Article ID: 1003-6326(2005)02-0384-05

Superplastic solid state welding of steel and copper alloy based on laser quenching of steel surface

ZHANG Ke-ke(张柯柯), HAN Cai-xia(韩彩霞), QUAN Shu-li(权淑丽),

CHENG Guang-hui(程光辉), YANG Jie(杨 洁), YANG Yun-lin(杨蕴林)

(College of Material Science and Engineering, Henan University of Science and Technology, Luoyang 471003, China)

Abstract: Based on the feasibility of isothermal superplastic solid state welding of steel and copper alloy, the welded surface of steel surface was ultra-fined through laser quenching, and then the welding process tests between different base metals of 40Cr and QCr0.5 were made under the condition of non vacuum and non shield gas. The experimental results show that, with the sample surface of steel after laser quenching and that of copper alloy carefully cleaned, and under the pre-pressed stress of 56.6-84.9MPa, at the welding temperature of 750-800℃ and at initial strain rate of (2.5-7.5)×10-4s-1, the solid state welding can be finished in 120-180s so that the strength of the joint is up to that of QCr0.5 base metal and the expansion rate of the joint does not exceed 6%. The plastic deformation of the joint was further analysed. The superplastic deformation of the copper alloy occurs in welding process and the deformation of steel are little.

Key words: copper alloy; steel; laser quenching; superplastic deformation; solid state welding CLC number: TG457

Document code: A

1 INTRODUCTION

The copper and copper alloys possess a number of superior properties, such as excellent electrical conductivity, excellent thermal conductivity and forming property, so the complex components of the steel, copper and copper alloy have complementary advantages on the economy and performance[1, 2]. But it is very difficult to realize the good bonding of them by adopting routine fusion welding and braze because of a rather large difference in the melting point, coefficient of thermal conductivity, coefficient of linear expansion between the copper and steel[3]. At present, the high-quality welding joint was acquired often by adopting vacuum diffusion welding at home and abroad[4-11]. For the example, after the transient liquid phase(TLP) diffusion bonding of CuAlBe alloy to 1Cr18Ni9Ti using Cu30Mu alloy as interlayer, the strength of joint is up to 487MPa[5, 7]. After the diffusion welding of QSn4-4-2.5 alloy and 45 steel using nickel as interlayer, the joint has a good performance[9, 10]. It was reported that the plunger of Russians aero-engine plunger pump is produced through vacuum diffusion welding of tin bronze and alloyed steel[2]. But the vacuum diffusion welding equipments are expensive, the technological requirement is rigorous and the efficiency is low. As a new solid state welding technology of materials, the isothermal superplastic solid state welding is assumed to have some advantages, i.e. the simple process, the low cost and the high quality of solid bonding of the heterogeneous materials. Therefore, much research has been carried out in solid state welding methods in recent years[12-15]. So far, the report of the superplastic solid state welding of non-ferrous alloy with steel is few[15]. Based on the research of the superplastic of and copper alloy and steel[16-18], the authors studied the feasibility and process of the isothermal superplastic solid state welding of QCr0.5 and 40Cr in this paper. The studied results provide important test reference to the new solid state welding procedure exploitation of non-ferrous alloy with steel.

2 EXPERIMENTAL

The China-made hot-squeezing chrome-bronze QCr0.5 and hot-rolling annealing steel 40Cr are machined into d15mm×25mm samples. The surface of the steel sample to be welded is ultra-fined through laser quenching (type: 5kW CW CO2 laser machine) to obtain a laser quenching layer of 0.45-0.65mm in thickness. Chrome-bronze QCr0.5 isnt ultra-fined.

After the surfaces of the QCr0.5 sample and 40Cr sample to be welded were polished (its surface roughness is 0.115-0.245μm) and cleaned by acetone, the samples were paired, packed and put into the pressure welding device with the pressing speed adjustable. The samples were heated by 3kW electric oven with ±2℃ error of temperature and pre-pressed under 28.3-84.9MPa, and then held at the temperature of superplastic deformation for 7.5min. The short-time pressure welding was done at superplastic strain rate and finally the load was removed and the samples were air-cooled.

The welding result was evaluated by following means. The welding deformation was evaluated through the expansion rate εd(εd =(d1-d0)/d0) on the side of QCr0.5 of the welded sample, where d0 is the diameter of the side of QCr0.5 before pressure welding and d1 is the maximum diameter after the welding. The welded samples were machined directly into d5mm×25mm tensile sample, then the strength of the joint was tested on the material testing machine AG-1/250kN. The microstructures of the welded zone and the welded surface fracture (40Cr side) were analyzed through metallurgical microscope and the scanning electron microscope JSM—5610LV.

