用锌焙砂中浸渣制备锰锌铁氧体共沉淀粉

彭长宏,张秀峰,程晓苏,陈带军

(中南大学 冶金科学与工程学院,湖南 长沙,410083)

摘 要:以湿法炼锌过程中的中浸渣和挥发窑渣为原料,经浸出、还原、净化和共沉淀等过程制备软磁铁氧体所需的锰锌铁氧体共沉淀粉料。确定浸出工艺条件、硫化沉淀和氟化沉淀工艺条件。实验结果表明,中浸渣的最佳浸出工艺条件如下:温度为90~95 ℃, 搅拌速度为200 r/min,硫酸用量为理论用量的1.15倍,时间为2.5 h, 液固比为4?1;制得的共沉淀粉料中铁、锰和锌的平均含量比例与理论配方较符合,尤其是共沉淀粉料中各杂质元素含量很低, 各杂质成分含量分别为Ca 0.018 0%,Mg 0.008 5%,Si 0.003 8%,Al 0.007 8%,Ni 0.017 0%,Pb 0.001 2%,Cu 0.003 3%,Cr 0.002 8%及Cd 0.000 2%,达到锰锌软磁铁氧体材料对粉料的要求。

关键词:锰锌铁氧体;共沉淀粉;中浸渣;挥发窑渣

中图分类号:TF803.2 文献标志码:A 文章编号:1672-7207(2009)06-1494-05

Preparation of Mn-Zn ferrite coprecipitation powders fromneutral leached residue of zinc calcine

PENG Chang-hong, ZHANG Xiu-feng, CHENG Xiao-su, CHEN Dai-jun

(School of Metallurgical Science and Engineering, Central South University, Changsha 410083, China)

Abstract: Mn-Zn ferrite coprecipitation powders were prepared from neutral leached residues and kiln slags in zinc hydrometallurgy after the processes of leaching, reduction, purification and coprecipitation. The optimum conditions of leaching, sulfide precipitation and fluorination precipitation were determined. The best leaching conditions are as follows: the leaching temperature 90-95 ℃, the stirring speed 200 r/min , the excess coefficient of sulfuric acid 1.15, the leaching time 2.5 h, and the ratio of liquid to solid 4?1.The results show that the content ratio of Fe, Mn and Zn of the coprecipitation powders accords well with theoretical prescription, especially with a low impurity content. The contents of impurity elements are as follows: Ca 0.018 0%, Mg 0.008 5%, Si 0.003 8%, Al 0.007 8%, Ni 0.017 0%, Pb 0.001 2%, Cu 0.003 3%, Cr 0.002 8%, Cd 0.000 2%, respectively, which can meet the qualification of powders being used in Mn-Zn soft magnetic ferrite.

Key words: Mn-Zn ferrite; coprecipitation powders; neutral leached residue; kiln slag

随着化工、冶金、材料科学的交叉与融合,利用矿物原料或工业废渣直接制取铁氧体材料的研究取得了重大进展,归纳起来有:利用黄钠铁矾渣制备铁氧体[2],利用废电池制备铁氧体[3-6],利用钢铁厂烟尘直接制备锰锌铁氧体材料,利用软锰矿,闪锌矿和铁屑制取锰锌铁氧体材料[7]。唐谟堂等[7]用直接法制备出的低功耗锰锌铁氧体产品质量完全达到日本TDK公司的PC30指标,接近PC40指标。这些研究充分利用工业废渣或生活废弃物,变废为宝,对于扩大铁氧体原料来源和降低铁氧体制取成本有很重要的意义,同时有利于环境保护。湿法炼锌过程中会产生大量的浸出渣,人们对于浸出渣的处理有大量的研究[1, 3, 8-9]。本文作者利用硫化锌精矿湿法炼锌过程中产生的中浸渣和中浸渣高温还原处理后产生的挥发窑渣为原料,采用共沉淀法制备锰锌铁氧体共沉淀粉料。这是一条废物利用的新思路,应用该工艺不仅可以消化湿法炼锌过程中多余的中浸渣,节约处理成本,而且可以回收挥发窑渣中的铁,有效减少挥发窑渣的堆存量,实现环境保护与经济效益的双赢。

