIAKOSE and SHUNMUGAM [5] used multiple regression models and optimized the WEDM process based on non-dominated sorting genetic algorithm (NSGA) which produces the Pareto optimal set of machining parameters. SARKAR et al [6] investigated the selection of the optimum cutting condition based on the Pareto-optimality for machining γ-titanium- aluminide alloy. They also carried out the parametric optimization of WEDM to maximize the cutting speed while keeping the surface roughness within limits using the feed forward back-propagation neural network model [7]. RAMAKRISHNAN and KARUNAMOORTHY [8,9] optimized the WEDM responses concurrently using multi response signal-to- noise (MRSN) ratio in addition to Taguchi’s parametric design approach. SPEDDING and WANG [10] presented an attempt at optimization of the process parametric combination using artificial neural networks and characterized the roughness and waviness of workpiece surface along with the cutting speed. CHIANG and CHANG [11] conducted experiments on Al2O3 particle reinforced material (6061 alloy) and optimized the responses based on the grey relational analysis. TOSUN et al [12] investigated the effect and optimization of machining parameters on the kerf (cutting width) and material removal rate (MRR) on AISI 4140 steel during WEDM operations. They used regression model and obtained optimum machining parameter combination by the analysis of signal-to-noise (S/N) ratio. SELVAKUMAR et al [13,14] investigated the corner accuracy aspects in wire electrical discharge machining of Monel 400 alloy and 5083 aluminium alloy, respectively. SARKAR et al [15] proposed an analytical model to measure gap force intensity and wire lag under any given machining condition.

In the present study, wire electrical discharge machining of 5083 (Tempered H112) aluminum alloy having following compositions of Mg 4.32%, Mn 0.74%, Cr 0.15%, Si 0.19%, Fe 0.27%, Cu 0.04% and the balance of Al, has been considered. Aluminium alloys have primary potential for lightweight structural application in automotive, missile and aerospace industries. Among these, 5083 aluminum alloy (5083 AA) is preferred for its reasonable strength, excellent low temperature properties (does not exhibit ductile to brittle transition and has very high toughness even at cryogenic temperatures to near absolute zero), better corrosion resistance, weldability and ability to take surface finish. It is predominantly used in marine and cryogenic industries. No or little specific machinability data are available for 5083 AA through conventional means such as turning, milling, drilling and grinding. However, TOTTEN and MACKENZIE [16] reported the machinability ratings of aluminium alloys span into five groups, with ratings of A, B, C, D and E, which are ordered in increasing order of chip length and decreasing order of surface quality. The 5083 aluminium alloy ranked D is an indicator for poor machinability. The challenges involved in machining aluminium alloys demand innovative approaches towards the design of cutting tools, especially diamond-based cutting tools. This can be totally avoided by choosing WEDM process. The WEDM is one of the attractive machining techniques to process 5083 AA to any complex shape with very high precision and accuracy.

The present work aimed at providing a customized technology table for shop floor engineers in machining aluminum alloys through WEDM process. Initial emphasis is placed on the influence of the parameters on the process criteria yield and the prediction of the responses through Taguchi-based additive models. Later, optimization of the responses has been carried out by applying Pareto-optimality approach. The optimal machining conditions proposed in this work have ample industrial applications because of the versatility of 5083 aluminium alloy.

2 Experimental design

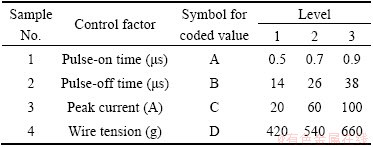

The experiments were performed on an electra supercut 734 series 2000 CNC wire cut-EDM machine. Based on the literature survey and the trial experiments, the variables such as pulse-on time (A), pulse-off time (B), peak current (C) and wire tension (D) were considered control variables. Table 1 shows the control factors with their levels. The levels of parameters were decided based on the trial runs. There are other factors, which would have little influence on the measure of performance, are kept constant, i.e. product size (5 mm× 5 mm), temperature of the dielectric (27 °C), conductivity of the dielectric (20 Ω), dielectric pressure 0.833 MPa, work piece thickness (15 mm), pulse peak voltage setting (100 V), wire feed setting (6 m/min), servo voltage (3 V), servo feed setting (30 proportional mode), wire type (0.25 mm-diameter brass) and angle of cut (vertical).

