DOI:10.19476/j.ysxb.1004.0609.2018.11.01

分步锻压工艺对AZ91镁合金组织演化及力学性能的影响

肖振宇1,杨 溢1,袁星宇1,张笃秀1,霍庆欢1,杨续跃1, 2, 3

(1. 中南大学 材料科学与工程学院,长沙 410083;

2. 中南大学 有色金属先进结构材料与制造协同创新中心,长沙 410083;

3. 中南大学 有色金属材料科学与工程教育部重点实验室,长沙 410083)

摘 要:结合光学显微镜(OM)、电子背散射衍射技术(EBSD)等,研究分步锻压对AZ91镁合金变形过程中组织演化及性能的影响。采用室温拉伸实验检测分步锻后样品的力学性能,并将分步锻后样品的组织、性能同普通一步锻压工艺样品的进行了比较。结果表明:分步锻压工艺可有效促进动态再结晶的发生,锻压过程中流变应力明显降低,锻后组织细化效果明显,变形织构弱化,综合力学性能提升。在623 K下分步锻压后,样品的再结晶体积分数升高至95%,在保持高强度的同时,锻后样品的室温伸长率达到19.6%,与相同温度普通一步锻压后的样品相比提升了约53%。

关键词:AZ91镁合金;分步锻压;动态再结晶;力学性能

文章编号:1004-0609(2018)-11-2173-09 中图分类号:TG146.2 文献标志码:A

镁及镁合金由于密度小、比强度和比刚度高、阻尼减震性好等优点,在航空航天、汽车电子、通讯家电等领域已有多年的应用历史。Mg-Al-Zn系(AZ系)和Mg-Zn-Zr系(ZK系)为开发较早且研究较充分的两种合金系。其中高Al含量的AZ91镁合金具有铸造性能优良、强度高等优点,被大量应用在汽车行业中[1-3]。然而,铸造镁合金组织粗大,存在大量铸造缺陷,力学性能仍不够理想,通过塑性加工及相关热处理工艺消除缺陷、细化组织是目前提升其性能的主要方法。其中,锻压工艺作为最常见的塑性加工开坯方法之一,不但可有效细化组织,消除铸件中的缩松、缩孔,破碎偏析相,还具有生产效率高、能制备出外形复杂工件等优点。然而,高Al含量的AZ91镁合金在高速锻压过程中表现出的变形行为并不理想。一方面, Al的固溶强化以及Mg17Al12的析出强化作用使AZ91镁合金的变形抗力上升得更快[4-5]。另一方面,变形速度越高,变形机制来不及协调变形,变形能力越差,锻件容易开裂,同时常常出现应变集中现象,锻后样品组织不均匀,最终导致后续加工性差[5-8]。

动态再结晶作为热变形过程中主要的软化机制及重要的组织细化机制[9],能有效地解决上述问题。一方面,动态再结晶的发生能大大缓解应变集中及开裂的现象,使热塑性变好,同时变形抗力减小[10]。另一方面,动态再结晶晶粒尺寸相对细小、稳定,充分的动态再结晶能均匀的细化初始组织,大大提升力学性能[9-10]。故如何促进热锻过程中动态再结晶的发生是目前研究的关键。XU等[6]在热变形前对铸造AZ91镁合金进行预时效处理,通过在初始晶粒内部置入均匀分布的析出相,来促进动态再结晶、细化组织,这种方法在低应变速率下效果明显,但在高速变形条件下却表现得差强人意。PARK等[11]则利用低温预压缩在AZ31镁合金板材中引入大量的孪晶组织,再对样品进行热变形,结果表明,孪晶的引入大大提升了材料在后续热变形中动态再结晶程度。然而这种方法对于本文所研究的塑性较差、组织粗大的铸态AZ91镁合金来说,是不易实现的[12-13]。

