文章编号: 1004-0609(2005)04-0614 -07

Mg-5Al-1.5Ca-0.4Zn基镁合金的等温法半固态压铸组织和性能

杨光昱, 郝启堂, 介万奇, 王武孝, 贾文平

(西北工业大学 材料科学与工程学院, 西安 710071)

摘要: 研究了Mg-5Al-1.5Ca-0.4Zn-0.2Mn-Sr-Ti合金的等温法半固态压铸组织和性能。 结果表明: 合金相组成为α(Mg)、 (α(Mg)+Al2Ca)共晶和少量球状Mg17Al12。 Sr变质合金在585℃等温法处理时, α(Mg)首先分离成核。 随着等温时间加长, α(Mg)由块状向球状转变。 25min时, 转变为粒径40μm的均匀球状组织。 此后, 球晶发生长大, 进而聚拢合并。 合金等温法压铸实验发现, 组织为均匀细小等轴晶, 粒径25μm。 合金室温和高温强度较砂铸大幅提高, 塑性略有下降。 这是由于细晶强化作用, 以及晶粒细化使得晶界上半连续分布的Al2Ca相更弥散, 这样Al2Ca高温下钉扎晶界的作用更加突出。 等温法半固态压铸合金200℃的高温强度优于AZ91压铸合金, 可达140MPa。

关键词: 半固态等温热处理; 半固态压铸; 显微组织; 力学性能; 镁合金 中图分类号: TG146.22; TG146.4

文献标识码: A

Microstructure and properties of Mg-5Al-1.5Ca-0.4Zn based alloy

by semi-solid isothermal heat-treatment-die-pressure-casting process

YANG Guang-yu, HAO Qi-tang, JIE WAN-qi, WANG Wu-xiao, JIA Wen-ping

(College of Materials Science and Engineering,

Northwestern Polytechnical University, Xian 710071, China)

Abstract: The microstructure and properties of Mg-5Al-1.5Ca-0.4Zn-0.2Mn-Sr-Ti magnesium alloy by semi-solid isothermal heat-treatment-die-pressure-casting process were studied. It is found that there are three main phases formed in the experimental alloy, i.e., α(Mg), (α(Mg)+Al2Ca) eutectic and Mg17Al12. When the alloy modified by Sr is heat-treated at 585℃, the primary α(Mg) phase divorces into lumps. Then the lumps evolve into spheroids gradually with isothermal time increasing. After treated for 25min, the well-distributed spheroidic semisolid-structure with the average grain diameter of 40μm is formed, then the spheroids agglomerate and coalesce. It is also found that the room temperature mechanical properties are improved greatly by semi-solid isothermal heat-treatment-die-pressure casting process. The elevated temperature strength of experimental alloy at 200℃ is up to 140MPa, better apparently than that of AZ91 die-casting alloy. Homogeneous equiaxied fine grains with the average grain diameter of 25μm are obtained in experimental alloy by the semi-solid isothermal heat-treatment-die-pressure casting process.

Key words: semi-solid isothermal heat-treatment(SSIT); SSIT-die-pressure casting; microstructure; mechanical properties; magnesium alloy

自从20世纪70年Flemings及其同事发现了合金的触变特性以来, 经过多年的研究开发, Dow公司于1988年申请了半固态触变成形工艺的专利, 之后公司生产出了第一台镁合金专用的半固态触变成形机, 使半固态镁合金的生产迈向了商业化[1, 2]。

获得半固态浆料的方法主要有电磁/机械搅拌法、 半固态等温热处理(Semi-solid isothermal heat-treatment, 简称SSIT)法和应变诱发熔化激活法。 半固态浆料的成形工艺主要有流变铸造、 触变铸造、 触变锻造、 半固态轧制、 注射成形。 半固态的工艺过程一般包括三步: 非枝晶锭料的制备、 二次加热和挤压成形[3, 4]。

对于镁合金的成形工艺, 目前只有注射成形用于工业生产中。 20世纪90年代初出现的半固态等温热处理法(SSIT)省略了半固态成形中专门的锭料制备这一步骤, 只是在合金熔炼浇注时加入变质剂, 在成形前的二次加热中完成组织转变, 使传统的触变工艺由三步变为两步, 其工艺相对简单, 成本大为降低, 是一种有前途的方法[5, 6]。 目前对这一方法的研究只是停留在坯料组织的转变机理上, 成形工艺和合金性能方面的报道较少[4]。 在半固态新合金开发上, Rudi等[7]开发出了适于PID工艺的半固态耐高温Mg-Zn-Al-Ca合金。 据报道[7], 该合金在200℃的抗拉强度可达150MPa。 而通常研究最多的仍是AZ91镁合金。

