Inconel 718合金δ相的溶解动力学

蔡大勇, 张伟红, 刘文昌, 姚 枚

(燕山大学 亚稳材料科学与技术国家重点实验室, 秦皇岛 066004)

摘 要: 采用X射线衍射技术测定了Inconel 718合金中δ相在980、 1000和1020℃时的溶解动力学, 并采用扫描电镜进行了组织观察。 结果表明: Inconel 718合金在980、 1000和1020℃保温过程中, δ相含量逐渐降低, 经1020℃保温2h后, δ相可完全溶入基体; 当温度为980和1000℃时, δ相的平衡含量分别约为3%及0.6%。 δ相的溶解过程可分为两个阶段, 溶解初期主要表现为长针状δ相长度方向的断裂, 且很快溶解断裂为短棒状及颗粒状, 同时在厚度方向上尺寸逐渐减小; 随着溶解过程的进行, 后续的溶解过程主要为短棒状及颗粒状δ相尺寸的减小。 δ相溶解动力学过程的控制环节并非Nb或Ni原子的长程扩散过程, 而为δ相分解的界面反应过程。

关键词: Inconel 718合金; 溶解动力学; 控制环节; 扩散; 界面反应 中图分类号: TG132.3

文献标识码: A

Dissolution kinetics of δ phase in Inconel 718 alloy

CAI Da-yong, ZHANG Wei-hong, LIU Wen-chang, YAO Mei

(State Key Laboratory of Metastable Materials Science and Technology,Yanshan University, Qinhuangdao 066004, China)

Abstract: The dissolution kinetics and microstructures evolution of δ phase in Inconel 718 alloy during holding at 980, 1000 and 1020℃ were analyzed using X-ray diffraction and scanning electron microscopy. The results indicate that the dynamic equilibrium state reaches after holding at 980℃ for more than 30min and at 1000℃ for more than 2h, the equilibrium contents are 3.0% and 0.6%, respectively. Nearly, the δ phase dissolves into the austenitic matrix holding at 1020℃ for more than 1h. The dissolution process of needle-like δ phase can be divided into two stages, the initial stage is mainly characterized as the fracture from long needle shape to short bars or particles. Then, the size of δ phase with short bars or particles decrease at the following stage. The dissolution models of δ phase were established and the controlling step was revealed. The whole dissolution process is governed by the interface reaction mechanism, but not by the long-distance diffusion of Nb or Ni atoms in the austenite matrix.

Key words: Inconel 718 alloy; dissolution kinetics; controlling step; diffusion; interface reaction

近年来, Inconel 718合金在航天、 航空及核能领域的应用日益广泛, 主要用于制造涡轮盘、 甩油盘及紧固件等关键零件, 由于各种盘件带有标齿、 紧固件上有螺纹, 所以保证合金在650℃无持久缺口敏感是至关重要的, 而其中的关键问题在于组织中δ(Ni3Nb)相的含量[1-4]。 Inconel 718合金中含有适量的δ相时, 可起到提高塑性和改善缺口敏感性的作用, 一般认为δ相过少时会导致合金缺口敏感。 在Inconel 718合金的锻造及热处理过程中, 已析出的δ相有可能部分或完全溶解, 如果工艺控制不当, 将造成奥氏体组织晶粒粗大, 甚至合金表现为严重的缺口敏感[3, 4]。 由此可见, 深入理解Inconel 718合金中δ相的溶解行为, 通过热加工过程控制合金中δ相的形貌、 含量及分布是保障合金具有优良强韧性的关键。

本文作者在实验测定Inconel 718合金中δ相溶解动力学及其溶解过程组织分析的基础上, 通过界面反应及扩散过程的分析确定了Inconel 718合金中δ相溶解的控制环节。

1 实验

实验材料采用Inconel 718合金热轧棒材, 直径为30mm, 原始晶粒尺寸约为20μm, 化学成分如表1所列。

表1 Inconel 718合金的主要化学成分

Table 1 Main chemical composition of Inconel 718 alloy (mass fraction, %)

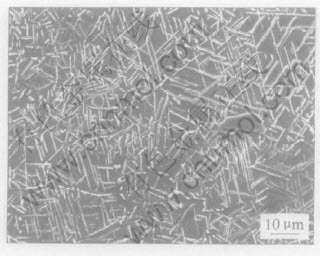

将所制备的试样首先进行固溶处理, 工艺为980℃, 3h, 空冷; 然后进行δ相时效处理, 工艺为890℃, 20h, 水冷, 此时合金组织中析出大量的针状δ相(图1)。 将上述经固溶及δ相时效处理的试样进行δ相溶解处理, 保温温度分别为980、 1000和1020℃, 保温时间为3~360min。