因此,本文作者采用分步锻压工艺(Interrupted forging)对铸造AZ91镁合进行加工,即在高速锻压前对样品进行低速高温预变形处理,利用预变形预置大量均匀分布的晶界,以促进其后续高速锻压中的动态再结晶的发生,旨在均匀细化铸造AZ91镁合金组织,改善其综合力学性能。结合光学显微镜(OM)和扫描电子显微镜(SEM)的电子背散射衍射(EBSD)技术分析分步锻压过程中显微组织的演化规律,并检测锻后样品的室温拉伸力学性能,将结果与普通一步高速锻压工艺(Continuous Forging)相比较,研究和讨论分步锻压工艺对AZ91镁合金微观组织演变以及后续力学性能等的影响。

1 实验

实验用所用材料为AZ91镁合金铸锭,其化学成分(质量分数,%)为Al 9.2、Zn 0.81、Mn 0.13、Cu 0.0015、Ni 0.0005、Mg 余量。铸锭在673 K温度下保温22 h固溶处理,取出空冷,获取组织较为均匀,平均晶粒尺寸约为300 μm的AZ91镁合金样品。

本锻压实验分别在573、623以及673 K这3个温度下进行。分步锻压工艺示意图如图1所示,先在 = 3×10-3 s-1的低应变速率下将样品锻压至ε0=0.36,保温10 min后再以3×10-1 s-1的高应变速率锻压至ε=1.5。同时另一样品则直接在3×10-1 s-1下一步锻压至ε=1.5,以作参照。锻压实验在具有保温功能的压机(WDW-100A型)上进行。锻压样品规格为10 mm×10 mm×10 mm。锻压前,在模具上涂上石墨作为高温润滑剂,在炉温达到设定温度后,再将样品放入炉内静置10 min让其热透,然后开始锻压。锻后5 s之内迅速将样品取出水淬。

= 3×10-3 s-1的低应变速率下将样品锻压至ε0=0.36,保温10 min后再以3×10-1 s-1的高应变速率锻压至ε=1.5。同时另一样品则直接在3×10-1 s-1下一步锻压至ε=1.5,以作参照。锻压实验在具有保温功能的压机(WDW-100A型)上进行。锻压样品规格为10 mm×10 mm×10 mm。锻压前,在模具上涂上石墨作为高温润滑剂,在炉温达到设定温度后,再将样品放入炉内静置10 min让其热透,然后开始锻压。锻后5 s之内迅速将样品取出水淬。

图1 分步锻压工艺示意图

Fig. 1 Schematic diagram of interrupted forging process

将锻后样品沿平行于锻压方向沿中心轴剖开,对剖面进行研磨、抛光处理后用腐蚀液进行浸蚀,腐蚀液成分为4.2 g苦味酸(C6H3N3O7)、10 mL冰醋酸(CH3COOH)、10 mL蒸馏水(H2O)和70 mL酒精(C2H5OH)。随后利用OLYMPUS光学显微镜(OM)进行显微组织观察。通过电解抛光制备EBSD样品后,采用Sirion200型场发射扫描电子显微镜(SEM)及其配备的OIM Data Collection 5.3和OIM Analysis 5.3对样品微观织构进行观测及分析。锻后拉伸力学性能测试实验在室温下进行,拉伸试样的计量尺寸为1.5 mm×5 mm×1.2 mm。

2 结果与讨论

2.1 锻压过程中合金的真应力-真应变曲线

图2 不同锻压工艺下的真实应力-应变曲线

Fig. 2 True stress-true strain curves at various temperatures during interrupted and continuous forging represented by dash and solid lines, respectively

表1 不同锻压工艺下峰值应力值和稳态应力值之间的差距

Table 1 Effects of interrupted forging on peak and steady-state value of flow stresses (Peak value involved under interrupted forging is value of second peak forged at high rate, marked by solid triangles in Fig. 2)