Table 1 Control factors and their levels

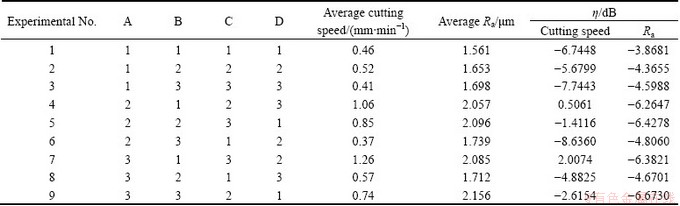

Based on the input factors and their levels listed in Table 1, experiments were conducted by employing Taguchi’s L9 orthogonal array shown in Table 2. In order to minimize the effect of random factors, each experiment was repeated thrice and the average of responses, namely cutting speed and surface roughness, are listed in Table 2. The cutting speed was recorded directly from the monitor of the machine and the surface roughness (Ra) was measured by Perthometer manufactured by Mahr, Germany.

In WEDM, the lower surface roughness and the higher cutting speed (CS) are the indication of better performance. Therefore, the lower Ra and higher CS were selected for obtaining optimum machining performance characteristics. For each experiment, the signal to noise ratio (S/N, η) was calculated and presented in Table 2.

3 Parametric analysis and discussion on experimental results

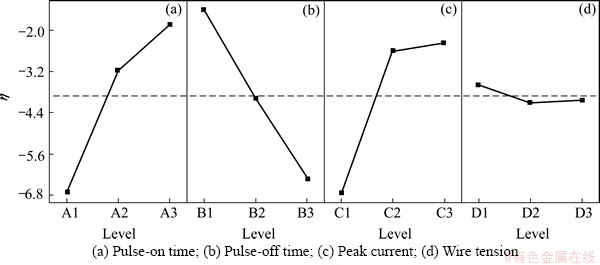

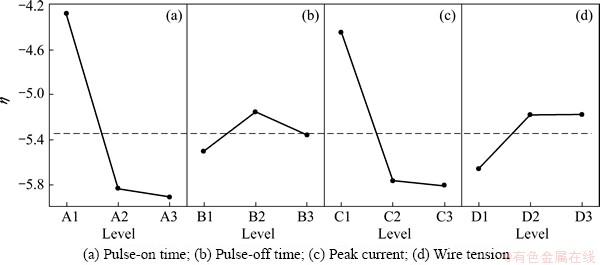

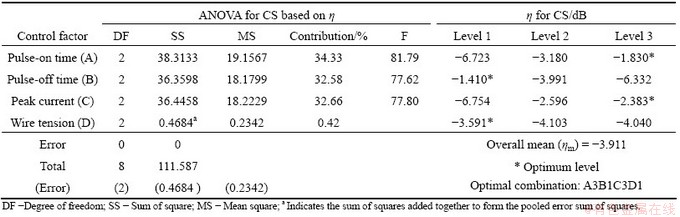

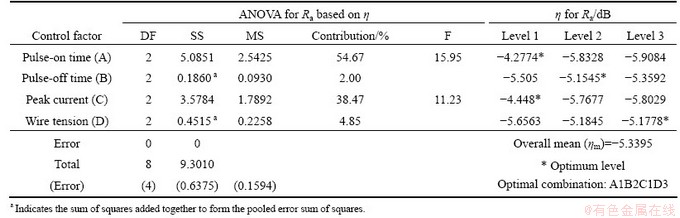

Figures 1 and 2 show the effect of control factors on cutting speed and surface roughness. Based upon the η values shown in Table 2, an analysis of variance was performed in order to estimate the predictive accuracy of the model and to determine the relative significances of the different factors. From the analysis of the CS data shown in Table 3, it is observed that pulse-on time, pulse-off time and peak current play significant roles in determining the CS and are not dependent on wire tension. From the analysis of the surface roughness Ra data presented in Table 4, it is observed that pulse-on time and peak current are the important process parameters and are independent of pulse-off time and wire tension.

Table 2 Experimental plan with S/N ratio

Fig. 1 Effects of factor on S/N ratio of cutting speed

Fig. 2 Effects of factor on S/N ratio of Ra

Table 3 Analysis of CS data

Table 4 Analysis of Ra data

The cutting speed has been found to have an increasing trend with the increase of pulse-on time and peak current. At the same time it decreases with the increase of pulse-off time, as depicted in Fig. 1. As the energy content of a single-pulse discharge is the product of pulse-on time and peak current, an increase in these values enhances the rate of melting and vaporizing of the workpiece material. Therefore, CS increases with the increase of pulse-on time and peak current. The decrease in CS owing to the increase in pulse-off time establishes the fact that the CS is also depending on the applied energy rate or power. From Fig. 2 it is observed that the surface finish decreases, namely Ra increases, with increase in pulse-on time and peak current. This is due to the higher energy pulses generated owing to the increase in pulse-on time or peak current. The higher energy pulse produces a greater depth of crater and over cut. Therefore, Ra depicts decreasing trend with pulse-on time and peak current.