图1 Inconel 718合金δ相时效态的微观形貌

Fig.1 Micrograph of Inconel 718 alloy under δ phase aging treatment condition

δ相溶解处理试样的组织分析采用KYKY 2800型扫描电镜(SEM), 加速电压25kV, 腐蚀剂为100mLCH3CH2OH+100mLHCl+5gCuCl2。 根据文献[5]采用X射线衍射(XRD)直接对比法测定不同溶解条件下δ相的含量。

2 δ相溶解过程的动力学行为及组织演变

在980、 1000及1020℃高温保持过程中, Inconel 718合金中δ相含量的变化规律如图2所示。 由图2可见, 在高温保持过程中, 随着保温时间的延长, δ相含量逐渐降低; 随着温度的升高, δ相溶解速度明显加快, 达到溶解平衡的时间缩短。 于980℃保温时, 还远未达到δ相的完全溶解温度, 溶解速度较慢; 保温30min后, δ相含量基本上保持不变, 约为3%, 接近溶解平衡; 保温6h后仍存在一定量的δ相。 于1000℃保温时, δ相的溶解速度加快; 保温2h后, δ相含量低于1%; 保温6h后, 仍存在少量δ相, 约为0.6%, 说明δ相的完全溶解温度略高于1000℃。 当温度为1020℃时, 溶解速度更快, 保温30min后, δ相含量就急剧降低; 1h后几乎完全溶解。 由见可见, δ相的溶解过程对于温度是非常敏感的, 温度既决定了溶解的速度, 同时又决定了溶解平衡时δ相的含量。

图2 Inconel 718合金δ相的溶解动力学

Fig.2 Dissolution kinetics of δ phase in Inconel 718 alloy

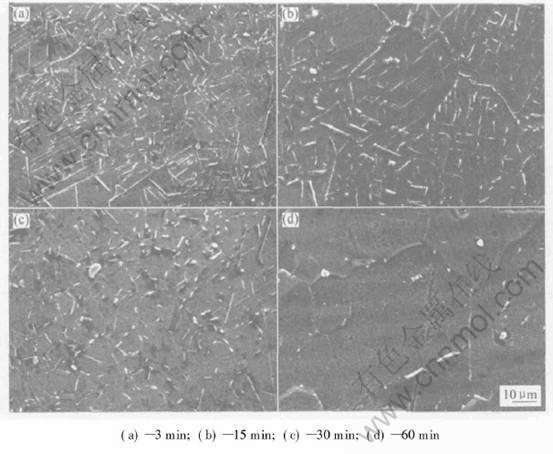

分析发现, Inconel 718合金在高温保持过程中, 已析出的δ相逐渐发生溶解, 不同温度下的组织演变特征非常相似, 典型特征如图3所示。 由图3可看出, δ相的溶解可以分为两个阶段, 溶解初期主要表现为长针状δ相长度方向的断裂, 长针状δ相在短时间内溶解断裂为短棒状及颗粒状; 随着溶解过程的进行, 后续的溶解过程主要为短棒状及颗粒状δ相尺寸的减小, 同时合金晶粒逐渐发生长大。

图3 Inconel 718合金经不同保温时间于1000℃溶解时的显微组织

Fig.3 Microstructures of Inconel 718 alloys during dissolution treatment at 1000℃ after different holding times

3 Inconel 718合金δ相溶解动力学分析

合金中第二相质点的溶解过程是材料科学中一个重要的相变过程, 但相对于相变析出过程而言, 远未得到广泛关注, 关于溶解过程的一些本质问题, 迄今为止尚未得到解决[8-17]。 从Inconel 718合金δ相溶解动力学过程分析, 其溶解过程包括3个环节, 即δ相的分解、 Nb原子及Ni原子由相界面δ相一侧向基体相一侧的短程扩散以及在固溶体中的长程扩散。 上述3个过程中进行最慢的过程为整个溶解过程的控制因素, 其中前两个过程为界面反应控制过程, 后一过程为扩散控制过程, 即Inconel 718合金中δ相溶解的动力学过程或受界面反应过程控制, 或受溶质原子的扩散过程控制。

本文作者首先假设Inconel 718合金中δ相溶解动力学过程受Nb或Ni原子的长程扩散过程所控制, 而在界面处存在溶质成分的局域平衡, 以扩散过程为基础, 建立δ相溶解的动力学模型, 根据δ相形态的差异分两种情况考虑, 即一维模型和三维模型。

为了用数学模型来研究问题, 做如下假设:

1)针状及颗粒状δ相具有相同的半厚度或直径, 棒状δ相近似为颗粒状, 且δ相在基体中均匀分布;

2)在固溶体中, 溶质原子扩散系数独立于时间和成分;