虽然人们对半固态技术的前景一直抱有信心, 但有一点可以肯定, 半固态成形技术并没有获得人们预期的广泛应用, 尚有许多实际问题有待解决。 因此, 对于镁合金的半固态研究, 新合金的开发和新工艺的探索仍是目前面临的主要问题。

为此, 作者采用Mg-5Al-1.5Ca-0.4Zn-0.2Mn-Sr-Ti合金作为实验合金, 通过SSIT工艺, 研究了实验合金在等温条件下的组织转变过程。 在此基础上, 在经改造过的压铸机上实现SSIT工艺条件下的半固态成形, 研究实验合金的组织和性能。

1实验

1.1实验合金的制备

实验合金坯料的熔炼在自制的20kg电阻坩埚炉中进行。 合金成分范围: 4.6% ~5.3% Al, 1.3%~1.6% Ca, 0.3%~0.5% Zn, 0.1%~0.2% Mn, >0.004% Ti, >0.02% Sr, 〈0.016% Fe, 余量Mg。 熔炼在RJ-6溶剂保护下进行。 Ca, Zn以纯金属(99.9%)的形式加入, Mn, Ti, Sr分别以中间合金Al-10Mn, Al-3Ti, Al-10Sr形式加入。 合金熔炼好后, 加Al-10Sr变质处理, 在740℃时分别浇铸成标称尺寸为d12mm×50mm的标准砂型拉伸试样、 d50mm×75mm的砂型毛坯棒料, 以及d18mm×180mm的砂型毛坯棒料。

1.2实验方法

实验合金的半固态等温实验过程为: 将d18mm×180mm 的棒料加工为d16mm×16mm的小试样, 用0.1mm厚的铜皮密封后, 放入升温至(580±3)℃的电阻炉中保温。 到预先设定的保温时间后, 迅速拿出试样淬入水中。 金相试样用3%的硝酸酒精溶液腐蚀, 在金相显微镜上观察组织变化。

实验合金等温半固态压铸实验的工艺流程为: 将d50mm×75mm的坯料加工成d48mm×70mm的棒料, 放入有氩气保护的带加热保温功能的压铸机压池中。 在设定的保温温度下, 保温至设定时间, 然后在设定压力下直接压铸成形。 压铸的试棒标准尺寸为d5mm×25mm。

1.3力学性能的测试

实验合金常温力学性能的测试在CSS1220型电子万能拉力试验机上进行, 每组测试3根试样, 结果采用其平均值。 高温瞬时力学性能的测试在Instron-1195型高温性能试验机上进行, 试样在200℃下保温时间15min。 每组测两根, 结果取平均值。

1.4微观组织的观察

显微组织观察采用XJL-02型光学显微镜和LEO1455VP型扫描电子显微镜(SEM)。 微区成分分析采用Oxford Inca型能量色散谱仪(EDS)。 X射线衍射仪型号为D/MAX2400。 合金组成相分析采用X射线衍射(XRD)和微区成分分析相结合的方法进行。 合金成分分析采用ICP分析方法。 合金的熔化温度范围采用DSC方法在DSC-2910差示量热分析仪上测定。

2结果与讨论

2.1合金的微观组织和熔化特性

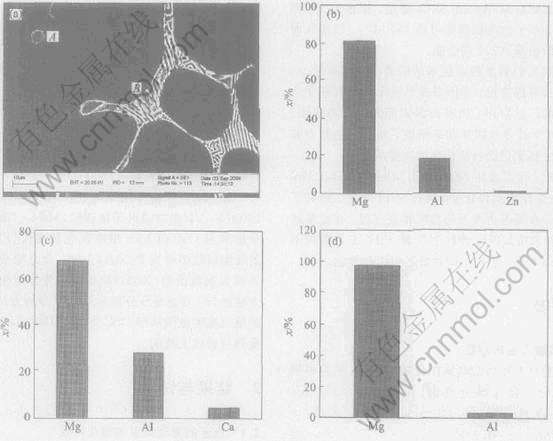

图1所示为实验合金的砂铸微观组织。 初生相α(Mg)大部分为近等轴晶, 小部分为不发达树枝晶。 由合金的X射线衍射分析(图谱省略)可知, 合金的基本相组成为: α(Mg), Al2Ca和 Mg17Al12。 图2所示为实验合金的EDS半定量分析结果。