3 RESULTS AND DISCUSSION

The experimental result shows that at different process conditions, some tensile fractures occur at the original interface and some at side of QCr0.5 base metal. The solid state welding of 40Cr/QCr0.5 can be finished under suitable pressure, with the strength of joint up to that of QCr0.5 base metal, very little deformation on the side of 40Cr, big deformation of QCr0.5 with radial expansion, and the expansion rate less than 6%.

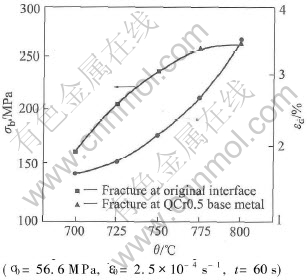

3.1 Pressure welding temperature

Fig.1 shows the influence of pressure welding temperature θ on the strength of joint and the expansion rate. Seen from Fig.1, when pressure welding is at 750-800℃, the strength of joint σb (230-260MPa) is close or up to that of QCr0.5 base metal (246-277MPa). At 750℃, the strength of joint is 95% of that of QCr0.5 base metal and the expansion rate is very low (2.17%). All the tensile fractures occur at QCr0.5 base metal after pressure welding at 775℃ and 800℃, which means that the strength of joint is up to that of the base metal, but the welding deformation increases with the temperature increasing. So when the requirement on the strength of joint is high, the pressure welding can be performed at 775-800℃; when the requirement of deformation is low, it can be done at 750-775℃. The range of the pressure welding temperature of 40Cr/QCr0.5 by the experiment in the paper is, in general, in accordance with that of the superplastic compression deformation temperature of the hot-squeezing QCr0.5 which is 740-820℃[16].

Fig.1 Curves of tensile strength and expansion rate vs temperature

3.2 Initial stain rate

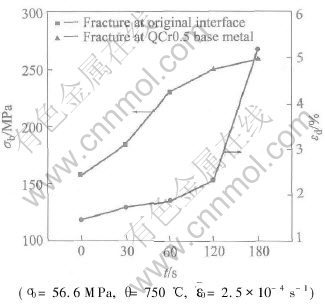

The influence of initial strain rate  on the strength of joint and the expansion rate is shown in Fig.2.

on the strength of joint and the expansion rate is shown in Fig.2.

Fig.2 Curves of tensile strength and expansion rate vs initial stain rate

When  ≥1.5×10-4s-1, the strength of joint can be close or up to that of QCr0.5 base metal. The deformation of the welded samples increases with the increase of

≥1.5×10-4s-1, the strength of joint can be close or up to that of QCr0.5 base metal. The deformation of the welded samples increases with the increase of  , which obviously results from the reason that the deformation is in proportion to

, which obviously results from the reason that the deformation is in proportion to  ×t (where t is pressure welding time). The pressure welding time can be decreased by increasing the initial strain rate. But if the strain rate is much higher the expansion rate would be too high. So based on the required strength of joint, we should prefer to the lower initial strain rate.

×t (where t is pressure welding time). The pressure welding time can be decreased by increasing the initial strain rate. But if the strain rate is much higher the expansion rate would be too high. So based on the required strength of joint, we should prefer to the lower initial strain rate.

3.3 Pressure welding time

The influence of pressure welding time t can be seen from Fig.3. Seen from Fig.3, if t=0s, the strength of joint can be about 60% of that of QCr0.5 base metal, which demonstrates that during the process of heating and holding the temperature, bondings are formed in some extent. With the time increasing, the strength of joint increases correspondingly and will be up to that of QCr0.5 base metal when t=120s; and the expansion rate increases with the extension of welding time, too. If t≥120s, it will have little effect on the strength of joint even if the pressure time is extended but the deformation will be bigger.

Fig.3 Curves of tensile strength and expansion rate vs welding time

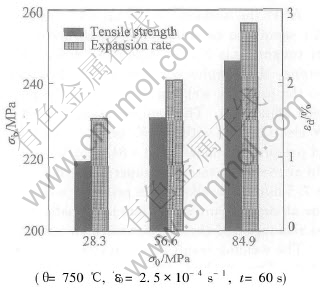

3.4 Pre-pressed stress

The influence of pre-pressed stress σ0 is shown in Fig.4. It can be seen from Fig.4 that under the experimental condition in the paper, with σ0 increasing, the strength of joint and expansion rate tend to increase. The strength of joint σb is up to 80% of that of the base metal QCr0.5 at pre-pressed stress of 28.3MPa and the sample breaks at the interface of 40Cr/QCr0.5. At pre-pressed stress of 84.9MPa , σb can be up to the strength of QCr0.5 base metal. So increasing the pre-pressed pressure properly can cut down the pressure welding time and decrease the expansion rate.