3)固溶体中的初始浓度均匀一致。

3.1 一维模型

在处于δ相时效态时, Inconel 718合金中δ相的形状为长针状, 可用一维模型描述其溶解的初期过程。 在扩散控制的溶解过程中, 固溶体中溶质浓度分布如图4所示。 其中b为δ相半厚度, cp和c0分别为δ相及基体中溶质元素浓度, ci为相界面基体一侧的溶质局域平衡浓度。

图4 扩散控制溶解时固溶体中的溶质分布

Fig.4 Solute concentration profile near a δ phase particle during diffusion-controlled dissolution

溶解过程的扩散方程满足Fick定律[8-11], 则:

代入初始条件及边界条件:

界面满足流体平衡方程:

将(4)式微分, 代入(6)可得:

式中 k为与浓度有关的常数:

将(7)式进行积分:

b0为δ相初始半厚度, 为了以质量分数w的变化来描述δ相的溶解速率, 引入表示δ相体积含量的参数f, 由于b/b0=f/f0=w/w0, 则(9)式可变换为[16]:

代入扩散系数, 则有:

3.2 三维模型

随着溶解过程的进行, Inconel 718合金中针状δ相很快转变为短棒状及颗粒状, 同时在初期也存在缺陷处的优先溶解。 因此, 有理由以球形粒子的三维模型来描述δ相后续的溶解过程。 对于固溶体中一个半径为r0的球形粒子的各向同性溶解, 其浓度变化关系为:

由溶解过程中δ相的组织演变可知, 在整个溶解过程中, δ相主要表现短棒状及颗粒状。 因此, 如果δ相溶解动力学过程的控制环节为扩散过程, 则可由公式(11)及(21)通过线性拟合得到控制δ相溶解的表观激活能, 拟合结果如图5所示。

图5 δ相溶解扩散激活能的线性拟合结果

Fig.5 Linear regression results of active energy during dissolution of δ phase

根据图5的拟合结果, 得到δ相溶解的表观激活能为120~180kJ/mol。 根据文献[18, 19], Inconel 718合金中Nb的扩散激活能为451kJ/mol, Ni的自扩散激活能一般为413~485kJ/mol。

采用扩散模型拟合得到的δ相溶解表观激活能既不同于Nb的扩散激活能, 也不同于Ni的自扩散激活能。 造成以上差异的原因主要由于在于扩散模型建立的过程中, 建模时认为Nb或Ni原子的长程扩散为δ相溶解动力学过程的控制环节, 而认为界面反应过程的速度为无限大的, 即相对于长程扩散过程, 界面反应过程瞬时完成, 不是整个溶解过程的控制因素, 但事实可能并非如此。 在很多情况下, 由于界面反应速率较低, 使得溶质进入固溶体的速度减慢, 造成界面处的局域平衡破坏, 甚至成为整个溶解过程的控制因素[9, 15, 18]。 由此可见, Inconel 718合金中δ相溶解的动力学过程为其分解的界面反应过程。

4 结论

1) Inconel 718合金在980、 1000和1020℃保温过程中, δ相含量逐渐降低; 于1020℃保温2h后, δ相可完全溶入基体; 当保温温度为980和1000℃时, δ相的平衡含量分别约为3%及0.6%。 在保温开始阶段, δ相的溶解速度较快并近似为常数, 且随着保温时间的延长, 溶解速度逐渐降低。

2) δ相的溶解过程可分为两个阶段, 溶解初期主要表现为长针状δ相长度方向的断裂, 且很快溶解断裂为短棒状及颗粒状, 同时在厚度方向上尺寸逐渐减小。 随着溶解过程的进行, 后续的溶解过程主要为短棒状及颗粒状δ相尺寸的减小。

3) δ相溶解动力学过程的控制环节并非Nb或Ni原子的长程扩散过程, 而为δ分解的界面反应过程。

REFERENCES

[1]LU Hong-jun, JIA Xin-chao, ZHANG Kai-feng. Fine-grained pretreatment process and superplasticity for Inconel 718 superalloy[J]. Materials Science and Engineering, 2002, 326 A (2): 382-385.

[2]李树祺, 庄景云, 杨锦炎, 等. Inconel 718合金显微组织对冲击韧性的影响[J]. 北京科技大学学报, 1991, 13(增刊): 182-187.

LI Shu-qi, ZHUANG Jing-yun, YANG Jin-yan, et al. Influence of microstructure of Inconel 718 on the impact toughness[J]. Journal of University of Science and Technology Beijing, 1991, 13(S): 182-187.

[3]邓波, 张荣武, 杨玉荣, 等. GH4169合金时效动力学与强韧化的研究[J]. 北京科技大学学报, 1991, 13(增刊): 253-259.

DENG Bo, ZHANG Rong-wu, YANG Yu-rong, et al. Study on the aging kinetics, hardening and toughness of GH4169[J]. Journal of University of Science and Technology Beijing, 1991, 13(S): 253-259.