图1 实验合金铸态组织

Fig.1 Sand-casting microstructure of experimental alloy

结合X射线衍射分析所确认的第二相形态可知, 图2中α(Mg)相晶间层片状组织为(α(Mg)+Al2Ca)共晶, 晶内极少量呈球状的相为Mg17Al12相。

图2 实验合金的EDS分析结果

Fig.2 EDS analysis results of experimental alloy

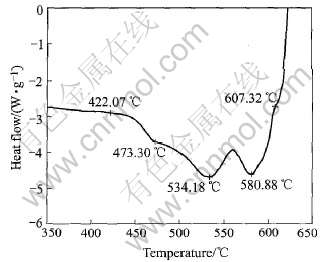

图3所示为测定的实验合金的DSC曲线( 升温速度为10℃/min)。 可知, 实验合金的熔化温度范围为422~607℃。 合金在加热熔化过程中, 出现3个吸热峰。 根据合金的相组成可知, 473℃的峰对应于Mg17Al12的熔化点[8], 而534℃的峰对应于Al2Ca的熔化点, 580℃的峰则是基体α(Mg)的熔化开始温度。

图3 实验合金的DSC分析曲线

Fig.3 DSC curve of experimental alloy

2.2合金在半固态等温热处理过程中的组织演变

通过不同等温时间和等温温度下的交叉等温实验和微观组织观察, 确定了d16mm×16mm试样能得到较佳半固态组织形态的合适工艺参数, 即, 等温温度585℃, 等温时间25min。

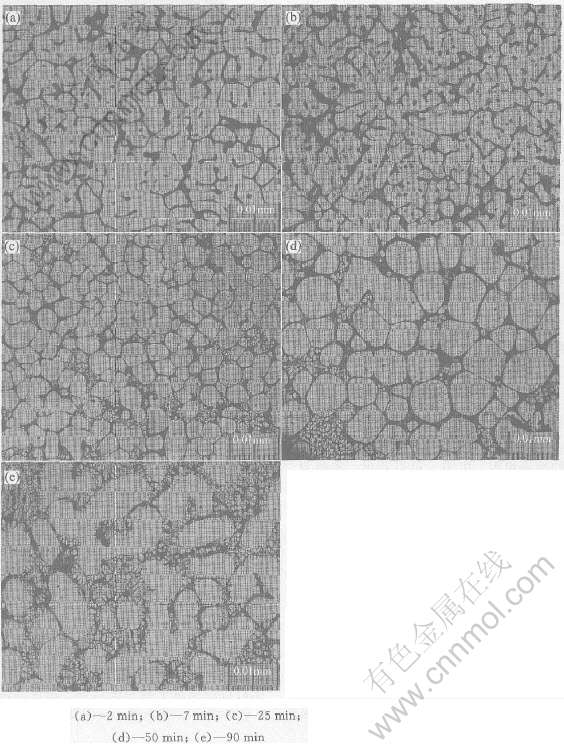

图4所示为d16mm×16mm试块在585℃下分别等温不同时间所观察到的等温法过程的等温组织演变情况。 试样未加热时的组织形态如图1所示。 当试样在585℃下等温2min时, 合金的淬火组织形态见图4(a), 晶内的Mg17Al12相率先熔化, 形成许多点状液体。 晶界上的低熔点共晶 (α(Mg) +Al2Ca) 也开始熔化。 随着等温时间的延长, 组织中的树枝状初生α(Mg)开始从二次枝晶臂与主干晶臂的交叉根部熔断, 在固/液相界面张力的作用下, 晶界液相和晶内液相连通, 大块状晶粒开始明显分离, 如图4(b)所示。 之后, 随着等温时间加长, 合金组织分离成小的粒状和块状, 晶界逐渐趋于圆整、 晶粒大小趋于均匀[6]。 等温25min 时, 合金组织完全转变为比较均匀的球状或蚕状组织, 晶粒平均直径为40μm(见图4(c))。 图4(d)所示为等温50min时的组织形态, 此时晶粒发生明显的长大, 平均粒径可达65μm, 而小晶粒进一步减少消失。 根据Ostwald熟化理论[9], 熟化过程一般遵循形核、 长大的变化规律。 对应于实验合金的等温转变, 也就是晶粒的分离和合并长大过程。 在整个等温处理过程中, 由于局部的能量起伏, 晶粒始终处于动态的分离和合并过程中。 在等温25min以前, 分离占主导, 在25~50min之间, 在二者的动态平衡中合并开始逐步占主导, 在50min后, 聚拢合并完全占主导。 在保温初期, 合金组织先发生分离, 分离后的粒状和块状晶粒只有在晶界趋于圆整的情况下, 液/固界面积缩小, 系统的能量才会降低, 所以就会出现晶粒的球化转变。 此过程是在无对流情况下进行的, 只能通过原子的扩散, 所以进行得较为缓慢。 当组织完全转变为球状晶后, 会发生晶粒的熟化, 其熟化长大的驱动力来自于系统中总的固/液界面积的减少, 即, 小的α(Mg)晶粒会逐渐熔化, 大的α(Mg)晶粒则不断长大球化。 只有这样, 液/固总界面积才会进一步减少, 系统能量降低。 随着等温时间的进一步加长, 长大到一定程度的球状晶粒会发生聚拢、 合并, 直至邻近的大晶粒相互连通聚合, 而中小晶粒熔化消失, 初生相会发生不规则的异常长大, 出现图4(e)所示的组织形态。

