文章编号: 1004-0609(2005)08-1162-05

变压边力条件下铝合金板的成形窗口

林忠钦, 于忠奇, 孙成智, 陈关龙

(上海交通大学 机械与动力工程学院, 上海 200030)

摘 要: 在由塑性成形理论和能量法分别建立的临界破裂和临界起皱压边力模型基础上, 构建了变压边力情况下汽车用铝合金板的成形窗口, 并分析了拉深比、 材料参数和模具参数对成形窗口的影响规律。 对比实验表明: 在整个有效压边力范围内, 数学模型构建的成形窗口能够与实验相吻合, 且铝合金6111-T4和5052-O的成形窗口明显小于钢板st14的。 而影响因素分析显示: 随着拉深比降低、 厚向异性系数(r)增加和凹模圆角半径(Rdp)增大, 成形窗口明显扩大; n值增加, 成形窗口虽然有所扩大, 但是效果并不明显。

关键词: 铝合金板; 变压边力; 成形能力; 起皱; 破裂

中图分类号: TG389

文献标识码: A

Formability window of aluminium alloy sheet at variable blank-holder force

LIN Zhong-qin, YU Zhong-qi, SUN Cheng-zhi, CHEN Guan-long

(School of Mechanical Engineering,Shanghai Jiao Tong University, Shanghai 200030, China)

Abstract: Based on the variable blank-holder force(VBHF) models of critical fracture and critical wrinkling derived respectively from plastic deformation theory and energy method, the formability windows of automotive aluminium alloy sheets at VBHF were established, and the effect of drawing ratio, material parameters and die profile radius on formability window were analyzed. The comparison results show that the above formability windows are in agreement with the experiments in the range of effective blank-holder force, and the formability windows aluminium alloy 6111-T4 and 5052-O are less than that steel st14. The influencing factor analysis shows that the formability window obviously expands with the decreasing of the drawing ratio and the increasing of the normal anisotropical coefficient r-value and the die profile radius, but the effect of the hardening exponent n-value on formability window is not obvious.

Key words: aluminium alloy sheet; variable blank-holder force(VBHF); formability; wrinkling; fracture

目前, 在激烈的汽车竞争市场中, 要求在保持原有汽车的尺寸、 安全性和性能的情况下, 降低油耗, 加强环保。 在汽车上增加铝合金使用量, 已被证明是解决这一问题的一种有效途径[1]。 铝的晶体结构属于面心立方, 而钢的属于体心立方, 由于晶体结构的不同, 所以铝合金的变形规律与钢板存在本质的差异。

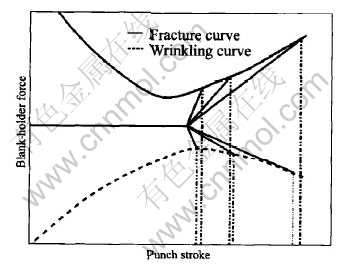

在板料拉深成形中, 起皱和破裂是阻碍成形顺利进行的主要障碍。 为了防止成形件法兰起皱发生, 通常设置压边圈, 靠压边力的大小来抑制或消除皱纹。 除此以外, 通过控制压边力, 还可以减少或消除成形件的回弹, 增加成形件的刚度等。 为此, 在整个成形过程中, 必须使压边力轨迹位于某一合理的范围内。 由所有合理压边力所构成的区域即为成形窗口, 它是由临界起皱曲线和临界破裂曲线构成, 并代表着某板料拉深能力的大小。

成形窗口是确定成形中最优压边力轨迹的一个重要依据。 早期的成形窗口都是建立在恒定压边力下的, 如万敏等[2]用实验方法确定出恒定压边力条件下圆锥件拉深的成形极限。 然而, 恒定压边力条件下建立的成形窗口, 可能是整个成形窗口的一部分。 近些年来, 随着变压边力技术的不断开发和完善[3-6], 学者们开始研究构建变压边力条件下成形窗口。 Obermeyer等[7]介绍了变压边力成形窗口的模式。 赵军等[8, 9]计算出圆锥件拉深中临界侧壁破裂和临界法兰起皱的压边力与凸模行程间关系曲线, 但这个模型忽略了胀形因素。 Manabe等[10]研究了圆筒件拉深的破裂和起皱极限压边力理论模型, 并开发出压边力的自适应控制算法。 Fratini等[11]在大量的数值模拟和实验基础上, 研究了压边力变化模式与材料成形性能的关系, 得出渐增压边力条件下其成形深度最大。 Asnafi等[12]实验研究了钢板的成形窗口, 并得出渐减压边力可以增加其成形性能。 此外, Novotny等[13]和Chu等[14]研究了液压成形中液压力与压边力(或轴向力)之间的成形窗口。

