文章编号:1004-0609(2010)S1-s0843-04

IMI834高温钛合金熔模铸造充型性能

赵而团,孔凡涛,肖树龙,陈艳飞,陈玉勇

(哈尔滨工业大学 金属精密热加工国家级重点实验室,哈尔滨 150001)

摘 要:采用10×10网格蜡网制备熔模铸造型壳,研究型壳预热温度、离心转速以及型壳面层材料对IMI834高温钛合金充型能力的影响。研究结果表明:在本实验条件下,当型壳预热温度为400~600 ℃,离心转速为300 r/min时,IMI834的充型性能最好。面层材料以CaO稳定的ZrO2和醋酸锆粘结剂制备的型壳充型性能远好于Al2O3和硅溶胶粘结剂制备的型壳的,表明界面反应对合金的充填性能有极大的影响。离心浇注实验结果表明:合金熔体在Coriolis力的作用下优先向与离心转向相反的方向充填。

关键词:高温钛合金;IMI834;充型性能;熔模铸造;界面反应

中图分类号:TF 804.3 文献标志码:A

Investment casting mold filling capacity of high temperature titanium alloy IMI834

ZHAO Er-tuan, KONG Fan-tao, XIAO Shu-long, CHEN Yan-fei, CHEN Yu-yong

(National Key Laboratory of Science and Technology on Precision Heat Processing of Metals,

Harbin Institute of Technology, Harbin 150001, China)

Abstract: The investment casting mold was prepared using wax pattern (10×10 squares with diameter of 0.5 mm). The mold filling capacity of high temperature titanium alloys IMI834 at different mold preheat temperatures, centrifugal speeds, and with different primary layer materials. The results show that IMI834 alloy exhibits the best mold filling capacity at the mold preheat temperature between 400 and 600 ℃ and centrifugal speed of 300 r/min. The primary material with ZrO2 (CaO stabilized) and zirconium acetate binder presents better mold filling capacity than the Al2O3 material and silica gel binder, indicating that the mold filling capacity is greatly influenced by interface reaction. With the effect of Coriolis force, the anti-centrifugal turn side is preferentially filled.

Key words: high temperature titanium alloys; IMI834; mold filling capacity; investment casting; interfacial reactions

随着航空工业的进一步发展,钛合金在飞机上的使用将越来越多。高温钛合金由于其比强度高、耐腐蚀、耐热等良好的综合性能而被广泛用于航空航天领域,多用于制造航空发动机中要求强度高与耐热性好的重要零部件和飞机机体结构件[1-4]。

IMI834(Ti-5.8Al-4Sn-3.5Zr-0.7Nb-0.5M-0.35Si)合金是英国在1984年研制成功的一种近α型钛合金,应用温度近600 ℃,具有高蠕变强度和良好的疲劳强度和变形能力,已在多种发动机上得到了试验和应用,如波音777飞机选用的民用大型发动机Trent700,其高压压气机的所有轮盘、鼓筒及后轴均用IMI834合金,明显地减轻了发动机的质量。EJ200发动机的高压压气机转子也采用了IMI834合金,IMI834也正用于普惠公司的PW350发动机上[1, 5]。

但是当前对600 ℃用高温钛合金的研究多集中在变形方面[6-8],对其铸造性能缺乏研究和了解。与其他成形方法相比,熔模精密铸造可以铸造形状复杂、薄壁的零件,铸件尺寸精度高,表面粗糙度低,且成本较低,适于批量生产[9]。因此研究高温钛合金IMI834的熔模铸造充型能力,对该合金的熔模铸造生产具有实际指导意义。

国内外研究者评价合金的充填性能多采用蜡网制备型壳,通过计算浇注后充填网格的边数[10-12]。本文作者采用10×10网格的蜡网制备型壳,研究了不同的型壳预热温度不同的离心转速以及不同的型壳面层材料对IMI834高温钛合金充型能力的影响,同时研究了水平离心方式下的合金熔体充填规律。

1 实验

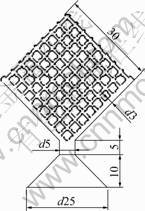

实验用合金名义成分为Ti-5.8Al-4Sn-3.5Zr- 0.7Nb-0.5M-0.35Si-0.06C(质量分数,%),采用高真空磁控钨极电弧熔炼炉熔炼,将熔炼的纽扣锭切割成 12 g的小块用于充型实验。实验采用10×10蜡网,共100个网格,220条边,其尺寸如图1所示。

图1 蜡网尺寸

Fig.1 Dimensions of wax pattern (mm)

由于和两侧直浇道的重合,实际参与计算的边数为200条。充填性能指标的计算为每一条充型完整的边数计数为1,将充型完整的边数除以整个网格的边数200,再乘以100%,计算公式如下:

(1)

(1)