图4 在585℃下保温不同时间合金的组织演变

Fig.4 Microstructures evolution of experimental alloy at 585℃ after different isothermal holding time

实验合金在585℃的等温组织转变实验是在空气循环电阻保温炉中进行。 发现等温试样表面出现了轻微的氧化。 等温时间加长, 氧化程度略有加重。 试样在半固态温度下等温时间越长, 试样产生的变形程度就越大。 为了防止在半固态压铸试验中出现棒料等温氧化现象而使铸件产生氧化夹渣, 实验合金棒料在压铸前的等温处理, 必须放在有氩气保护的带加热保温功能的压铸机压池中进行。

2.3合金的等温半固态压铸实验

结合等温半固态实验结果, 考虑到半固态压铸用棒料的尺寸为d48mm×70mm, 故要加上棒料加粗需要的额外均匀热透时间, 所以将半固态压铸的工艺参数设置为: 等温时间30~35min, 等温温度585℃。

图5所示为实验合金等温法压铸试验压铸出来的试棒照片。 图6(a), 6(b)分别为拉伸试样横断面和纵断面上的微观组织。 由图6可以看出, 实验合金等温法压铸后, 合金的晶粒尺寸大大减小, 晶粒平均尺寸为25μm。

半固态坯料具有宾汉体(Bingham body)的假塑性流体特性, 作用在其上的应力σ可表示为[4]

只有当外加应力(此处即为压铸机的冲头压力)σ>σs时, 坯料的网状结构被破坏, 显示出牛顿流体的特性。 由于设计的浇注系统是收缩式的, 直浇道、 横浇道、 内浇道横截面积(F直∶F横∶F内≈16∶1.7∶1)是逐步缩小的, 坯料在高的压力 (>80MPa)、 快速(冲头速度为2cm/s)条件下充填铸型时, 晶粒在流经横浇道和内浇道时, 会受到平行于坯料流向的越来越大的压力, 使流动速度加快, 坯料迅速充填型腔。 同时坯料会受到垂直于坯料流向的、 因浇道截面积缩小而产生于横浇道和内浇道侧壁很高的横向挤压力。 二力的综合作用会使半固态合金晶粒进一步碎断、 变形、 变小, 组织变得密实细小。 实验合金SSIT压铸的横断面和纵断面组织是一致的较为均匀的等轴晶, 这根本有别于一般合金的热塑性变形组织。

图5 SSIT压铸的试棒

Fig.5 Specimens by SSIT-die-pressure-casting

图6 半固态压铸拉力试棒横断面和纵断面上的微观组织

Fig.6 Microstructures of specimens of SSIT-die-pressure-casting samples on transversal and longitudinal sections

半固态金属的内部特征就是固液共存。 研究表明[10], 高固相率的半固态坯料内部结构特征为液相分布仅限于部分晶界。 而实验合金在25min时的组织结构特征(见图4(b))与此吻合, 这说明实验合金压铸时的固相率偏高。 而且实验合金在压铸条件下坯料的变形速率较高, 由此可以推断, 实验合金半固态浆料在上述工艺条件下的流动机制应以固相颗粒间的滑移机制和固相颗粒间的塑性变形机制[10]为主。 该分析和图4(c)的金相组织是一致的。

