文章编号:1004-0609(2011)05-0988-07

含钪Al-Cu-Li-Zr合金的热变形行为及组织演化

梁文杰1,2,潘清林2,何运斌2

(1. 中南大学 化学化工学院,长沙 410083;2. 中南大学 材料科学与工程学院,长沙 410083)

摘 要:在实验温度范围为380~500 ℃、应变速率范围为0.001~10.0 s-1,采用Gleeble-1500热模拟机,对含钪Al-Cu-Li-Zr合金的高温热变形行为进行研究,采用金相显微镜和透射电镜观察合金在压缩变形时的组织变化。结果表明:变形温度和应变速率的变化强烈影响合金的流变应力,合金的流变应力随变形速率的增加而增大,随变形温度的升高而降低,可用包含Arrhenius项的Zener-Hollomon参数描述合金在高温压缩变形时的流变应力行为。当合金在温度低于440 ℃变形时,合金中主要形成亚晶组织,仅发生动态回复;在ln Z≤36.7变形时,合金发生部分动态再结晶,其动态再结晶形核机制主要为晶界弓出和亚晶合并形核。

关键词:含钪Al-Cu-Li-Zr合金; 热压缩变形; 动态回复; 动态再结晶

中图分类号:TG 146.4 文献标志码:A

Hot deformation behavior and microstructural evolution of Al-Cu-Li-Zr alloy containing Sc

LIANG Wen-jie1, 2, PAN Qing-lin2, HE Yun-bin2

(1. School of Chemistry and Chemical Engineering, Central South University, Changsha 410083, China;

(2. School of Materials Science and Engineering, Central South University, Changsha 410083, China)

Abstract: The deformation behavior of Al-Cu-Li-Zr alloy containing Sc was investigated with compression tests in the temperature range of 380-470 ℃ and the strain rate range of 0.001-10.0 s-1 using Gleeble-1500 system, and the associated microstructural evolutions was studied by metallographic microscopy and transmission electron microscopy. The results indicate that the flow stress of the alloy increases with increasing strain rate at a given temperature, and decreases with increasing temperature at a given imposed strain rate. The flow stress of the alloy during the elevated temperature deformation can be represented by a Zener-Hollomon parameter with the inclusion of Arrhenius term. At 440 ℃, the hot deformation structure of the alloy is mainly the sub-grain structure, and when ln Z≤36.7, the dynamic recrystallization occurs in the alloy. The nucleation mechanism of recrystallizing process is grain-boundary protrude and subgrain coalescence.

Key words: Al-Cu-Li-Zr alloy containing Sc; hot compression deformation; dynamic recovery; dynamic recrystallization

铝锂合金由于具有密度低和比强度高等优良特性,近年来发展迅速。但铝锂合金的塑性差、断裂韧性低,限制了其发展与应用。微合金化是改善铝锂合金性能的重要途径之一[1]。在微合金化元素中,Sc是迄今为止所发现的对铝合金最为有效的微合金化元素。用Sc作为合金化元素不仅能改善合金铸锭组织和抑制合金热变形过程中的再结晶,而且能大幅度地提高铝合金强度和塑韧性,改善合金的焊接性能、抗蚀性能、辐照稳定性和超塑性[2-4]。

与其他常规铝合金一样,含Sc铝锂合金一般需经高温塑性加工成形。铝及铝合金在热变形过程中同时存在着硬化和软化现象,这两个相互矛盾的因素使金属材料在热变形过程中显微组织发生复杂的变化,软化机制主要有动态回复和动态再结晶。近年来,国内外的材料研究者对铝合金在热变形过程中的动态回复和动态再结晶进行了大量的研究[5-8],这些研究表明,铝合金在热变形过程中的软化机制和显微组织演化主要取决于热变形时的变形温度(T)、应变速率( )和应变(

)和应变( )。合金在热变形过程中的动态回复和动态再结晶程度以及由此形成的组织特征决定了材料热加工态的性能,并影响材料在后续加工和热处理过程中的组织和性能变化,因此,研究铝合金动态回复和动态再结晶组织演化对性能的预测和控制至关重要。

)。合金在热变形过程中的动态回复和动态再结晶程度以及由此形成的组织特征决定了材料热加工态的性能,并影响材料在后续加工和热处理过程中的组织和性能变化,因此,研究铝合金动态回复和动态再结晶组织演化对性能的预测和控制至关重要。