本文作者在自己较早建立的临界破裂和临界起皱压边力数学模型[15]基础上, 构建了铝合金板拉深成形中的变压边力成形窗口, 用实验验证了其成形窗口的正确性, 并讨论了材料参数等关键因素对成形窗口的影响规律。

1 成形窗口的生成

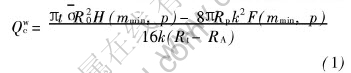

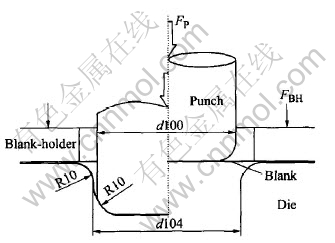

基于能量法建立的临界起皱压边力数学模型为

基于塑性变形理论建立的临界破裂压边力数学模型为

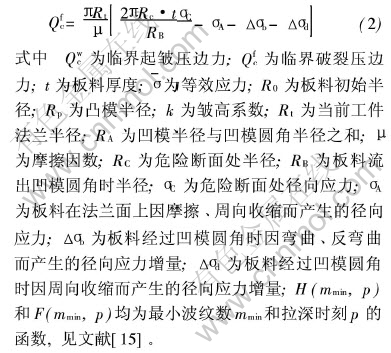

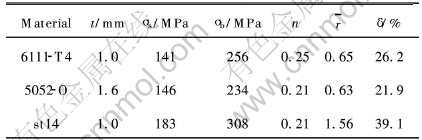

当给定板料的初始直径及模具几何参数, 根据式(1)和式(2)可分别计算出临界起皱压边力曲线和临界破裂压边力曲线。 由这两条临界压边力曲线即构成给定参数下的变压边力成形窗口。 图1所示是铝合金板6111-T4的变压边力成形窗口, 其中初始板料直径为d200mm, 模具基本尺寸如图2所示, 材料参数见表1, 摩擦因数假定为0.1。

图1 6111-T4的成形窗口

Fig.1 Formability window of 6111-T4

表1 材料参数

Table 1 Material parameters

从图1中可以看出, 成形过程中, 施加的压边力轨迹只有位于成形窗口内, 才能顺地完成, 否则, 就会出现破裂或者起皱。 对于临界起皱压边力曲线来说, 随着凸模行程的增加, 所需临界压边力增大, 但到成形末期时, 所需临界压边力有所下降。 而对于临界破裂压边力曲线来说, 当初始压边力很大时, 变形模式为胀形, 凸模行程即为极限胀形高度; 在整个成形过程中, 临界破裂压边力存在一个最小值, 此处为成形窗口的“瓶颈地带”, 当超过这一数值后, 临界破裂压边力大大提高, 成形窗口将明显扩大, 为利用变压边力提高板料成形能力提供了更大的空间。

2 实验验证

为了验证所建立的理论成形窗口的正确性, 在上海交通大学车身制造技术中心的多点可变压边力液压机[16]上进行实验验证。 实验工具基本尺寸如图2所示, 实验板料及其材料参数列于表1中。 实验时, 试样为圆形坯料, 初始直径均为d200mm, 试样及工具均采用拉深润滑油进行均匀润滑, 拉深速度为5.0mm/s。 成形过程中, 临界压边力是通过检测压边圈和凹模间的间隙以及冲压力的变化来确定。 当压边圈和凹模法兰间的间隙是板料初始厚度的1.13倍时, 认为板料发生起皱; 而临界破裂压边力为冲压力发生突然降低时所对应的压边力载荷。

图2 拉深模具示意图

Fig.2 Sketch of deep drawing tools

本研究中, 实验的变压边力轨迹按图3所示方式施加, 即成形开始时, 压边力为恒定值, 当凸模行程超过“瓶颈地带”对应的凸模行程后, 采用不同斜率的上升或下降压边力来确定临界破裂或临界起皱压边力。