Fig.4 Curves of tensile strength and expansion rate vs pre-pressed stress

The result shows that the superplastic pressure welding temperature of 40Cr and QCr0.5, on the surface of 40Cr steel quenched by laser, is normally within the range of superplastic deformation temperature of the sample of 40Cr and QCr0.5. But the average real strain rates of two sides are different from each other because of the different deformation. The range of QCr0.5 side is (5.5-13.1)×10-4s-1, which is within that of the superplastic initial strain rate of QCr0.5 which is (1.7-13.3)×10-4s-1[16]. On the side of 40Cr, the range is (0.03-0.4)×10-4s-1, which is outside of the range of superplastic strain rate which is (0.8-3)×10-4s-1[13, 18]. So in the experiment, the welding of 40Cr/QCr0.5 is the solid state welding mainly based on the superplastic deformation of QCr0.5. The deformation of 40Cr steel is little, but the ultra-fined microstructure of the surface to be welded through laser quenching has a promotional effect on the formation of superplastic welding joint. This can be testified by the welding experiment of the sample of 40Cr without laser pre-treatment and QCr0.5, which is simultaneously performed under the same condition in the paper. The experiment shows that the sample after pressure welding at 750-800℃ always breaks interface at the tensile test and σb is just about 70%-80% of tensile strength of the QCr0.5 base metal.

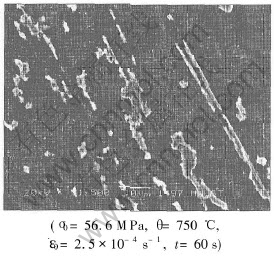

3.5 Observation and analysis of welded surface fracture and microstructure for welded zone of joint

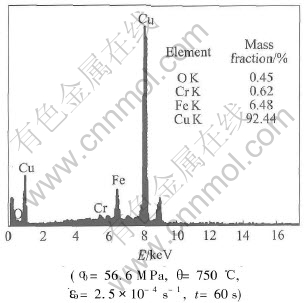

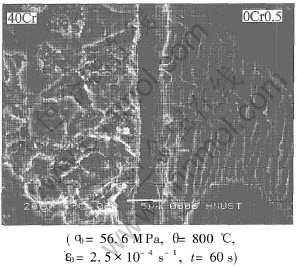

The observation to the superplastic welding joint of 40Cr/QCr0.5 demonstrates that welding joint almost without any welding defection can be acquired by adopting proper welding process parameters, otherwise the joint area tends to generate welding defection like mechanical bonding area, interface micro-void and so on. The SEM photograph of the tensile fracture near the side of 40Cr steel is shown in Fig.5. Seen from Fig.5, the fracture at weld interface consists of two types of regions. The light-colored regions (A) are in correspondence with the convexes of machining trace (here is grinding crack). The gray-colored regions (B) are no welded together regions.The energy spectrum analysis (Fig.6) of light-colored regions (A) indicates that the main component is copper. This demonstrates that the local connection of QCr0.5 and 40Cr has formed at the interface. The possible reason is that the flow resistance of QCr0.5 is obviously lower than that of 40Cr and the deformation temperature as well as the rate of deformation is more suitable for the superplastic flow of QCr0.5. So the plastic flow or superplastic flow is prior occur at the side of QCr0.5. Since the deformation is in correspondence with the convex of machining trace (here is grinding crack) in the 40Cr surface which is formed by grinding before welding, the pioneer seam regions distribute as a discontinuous strip along the convex of machining traces. Through the more particular analysis of the tensile fracture, it is found that with the process of pressure-welding, the proportion of light-colored regions (A) augments, and the strength of joint increases and reaches the strength of base metal(QCr0.5). The welded joint zone without defect are formed(Fig.7).

Fig.5 SEM photograph of welded surface fracture(40Cr side)

Fig.6 Energy spectrum analysis of light-colored regions in Fig.5

Fig.7 SEM photograph of welded joint zone of 40Cr/QCr0.5

4 CONCLUSIONS

After the sample of 40Cr to be welded was pre-treated through laser quenching and QCr0.5, under the pre-pressure stress of 56.6-84.9MPa, the welding temperature of 750-800℃ and the initial strain rate of (2.5-7.5)×10-4s-1, the isothermal superplastic solid state welding of the two heterogeneous materials can be performed in 120-180s, so that the strength of the joint is up to or close to that of QCr0.5 base metal. The superplastic deformation of the copper alloy occurs in the experiment and its expansion rate is less than 6% in welding process, and the deformation of 40Cr steel is little. The superplastic flow deformation of QCr0.5 is the main reason for the formation of joint while the ultra-fined microstructure on the side of 40Cr through laser quenching can also contribute to the formation of joint.