本文作者在Gleeble-1500热模拟机上,采用圆柱体轴对称高温等温压缩实验,研究含Sc的Al-Cu-Li-Zr合金在高温变形时的组织变化特征以及变形条件与组织间的关系,以期为这种合金合理制定热塑性加工工艺参数提供依据。

1 实验

以99.8%Al、99.9%Li和Al-48.7%Cu、Al-3.72%Zr、Al-2.23%Sc中间合金为原料,在氩气保护下,采用水冷铜模激冷铸造法制备实验用合金,其化学成分为Al-3.5Cu-1.5Li-0.22(Sc+Zr)。合金铸锭经520 ℃、24 h均匀化处理后加工成尺寸为d 10 mm×15 mm的圆柱型压缩试样。为了保证润滑剂在热压缩过程中不流失,在圆柱型压缩试样的两端车有深度为0.2 mm的凹坑。压缩过程中,以石墨和机油的混合物作为润滑剂,填充在圆柱试样两端的凹槽内,以减少摩擦对应力状态的影响。试样加热速度为1 ℃/s,加热至预定温度后保温300 s,然后进行压缩实验。热压缩实验在Gleeble-1500热模拟实验机上进行,实验温度范围为380~500 ℃,应变速率范围为0.001~10.0 s-1,压缩变形量为50%。在热变形过程中,自动控制应变、温度和应变速率等变形条件并自动采集数据。热压缩变形结束后,试样立即淬入水中冷却,然后,平行压缩轴线方向截开试样,金相试样经氟硼酸水溶液电解抛光后阳极复膜,采用POLYVER-MET金相显微镜对试样进行观察;透射电镜试样经机械预减薄后双喷穿孔而成,电解液为硝酸和甲醇的混合溶液(体积比为1?3),温度约为-20 ℃。显微组织观察在TECNAI G2 20分析电镜上进行。

2 结果与讨论

2.1 流变应力

图1所示为合金在不同变形温度和应变速率下热压缩变形的真应力—真应变曲线。由图1可以看出,合金热压缩变形流变应力在变形初期(ε<0.1)随着应变的增加而迅速提高至峰值应力,显示出明显的加工硬化效应;然后,随着变形的进一步增大,流变应力逐渐降低,合金出现明显的软化现象。从图1还可以看出,在同一应变速率下,随变形温度的升高,真应力下降;而在同一变形温度下,真应力随应变速率的增加而增大,说明合金是一种正应变敏感性材料。

在合金的热变形过程中,其流变应力受应变速率、变形程度和变形温度等的影响。合金的流变应力s 与应变速率 和变形温度T之间的关系可以用以下几个方程式来表示[9-10]:

和变形温度T之间的关系可以用以下几个方程式来表示[9-10]:

(1)

(1)

(2)

(2)

(3)

(3)

(4)

(4)

式中:A1、A2、A、n1、n、α和β均为常数;R为理想气体常数;T为热力学温度;Q为变形激活能;Z为Zener-Hollomon参数(Z参数); 流变应力s 对应于峰值流变应力sp 或稳态流变应力。方程(1)适应于低应力水平,方程(2)适应于高应力水平,方程(3)适应于所有应力水平。

通过研究合金峰值流变应力sp 与应变速率 和变形温度T之间的关系,利用Zener-Hollomon参数法可以计算出合金的热变形材料常数。计算结果为:Q=240.85 kJ/mol,α=0.019 3 mm2/N,n=5.62,A= 1.51×1016 s-1。由此可以绘制流变应力s和Z参数之间的关系曲线,如图2所示。从图2可以看出,

和变形温度T之间的关系,利用Zener-Hollomon参数法可以计算出合金的热变形材料常数。计算结果为:Q=240.85 kJ/mol,α=0.019 3 mm2/N,n=5.62,A= 1.51×1016 s-1。由此可以绘制流变应力s和Z参数之间的关系曲线,如图2所示。从图2可以看出, 和ln[sinh(ασ)]之间存在线性关系,表明合金热压缩变形的流变应力与应变速率和变形温度之间的关系可用双曲正弦形式修正的Arrhenius 关系来描述,合金的高温塑性变形过程是受热激活控制的,其变形和软化机制与热激活有关。

和ln[sinh(ασ)]之间存在线性关系,表明合金热压缩变形的流变应力与应变速率和变形温度之间的关系可用双曲正弦形式修正的Arrhenius 关系来描述,合金的高温塑性变形过程是受热激活控制的,其变形和软化机制与热激活有关。