It is interesting to note from Table 4 that the surface roughness is almost independent of pulse-off time as energy contained in a pulse is dependent on pulse-off time. This inference has got great practical importance for machining complex profiles and sharp corners as they require reduction in cutting speed. The pulse-off time could be increased to reduce the cutting speed in order to avoid frequent wire breakage or to achieve better corner accuracy without affecting surface finish distinctly.

The task of determining the best setting for each control factor is complicated when multiple characteristics are present. Figures 1 and 2 show that the best level of significant factor for CS, i.e. A3B1C3D1, is not same for the best level of significant factor for surface roughness, i.e. A1B2C1D3. The most influencing common factors for CS and Ra are pulse-on time and peak current. They are entirely contradictory. This elucidates that these two objectives are conflicting in nature and are not possible to have single combination of levels of different factors which would give optimal responses at all circumstances. Hence, there is a need to explore a suitable strategy for optimization of this process. The next section will brief about the additive model and later this model will be used to carry out optimization.

4 Additive modeling of WEDM process

Additive model has been employed on the basis of matrix experiments using orthogonal arrays [17]. An additive model can be viewed as superposition model or a variable separable model. It can be noted that superposition model implies that the total effect of several factors is equal to the sum of individual factor effects. It is possible for the individual factor effects to be linear, quadratic or higher order. In an additive model cross product terms involving two or more factors are not considered.

The predicted S/N ratio  using the optimal levels of the machining parameters can be calculated as [12]

using the optimal levels of the machining parameters can be calculated as [12]

(1)

(1)

where ηm is total mean of S/N ratio,  is the mean of S/N ratio at the optimal level and p is the number of main machining parameters which significantly affect the performance. The model given in Eq. (1) was used for analysis and optimization of various process parameters in WEDM process.

is the mean of S/N ratio at the optimal level and p is the number of main machining parameters which significantly affect the performance. The model given in Eq. (1) was used for analysis and optimization of various process parameters in WEDM process.

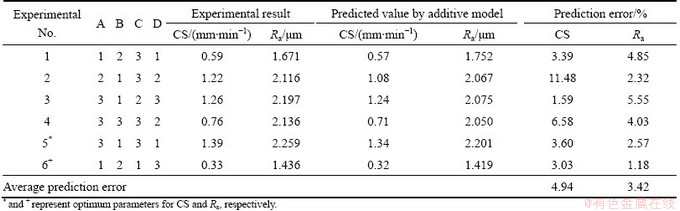

This additive model can predict the response parameters for any arbitrary level of input factors. Experimental results shown in Table 2 were used for modeling of WEDM process. To verify the proposed model, verification experiments have been performed and the results are listed in Table 5.

From Table 5, it is observed that the predicted values through additive model are very close to the experimental observations. Hence, this model is plausible for prediction.

5 Multi-objective optimization of WEDM

The optimal parameter setting found by Taguchi methodology for cutting speed (A3B1C3D1) and surface roughness (A1B2C1D3) did not have any industrial value as it dealt with single response. Generally, shop floor engineers need to produce components according to the surface finish and other accuracy features specified by the customers. As the cutting speed and surface finish are conflicting in nature, it is seldom possible to achieve a single-optimal parametric setting for the both responses. Nonetheless, some researchers [8,9,11,12,18,19] have employed response surface methodology (RSM), genetic algorithm (GA), simulated annealing (SA), grey relational analysis and Taguchi methods to obtain optimal parameter setting by assigning weights to the objective functions. These methods have also ended up with a single-optimal solution. Further, the selection of weights is a very difficult task even for a field expert.

Optimizing a particular problem concerning with one objective function can produce adverse results with respect to others. Therefore, Pareto-optimality approach has been used for searching Pareto-optimal solution set or Pareto front. A Pareto-optimal set is a set of solutions that are non-dominated with respect to each other. While moving from one Pareto solution to another, there is always a certain amount of importance in one objective to achieve a certain amount of gain in the other. Generating the Pareto set has several advantages, e.g. it allows the user to make an informed decision by seeing a wide range of options. This was ignored by other methods. Therefore, this approach is considered superior to other methods.

