固液反应球磨制备Al-Cu-Fe与Al-Si-Fe三元合金

来源期刊:中南大学学报(自然科学版)2004年第4期

论文作者:陈鼎 黄培云

文章页码:537 - 542

关键词:固液反应球磨;机械合金化;三元合金

Key words:solid-liquid reaction milling; mechanical alloying; ternary alloy

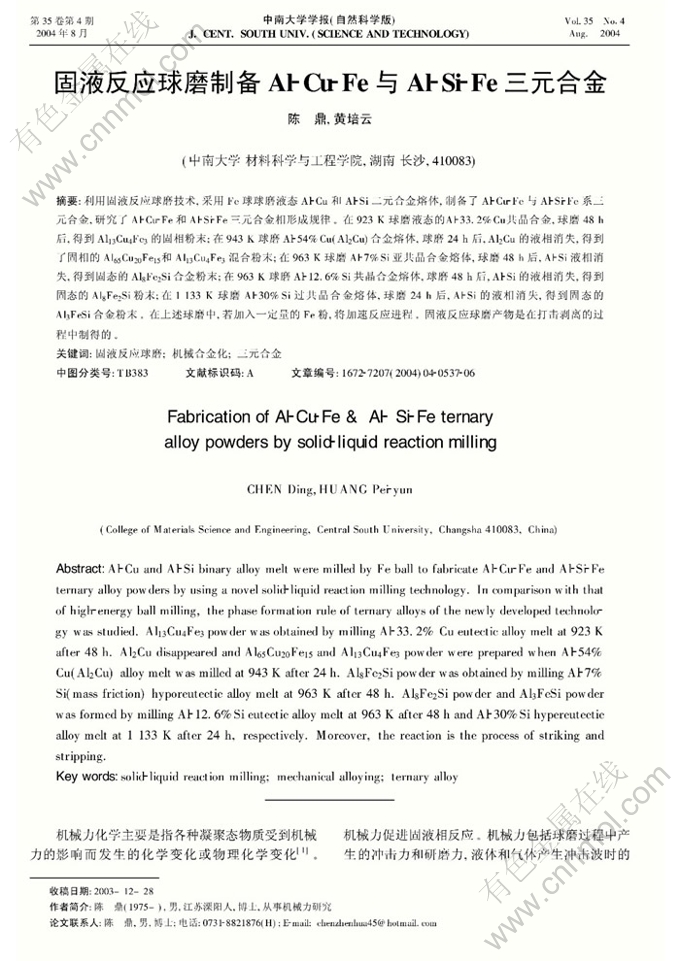

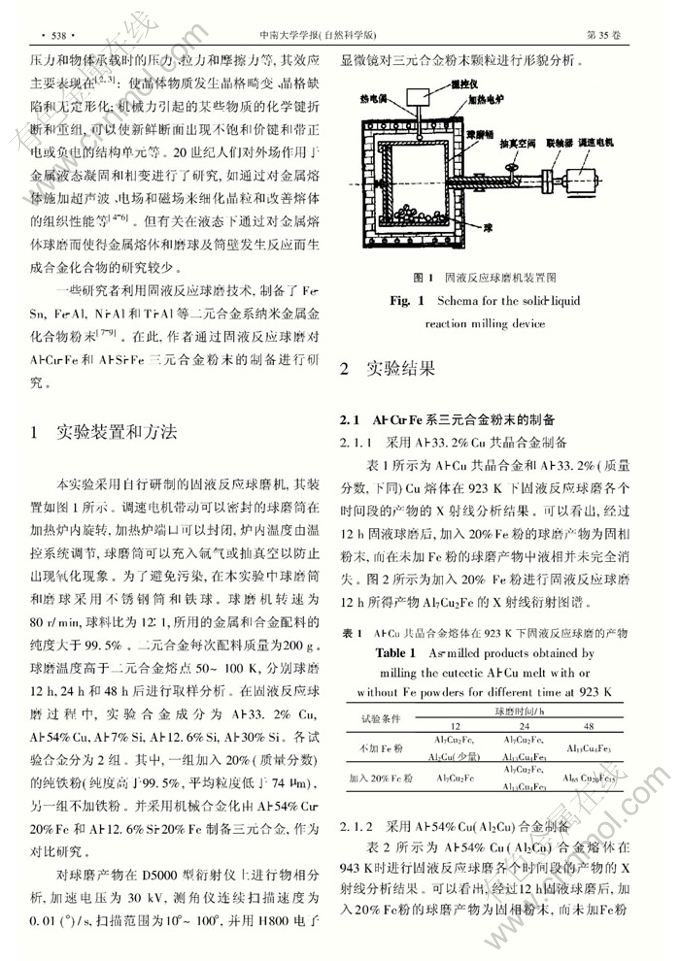

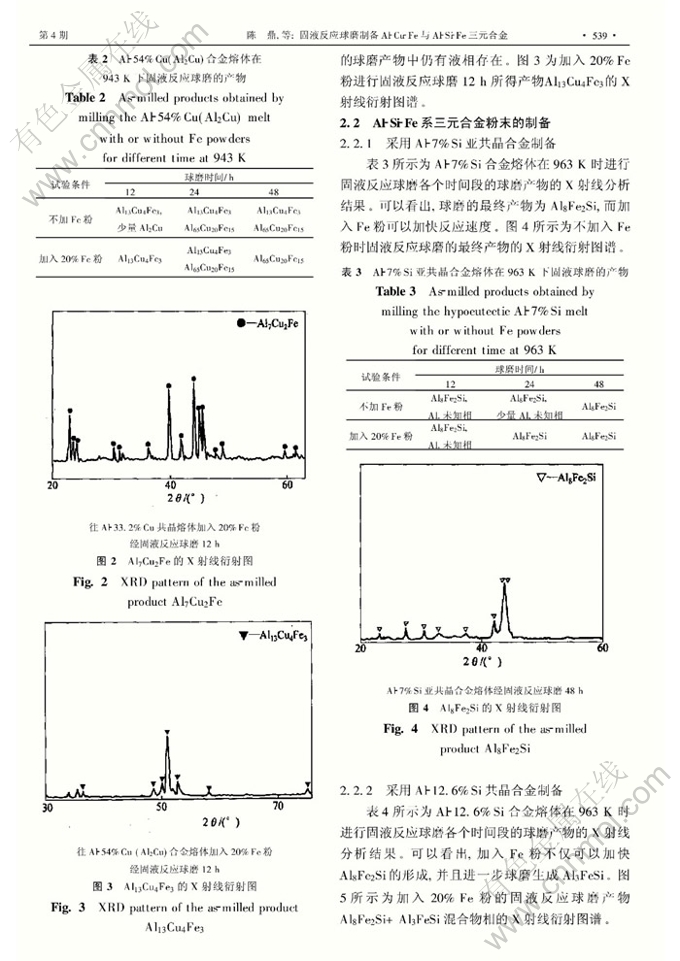

摘 要:利用固液反应球磨技术,采用Fe球球磨液态Al-Cu和Al-Si二元合金熔体,制备了Al-Cu-Fe与Al-Si-Fe系三元合金,研究了Al-Cu-Fe和Al-Si-Fe三元合金相形成规律。在923 K球磨液态的Al-33.2%Cu共晶合金,球磨48 h后,得到Al13Cu4Fe3的固相粉末;在943 K球磨Al-54%Cu(Al2Cu)合金熔体,球磨24 h后,Al2Cu的液相消失,得到了固相的Al65Cu20Fe15和Al13Cu4Fe3混合粉末;在963 K球磨Al-7%Si亚共晶合金熔体,球磨48 h后,Al-Si液相消失,得到固态的Al8Fe2Si合金粉末;在963 K球磨Al-12.6%Si共晶合金熔体,球磨48 h后,Al-Si的液相消失,得到固态的Al8Fe2Si粉末;在1 133 K球磨Al-30%Si过共晶合金熔体,球磨24 h后,Al-Si的液相消失,得到固态的Al3FeSi合金粉末。在上述球磨中,若加入一定量的Fe粉,将加速反应进程。固液反应球磨产物是在打击剥离的过程中制得的。

Abstract: Al-Cu and Al-Si binary alloy melt were milled by Fe ball to fabricate Al-Cu-Fe and Al-Si-Fe ternary alloy powders by using a novel solid-liquid reaction milling technology. In comparison with that of high-energy ball milling, the phase formation rule of ternary alloys of the newly developed technolo-gy was studied. Al13Cu4Fe3 powder was obtained by milling Al-33.2% Cu eutectic alloy melt at 923 K after 48 h. Al2Cu disappeared and Al65Cu20Fe15and Al13Cu4Fe3 powder were prepared when Al-54% Cu(Al2Cu) alloy melt was milled at 943 K after 24 h. Al8Fe2Si powder was obtained by milling Al-7% Si(mass friction) hyporeutectic alloy melt at 963 K after 48 h. Al8Fe2Si powder and Al3FeSi powder was formed by milling Al-12.6%Si eutectic alloy melt at 963 K after 48 h and Al-30%Si hypereutectic alloy melt at 1 133 K after 24 h, respectively. Moreover, the reaction is the process of striking and stripping.