2.2 高温压缩变形过程中的组织演变

图3所示为合金在不同变形条件下的金相组织。从图3可以看出,合金在热变形过程中,原始晶粒破碎被拉长变形;且随着变形温度的升高、应变速率的降低,即Z参数的减小,合金组织发生了部分动态再结晶。当应变速率为0.1 s-1时,合金在440 ℃以下的热变形组织呈现稍微拉长的特征,其延伸方向与压缩轴垂直,且随着温度的升高,晶粒的形貌逐渐由拉长状向等轴变化,如图3(a)、(b)和(c)所示。但是,440℃以下的热变形组织均为未再结晶组织,表明合金组织仅发生了动态回复。当温度升高至470 ℃时,合金的热变形组织为等轴或近似等轴的亚晶粒,亚晶界更为平直和清晰,沿晶界能观察到细小的再结晶晶粒,表明合金组织发生了部分动态再结晶(见图3(d));当变形温度进一步升高至500 ℃时,合金组织再结晶程度增加(见图3(e))。此外,从图3(d)、(f)和(g) 还可以看出,当变形温度为470 ℃时,应变速率越慢,晶粒越趋于等轴状,合金组织越易发生动态再结晶。

图1 不同温度下合金热压缩变形的真应力—真应变曲线

Fig.1 True stress—strain curves for alloy during hot compression deformation at different temperatures: (a) 380 ℃; (b) 410 ℃; (c) 440 ℃; (d) 470 ℃; (e) 500 ℃

图2 流变应力与Z参数的关系曲线

Fig.2 Linear relationship between ln Z and ln [sinh(ασ)]

图3 合金在不同变形条件下的金相显微组织

Fig.3 Optical micrographs of alloy deformed under different conditions: (a) 380 ℃, 0.1 s-1; (b) 410 ℃, 0.1 s-1; (c) 440 ℃, 0.1 s-1; (d) 470 ℃, 0.1 s-1; (e) 500 ℃, 0.1 s-1; (f) 470 ℃, 0.001 s-1; (g) 470 ℃, 10.0 s-1

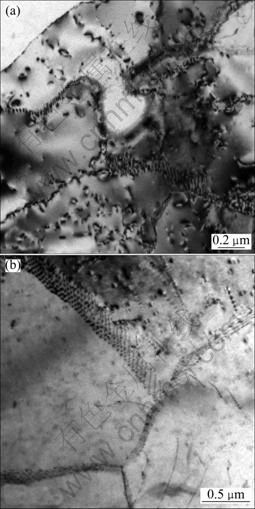

合金在440 ℃以下变形时,因温度较低,且铝合金的层错能较高,动态再结晶较难发生,变形过程中主要是动态回复软化与加工硬化相平衡。在动态回复过程中,由于加工硬化过程中位错增殖和回复软化时的位错相互抵消和重组之间存在动态平衡,容易形成丰富的亚晶组织。图4所示为合金在不同变形条件下的亚晶组织。从图4可以看出,合金高温变形后形成了典型的亚晶组织,且亚晶尺寸随变形温度的升高及应变速率的降低(即随ln Z的减小)而增大。

图4 合金在不同变形条件下的亚晶组织

Fig.4 Subgrain structures of alloy deformed under different conditions: (a) 440 ℃, 0.1 s-1; (b) 470 ℃, 0.1 s-1

根据金属变形热激活理论,在稳态流变阶段,材料的软化主要由螺型位错的交滑移和刃型位错的攀移提供。当两个以上滑移系开动或温度足够高致使位错能快速攀移时,位错通过多边形化塞积效应可排列成垂直于滑移面的墙和其他低能位错组态,形成亚晶粒。在外加应力的作用下,合金中的可动位错可脱离亚晶界,使亚晶界的稳定性降低。同时,应变产生的大量空位的聚集使位错的攀移速率增加。大量位错通过交滑移和攀移又重新进入亚晶界,从而使其发生有限的迁移(重新形成新的亚晶界)。外加应力引起的亚晶界的破碎和位错运动引起的亚晶界的重组使合金中亚晶界发生快速重排。这一位错的相互抵消和重排过程通常称为“重复多边形化”。随变形Z参数的减小,原子热激活能力增强,应变产生的大量空位使攀移迅速进行。位错的相互抵消和重组更加彻底,可动距离也相应增大,重复多边形化更加完善,形成尺寸更大、更为完整的亚晶组织[11]。