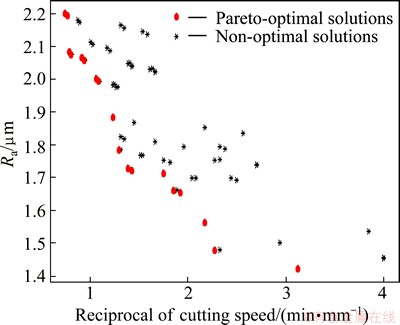

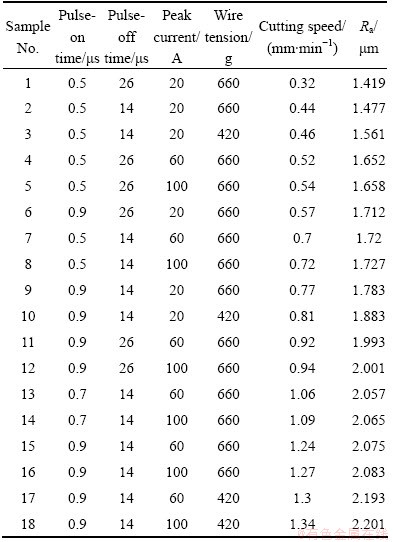

The additive model presented in Eq. (1) was used to predict the response parameters, i.e. cutting speed and surface roughness for all possible combinations (34 = 81) of the control factors. Later, simultaneous optimization of CS and Ra has been carried out by employing Pareto-optimality approach. All the Pareto-optimal solutions are equally significant as far as surface roughness and cutting speed are concerned. A non-dominated sorting scheme proposed by DEB et al [20] has been used to rank all (34) machining combinations. The optimal solutions obtained through Pareto-optimality approach were listed in Table 6 and shown in Fig. 3 along with the non-optimal solutions. Table 6 may be used as technology guideline for optimum machining of 5083 Al alloy.

For instance, if a customer demands a component with Ra≤1.8 μm, the WEDM operator has to select an appropriate parameter combination which would yield the maximum cutting speed for the specified surface finish with Ra≤1.8 μm. By referring Table 6 (Sample 9), the optimal parameter combination can be easily selected as pulse-on time of 0.9 μs, pulse-off time of 14 μs, peak current of 20 A and wire tension of 660 g, which would produce a surface finish (Ra) of 1.783 μm. The maximum cutting speed for this setting would be 0.77 mm/min. Thus, Table 6 can be effectively used as technology table for optimal processing of 5083 Al alloy. Table 6 and Fig. 3 further reveal the fact that the surface finish quality deteriorates as the cutting speed increases.

Table 5 Confirmation test along with prediction error

Fig. 3 Pareto-optimal solutions along with non-optimal solutions in response space

Table 6 Technology table

6 Conclusions

An experimental investigation on single-pass cutting of wire electrical discharge machining of 5083 Al alloy was presented. ANOVA test was performed to determine the level of significance of the parameters on the cutting speed and surface roughness. ANOVA revealed that the CS was independent on wire tension and Ra was independent on pulse-off time and wire tension. An optimum parameter combination for the minimum Ra and the maximum CS was obtained by the analysis of signal-to- noise (S/N) ratio.

The additive model was used to model the process. The predictions of this model agreed very well with the experimental results. The process was optimized by Pareto-optimality approach and a technology table was proposed for optimum machining 5083 Al alloy. The present research approach is extremely useful for maximizing the productivity while maintaining surface finish within desired limit.

References

[1] SPEDDING T A, WANG Z Q. Study on modeling of wire EDM process [J]. Journal of Materials Processing Technology, 1997, 69: 18-28.

[2] HO K H, NEWMAN S T, RAHIMIFARD S, ALLEN R D. State of the art in wire electrical discharge machining (WEDM) [J]. International Journal of Machine Tools & Manufacture, 2004, 44: 1247-1259.

[3] HEWIDY M S, EL-TAWEEL T A, EL-SAFTY M F. Modelling the machining parameters of WEDM of Inconel 601 using RSM [J]. Journal of Materials Processing Technology, 2005, 169: 328-336.

[4] PRASAD D V S S S V, GOPALAKRISHNA A. Empirical modeling and optimization of wire electrical discharge machining [J]. Int J Adv Manuf Technol, 2009, 43: 914-925.

[5] KURIAKOSE S, SHUNMUGAM M S. Multi-objective optimization of WEDM process by non-dominated sorting genetic algorithm [J]. Journal of Materials Processing Technology, 2005, 170: 133-141.