1 实 验

1.1 原 料

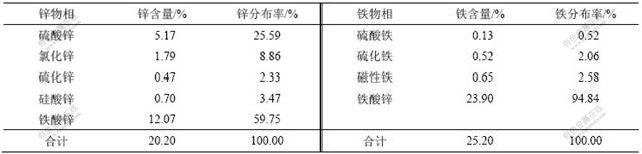

湿法炼锌中浸渣和挥发窑渣,均取自河南豫光锌业有限公司,化学成分见表1,中浸渣的锌和铁物相分析结果见表2。从表1,表2可以看出,中浸渣含有大量的铁和锌,且主要以铁酸锌形式存在,用常规酸浸难以浸出,须采用高温高酸浸出。辅助试剂为:硫化铵、氟化铵、氨水、锰粉、七水合硫酸亚铁、一水硫酸锰和七水合硫酸锌,均为分析纯;碳酸氢铵,为农用碳铵;工业硫酸。

表1 中浸渣和挥发窑渣的化学成分

Table 1 Chemical composition of neutral leached residue and kiln slag 质量分数/%

表2 中浸渣中锌铁的物相分布

Table 2 Phase distribution of Zn and Fe in neutral leached residue 质量分数/%

1.2 分析与检测

Mn2+采用硫酸亚铁铵滴定法检测;Zn2+采用EDTA滴定法检测;Fe2+采用重铬酸钾滴定法检测;其他杂质元素采用ICP-AES测定。

1.3 工艺流程与原理

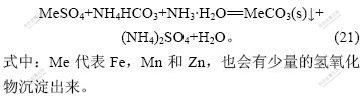

工艺流程如图1所示。锌焙砂中浸渣先经硫酸高温高酸浸出,然后以挥发窑渣还原,得到硫酸盐溶液,该溶液经净化除重金属和钙、镁后,补加分析纯的硫酸锰和硫酸锌来达到配方要求,之后用碳酸氢铵共沉淀铁、锰和锌制取铁锰锌共沉粉。

图1 工艺流程

Fig.1 Process flow

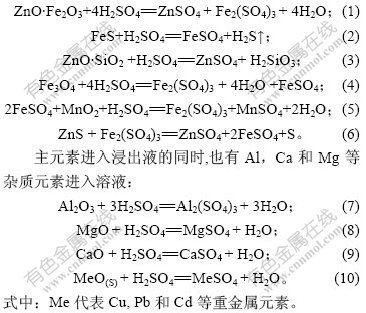

1.3.1 浸出过程

高温高酸浸出过程主要反应如下[1, 8-9]:

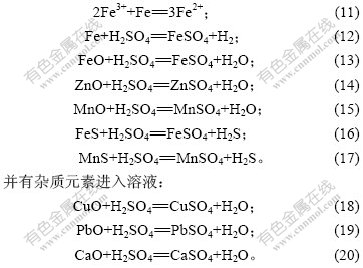

1.3.2 还原过程

浸出液中铁、锰、锌的比例与理论配方相比有一定差距,需添加辅助原料调整各组分的含量,同时为了减少在净化阶段铁的损失,需向浸出液中加入还原剂将Fe3+还原为Fe2+。挥发窑渣的主体成分是海绵铁,还含有少量铁、锌和锰的氧化物、硫化物及重金属元素。因此,通过物料计算向浸出液中加入挥发窑渣,

以挥发窑渣中的铁为还原剂将Fe3+还原为Fe2+。由于浸出液中含Fe3+,且呈酸性,则发生以下反应:

、1.3.3 硫化沉淀去除重金属

根据硫化物溶度积的不同,用(NH4)2S作为沉淀剂除去Sb3+,Ni2+,Pb2+和Cd2+等重金属离子[10],实现其与主体成分Zn2+,Fe2+和Mn2+的分离。