图2所示为不同温度下分步锻压(实线)及普通一步锻压(虚线)过程中合金的真实应力-应变曲线。由图2可以看出,AZ91镁合金在锻压初期具有加工硬化特征,随着应变的增加,应力在达到峰值后开始下降,出现软化,最后当硬化和软化达到平衡时,曲线进入稳态流变阶段。表1所列为两种锻压工艺后合金的峰值应力值(Peak value)和稳态应力值(Steady-state value)之间的差距大小。其中,分步锻压由于涉及到两次加载,故应力峰值有两个,表1中用到的是在第二步高速锻压过程中产生的峰值(见图2中实心三角标出)。结合图2可知,分步锻压过程中的流变应力要比一步锻压低,在锻压温度为623 K时差距最为明显。相比一步锻压时的流变应力,分步锻压使峰值应力降低了18 MPa,下降约15%,与此同时,稳态应力下降14 MPa,下降约23%。同时,分步锻压也使573 K的峰值应力明显降低,但对673 K的流变应力影响较小。这些都与其不同温度下硬化、软化机制之间的相互作用及显微组织的演变相关。

2.2 锻压过程中的显微组织分析

2.2.1 不同温度下的锻后显微组织

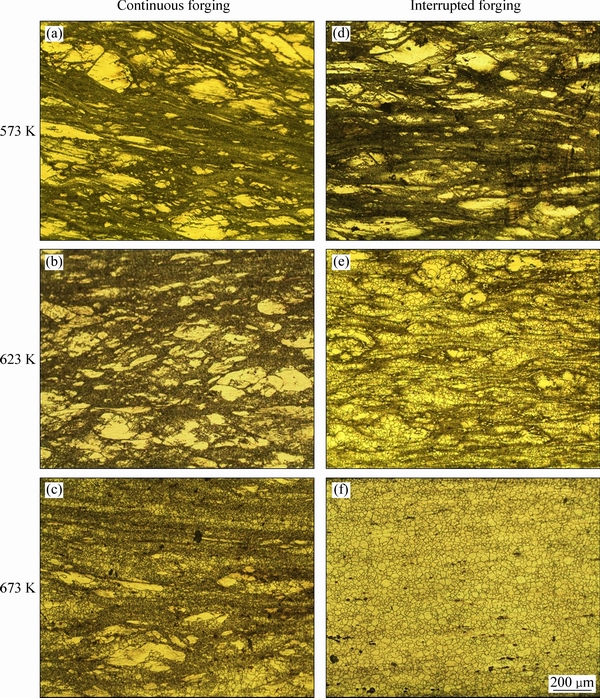

图3所示为不同温度下一步锻压和分步锻压后(ε=1.5)的光学组织对比。在573 K的温度下,两种工艺锻后组织中都存在被变形带分割的初始变形晶粒及极细的再结晶晶粒。在623 K下,一步锻压后的样品中仍可看到较多的变形带,再结晶晶粒尺寸变大;而分步锻压后的样品中基本上观测不到初始的变形组织了,再结晶程度明显提高。当温度升至673 K时,即使在普通一步高速锻压下,再结晶也很容易发生,变形带基本上消失,但仍有部分初始变形晶粒存在,而分步锻压后的组织则已完全再结晶。值得注意的是,在623 K(见图3(b))及673 K(见图3(c))的一步锻后组织中,再结晶晶粒尺寸呈双峰分布,673 K时这种分布更为明显,这与初始晶粒中Al原子的偏聚及Mg17Al12相的分布情况等有关[14-15]。据文献[14]报道,Al原子在初始晶界处的偏聚及Mg17Al12相在该处的强烈动态析出会导致附近动态再结晶受阻,相比晶内出现的动态再结晶晶粒,初始晶界处的再结晶晶粒尺寸较小,总体再结晶尺寸才会出现双峰分布。这种现象虽在623 K下分步锻后组织(见图3(e))中也出现了,但温度升高至673 K(见图3(f))时,分步锻压后的组织则是由大小相近、均匀的等轴晶粒组成。由此可见,分步锻压工艺可明显促进动态再结晶的发生,加速组织的细化过程。