[6] SARKAR S, MITRA S, BHATTACHARYYA B. Parametric analysis and optimization of wire electrical discharge machining of γ-titanium aluminide alloy [J]. Journal of Materials Processing Technology, 2005, 159: 286-294.

[7] SARKAR S, MITRA S, BHATTACHARYYA B. Parametric optimisation of wire electrical discharge machining of γ titanium aluminide alloy through an artificial neural network model [J]. Int J Adv Manuf Technol, 2006, 27: 501-508.

[8] RAMAKRISHNAN R, KARUNAMOORTHY L. Multi response optimization of wire EDM operations using robust design of experiments [J]. Int J Adv Manuf Technol, 2006, 29: 105-112.

[9] RAMAKRISHNAN R, KARUNAMOORTHY L. Modeling and multi-response optimization of Inconel 718 on machining of CNC WEDM process [J]. Journal of Materials Processing Technology, 2008, 207: 343-349.

[10] SPEDDING T A, WANG Z Q. Parametric optimization and surface characterization of wire electrical discharge machining process [J]. Precision Engineering, 1997, 20: 5-15.

[11] CHIANG K T, CHANG F P. Optimization of the WEDM process of particle-reinforced material with multiple performance characteristics using grey relational analysis [J]. Journal of Materials Processing Technology, 2006, 180: 96-101.

[12] TOSUN N, COGUN C, TOSUN G. A study on kerf and material removal rate in wire electrical discharge machining based on Taguchi method [J]. Journal of Materials Processing Technology, 2004, 152: 316–322.

[13] SELVAKUMAR G, SARKAR S, MITRA S. Experimental investigation on die corner accuracy for wire electrical discharge machining of Monel 400 alloy [J]. Proc IMeChE Part B: J Engineering Manufacture, 2012, 226(10): 1694-1704.

[14] SELVAKUMAR G, SARKAR S, MITRA S. An experimental analysis of single pass cutting of aluminium 5083 alloy in different corner angles through WEDM [J]. Int J Machining and Machinability of Materials, 2013, 13(2-3): 262-275.

[15] SARKAR S, SEKH M, MITRA S, BHATTACHARYYA B. A novel method of determination of wire lag for enhanced profile accuracy in WEDM [J]. Precision Engineering, 2011, 35: 339-347.

[16] TOTTEN G E, MACKENZIE D S. Handbook of aluminum [M]//Volume 1—Physical metallurgy and processes. New York and Basel: Marcel Dekker, Inc, 2003: 1063-1103.

[17] PHADKE M S. Quality engineering using robust design [M]. Englewood Cliffs, New Jersey: Prentice Hall, 1989.

[18] MAHAPATRA S S, AMAR PATNAIK. Optimization of wire electrical discharge machining (WEDM) process parameters using Taguchi method [J]. Int J Adv Manuf Technol, 2007, 34: 911-925.

[19] TARNG Y S, MA S C, CHUNG L K. Determination of optimal cutting parameters in wire electrical discharge machining [J]. Int J Mach Tools Manufact, 1995, 35(12): 1693-1701.

[20] DEB K, PRATAP A, AGARWAL S, MEYARIVAN T. A fast and elitist multiobjective genetic algorithm: NSGA–II [J]. IEEE Transactions on Evolutionary Computation, 2002, 6(2): 182-197.

G. SELVAKUMAR1, G. SORNALATHA2, S. SARKAR3, S. MITRA3

1. Department of Mechanical Engineering, National Engineering College, K.R. Nagar 628503, Tamilnadu, India;

2. Mechanical Engineering Department, SCAD College of Engineering & Technology, Cheranmahadevi 627414, Tamilnadu, India;

3. Production Engineering Department, Jadavpur University, Kolkata 700032, India

摘 要:通过实验分析,优化电火花线切割5083 Al合金的工艺参数。基于Taguchi优化法,将脉宽、脉间、峰电流和线张力作为输入参数进行了系列实验。将表面粗糙度和切割速度作为响应,基于信噪比,测定了输入参数对响应的影响。通过Taguchi优化方法,得到了最大切割速度和最小表面粗糙度的最佳加工参数。再采用附加的模型预测可能的加工组合。最后,通过使用Pareto优化法,得到一个简明的工艺参数表。

关键词:丝电火花加工;铝合金;Taguchi方法;附加模型;优化;Pareto优化

(Edited by Xiang-qun LI)

Corresponding author: G. SELVAKUMAR; E-mail: selvakumaratju@gmail.com

DOI: 10.1016/S1003-6326(14)63071-5