DOI: 10.11817/j.issn.1672-7207.2020.01.006

基于线激光传感器的盾构管片位姿检测方法

高翔1,陶建峰1,王明斗1,刘成良1,杨正2,庄欠伟2

(1. 上海交通大学 机械与动力工程学院,上海,200240;

2. 上海隧道工程有限公司,上海,200032)

摘要:针对盾构管片初始摆放误差与拼装累积误差问题,提出一种新的管片位姿检测方案。该方案无须在管片上添加额外标记点,利用安装在管片拼装机器人上的3个线激光传感器对管片边缘进行扫描,根据边缘点的相对位置坐标计算管片上特征点的坐标,并依此推导出待安装管片的抓取位姿和安装位姿表达式。使用SolidWorks软件建立三维模型以提供算例,比较不同检测点位置对位姿计算精度的影响,验证该方案的可行性。研究结果表明:本文提供方案计算得到的管片位姿误差较小,可以满足盾构管片抓取和安装要求;增大管片边缘扫描点的距离能够提高姿态检测精度。

关键词:盾构管片;位姿检测;线激光传感器;拼装机

中图分类号:TH112;TU6 文献标志码:A 开放科学(资源服务)标识码(OSID)

文章编号:1672-7207(2020)01-0041-08

Position and posture detection method of shield segments using line laser sensors

GAO Xiang1, TAO Jianfeng1, WANG Mingdou1, LIU Chengliang1, YANG Zheng2, ZHUANG Qianwei2

(1. School of Mechanical Engineering, Shanghai Jiaotong University, Shanghai 200240, China;

2. Shanghai Tunnel Engineering Co. Ltd, Shanghai 200032, China)

Abstract: Considering the initial placement error and the cumulative error in segment assembly, a new method for detecting the position and pose of the shield segment was proposed. Three line laser sensors on the segment erector were used to scan the edges of the shield segment without any additional marks, and the coordinates of feature points on the segment were calculated through the relative position coordinates of edge points. According to the position coordinates of the feature points, the grasping pose and installation pose of the segment to be installed were deduced. With the SolidWorks software, the three-dimensional model was used to provide an example to compare the pose accuracy of different detection points and the feasibility of the scheme was verified. The results show that the position errors and orientation errors of the segment calculated by the scheme are small. This method can meet the requirements of the capture and installation of shield segments. Increasing the distance of the scanning points on the segment can improve the pose detecting accuracy.

Key words: shield segment; pose detection; line laser sensor; segment erector

盾构掘进技术主要是用于地下隧道挖掘工作,在当前城市公路[1]、铁路[2]和桥梁[3]建设中占据关键地位。管片拼装机是盾构掘进机中的重要子系统,主要负责盾构施工中的管片拼装工作[4]。管片拼装机运动工况复杂,人工操纵拼装机器人严重影响了管片拼装的效率和质量,且给安全施工带来隐患[5],因此全自动管片拼装成为拼装机发展的方向之一。管片拼装机的工作主要分为3个流程,分别为管片抓取、管片递送和管片安装[6]。在管片抓取时,管片的摆放位置存在误差,需要对抓取装置姿态进行调整。在安装时串联机构所造成的关节累积误差[7]与已拼装管片的施工拼装误差[8]也会对管片安装精度造成影响。通过拼装机机构优化、运动解耦和控制算法的改进能够显著提升末端执行机构的定位精度[9-11],但无法解决管片初始摆放误差和目标位置误差问题。因此准确检测管片的初始位姿和安装位姿是实现精准拼装的重要前提。国外对于管片位姿检测的研究较多,其中日本最为领先。 WADA[12]阐述了一种全自动管片系统,该系统采用光学传感器测量管片安装位姿。 TANAKA[13]采用了9组激光发射器和相机检测管片高差和间隙,结合光截面检测法、数字伺服技术和远程遥控混合控制技术,大大减少了拼装时间,但该方法不适用于管片抓取工作。 HIRASAWA等[14]对全自动拼装机偏差补偿方法、相机视距以及图像处理算法进行改进,拼装机识别管片性能得到了进一步完善。日本三菱重工提出利用超声波装置对管片位姿进行精确测量的方法[15]。时至今日,日本三菱重工业株式会社、日本川崎重工业株式会社已成为国际上知名的盾构掘进机生产商,但激光检测、力控导向等技术仍未被广泛应用于实际施工中[16]。国内对于拼装机研究主要在于微调机构和控制算法,对管片姿态精准识别技术的研究较少[6]。SHI等[17]采用摄动法分析了管片安装的位置和姿态精度,建立了管片安装误差模型,认为误差源在管片安装中对位置误差影响高于姿态误差。张龙等[18]基于图像识别技术识别布置在盾构管片特定位置的靶标,从而计算管片位姿,但该方式需要事先在每个待安装管片上布置靶标。本文作者针对待安装管片的初始摆放位姿的偶然偏差和施工过程中累积的拼装误差,提出采用3个线激光检测管片位姿的方案及算法,该方法适用于管片抓取位姿和管片安装位姿的精确计算,从而有效提高管片拼装精度和实现管片拼装自动化。