另一方面,随着变形温度的升高和应变速率的降低,即随Z值的减小,压缩变形时单位应变内的热激活次数增加,位错的可动性增强,并由此增大其相消速率,使位错增殖和相消的平衡向低位错密度方向变化。同时,位错可动性的增强也增大了亚晶界应力场的影响范围,使亚晶界之间的距离增大,亚晶界上的位错将排列成为更稳定和简单的组态。因此,随着Z值的减小,合金热压缩变形后的亚晶尺寸增大。

当变形温度升高到470 ℃、应变速率小于0.1 s-1,即在低Z值条件下压缩时,合金发生了部分动态再结晶。图3所示的金相观察结果表明,实验合金在热变形过程中发生部分动态再结晶的趋势主要取决于变形温度和变形速率,即取决于Z参数的大小。

SHEPPARD和RAYBOULD[12]研究了高纯铝、Al-7%Zn及Al-7%Zn-3%Mg合金热挤压变形时的动态再结晶行为,发现挤压后在水淬条件下,变形时发生动态再结晶时的温度补偿应变速率Z值的自然对数小于某一临界值,即

≤CR (5)

≤CR (5)

式中:CR为与材料和冷却速率有关的经验常数。根据此公式可以大致推断动态再结晶的温度范围。本合金在不同热变形条件下的金相和透射电子显微组织观察结果表明,只有当变形温度达到或超过470 ℃时,合金在热压缩变形时才会发生动态再结晶,而且温度越高,对应的应变速率范围越宽,说明合金发生动态再结晶时的ln Z均小于某一值。经计算可得出,实验合金热压缩变形发生动态再结晶的临界条件为

(6)

(6)

和静态再结晶一样,动态再结晶也存在形核长大的过程,但它只是一种快速形核和有限长大的过程。这是因为动态回复降低了再结晶形核驱动力,同时新形成的晶粒又会发生塑性变形并迅速硬化(至少在移动的界面后面是这样),由此新核失去继续长大的驱动力,形成不久便停止继续长大,因此,晶核的形成机制决定了动态再结晶的特征。

图5所示为合金在不同变形条件下的透射电镜显微组织。从图5可以看出,合金在热变形过程中,再结晶形核是多种机制在起作用。图5(a)显示合金在热变形过程中,新形成的大角度晶界呈现明显的凸出特征,这种弓出是由已形成的亚晶粒界面的局部有限迁移形成的。合金在高温压缩变形过程中,原有大角度晶界两侧在变形时会形成大小不同的亚晶粒。大尺寸亚晶的界面由于具有较高的界面迁移率而向小尺寸亚晶一侧发生迁移,迁移的速率由分布于界面两侧的应变能梯度与界面曲率半径之间的平衡状态决定。亚晶界局部范围内的迁移使原始大角度晶界部分弓出。当弓出曲率半径达到某一特定值时,界面就会连续迅速地往外迁移而发生再结晶形核。图5(b)显示合金中的某些区域的亚晶界正在合并。一组亚晶粒的公共边界上两列位错发生反应后合二为一,这可以认为是亚晶合并成核机制在起作用。相邻亚晶粒的公共边界上的位错通过攀移和滑移,转移到周围晶界或角度较大的亚晶界上,导致中间亚晶界消失,即完成再结晶的成核。之后,通过原子扩散和位置调整,最终使一组亚晶取向一致,合并成为一个大晶粒。从图5(b)中可以看出,左右两个亚晶界面上的刃型位错通过攀移而离开亚晶界,使亚晶界变得模糊,这两个亚晶粒的衬度越来越接近,最终这两个亚晶粒合并成一个晶粒。因此,合金在高温塑性变形时动态再结晶形核机制主要为晶界弓出和亚晶合并形核。

图5 合金在不同变形条件下的TEM像

Fig.5 TEM images of alloy deformed under different conditions: (a) 470 ℃, 0.1 s-1; (b) 500 ℃, 0.1 s-1

3 结论

1) Al-3.5Cu-1.5Li-0.22(Sc+Zr)合金热压缩流变应力双曲正弦项的自然对数(ln [sinh(ασ)])和温度补偿应变速率Z参数的自然对数(ln Z)间满足线性关系,说明合金的热压缩变形过程是受热激活过程控制的。

2) 在440 ℃以下变形时,合金主要形成亚晶组织,仅发生了动态回复,其特征取决于变形时Z参数的大小。随变形温度的升高和应变速率的降低,即随Z值的降低,合金中形成的亚晶尺寸增大。

3) 在470 ℃以上变形且ln Z≤36.7时,合金发生部分动态再结晶,其动态再结晶形核机制主要为晶界弓出和亚晶合并形核。

REFERENCES

[1] 王芝秀, 郑子樵, 李 海. 铝锂合金的微合金化及其作用机理[J]. 材料导报, 2005, 17(10): 11-15.