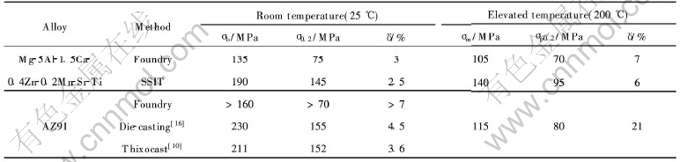

实验合金的砂铸力学性能和SSIT半固态压铸力学性能列于表1。 可以发现, 经过SSIT半固态压铸后, 实验合金的强度明显得到了提升。 根据Hall-Petch机制:

SSIT半固态压铸工艺使得实验合金组织的晶粒直径由砂铸组织的125μm减小到25μm, 晶粒得到极大细化, 所以实验合金的室温屈服强度σ0.2由75MPa提高到145MPa, 合金的室温强度也相应大幅提高。 同时发现, 实验合金的塑性略有下降, 这与实验合金的SSIT工艺过程有关。 SSIT工艺的保温过程会使合金晶界上的熔化液相部分中的溶质进一步富集, 半固态凝固组织中晶界局部的共晶相(α(Mg)+Al2Ca) 增加。 而(α(Mg)+Al2Ca) 共晶相为脆性相, 这对合金的塑性是不利的。

在Mg-Al系合金中加入能形成稳定的金属间化合物的合金元素, 就可改善合金的抗蠕变性能[11, 12]。 Ca位于元素周期表ⅡA族, 在合金中优先与Al结合, 形成Al2Ca相。 Al2Ca相熔点很高(1079℃), 远高于Mg17Al12相(437℃), 所以其热稳定性好。 由于镁合金晶粒内部对蠕变变形的阻碍远比晶界的阻碍作用小[13], 晶界上第二相的分布对提高基体的抗高温性能非常有利。 由于镁合金低温下的蠕变是以位错攀移机制为主, 高温下的蠕变则以晶界滑移机制为主[14]。 实验合金晶界上的Al2Ca相在高温下能起到钉扎晶界、 防止晶界滑移的强化作用, 对合金的高温蠕变过程有很好的阻碍作用。 同时Ca的加入阻碍了高温下原子的扩散, 使得合金的晶界强度提高[15]。 因此, 砂铸合金于200℃的高温强度较好。 而SSIT 半固态工艺使合金组织晶粒极大细化, 从而产生细晶强化作用。 同时, 晶粒的细化也会使Al2Ca相在晶界上的分布更加弥散, 这样, Al2Ca高温下对晶界的钉扎作用也就更为有效。 因此, 实验合金在等温法半固态压铸工艺条件下的高温强度(σm, σp0.2)较砂铸显著提高。

将表1中列出的AZ91合金压铸性能[16]与触变铸造性能[10]进行比较发现, 实验合金的常温性能稍低于AZ91合金的性能, 但其在200℃的高温强度(σm为140MPa)却明显高于AZ91压铸合金(σm为115MPa)。 这说明实验合金采用SSIT半固态压铸工艺是合适的。

3结论

1) Mg-5Al-1.5Ca-0.4Zn-0.2Mn-Sr-Ti合金铸态的相组成为: α(Mg) 基体相, (α(Mg)+Al2Ca)层片状共晶和晶内极少量呈球状的Mg17Al12相。 合金的熔化温度范围为422~607℃。 合金的加热熔化DSC曲线中, 473℃的吸热峰对应于Mg17Al12的熔化点, 而534℃的峰对应于Al2Ca的熔化点, 580℃的峰则是基体α(Mg)的熔化开始温度。

表1 实验合金的砂铸和SSIT半固态压铸力学性能

Table 1 Mechanical properties of as-sand-cast and as-SSIT experimental alloy

2) Sr变质后的实验合金在585℃进行SSIT处理时, α(Mg) 基体相晶粒首先分离成核, 并随着等温时间的加长, 逐步演变为球状半固态组织。 在等温25min时, 组织完全转变为平均粒径为40μm的较为均匀的球状半固态组织。 之后随着等温时间的进一步加长, 球状组织会进一步长大, 进而发生聚拢合并。

3) 通过实验合金的SSIT压铸实验发现, 合金的等温法压铸组织为均匀细小的等轴晶, 横断面和纵断面组织均匀, 晶粒平均直径为25μm。 晶粒较砂铸得到极大细化, 常温力学性能较砂铸得到了大幅提高。 但塑性略有下降。 合金高温力学性能较砂铸高温性能的显著提高首先是由于细晶强化, 其次是晶粒细化使得晶界上半连续的Al2Ca金属间化合物分布更加弥散, 从而使得Al2Ca相高温下钉扎晶界、 防止晶界滑移的作用更加有效。

4) 合金200℃的高温强度明显优于AZ91压铸合金的, 可达140MPa。

REFERENCES

[1]Nussbaum A I. Semi-solid forming of aluminum and magnesium[J]. Light Metalage, 1996(6): 6-12.