1 管片检测方案

检测外界物体位姿有相机视觉、激光测距等方法。盾构施工感知系统需要在恶劣环境下仍有较强的稳定性,所以,采用激光传感器保证施工过程中的确定性。将3个线激光传感器安装在机械手固定板上。通过线激光传感器检测管片边缘的方法,计算待安装管片初始摆放位姿和管片安装目标位姿。该位姿计算方法同时适用于管片抓取阶段的初始摆放位姿和管片安装阶段的目标安装位姿。

1.1 管片抓取位姿检测

矩形盾构管片拼装机器人主要工作过程为抓取管片、递送管片和安装管片3个工作过程。其中在抓取管片过程中,末端执行机械手抓取后方传送过来的管片存在初始摆放误差。机械手需要首先检测到管片的实际摆放位姿,然后沿着已规划的轨迹完成管片抓取动作。

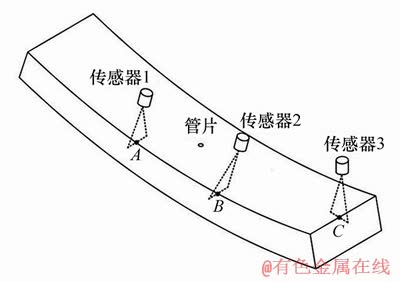

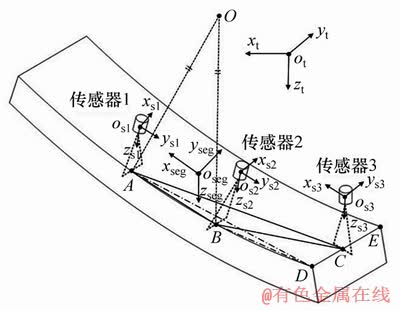

隧道拼装管片为预制弧形管片,其内表面是半径为R的弧形面。如图1所示,使用3个线激光传感器检测管片内表面边缘的方法确定管片位姿。

图1 激光传感器检测管片抓取位姿原理

Fig. 1 Principle of measuring grasping pose of segment by laser sensors

线激光传感器发射一道直线激光并照射在管片边缘上,在管片边缘上会形成深度突变。线激光传感器的摆放位置布置为2个线激光传感器照射管片的内表面圆弧边,1个线激光传感器照射相邻的内表面侧直边。通过检测反馈激光深度突变的位置,即可确定被检测到的边缘点(点A,点B和点C)分别相对于激光传感器的三维坐标。其中A点和B点为内表面圆弧边上随机不同2点,C点为侧直边上随机一点。然后结合管片内表面几何特征和检测的3个边缘点,计算管片位姿检测面上的侧直边顶点和圆弧边缘圆心等特征点相对于机械手坐标系的空间坐标值。再根据特征点相对于管片抓取坐标系的空间坐标值,进而算得管片抓取坐标系与机械手坐标系的相对位姿关系。

1.2 管片安装位姿检测

管片安装阶段主要运动为将管片从安装位置附近移动至正确的安装位置。施工过程中的不确定性因素导致已装好的管片与理论位置相比有所偏差,且在同环内所装管片位姿误差具有累积效应,若依照理论位置进行拼装可能会造成管片碰撞或产生间隙,因此,管片拼装机器人将管片递送至安装目标位置附近,需要进一步检测实际的安装位姿,然后再进行管片微调安装。