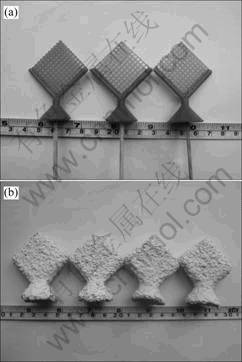

第一种型壳的面层材料采用CaO稳定的ZrO2粉料(45 μm)和醋酸锆粘结剂,第二种为Al2O3粉料 (45 μm)和硅溶胶粘结剂,背层制壳材料均为Al2O3耐火材料及硅溶胶粘结剂。制备的蜡模及型壳如图2所示。充型实验在德国利恒离心铸钛机(High frequency casting unit vacutherm-3.3-titan)上进行。

图2 蜡网及型壳

Fig.2 Wax patterns(a) and shells(b)

2 结果及分析

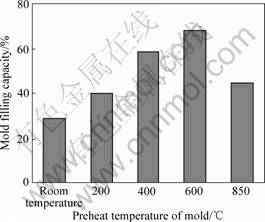

2.1 型壳预热温度对充型性能的影响

合金的充填性能并没有随着型壳的预热温度提高而提高,如图3所示。由图3可看出,在600 ℃以下时,随着型壳的预热温度提高,充填性能变好,但是当型壳的预热温度提高到850 ℃时,充填性能急剧下降,充型性能随温度的升高呈抛物线趋势。分析认为,

图3 型壳预热温度对充型性能的影响

Fig.3 Effect of preheat temperature of mold on mold filling capacity

型壳预热温度的提高和型壳透气性的变好均有利于合金熔体的充型,但是由于钛合金的高温活性,几乎与所有的耐火材料发生反应。随着温度的升高,界面反应将会加剧。本实验结果表明,当型壳预热为850 ℃时,界面反应的加剧严重影响合金熔体的充填,因此,不能单纯的靠提高型壳的预热温度来提高合金的充型性能,IMI834高温钛合金在本实验条件下最佳的型壳预热温度为400~600 ℃。

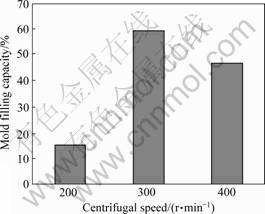

2.2 离心转速对充型性能的影响

实验分别在200、300和400 r/min的离心转速下对比了合金的充型能力,其结果如图4所示。结果表明:在本实验条件下,合金熔体的充型能力没有随着离心转速的提高而增加,在所取的3种离心转速条件下,离心转速为300 r/min时,合金表现出较好的充型能力。一般来讲,在一定范围内,离心转速越大,充型性能越好。但在本实验条件下,在400 r/min离心转速时,充填性能出现下降。这是因为离心转速越大,离心力越大,合金熔体的充填速度和充填力变大,合金熔体对型壳的面层冲刷加剧。而每条蜡网边的直径为0.5 mm,制成型壳的流道仅为0.5 mm左右。如果合金熔体冲刷面层型壳并夹杂耐火材料,就会极易的堵塞网格的流道,表现为充型性能的降低。同时,离心力越大使合金熔体和型壳的面层材料更为有效的接触,加剧了界面反应的进行,从而影响充填性能。但当流动通道的内腔尺寸较大时,这种影响将会变弱,离心力的作用对合金熔体的充填起主要作用,即离心力越大,充填性能越好。

2.3 型壳面层材料对充型性能的影响

传统的熔模精铸型壳一般以水玻璃、硅溶胶或硅

图4 离心转速对充型性能的影响

Fig.4 Effect of centrifugal speed on mold filling capacity

酸乙脂为粘结剂,由于这些粘结剂靠Si—O链结合,焙烧后的产物均含有SiO2,而熔融钛液会与SiO2发生激烈的反应。为研究界面反应对充填性能的影响,实验特意选用Al2O3粉料(45 μm)和硅溶胶粘结剂作为型壳的面层材料,与ZrO2粉料(45 μm)和醋酸锆粘结剂制成的型壳面层来做对比。实验结果表明:型壳的面层材料严重影响合金熔体的充型性能,前者几乎没有充填进网格,只能充满两侧的直浇道,如图5所示。当型壳的预热温度提高到400 ℃时,充型性能并没有得到提高,界面反应加剧,整个浇注系统呈较深的氧化反应色,如图5(b)所示。由本实验结果可见,界面反应对合金熔体的充型性能影响较大,剧烈的界面反应对充型能力的影响超过了型壳预热温度对充型能力的影响。因此,在浇注薄壁铸件时要特别注意界面反应对充型性能的影响。

图5 Al2O3面层型壳的充型结果

Fig.5 Mold filling capacity of Al2O3 primary layer material: (a) At room temperature; (b) At 400 ℃