图3 573、623及673下一步锻压及分步锻压后(ε=1.5)合金的显微组织

Fig. 3 Microstructures of alloys developed at ε=1.5 during continuous and interrupted forging under various temperatures from 573 K to 673 K

图4所示为不同温度下两种工艺锻后组织再结晶体积分数对比图。由图4可见,随着变形温度的升高,锻后组织的再结晶体积分数都有不同程度的增大。分步锻压后的再结晶体积分数(实线)随温度的上升幅度要明显高于一步锻压(虚线),二者在623 K和673 K条件下的差距最明显,其中623 K下分步锻后的再结晶体积分数已经达到95%,而一步锻后的再结晶体积分数只有47%。结合图3和4可以得出,分步锻压对AZ91镁合金再结晶的促进作用更大,这种现象在623 K时最为明显。这与分步锻压工艺对流变应力的影响规律基本相符(见图3),即在623 K时可最大程度地降低变形过程中的峰值应力和稳态应力。

图4 分步锻压工艺对锻后再结晶体积分数的影响

Fig. 4 Effect of interrupted forging on volume fraction of recrystallization grains developed at ε=1.5 as function of deformation temperature

2.2.2 锻压过程中的显微组织演化

图5所示为AZ91镁合金在623 K下普通一步锻压过程中的组织演化。在变形初期(ε=0.36),晶粒内部出现大量相互交截的变形带(见图5(a)),晶界开始粗化、弯曲。为进一步分析其内部结构,通过SEM-EBSD检测技术绘制出其取向分布图(见图5(d)),其中白色细线代表取向差角度为3°~5°的低角度界面,黑色细线代表取向差角度为5°~15°的低角度界面,黑色粗线代表取向差角度为15°~180°的高角度晶界,红色粗线为86°< 110>拉伸孪晶的界面。图5(a)所示的金相组织中变形带主要为孪晶,在组织粗大镁合金的高速变形过程中极易出现[15-16]。同时组织中还存在一系列相互平行的、取向差角度为5°~15°的变形带,这种变形带常被称为扭折带,是基面滑移受阻的结果[17-19]。此外,从图5(d)中还可以看出,变形后的晶界主要成锯齿状并有尺寸细小的再结晶晶粒在晶界附近形成。当变形至ε=0.9时,如图5(b)所示,初始晶界及上述变形带附近出现大量动态再结晶晶粒。随着变形量继续增大到ε=1.5时(见图5(c)),动态再结晶程度进一步增高,新形成的再结晶区域几乎完全覆盖掉了初始晶界及变形带,初始晶粒则被压扁、分割,但再结晶区域并没有完全延伸至晶内。

110>拉伸孪晶的界面。图5(a)所示的金相组织中变形带主要为孪晶,在组织粗大镁合金的高速变形过程中极易出现[15-16]。同时组织中还存在一系列相互平行的、取向差角度为5°~15°的变形带,这种变形带常被称为扭折带,是基面滑移受阻的结果[17-19]。此外,从图5(d)中还可以看出,变形后的晶界主要成锯齿状并有尺寸细小的再结晶晶粒在晶界附近形成。当变形至ε=0.9时,如图5(b)所示,初始晶界及上述变形带附近出现大量动态再结晶晶粒。随着变形量继续增大到ε=1.5时(见图5(c)),动态再结晶程度进一步增高,新形成的再结晶区域几乎完全覆盖掉了初始晶界及变形带,初始晶粒则被压扁、分割,但再结晶区域并没有完全延伸至晶内。