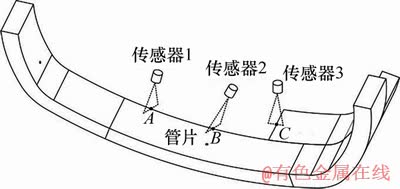

同样,采用安装在机械手上的3个线激光传感器照射至相邻已安装好的管片边缘上。如图2所示,2个线激光传感器照射待安装管片目标位置圆弧边的相邻管片的弧边,A点和B点为该弧边上的随机不同两点。最后1个线激光照射,同环相邻管片的侧直边,C点为该侧直边上随机一点。根据线激光深度突变现象提取出边缘点(点A,点B和点C),并计算出边缘点在机械手坐标系中的三维坐标值。

图2 激光传感器检测管片安装位姿原理

Fig. 2 Principle of measuring assembly pose of segment by laser sensors

结合待装管片的内表面几何特征,计算管片在目标安装位置时的特征点相对于机械手坐标系的三维坐标值。最后结合已知的特征点在管片目标安装坐标系的三维坐标值。计算得到管片目标安装坐标系与机械手坐标系的位姿关系。

2 管片位姿计算方法

2.1 计算管片特征点坐标

采用线激光传感器感知管片边缘位姿,结合管片内表面几何形状计算管片特征点的位姿坐标。再根据特征点位姿坐标计算得到待装管片的抓取坐标系和安装坐标系的位姿。管片抓取阶段的初始摆放位姿和管片安装阶段的目标安装位姿,2种位姿计算方法相同,下面以管片抓取阶段的管片初始摆放位姿计算为例进行介绍。

机械手坐标系即拼装机工作坐标系 ,3个线激光传感器安装在机械手上其坐标系分别是坐标系

,3个线激光传感器安装在机械手上其坐标系分别是坐标系 、坐标系

、坐标系 和坐标系

和坐标系 ,其与机械手坐标系

,其与机械手坐标系 的转移矩阵分别为

的转移矩阵分别为 ,

, 和

和 。如图3所示,点A和点B为弧形边缘上的随机不重合两点,其相对于各自传感器坐标为

。如图3所示,点A和点B为弧形边缘上的随机不重合两点,其相对于各自传感器坐标为 和

和 。点C为侧面直线边缘上的随机一点,其相对激光传感器3的坐标为

。点C为侧面直线边缘上的随机一点,其相对激光传感器3的坐标为 。假设B点距离C点距离较近,此3点相对于机械手坐标系具有如下式关系:

。假设B点距离C点距离较近,此3点相对于机械手坐标系具有如下式关系:

图3 激光传感器计算管片位姿示意图

Fig. 3 Calculation of position and position of segment by laser sensors

(1)

(1)

使用线激光检测管片位姿问题即:已知前面圆弧边上2点A和B坐标分别为 和

和 ,侧面圆弧边上点C坐标为

,侧面圆弧边上点C坐标为 。点D为管片端点,其中向量垂直于面ABD,以及内表面圆弧半径R。求解管片坐标系相对于机械手坐标系的转换矩阵

。点D为管片端点,其中向量垂直于面ABD,以及内表面圆弧半径R。求解管片坐标系相对于机械手坐标系的转换矩阵 。

。

线激光传感器通过高度突变误差提取出的管片边缘点仅表示该点在该管片边缘上,并无该点所在管片上的具体位置信息。所以,需要结合检测面几何特征约束获得已知管片具体位置的特征点。通过特征点在抓取管片坐标系 和机械手坐标系

和机械手坐标系 的三维坐标值,计算抓取管片坐标系

的三维坐标值,计算抓取管片坐标系 和机械手坐标系

和机械手坐标系 的相对位置关系。管片上的特征点是相对管片抓取坐标系位置已知的点。通过本节方法可以计算出图3中的点D,点E和点O在机械手坐标系

的相对位置关系。管片上的特征点是相对管片抓取坐标系位置已知的点。通过本节方法可以计算出图3中的点D,点E和点O在机械手坐标系 中的三维坐标值。

中的三维坐标值。

在图3的三角形△BCD和三角形△ACD运用勾股定理得式(2)前2个方程。圆弧 对应圆心角与圆弧

对应圆心角与圆弧 对应圆心角之和等于圆弧

对应圆心角之和等于圆弧 对应的圆心角,采用三角函数两角和公式得式(2)第3个方程,得方程组如下:

对应的圆心角,采用三角函数两角和公式得式(2)第3个方程,得方程组如下:

(2)

(2)

经代数求解后取其正根得:

(3)

(3)

其中:

(4)

(4)

(5)

(5)

(6)

(6)

根据式(2)中第2个方程,求解 ,

,  ,

, 和

和 :

:

(7)

(7)

(8)

(8)

(9)

(9)

(10)

(10)

至此图3中四面体ABCD中的角度和长度即可完全求出。下面根据上述已知参数,计算点D、点E和点O在机械手坐标系 中的三维坐标值。

中的三维坐标值。

已知 ,

, ,

,

列方程组如下:

列方程组如下:

(11)

(11)

根据式(11)求解得到点D相对于机械手坐标系 的三维坐标值

的三维坐标值 。

。

已知侧边长度为 ,计算向量

,计算向量 上的另一个端点E:

上的另一个端点E:

(12)

(12)

进而求得点E相对于机械手坐标系 的三维坐标值

的三维坐标值 :

:

(13)

(13)

根据点A,B和D外接圆心O几何关系,计算点A,B和D的外接圆心O相对于机械手坐标系 的三维坐标值

的三维坐标值 :

:

(14)

(14)

至此已求出管片顶点D、管片顶点E、管片圆心点O在机械手坐标系 中的三维坐标值。

中的三维坐标值。

2.2 计算管片坐标系位姿

已求出管片顶点D、管片顶点E、管片圆心点O在机械手坐标系 中的三维坐标值

中的三维坐标值 ,

, 和

和 ,结合三点在在管片坐标系

,结合三点在在管片坐标系 中的坐标值

中的坐标值 ,

, 和

和

。计算管片坐标系

。计算管片坐标系 在机械手坐标系{t}的位姿。位姿关系采用旋转矩阵

在机械手坐标系{t}的位姿。位姿关系采用旋转矩阵 和平移向量

和平移向量 表示,

表示, 和

和 有如下关系:

有如下关系:

(15)

(15)

首先计算点D,E和O在坐标系 中的重心坐标

中的重心坐标 ,以及这3点在坐标系

,以及这3点在坐标系 中的重心坐标

中的重心坐标 :

:

(16)

(16)

(17)

(17)

重心化可减少平移向量 的影响,进而可以先计算旋转矩阵

的影响,进而可以先计算旋转矩阵 。因此,对于点D,E和O在2个坐标系中的坐标进行重心化处理得:

。因此,对于点D,E和O在2个坐标系中的坐标进行重心化处理得:

(18)

(18)

由于旋转矩阵 可以分解为[19]

可以分解为[19]

(19)

(19)

其中: 为单位阵;

为单位阵; 为反对称矩阵;

为反对称矩阵; 为罗德格里参数。

为罗德格里参数。

(20)

(20)

则式(15)可描述为

(21)

(21)

展开式(21),整理得到

×

×

(22)

(22)

将式(22)简写如下:

(23)

(23)

根据最小二乘原理,得到罗德格里参数:

(24)

(24)

将求得的 代入式(20)得到旋转矩阵

代入式(20)得到旋转矩阵 ,将旋转矩阵代入式(15)中,求得平移向量

,将旋转矩阵代入式(15)中,求得平移向量 。至此,管片坐标系

。至此,管片坐标系 在机械手坐标系{t}的位姿已求出。

在机械手坐标系{t}的位姿已求出。

3 算例计算

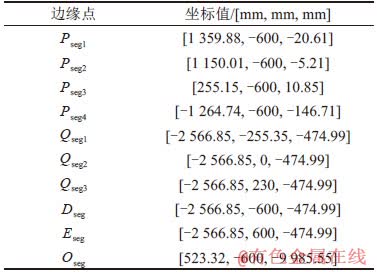

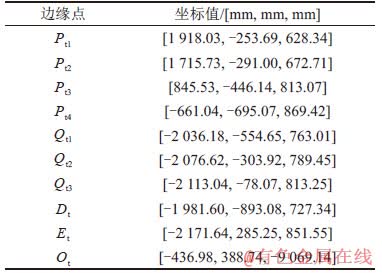

在SolidWorks软件中建立比例为1:1的管片三维模型,建立坐标系 ,在管片外侧弧线和右侧直线选取若干测点模拟线激光检测到的边缘点,其中P为圆弧边上的测点,Q为侧直边上测点,各个测点坐标如表1所示。