[2]Bradley N L, Weiland R D, Schafer W J, et al. Method and Apparatus for the Injection of Metal Alloys[P]. US Patent 040589, 1989.

[3]陈体军, 郝远. 金属的半固态成形与应用[J]. 铸造, 2001, 50(11): 645-649.

CHEN Ti-jun, HAO Yuan. Semi-solid forming technology of metals and its application[J]. Foundry, 2001, 50(11): 645-649.

[4]Kirkwood D H. Semisolid metal processing[J]. International Materials Reviews, 1994, 39(5): 173-189.

[5]Flemings M C. Behavior of metal alloys in the semisolid state[J]. Metallurgical Transaction A, 1991, 22(5): 957-981.

[6]李元东, 郝远, 闫润峰, 等. AZ91D在半固态等温热处理中的组织转变[J]. 中国有色金属学报, 2001, 11(4): 571-575.

LI Yuan-dong, HAO Yuan, YAN Yun-feng, et al. Structural evolution of AZ91D magnesium alloy during semisolid isothermal heat treatment[J]. The Chinese Journal of Nonferrous Metals, 2001, 11(4): 571-575.

[7]Kamado S, Ikeya N, Rudi R S, et al. Application of semi-solid forming to Mg-Zn-Al-Ca alloys[J]. Materials Science Forum, 2000, 350: 250-214.

[8]肖晓玲, 罗承萍, 刘江文, 等. AZ91镁铝合金中HCP/BCC相界面结构[J]. 中国有色金属学报, 2003, 13(1): 15-20.

XIAO Xiao-ling, LUO Cheng-ping, LIU Jiang-wen, et al. Structure of hcp/bcc interphase boundaries in AZ91 Mg-Al alloy[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(1): 15-20.

[9]Hardy S C, Voorhees P W. Ostwald ripening in a system with high volume fraction of coarsening phase[J]. Metallurgical Transaction A, 1988, 19A(11): 2713-2721.

[10]康永林, 毛卫民, 胡壮麒. 金属材料半固态加工理论与技术[M]. 北京: 科学出版社, 2004.

KANG Yong-lin, MAO Wei-min, HU Zhuang-qi. Semi-solid Metallurgy of Metal Materials[M]. Beijing: Science Press, 2004.

[11]Regev M, Aghion E, Rosen A. Creep studies of AZ91D pressure die casting[J]. Materials Science & Engineering A, 2001, A234-236: 46-50.

[12]余琨, 黎文献, 王日初, 等. 变形镁合金的研究、 开发及应用[J]. 中国有色金属学报, 2003, 13(2): 277-288.

YU Kun, LI Wen-xian, WANG Ri-chu, et al. Research, development and application of wrought magnesium alloys[J]. The Chinese Journal of Nonferrous Metals, 2003, 13 (2): 277-288.

[13]Polmear I J. Magnesium alloy and application[J]. Materials Science and Technology, 1994(1): 1-16.

[14]吴炳尧. 镁合金压铸技术分析[J]. 铸造, 2000, 49(8): 443-448.

WU Bing-yao. Technical analysis of magnesium alloys die-casting[J]. Foundry, 2000, 49(8): 443-448.

[15]陆树荪, 顾开道, 郑来苏. 有色铸造合金及熔炼[M]. 北京: 冶金工业出版社, 1983.

LU Shu-xun, GU Kai-dao, ZHENG Lai-su. Metallurgy of Nonferrous Metals[M]. Beijing: Metallurgical Industry Press, 1983.

[16]Matucha K H. Structure and Properties of Nonferrous Alloys: Vol8[M]. Germany: VCH, 1996.

基金项目:国家重大基础研究发展规划资助项目(G2000067202)

收稿日期:2004-10-18; 修订日期:2005-01-04

作者简介:杨光昱(1967-), 男, 高级工程师, 博士研究生.

通讯作者:杨光昱, 博士; 电话: 029-88494276; 传真: 029-6522808; E-mail: seniorygy.student@sina.com

(编辑陈爱华)