图6所示为AZ91镁合金在623 K下分步锻压过程中的组织演化。其中,图6(a)所示为第一步低速变形后的组织(ε0=0.36)。再结晶晶粒主要在初始晶界附近形成,同时在晶粒内部也出现了部分再结晶区域,对比图5 (a)和图6(a)可以看出,在同等应变量下,低速锻后的组织再结晶程度明显要高于高速锻后的组织再结晶程度。在卸载的10 min内,低速变形后的组织经历了等温退火,图6(a)中出现的细小晶粒迅速长大,吞噬初始变形晶粒,同时一部分变形结构消除,样品得到软化,组织变得均匀,如图6(b)所示。图6(c)所示为第二步高速锻压至ε=0.9时的显微组织:在图6(b)中组织的基础上,新的动态再结晶区域出现在图6(b)中的晶界处,并向晶内扩展;在部分较粗的变形晶粒中也可观测到变形带及附近出现的再结晶,虽区域较小,但也能加速组织的细化进程。当应变量增大到ε=1.5时(见图6(d)),可看出组织基本上由等轴状的再结晶晶粒组成,并且再结晶程度高达95%。

对比图5和6可发现,两种工艺中组织细化过程都与动态再结晶相关,但却有所差异。在普通一步锻压过程中,组织的细化一方面是通过变形带(孪晶、扭折带)分割完成,另一方面是通过在这些变形带及初始晶界处的动态再结晶完成,这两种机制同步、连续地进行,而分步锻压则是分步、不连续地完成的:Ⅰ低速预变形+退火,通过初始晶界处的动态再结晶及这些晶粒的长大,引入大量新的晶界分割初始晶粒;Ⅱ高速锻压过程中,在新晶界上再次发生动态再结晶,这一步变形过程中动态再结晶充分进行。无论哪种工艺,晶界处的动态再结晶机制是细化组织的重要机制,也是动态再结晶机制中相对容易启动的一种[20],而分步锻压工艺引入的大量晶界明显促进了这种机制,大大提升了组织的细化效果。结合图5和6可以判断,对于初始组织粗大的铸造AZ91镁合金来说,分步锻压更能保证其组织细化过程的均匀推进。从图6(c)中可看到,分步锻压变形至ε=0.9时,组织中的再结晶体积分数就远远超过了50%;到ε=1.5时,基本得到了相对均匀、完全的再结晶组织(见图6(d))。

图5 一步锻压过程中显微组织演化过程

Fig. 5 Microstructures developed at different strains during continuous forging at 623 K

图6 分步锻压过程中显微组织演化过程

Fig. 6 Microstructures developed at different strains during interrupted forging at 623 K

2.2.3 锻后组织的微观取向

图7所示为623 K下普通一步锻压及分步锻压后组织的取向分布图及对应的{0001}极图。取向分布图中不同晶粒颜色代表不同的取向,不同类型的线条代表不同角度的界面。从图7可知,两种工艺下锻后组织中的大部分晶粒呈绿色或蓝色,从图7(a)中的三角反极图可知,这些颜色分别代表{10 0}或{1

0}或{1 10}柱面,即锻压后大部分晶粒的柱面都平行于锻压轴。结合右侧的{0001}极图,变形晶粒的{0001}基面都转向了与锻压方向垂直的方向。这种择优取向是变形镁合金中常见的织构组分,被称为基面织构或板织构[6]。然而,一步锻后的组织(见图7(a))中存在较大体积的扁平状初始晶粒,这些晶粒基本上呈绿、蓝色,相对其他等轴细小晶粒择优取向更加严重。因此,一步锻后组织的织构强度相对较高。而分步锻后组织(见图7(b))中大部分晶粒都为再结晶晶粒,取向相对随机,织构得到一定程度的弱化。从图7右侧的{0001}极图可知,分步锻后的组织织构峰值强度从一步锻时的32.6降低到了14.2。

10}柱面,即锻压后大部分晶粒的柱面都平行于锻压轴。结合右侧的{0001}极图,变形晶粒的{0001}基面都转向了与锻压方向垂直的方向。这种择优取向是变形镁合金中常见的织构组分,被称为基面织构或板织构[6]。然而,一步锻后的组织(见图7(a))中存在较大体积的扁平状初始晶粒,这些晶粒基本上呈绿、蓝色,相对其他等轴细小晶粒择优取向更加严重。因此,一步锻后组织的织构强度相对较高。而分步锻后组织(见图7(b))中大部分晶粒都为再结晶晶粒,取向相对随机,织构得到一定程度的弱化。从图7右侧的{0001}极图可知,分步锻后的组织织构峰值强度从一步锻时的32.6降低到了14.2。