图3 变压边力轨迹方案

Fig.3 Experimental trajectory of VBHF

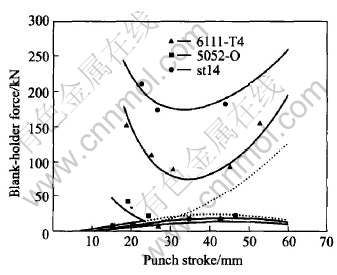

图4所示是不同实验板料的理论成形窗口与实验值的比较。 从图中可看出, 式(1)和式(2)所计算的理论临界压边力曲线能够与实验相吻合, 并且在相同条件下钢板的成形窗口明显大于铝合金板的。 而对图中的5052-O来说, 由于在“瓶颈地带”之前, 临界起皱压边力曲线和临界破裂压边力曲线已经相交, 说明在即不起皱也不破裂的情况下, 无论采取何种变压边力轨迹, 它的拉深成形都不可能顺利完成。

图4 成形窗口的实验验证

Fig.4 Comparison between calculations and experiments

3 成形窗口的关键影响因素

在成形过程中, 工艺及模具参数难免要发生一定的波动, 势必影响成形窗口的改变。 为增强变压边力控制的鲁棒性, 以6111-T4板为例, 分析关键影响因素对成形窗口的影响规律。

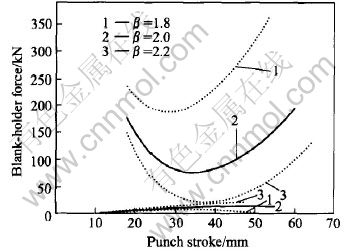

拉深比对6111-T4成形窗口的影响如图5所示, 随拉深比的增加, 临界破裂压边力明显下降, 而临界起皱压边力有所增加, 成形窗口显著减小。 当拉深比大于2.2时, 临界破裂压边力和临界起皱压边力相交, 表明此条件下不存在任何形式的压边力可以顺利完成板料的拉深。

图5 拉深比对成形窗口的影响

Fig.5 Effects of drawing ratio on formability window

板料加工硬化指数(n)对6111-T4成形窗口的影响如图6所示。 从图中可以看出, 在成形窗口“瓶颈地带”的左侧, 随n值的增大, 临界破裂压边力而升高; 而在其右侧, 则临界压边力下降, 且临界破裂压边力向右上移动, 但是n值对成形窗口的影响效果并不显著。

图6 n值对成形窗口的影响

Fig.6 Effects of n-value on formability window

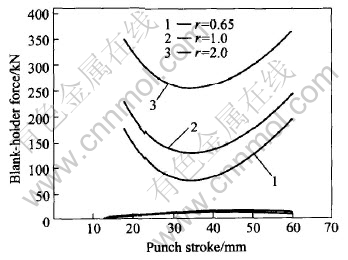

厚向异性系数r对6111-T4成形窗口的影响规律见图7。 从该图中可得到, 成形窗口随着r值的增大而明显扩大, 其中临界破裂压边力曲线随r值增大而增加, 而临界起皱压边力几乎不受r值的影响。

图7 r值对成形窗口的影响

Fig.7 Effects of r-value on formability window

凹模圆角半径(Rdp)对临界压边力的影响规律如图8所示。 Rdp值主要影响临界破裂压边力曲线, 对临界起皱压边力曲线影响较小, 较大的Rdp值有利于扩大成形窗口。 且计算表明, Rdp值对临界破裂压边力的影响大于凸模圆角半径Rpp的影响。

图8 模具圆角半径对成形窗口的影响

Fig.8 Effects of die profile radius on formability window

4 结论

1) 理论成形窗口能够与实验相吻合, 这说明式(1)和式(2)具有较高的计算精度, 为确定铝合金板最优变压边力轨迹提供了一个重要的工具。

2) 关键影响因素中, 拉深比、 r值、 模具圆角半径对成形窗口有着显著的影响; 而n值对成形窗口的影响并不明显。 在成形中, 应严格控制上述影响显著的因素。

REFERENCES

[1] Miller W S, Zhuang L. Recent development in aluminium alloys for the automotive industry[J]. Mater Sci Eng A, 2000, A280: 37-49.