1.3.4 氟化沉淀除钙和镁

对于Ca2+和Mg2+,在室温下,Ksp(CaF2)= 2.7×10-11,Ksp(MgF2)=6.4×10-9,均很小,加入NH4F即可除去Ca2+和Mg2+。Ca2+,Mg2+与F-形成难溶CaF2和MgF2沉淀而被除去。但要在较高温度下,形成的氟化物沉淀才较易过滤。

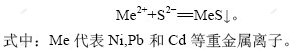

1.3.5 共沉淀过程

以碳酸氢铵和氨水的混合溶液作为沉淀剂,将净化后的硫酸盐混合溶液加入到盛有沉淀剂的反应器中进行共沉淀,其反应如下:

2 结果与讨论

2.1 浸出过程

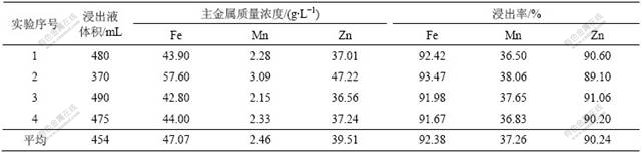

在单因素条件实验基础上,确定浸出过程的最优条件如下:温度为90~95 ℃,搅拌速度为200 r/min,酸用量为理论用量的1.15倍,时间为2.5 h,液固比为4?1。进行4次硫酸浸出综合实验,浸出液的体积、主金属浓度及主金属浸出率如表3所示。

表3 浸出液中主金属含量和主金属浸出率

Table 3 Concentration of main metals in leached solution and their leached rates

由表3可以看出,在上述高温高酸的浸出条件下,占中浸渣大部分的铁酸锌被溶解进入溶液中,铁和锌的浸出率都达到90%以上,而锰的浸出率比较低,还不到40%,这是因为中浸渣中的锰主要以MnO2形式存在,而MnO2不溶于硫酸。

2.2 还原过程

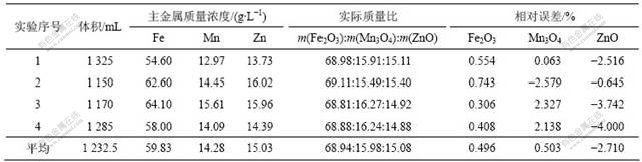

中浸渣经高温高酸浸出后,浸出液中存在大量Fe3+,需要对溶液中的Fe3+进行还原。一方面使铁都以Fe2+形式存在,防止在净化时铁水解以Fe(OH)3形式损失掉;另一方面,因为Fe2+与锰和锌碳酸盐沉淀的pH值更接近,有利于铁、锰和锌共沉淀。此外,浸出液中的主成分与理论配方有一定差距,为了确保还原液中主成分符合或接近铁氧体理论配方,在本实验中采用定比例还原技术,一方面添加挥发窑渣使Fe3+全部还原成Fe2+,另一方面,补加锰粉,确保还原液中主成分符合或接近铁氧体理论配方。以上述浸出液为原料,终点pH值控制在2.0~3.0,进行4次定比例还原实验,结果见表4。

表4 还原液中Fe,Mn和Zn的含量及比例

Table 4 Composition of Fe, Mn, Zn in reducing solution and their prescription

从表4可以看出,还原液中Fe, Mn和Zn 3种主成分含量与理论配方的平均相对误差分别为0.496%,0.503%和-2.710%,Fe和Mn的实际含量与理论配方较符合,Zn的实际含量与理论配方偏差较大。不过这个影响不大,在共沉淀之前还会通过补加七水合硫酸亚铁、一水硫酸锰和七水合硫酸锌使铁、锰和锌在共沉淀粉中达到理论配方。此外,经检测还原液中Fe3+质量浓度为0.1 g/L,还原率达到99.8%,说明定比例还原过程进行十分彻底,铁基本上以Fe2+形式存在。