2.3 锻后样品的室温力学性能

图7 锻后组织取向分布图及对应的{0001}极图

Fig. 7 Typical IPF maps and corresponding {0001} pole figure developed at ε=1.5 after continuous (a) and interrupted forging (b) at 623 K

图8所示为将AZ91锻后样品的典型力学性能如拉伸断裂伸长率(Tensile elongation)与抗拉强度(Ultimate tensile strength)随锻压温度的变化曲线。图8中给出了分步锻压对AZ91锻后样品室温拉伸性能的影响,其中实线为分步锻后样品,虚线为一步锻后样品。由图8可知,分步锻压工艺可以提高AZ91的拉伸伸长率,而对其抗拉强度的影响则无明显规律。在573 K下,分步及一步锻后的抗拉强度分别为300和301 MPa,伸长率分别为12.6%和11.8%。此时,分步锻压对性能的提升效果并不明显。当温度为623 K时,两者性能差距最大,强度分别为310和300 MPa,伸长率分别为19.6%和12.8%,采用分步锻压可使强度提升3.4%,伸长率提升53%,力学性能提升最明显。当锻压温度升高至673 K时,两者的强度分别为294和300 MPa,伸长率分别为20.4%和14.2%,可见在此温度下分步锻压对伸长率提升明显,但样品的抗拉强度则有略微下降。

图8 AZ91锻后样品室温拉伸力学性能随锻压温度的变化

Fig. 8 Changes in tensile elongation to fracture (a) and ultimate tensile strength (b) at room temperature as function of deformation temperature

图9所示为不同锻压工艺变形后样品室温伸长率与再结晶体积分数之间的关系。其中实线为分步锻后样品,虚线为一步锻后样品。可以看出,无论是哪种锻压工艺,样品的锻后性能都与其再结晶程度成正比,这说明样品伸长率的提升主要与组织中的再结晶程度相关。但再结晶体积分数对分步锻后样品伸长率的影响要相对大些,这可能是因为分步锻后样品组织要更为均匀。分步锻压工艺通过促进再结晶的发生加速了组织的细化,在保持高强度的同时能有效地提高锻后样品的伸长率。综上所述可知,高速下对样品直接锻压,不仅流变应力高,机器受载荷较大,而且锻件本身的再结晶程度也低,塑性不好、二次成型性能也差。而经低速预变形,再对其进行高速锻压,即分步锻压,其峰值应力以及稳态应力值都有了明显的降低,锻后样品再结晶程度高,塑性明显提升、有利于后续加工。分步锻压在保留高速锻压优点同时,还降低了对加工设备的要求和损耗,这符合现今节能环保的需求,在实际应用中有较大前景。

图9 不同锻压工艺变形后样品室温伸长率与再结晶体积分数之间的关系

Fig. 9 Relationship between ambient fracture elongation to fracture and volume fraction of developed deformed to ε=1.5 at various forging temperatures

3 结论

1) 分步锻压促进了AZ91镁合金中动态再结晶的发生,加速了组织的细化过程。与普通一步锻压相比,分步锻后组织的再结晶程度有较大的提升,变形织构得到弱化,进而锻后力学性能尤其是室温拉伸伸长率得到明显改善。623 K下,分步锻压将样品的再结晶体积分数提高到了95%,锻后样品室温伸长率达到19.6%。

2) 分步锻压能有效降低AZ91镁合金的流变应力。相比普通一步锻压,分步锻压使其峰值应力下降了18 MPa,约15%,稳态应力下降了14 MPa,约为23%。

3) 普通一步锻压组织的细化过程通过晶内变形带的分割初始晶粒并同时在这些变形带及初始晶界处发生动态再结晶来完成,而分步锻压对组织的细化则是通过预变形引入大量新的晶界并在新晶界上进一步发生充分的动态再结晶来完成的。

REFERENCES

[1] 余 琨, 黎文献, 王日初, 马正青. 变形镁合金的研究、开发及应用[J]. 中国有色金属学报, 2003, 13(2): 277-288.