[4]李树祺, 庄景云. Inconel 718合金显微组织对合金裂纹扩展速率的影响[J]. 材料工程, 1998(5): 26-27.

LI Shu-qi, ZHUANG Jing-yun. Influence of microstructure of Inconel 718 on the crack propagation rate[J]. Materials Engineering, 1998(5): 26-27.

[5]刘文昌, 陈宗霖, 姚枚, 等. 冷轧变形对Inconel 718合金δ相析出动力学的影响[J]. 金属学报, 1998, 34(10): 1049-1054.

LIU Wen-chang, CHEN Zong-lin, YAO Mei, et al. Influence of cold rolling on the precipitation kinetics of δ phase of Inconel 718[J]. Acta Metallurgica Sinica, 1998, 34(10): 1049-1054.

[6]Sagaradze V V, Koloskov V M, Goshchitskii B N. Dissolution kinetics of intermetallics in aging austenitic steels during neutron irradiation[J]. Journal of Nuclear Materials, 2002, 307-311: 317-321.

[7]Martin J W, Doherty R D. 金属系中显微结构的稳定性[M]. 李新立, 译. 北京: 科学出版社, 1984. 66- 72.

Martin J W, Doherty R D. Stability of Microstructure in Metal System[M]. LI Xin-li, tranl. Beijing: Science Press, 1984. 66- 72.

[8]ZHANG Rong, CAO Qiu-fang, PANG Shu-xian, et al. Dissolution kinetics of primary silicon in hypereutectic Al-Si melt[J]. Science and Technology of Advanced Materials, 2001, 2(1): 3-5.

[9]Ulrich J, Stávek J, Momonaga M. Interpretation of dissolution rates by the reaction fractual dimensions[J]. Journal of Crystal Growth, 1996, 166( 1-4): 1053-1057.

[10]张荣, 曹秋芳, 庞述先, 等. Al-Si过共晶合金中初生硅的溶解动力学[J]. 中国有色金属学报, 2000, 10(2): 89-91.

ZHANG Rong, CAO Qiu-fang, PANG Shu-xian, et al. Dissolution kinetics of primary silicon for hypereutectic Al-Si alloy[J]. The Chinese Journal of Nonferrous Metals, 2000, 10(2): 89-91.

[11]张荣, 赵志龙, 刘汉武, 等. 初生硅在溶体中的溶解动力学[J]. 金属学报, 2002, 38(4): 397-399.

ZHANG Rong, ZHAO Zhi-long, LIU Han-wu, et al. Dissolution kinetics of primary silicon[J]. Acta Metallurgica Sinica, 2002, 38(4): 397-399.

[12]Chen S P, Vossenberg M S, Vermolen F J. Dissolution of β particles in an Al-Mg-Si alloy during DSC runs[J]. Mater Sci Eng A, 1999, A272(2): 250-256.

[13]Vermolen F, van der Zwaag S, Vuik K. The dissolution of a stoichiometric second phase in ternary alloys: a numerical analysis[J]. Mater Sci Eng A, 1998, A246(1-2) : 93-103.

[14]Vermolen F J, Vuik S C. Particle dissolution and cross-diffusion in multi-component alloys[J]. Mater Sci Eng A, 2003, A347(1-2): 265-279.

[15]Vermolen F J, van der Zwaag S. A numerical model for the dissolution of spherical particles in binary alloys under mixed mode control[J]. Mater Sci Eng A, 1996, A220(1-2): 140-146.

[16]Bjrneklett B I, Grong , Myhr O R. Additivity and isokinetic behaviour in relation to particle dissolution[J]. Acta Materialia, 1998, 46(17): 6257-6266.

[17]Vermolen F, Vuik K, van der Zwaag S. A mathematical model for the dissolution kinetics of Mg2Si-phases in Al-Mg-Si alloys during homogenisation under industrial conditions[J]. Mater Sci Eng A, 1998, 254(1-2): 13-32.

[18]Rodriguez R, Hayes R W, Berbon P B, et al. Tensile and creep behavior of cryomilled Inco625[J]. Acta Materialia, 2003, 51: 911-929.

[19]刘文昌. Inconel 718合金在冷热变形条件下组织变化的研究[D]. 哈尔滨: 哈尔滨工业大学, 1997.

LIU Wen-chang. Microstructure Evolution of Inco-nel 718 on the Cold and Hot Deformation Conditions[D]. Harbin: Harbin Institute of Technology, 1997.

(编辑李艳红)

基金项目: 国家自然科学基金资助项目(59971039)

收稿日期: 2005-11-10; 修订日期: 2006-04-20

通讯作者: 蔡大勇, 副教授, 博士; 电话: 0335-8060103; E-mail: dayongcai@sina.com