2.3 净化过程

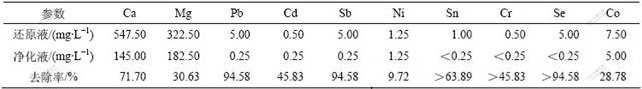

还原液的净化包括硫化沉淀除重金属离子和氟化沉淀除钙镁2个过程。在每一过程中,均先进行条件实验,确定出最优工艺条件,然后,在优化条件下进行相对应的综合实验。实验得出的硫化沉淀优化条件如下:温度为45~55 ℃,pH值为3.0~3.5,反应时间为1 h,硫化铵用量为理论用量的2倍。以硫化除重金属离子后的溶液为试液,进行相对应的氟化除钙镁试验。氟化沉淀除钙镁综合条件如下:温度为45~55 ℃,pH值为4.5~5.0,时间为1.0~1.5 h,氟化铵用量为理论量3.0倍,浓度为30%。还原液和净化液杂质元素含量及其去除率如表5所示。

表5 还原液和净化液杂质元素含量及去除率

Table 5 Content of impurity elements and their removal rates in reducing solution and purification solution

从表5可以看到,Pb,Sb和Se的去除效果最好,去除率在90%以上;Ca和Mg的去除率较低,但净化后溶液中Ca和Mg的浓度降低了很多。

2.4 共沉淀过程

参考文献[11-14],并结合本文研究,确定共沉淀条件如下:沉淀剂中NH4HCO3用量为其理论用量的1.2倍,pH=7.2~7.5,搅拌速度为200 r/min,温度为40~50 ℃,时间为2 h。先根据铁氧体的理论配方,结合净化液中铁、锰及锌主体成分含量,偏离配方的成分,可配入分析纯MeSO4(Me代表Fe, Mn或Zn)。共沉淀粉料中杂质元素含量如表6所示。

表6 共沉粉中的杂质含量

Table 6 Impurity contents of coprecipitation powder 质量分数/%

从表6可以看到,除Ni的含量比较高以外,其他的杂质元素含量都很低,尤其是Si的含量(质量分数)只有38×10-6,可以成为制备高性能铁氧体的原料。

3 结论

a. 中浸渣的最优浸出工艺如下:温度为90~ 95 ℃,搅拌速度为200 r/min,硫酸用量为理论用量的1.15倍,时间为2.5 h,液固比为4?1。

b. 还原过程使铁、锰和锌主成分与理论配方吻合较好。

c. 经配料计算、浸出、还原、除杂净化和共沉淀等过程,制备出纯度高、杂质含量低的锰锌铁氧体 共沉淀粉,其中杂质成分的含量分别为:Ca 0.018 0%,Mg 0.008 5%,Si 0.003 8%,Al 0.007 8%,Ni 0.017 0%,Pb 0.001 2%,Cu 0.003 3%,Cr 0.002 8%,Cd 0.000 2%。

d. 由湿法炼锌中浸渣和挥发窑渣可以生产锰锌软磁铁氧体共沉淀粉,而且制得的共沉粉杂质含量低,具有原料廉价、来源广泛、生产成本低、产品附加值高等优点。

参考文献:

[1] 梅光贵, 王德润, 周敬元, 等. 湿法炼锌学[M]. 长沙: 中南大学出版社, 2001: 95-121.

MEI Guang-gui, WANG De-run, ZHOU Jing-yuan, et al. Hydrometallurgy of zinc[M]. Changsha: Central South University Press, 2001: 95-121.

[2] 阳征会, 龚竹青, 李宏煦, 等. 用黄钠铁矾渣制备复合镍锌铁氧体[J]. 中南大学学报: 自然科学版, 2006, 37(4): 685-691.

YANG Zheng-hui, GONG Zhu-qing, LI Hong-xu, et al. Preparation of Ni-Zn ferrite from sodium jarosite residue[J]. Journal of Central South University: Science and Technology, 2006, 37(4): 685-691.

[3] 付运康. 锌浸出渣不同处理工艺浅析[J]. 四川有色金属, 2003(1): 35-38.

FU Yun-kang. Analysis of different treating technology of zinc leaching residue[J]. Sichuan Nonferrous Metals, 2003(1): 35-38.

[4] Mauro B, Gaetano B, Filippo M, et al. Recovery of zinc and manganese from spent batteries[J]. Journal of Power Source, 1994, 48(3): 389-392.