REFERENCES

[1]JI Jie, MA Xue-zhi. Welding of copper and copper-alloy [J]. Welding Technology,1999(2): 13-15.(in Chinese)

[2]HAN Cai-xia, ZHANG Ke-ke, YANG Yun-lin, et al. Welding present situation of steel and copper or copper alloy [J]. Hot Working Technology, 2003(6): 53-55.(in Chinese)

[3]ZHANG Bing-gang, HE Jing-shan, FENG Ji-cai, et al. Microstructures and formation of electron beam welding joint of QCr0.8 and 1Cr21Ni5Ti [J]. The Chinese Journal of Nonferrous Metals, 2004, 14(9): 1569-1574.(in Chinese)

[4]Malin V. Development of solidification welding for depositing non-ferrous alloys onto steel [J]. Weld Journal,1992, 71(5): 35-36.

[5]YU Zhi-shui, WU Ming-fang, WANG Feng-jiang, et al. Transient liquid phase(TLP) diffusion bonding of copper alloy to stainless steel using CuMu alloy as interlayer [J]. Transactions of the China Welding Institution, 2000, 21(3): 32-35.(in Chinese)

[6]YU Zhi-Shui, WANG Feng-jiang, LI Xiao-quan, et al. Diffusion bonding of copper alloy to stainless steel with Ni and Cu interlayer [J]. Trans Nonferrous Met Soc China, 2000, 10(1): 88-91.

[7]YU Zhi-Shui, WANG Feng-jiang, LI Xiao-quan, et al. Transient liquid phase diffusion bonding of copper alloy to stainless steel using CuMu alloys as interlayer [J].Trans Nonferrous Met Soc China, 2000, 10(3): 349-352.

[8]LI Ya-jiang, WU Hui-qiang, CHEN Mao-ai, et al. Microstructure analyses in vacuum diffusion welded joint of copper and aluminum [J].The Chinese Journal of Nonferrous Metals, 2001, 11(3): 424-427.(in Chinese)

[9]LI Zhuo-ran, ZHANG Jiu-hai, FENG Ji-cai. Diffusion bonding of tin bronze and steel [J]. Aerospace Material Technology, 1999(3): 51-54.(in Chinese)

[10]LI Zhuo-ran, ZHANG Jiu-hai, FENG Ji-cai. Investigation on diffusion bonding technology of tin bronze-nickel-steel [J]. Welding Technology, 1999(2): 6-7.(in Chinese)

[11]ZENG Yue-jian, ZHANG Bing-fan, ZHAO Yu-min, et al. Diffusion welding between stainless steel and copper [J]. Welding and Joining, 1986(4): 19-21.(in Chinese)

[12]Maehara Y, Komizo Y, Langdon T G. Principles of superplastic diffusion bonding [J]. Mater Sci Technol,1988, 4(8): 669-674.

[13]ZHANG Ke-ke, YANG Yun-lin, WANG Chang-sheng, et al. The superplastic solid-phase welding of 40Cr/T10A steel [J]. Journal of Materials Science & Technology, 2001, 17(1): 189-190.

[14]DING Hua, ZHANG Kai-feng. Current status and developments in superplastic studies of materials [J]. The Chinese Journal of Nonferrous Metals, 2004, 14(7): 1059-1067.(in Chinese)

[15]YANG Yun-lin, MA Feng,WANG Chang-sheng, et al. Solid phase welding between chromium bronze and wolfram alloy based on superplasticity of chromium bronze [J]. Transactions of the China Welding Institution, 2001, 22(2): 15-18.(in Chinese)

[16]MA Feng, YANG Yun-lin, WANG Chang-sheng. Experiment of superplasticity of QCr0.5 under compression state [J]. Journal of Luoyang Institution of Technology, 1999, 20(1): 14-17.(in Chinese)

[17]YAO Zu-bin, WU Luo-ping, YAO Tian-chang, et al. A study of superplastic compressive on received HPb59-1 brass [J]. Hot Working Technology, 1993(1): 5-9.(in Chinese)

[18]ZHANG Ke-ke, YANG Yun-lin, LIU Shan-zhong, et al. Constitute equations of 40Cr steel under superplastic compressive deformation [J]. Acta Metallurgica Sinica, 2003, 16(6): 538-542.

Foundation item: Project(2004-294) supported by the Innovative Talents Foundation in University of Henan Province, China; Project(0511050800) supported by the Natural Science Foundation of Henan Province, China; Project(2003430211)supported by the Natural Science Foundation of Education Department of Henan Province, China

Received date: 2004-12-16; Accepted date: 2005-01-18

Correspondence: ZHANG Ke-ke, Professor, PhD; Tel: +86-379-64212231; E-mail:zhkeke@mail.haust.edu.cn

(Edited by HE Xue-feng)