YU Kun, LI Wen-xian, WANG Ri-chu, MA Zheng-qing. Research, development and application of wrought magnesium alloys[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(2): 277-288.

[2] HIRSCH J, Al-SAMMAN T. Superior light metals by texture engineering: Optimized aluminum and magnesium alloys for automotive applications[J]. Acta Materialia, 2013, 61: 818-843.

[3] JOOST W J, KRAJEWSKI P E. Towards magnesium alloys for high-volume automotive applications[J]. Scripta Materialia, 2017, 128: 107-112.

[4] MENG M, ZHANG Z M, ZHANG B H, DOU J. Flow behaviors and processing maps of as-cast and as-homogenized AZ91 alloy[J]. Journal of Alloys and Compounds, 2012, 513: 112-117.

[5] 方正午, 肖振宇, 张笃秀, 尹 勇, 杨续跃. AZ61镁合金降温多向压缩中的动态析出及其对晶粒细化和力学性能的影响[J]. 中国有色金属学报, 2018, 28(2): 223-232.

FANG Zheng-wu, XIAO Zhen-yu, ZHANG Du-xiu, YIN Yong, YANG Xu-yue. Dynamic precipitation and its effect on grain refinement and mechanical properties in AZ61 Mg alloy during multi-directional forging under decreasing temperature conditions[J]. The Chinese Journal of Nonferrous Metals, 2018, 28(2): 223-232.

[6] XU S W, MATSUMOTO N, KAMADO S, HONMA T, KOJIMA Y. Effect of pre-aging treatment on microstructure and mechanical properties of hot compressed Mg-9Al-1Zn alloy[J]. Materials Science and Engineering A, 2009, 517(1): 354-360.

[7] XU S W, KAMADO S, HONMA T. Effect of homogenization on microstructures and mechanical properties of hot compressed Mg-9Al-1Zn alloy[J]. Materials Science and Engineering A, 2011, 528(6): 2385-2393.

[8] XU Y, HU L, SUN Y. Processing map and kinetic analysis for hot deformation of an as-cast AZ91D magnesium alloy[J]. Materials Science and Engineering A, 2013, 578(31): 402-407.

[9] 郑子樵. 材料科学基础[M]. 2版. 长沙: 中南大学出版社, 2013.

ZHENG Zi-qiao. Fundamentals of materials science[M]. 2nd ed. Changsha: Central South University Press, 2013.

[10] 彭大暑. 金属塑性加工原理[M]. 长沙: 中南大学出版社, 2014.

PENG Da-shu. Principle of Plastic deformation in metals processing[M]. Changsha: Central South University Press, 2014.

[11] PARK C H, OH C, KIM S. Dynamic recrystallization of the H-and O-tempered Mg AZ31 sheets at elevated temperatures[J]. Materials Science and Engineering A, 2012, 542(8): 127-139.

[12] ASGARI H, SZPUNAR J A, ODESHI A G. Texture evolution and dynamic mechanical behavior of cast AZ magnesium alloys under high strain rate compressive loading[J]. Materials and Design, 2014, 61: 26-34.

[13] STANFORD N, GENG J, CHUN Y B, DAVIES C H J, NIE J F, BARNETT M R. Effect of plate-shaped particle distributions on the deformation behaviour of magnesium alloy AZ91 in tension and compression[J]. Acta Materialia, 2012, 60(1): 218-228.

[14] ZHU Q F, LI L, ZHANG Z Q, ZHAO Z H, ZUO Y B, CUI J Z. Microstructure evolution of AZ80 magnesium alloy during multi-directional forging process[J]. Materials Transactions, 2014, 55(2): 270-274.