[2] 万 敏, 杨玉英. 圆锥形零件冲压成形极限[J]. 哈尔滨工业大学学报, 1995, 27(4): 121-125.

WAN Min, YANG Yu-ying. Forming limit of conical cup drawing[J]. Journal of Harbin Institute of Technology, 1995, 27(4): 121-125.

[3] SUN Cheng-zhi, CHEN Guan-long, LIN Zhong-qin. Novel algorithm for dertermining optimal blankholder forces in deep drawing of aluminum alloy sheet[J]. Trans Nonferrous Met Soc China, 2004, 14(4): 676-680.

[4] Shulkin L B, Posteraro R A. Blank holder force control in viscous pressure forming of sheet Metal[J]. Journal of Materials Processing Technology, 2000, 98(1): 7-16.

[5] Lars G, Erik S. Improving the properties of exterior body panels in automobiles using variable blank holder force[J]. Journal of Materials Processing Technology, 2001, 114(2): 168-173.

[6] Sheng Z Q, Jirathearanat S, Altan T. Adaptive FEM simulation for prediction of variable blank holder force in conical cup drawing[J]. International Journal of Machine Tools & Manufacture, 2004, 44(5): 487-497.

[7] Obermeyer E J, Majlessi S A. A review of recent advances in the application of blank-holder force towards improving the forming limit of sheet metal parts[J]. Journal of Materials Processing Technology, 1998, 75(1-3): 222-234.

[8] 赵 军, 张双杰. 拉深过程智能化控制中的法兰起皱临界条件[J]. 燕山大学学报, 1998, 22(3): 197-201.

ZHAO Jun, ZHANG Shuang-jie. Critical flange wrinkle condition in intelligent control of deep drawing process[J]. Journal of Yanshan University, 1998, 22(3): 197-201.

[9] 赵 军, 王祖伟. 拉深过程智能化控制中的破裂失稳临界条件[J]. 燕山大学学报, 2000, 24(4): 330-337.

ZHAO Jun, WANG Zu-wei. The critical condition for the wall-side rupture in the intelligent control of deep drawing process[J]. Journal of Yanshan University, 1998, 22(4): 197-201.

[10] Manabe K, Yang M. Artificial intelligence identification of process parameters and adaptive control system for deep-drawing process[J]. Journal of Material Processing Technology, 2000, 24(4): 330-337.

[11] Fratini L, Micari F. Investigation effective blankholder force paths to improve the maximum component height in deep drawing process[A]. Numisheet99[C]. Besancon: France, 1999. 267-272.

[12] Lars G, Nader A. In-process control of blank holder force in axi-symmetric deep drawing with degressive gas springs[J]. Journal of Material Processing Technology, 1998, 73(1-3): 89-96.

[13] Novotny S, Hein P. Hydroforming of sheet metal pairs from aluminium alloys[J]. Journal of Materials Processing Technology, 2001, 115(1): 65-69.

[14] Chu E, Xu Y. Hydroforming of aluminum extrusion tubes for automotive applications[J]. International Journal of Mechanical Sciences, 2004, 46(2): 285-297.

[15] LIN Zhong-qin, SUN Cheng-zhi, et al. Analytical and experimental studies on critical blank-holder forces in cylindrical cup deep drawing[J]. Journal of Shanghai Jiaotong University, 2004, 38(Sup): 101-107.

[16] 余海燕, 陈关龙, 林忠钦. 新型多点变压的压边力控制系统研制[J]. 塑性工程学报, 2004, 11(5): 29-32.

YU Hai-yan, CHEN Guan-long, LIN Zhong-qin. Development of multipoint blank holding force control system[J]. Journal of Plasticity Engineering, 2004, 11(5): 29-32.

基金项目: 国家杰出青年基金资助项目(50225520)

收稿日期: 2005-01-05;

修订日期: 2005-04-25

作者简介: 林忠钦(1957-), 男, 教授.

通讯作者: 于忠奇, 博士; 电话: 021-62932660-111; E-mail: yuzhq@sjtu.edu.cn

(编辑 龙怀中)