,在管片外侧弧线和右侧直线选取若干测点模拟线激光检测到的边缘点,其中P为圆弧边上的测点,Q为侧直边上测点,各个测点坐标如表1所示。

管片坐标系 相对于机械手坐标系{t},按照RPY角描述方法进行旋转和平移[20]。设旋转参数为[10°, 8°, 6°],即先绕坐标系{t}的

相对于机械手坐标系{t},按照RPY角描述方法进行旋转和平移[20]。设旋转参数为[10°, 8°, 6°],即先绕坐标系{t}的 轴旋转10°,再绕坐标系{t}的

轴旋转10°,再绕坐标系{t}的 轴旋转8°, 最后绕坐标系{t}的

轴旋转8°, 最后绕坐标系{t}的 轴旋转6°。然后分别沿着

轴旋转6°。然后分别沿着 轴,

轴, 轴和

轴和 轴平移500 mm,100 mm和900 mm。得到管片坐标系

轴平移500 mm,100 mm和900 mm。得到管片坐标系 相对于机械手坐标系{t}的位姿矩阵如下式所示:

相对于机械手坐标系{t}的位姿矩阵如下式所示:

表1 边缘点在坐标系 中的坐标值

中的坐标值

Table 1 Coordinates of edge points in coordinate system

表2 边缘点在坐标系{t}中的坐标值

Table 2 Coordinates of edge points in coordinate system{t}

(25)

(25)