[5] 席国喜, 张存芳, 路迈西. 废旧碱性电池共沉淀法制备锰锌铁氧体的研究[J]. 人工晶体学报, 2006, 35(2): 373-377.

XI Guo-xi, ZHANG Cun-fang, LU Mai-xi. Study on preparation of manganese-zinc ferrites by co-precipitation method using spent alkaline Zn-Mn batteries[J]. Journal of Synthetic Crystals, 2006, 35(2): 373-377.

[6] PENG Chang-hong, BAI Ben-shuai, et al. Study on the preparation of Mn-Zn soft magnetic ferrite powders from waste Zn-Mn dry batteries[J]. Waste Management, 2008, 28: 326-332.

[7] 黄小忠, 唐谟堂. 由软锰矿、闪锌矿、铁屑直接制取锰锌铁氧体软磁材料新工艺研究[J]. 中国锰业, 1996, 14(1): 42-44.

HUANG Xiao-zhong, TANG Mo-tang. The novel process of manufacturing Mn-Zn ferrites from pyxro-lusite, sphalerite and steel scraps[J]. China’s Manganese Industry, 1996, 14(1): 42-44.

[8] 夏志华, 唐谟堂, 李仕庆, 等. 锌焙砂中浸渣高温高酸浸出动力学研究[J]. 矿冶工程, 2005, 25(2): 53-57.

XIA Zhi-hua, TANG Mo-tang, LI Shi-qing, et al. A study on the kinetics of leaching the residues from the neutral leaching process with high concentration of sulfuric acid at high temperature[J]. Mining and Metallurgical Engineering, 2005, 25(2): 53-57.

[9] 肖 纯, 唐谟堂, 何 静, 等. 用锌焙砂中浸渣制备铁精矿[J]. 金属矿山, 2007(12): 131-134.

XIAO Chun, TANG Mo-tang, HE Jing, et al. Preparation of iron concentrate from residue of neutral leaching of zinc calcine[J]. Metal Mine, 2007(12): 131-134.

[10] 李洪贵. 湿法冶金学[M]. 长沙: 中南大学出版社, 2002: 83-85.

LI Hong-gui. Science of hydro-metallurgy[M]. Changsha: Central South University Press, 2002: 83-85.

[11] Robbins H. The preparation of Mn-Zn ferrites by co-precipitation[C]//Proceedings of the 4th International Conference on Ferrites. Japan, 1980: 7-10.

[12] 李伯刚, 尹光福, 查忠勇, 等. 软磁MnZn铁氧体粉料可连续化生产新工艺[J]. 有色金属, 1999, 51(3): 87-89.

LI Bo-gang, YIN Guang-fu, CHA Zhong-yong, et al. Successively productive process to prepare soft MnZn ferrite powder[J]. Nonferrous Metals, 1999, 51(3): 87-89.

[13] 李自强, 李 春, 何良惠, 等. 软磁材料锰锌铁氧体共沉粉料的研制[J]. 四川联合大学学报, 1997, 1(5): 24-28.

LI Zi-qiang, LI Chun, HE Liang-hui, et al. Investigation on preparation of Mn-Zn ferrite powders by a co-precipitation process[J]. Journal of Sichuan Union University, 1997, 1(5): 24-28.

[14] 陈燕华, 丘 泰. 共沉淀法制备锰锌铁氧体粉工艺条件研究[J]. 材料导报, 2006, 11(S2): 347-348.

CHENG Yan-hua, QIU Tai. Study on the techniques of Mn-Zn ferrites with Co-precipitation method[J]. Materials Review, 2006, 11(S2): 347-348.

收稿日期:2008-12-08;修回日期:2009-03-02

基金项目:国家高技术研究发展计划项目(2006AA06Z373);广东省科技计划项目(2008A080403007-03)

通信作者:彭长宏(1966-),男,湖南长沙人,博士,教授,从事直接法制备锰锌铁氧体功能材料及新型离子液体合成与应用研究;电话:0731-88836940;E-mail: peng9103@163.com