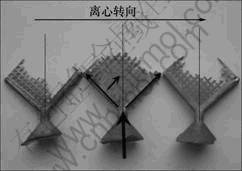

2.4 离心力场下的充型规律

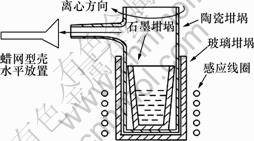

充型浇注采用德国利恒离心铸钛机,离心方式为水平离心,蜡网型壳水平放置在工装内,如图6所示。从充型的实验结果来看,离心方式对充填方式有较大的影响,由中心直浇道划线,可以明显地看到左侧的充填率明显高于右侧的,即充型优先在与离心转向相反的方向上充满,如图7所示。分析认为,合金熔体在离心浇注时同时受到重力和离心力的作用,在径向离心力的作用下,合金熔体优先由浇口杯充填两个直浇道,在Coriolis力的作用下,合金熔体在反离心转向的方向上贴紧型壳内壁,在后续合金熔体的连续作用下充填网格,如图7中间箭头所示。

图6 离心浇注示意图

Fig.6 Schematic diagram of capacity titanium centrifugal casting

图7 充型规律

Fig.7 Regularity of mold filling

3 结论

1) 在本实验条件下,随型壳预热温度、离心转速的提高,IMI834高温钛合金的充型性能呈抛物线规律;型壳预热温度为400~600 ℃、离心转速为300 r/min时,IMI834的充型性能最好。

2) 型壳的面层材料对充型性能有较大的影响,主要是由于界面反应所致,但界面反应的影响机理及程度等需要进一步的研究。

3) 离心方式对充型行为有较大的影响,在水平离心方式下,受Coriolis力的作用,优先充填与离心转速相反的方向。

REFERENCES

[1] 蔡建明, 李臻熙, 马济民, 黄 旭, 曹春晓. 航空发动机用600 ℃高温钛合金的研究与发展[J]. 材料导报, 2005, 19(1): 50-53.

CAI Jian-ming, LI Zhen-xi, MA Ji-min, HUANG Xu, CAO Chun-xia. Research and development of 600 ℃ high temperature titanium alloys for aeroengine[J]. Materials Review, 2005, 19(1): 50-53.

[2] 许国栋, 王凤娥. 高温钛合金的发展和应用[J]. 稀有金属, 2005, 32(6): 774-780.

XU Guo-dong, WANG Feng-e. Development and application of high-temperature Ti-Based alloys[J]. Chinese Journal of Rare Metals, 2005, 32(6): 774-780.

[3] 赵永庆. 高温钛合金研究[J]. 钛工业进展, 2001(1): 33-39.

ZHAO Yong-qing. Research on high temperature titanium alloys[J]. Titanium Industry Progress, 2001(1): 33-39.

[4] GOGIA A K. High-temperature titanium alloys[J]. Defence Science Journal, 2005, 55(2): 149-173.

[5] 彭艳萍, 曾凡昌, 王俊杰, 章怡宁, 夏绍玉. 国外航空钛合金的发展应用及其特点分析[J]. 材料工程, 1997(10): 1-6.

PENG Yan-ping, ZENG Fan-chang, WANG Jun-jie, ZHANG Yi-ning, XIA Shao-yu. Development, application and feature of titanium alloys in foreign aviation industry[J]. Journal of Materials Engineering, 1997(10): 1-6.

[6] ZHOU M. Constitutive modeling of the viscoplastic deformation in high temperature forging of titanium alloy IMI834[J]. Materials Science and Engineering A, 1998, 245(1): 29-38.

[7] WANJARA P, JAHAZI M, MONAJATI H, YUE S, IMMARIGEON J P. Hot working behavior of near-alpha alloy IMI834[J]. Materials Science and Engineering A, 2005, 396(1/2): 50-60.

[8] VO P, JAHAZI M, YUE S. Recrystallization during thermomechanical processing of IMI834[J]. Metallurgical and Materials Transactions A, 2008, 39A(12): 2965-2980.

[9] NASTAC L, GUNGOR M N, UCOK I, KLUG K L, TACK W T. Advances in investment casting of Ti-6Al-4V alloy: A review[J]. International Journal of Cast Metals Research, 2006, 19(2): 73-93.

[10] 彭勤建. 牙科铸钛包埋料的研制及应用基础研究[D]. 西安: 第四军医大学, 1999.

PENG QIN-jian. Basic research for the development and application of dental titanium casting material[D]. Xi’an: The Fourth Military Medical University, 1999.

[11] OLIVEIRA P C, ADABO G L, RIBEIRO R F, ROCHA S S. The effect of mold temperature on castability of CPTi and Ti-6Al-4V castings into phosphate bonded investment materials[J]. Dental Materials, 2006, 22(12): 1098-1102.

[12] FISCHER J, EBINGER A, HAGI T, STAWARCZYK B, WENGER A, KELLER E. Mold filling and dimensional accuracy of titanium castings in a spinel-based investment[J]. Dental Materials, 2009, 25(11): 1376-1382.

(编辑 杨幼平)

通信作者:赵而团;电话:0451-86418802;E-mail: zhaoertuan@yahoo.com.cn