[15] CHANGIZIAN P, ZAREI-HANZAKI A, ABEDI H R. On the recrystallization behavior of homogenized AZ81 magnesium alloy: The effect of mechanical twins and γ precipitates[J]. Materials Science and Engineering A, 2014, 558: 44-51.

[16] 蒋莉萍, 王军, 肖振宇, 张笃秀, 杨续跃. 室温多向锻压AZ31镁合金的静态再结晶行为[J]. 中国有色金属学报, 2015, 25(11): 3051-3059.

JIANG Li-ping, WANG Jun, XIAO Zhen-yu, ZHANG Du-xiu, YANG Xu-yue. Static recrystallization behavior of multi-directionally forged AZ31 magnesium alloy at room temperature[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(11): 3051-3059.

[17] YANG X Y, MIURA H, SAKAI T. Dynamic evolution of new grains in magnesium alloy AZ31 during hot deformation[J]. Materials Transactions, 2003, 44(1): 197-203.

[18] 杨续跃, 姜育培. 镁合金热变形下变形带的形貌和晶体学特征[J]. 金属学报, 2010, 46(4): 451-457.

YANG Xu-yue, JIANG Yu-pei. Morphology and crystallo- graphic characteristics of deformation bands in Mg alloy under hot deformation[J]. Acta Metallurgica Sinica, 2010, 46(4): 451-457.

[19] 杨续跃, 张之岭, 张雷, 吴新星, 王军. 应变速率对AZ61镁合金动态再结晶行为的影响[J]. 中国有色金属学报, 2011, 21(8): 1801-1807.

YANG Xu-yue, ZHANG Zhi-ling, ZHANG Lei, WU Xin-xing, WANG Jun. Influence of strain rate on the behavior of dynamic recrystallization of AZ61 magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(8): 1801-1807.

[20] SAKAI T, BELYAKOV A, KAIBYSHEV R, MIURA H, JONAS J J. Dynamic and post-dynamic recrystallization under hot, cold and severe plastic deformation conditions[J]. Progress in Materials Science, 2014, 60(1): 130-207.

Effects of interrupted forging on microstructural development and mechanical properties of cast AZ91 Mg alloy

XIAO Zhen-yu1, YANG Yi1, YUAN Xing-yu1, ZHANG Du-xiu1, HUO Qing-huan1, YANG Xu-yue1, 2, 3

(1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. Nonferrous Metal Oriented Advanced Structural Materials and Manufacturing Cooperative Innovation Center, Central South University, Changsha 410083, China;

3. Key Laboratory of Nonferrous Materials Science and Engineering, Ministry of Education, Central South University, Changsha 410083, China)

Abstract: The effects of interrupted forging on the microstructural evolution of a cast AZ91 magnesium alloy were investigated by optical microscopy (OM) and electron back-scattering diffractometry (EBSD) and resultant mechanical properties were detected through tensile tests at ambient temperature. The results show that dynamic recrystallization (DRX) is remarkably accelerated and a decreased flow stress is observed under the condition of interrupted forging. Accordingly, there is an obvious grain refinement and the basal texture is weakened after interrupted forging, resulting in an improvement in mechanical property. As the volume fraction of dynamic recrystallized grains increases from 47% to 95% after interrupted forging at 623 K, the ambient tensile elongation of deformed sample increases by 53%, reaching the maximum of 19.6%, with little or no drop in strength.

Key words: AZ91 Mg alloy; interrupted forging; dynamic recrystallization; mechanical properties

Foundation item: Projects(51474241, 51771230) supported by the National Natural Science Foundation of China

Received date: 2017-02-14; Accepted date: 2018-07-16

Corresponding author: YANG Xu-yue; Tel: +86-13873133470; E-mail: yangxuyue@csu.edu.cn

(编辑 龙怀中)

基金项目:国家自然科学基金资助项目(51474241,51771230)

收稿日期:2017-02-14;修订日期:2018-07-16

通信作者:杨续跃,教授,博士;电话:13873133470;E-mail:yangxuyue@csu.edu.cn