WANG Zhi-xiu, ZHENG Zi-qiao, LI Hai. Microalloying of Al-Li alloys and its mechanisms[J]. Materials Review, 2005, 17(10): 11-15.

[2] 王新宇, 潘青林, 周昌荣, 梁文杰, 尹志民. 含钪铝锂合金的研究与发展[J]. 稀土, 2005, 26(6): 70-75.

WANG Xin-yu, PAN Qing-lin, ZHOU Chang-rong, LIANG Wen-jie, YIN Zhi-min. Recent situation and development trend of Sc containing Al-Li alloy[J]. Chinese Rare Earths, 2005, 26(6): 70-75.

[3] GILMORE D L, STARKE E A. Trace element effects on precipitation processes and mechanical properties in an Al-Cu-Li alloy[J]. Metallurgical and Materials Transactions A, 1997, 28(7): 1399-1415.

[4] 黄兰萍, 郑子樵, 黄永平, 钟莉萍. 微量Sc对2197铝锂合金组织和力学性能的影响[J]. 中南大学学报: 自然科学版, 2005, 36(1): 20-24.

HUANG Lan-ping, ZHENG Zi-qiao, HUANG Yong-ping, ZHONG Li-ping. Effect of Sc on microstructure and mechanical properties of 2197 Al-Li alloy[J]. Journal of Central South University: Science and Technology, 2005, 36(1): 20-24.

[5] GOURDET S, MONTHEILLET F. An experimental study of the recrystallization mechanism during hot deformation of aluminum[J]. Materials Science and Engineering A, 2000, 283(1/2): 274-288.

[6] LIN G Y, ZHANG Z F, ZHANG H, PENG D S, ZHOU J. Study on the hot deformation behaviors of Al-Zn-Mg-Cu-Cr aluminum alloy[J]. Acta Metallurgica Sinica: English Letters, 2008, 21(2): 109-115.

[7] 沈 健, 尹志民, 章四琪, 张新明. 变形条件对2091铝锂合金高温变形组织的影响[J]. 矿冶工程, 1996, 16(4): 57-61.

SHEN Jian, YIN Zhi-min, ZHANG Si-qi, ZHANG Xin-ming. The effect of deformation variables on the structures of 2091 aluminium-lithium alloy at elevated temperatures[J]. Mining and Metallurgical Engineering, 1996, 16(4): 57-61.

[8] ZHANG Hui, LI Luo-xing, YUAN Deng, PENG Da-shu. Hot deformation behavior of the new Al-Mg-Si-Cu aluminum alloy during compression at elevated temperatures[J]. Materials Characterization, 2007, 58(2): 168-173.

[9] 韩冬峰, 郑子樵, 蒋 呐, 李劲风. 高强可焊2195铝-锂合金热压缩变形的流变应力[J]. 中国有色金属学报, 2004, 14(12): 2090-2095.

HAN Dong-feng, ZHENG Zi-qiao, JIANG Na, LI Jing-feng. Flow stress of high-strength weldable 2195 aluminium-lithium alloy during hot compression deformation[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(12): 2090-2095.

[10] SPIGARELLI S, EVANGELISTA E, MCQUEEN H J. Study of hot workability of a heat treated AA6082 aluminum alloy[J]. Scripta Materialia, 2003, 49(2): 179-183.

[11] 沈 健, 唐京辉, 谢水生. Al-Zn-Mg合金的热变形组织演化[J]. 金属学报, 2000, 36(10): 1033-1036.

SHEN Jian, TANG Jing-hui, XIE Shui-sheng. Microstructure evolution of Al-Zn-Mg alloy during hot deformation[J]. Acta Metallurgica Sinica, 2000, 36(10): 1033-1036.

[12] SHEPPARD T, RAYBOULD D. A new approach to the construction of extrusion-limit diagrams, giving structural information with application to superpure aluminum and Al-Zn-Mg alloys[J]. J Inst Metals, 1973, 101(3): 73-78.

(编辑 陈卫萍)

基金项目:国家高技术研究发展计划资助项目(2006AA03Z523); 中南大学博士后科学基金资助项目

收稿日期:2010-05-07;修订日期:2010-09-19

通信作者:梁文杰; 博士; 电话: 0731-88879616; E-mail: liang_wenjie@163.com