则表1 中的边缘点在坐标系{t}中的坐标如表2所示。

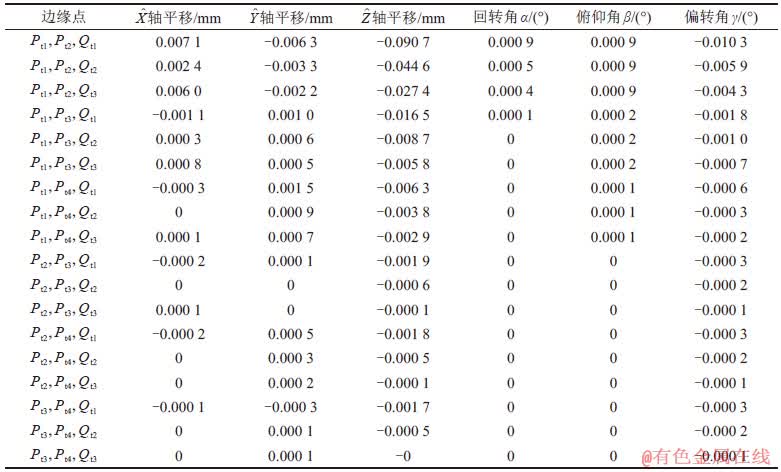

对盾构管片位姿进行计算时,根据算法在前弧线测点 中任意选择2个坐标数据作为图3中传感器1和传感器2的测点数据,侧直线测点

中任意选择2个坐标数据作为图3中传感器1和传感器2的测点数据,侧直线测点 中任意选择1个数据作为传感器3的测点数据,参考

中任意选择1个数据作为传感器3的测点数据,参考 ,

, 和

和 这3个特征点在坐标系

这3个特征点在坐标系 中的参数。采用第2节的计算方法对各个管片的位姿进行计算,并与真实姿态比较并计算误差,结果如表3所示。

中的参数。采用第2节的计算方法对各个管片的位姿进行计算,并与真实姿态比较并计算误差,结果如表3所示。

表3 盾构管片位姿计算误差

Table 3 Calculation error of position and posture of shield segment

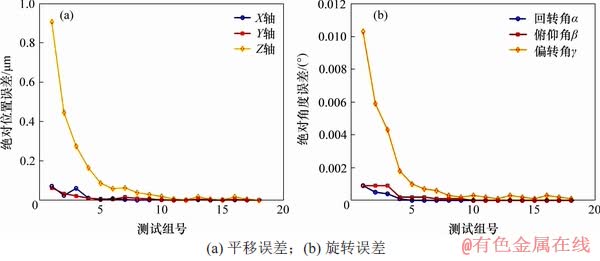

图4 各组盾构管片位姿计算误差曲线

Fig. 4 Calculation error of pose of segment for every group

从表3可知:误差绝对值最大分别为0.007 1 mm,0.006 3 mm,0.090 7 mm,0.000 9°,0.000 9°和0.010 3°。将各组数据按照平移误差和旋转角度误差分别绘制出曲线见图4。

从图4可知:弧线检测点越接近右侧,弧线上检测点距离越远,位姿误差越小。同时,侧边直线上的检测点距离D点越远,姿态精度也越高。因此,在保证弧线检测点距离不至于过小的情况下,选择检测靠近管片顶点D处弧线检测点,选择检测靠近管片定点E处直线检测点,能够获得较好的检测精度。

4 结论

1) 提出了采用3个线激光传感器检测待抓管片和检测待装管片位姿的方法。该方法只需要检测管片边缘,无需在预制管片上做其他改动,实施方便可靠。

2) 推导了管片位姿检测算法,该算法可根据圆弧边上2个检测点和侧直边上1个检测点确定管片坐标系相对于机械手坐标系的位姿关系。

3) 在圆弧边上选择4个检测点,在侧直边上选择2个测点,随机组合形成18组检测点,算法计算检测点均能获得良好的结果。分析算法误差,发现弧线检测点越接近右侧,弧线上两检测点距离越远,位姿误差越小;侧边直线上的检测点距离D点越远,姿态精度也越高。

参考文献:

[1] GONG Wenping, WANG Lei, JUANG C H, et al. Robust geotechnical design of shield-driven tunnels[J]. Computers and Geotechnics, 2014, 56: 191-201.

[2] XU Qianwei, ZHU Hehua, MA Xianfeng, et al. A case history of shield tunnel crossing through group pile foundation of a road bridge with pile underpinning technologies in Shanghai[J]. Tunnelling and Underground Space Technology, 2015, 45: 20-33.

[3] SUN Guangchen, XIE Jiayou, HE Shan, et al. Dynamic responses of bridge–tunnel overlapping structure for high-speed railway under different seismic excitations[J]. Geotechnical and Geological Engineering, 2019, 37(1): 43-60.

[4] 陈雁冰, 张闵庆, 陈晓阳, 等. 多功能长平移管片拼装机的设计[J]. 现代隧道技术, 2012, 49(1): 166-170.

CHEN Yanbing, ZHANG Minqing, CHEN Xiaoyang, et al. Design of multifunctional long translation segment erector[J]. Modern Tunnelling Technology, 2012, 49(1): 166-170.

[5] YUAN Yingchao, ZHANG Yu. Building of fine-tuning mechanism posture and kinematics model for shield segment erector[J]. Advanced Materials Research, 2013, 634/635/636/637/638(1): 3737-3740.

[6] 张碧, 赵海峰, 杨涛, 等. 盾构管片拼装机国内外研究现状[J]. 矿山机械, 2014(4): 1-6.

ZHANG Bi, ZHAO Haifeng, YANG Tao, et al. Research status of segment erector in shield tunneling machine at home and abroad[J]. Mining and Processing Equipment, 2014(4): 1-6.

[7] 陈纬. 盾构管片拼装机结构及功能简介[J]. 机械工程与自动化, 2012(1): 92-94.

CHEN Wei. Introduction to structure and features of shield erector[J]. Mechanical Engineering & Automation, 2012(1): 92-94.

[8] 曾格华, 夏才初. 管片径向拼装偏差对盾构隧道管片环防水性能的影响分析[J]. 岩土工程学报, 2016, 38(11): 2017-2025.

ZENG Gehua, XIA Caichu. Effect of radial erection error of segments on waterproofness of segment rings of shield tunnels[J]. Chinese Journal of Geotechnical Engineering, 2016, 38(11): 2017-2025.

[9] GUO Wentao, GUO Weizhong, GAO Feng, et al. Innovative group-decoupling design of a segment erector based on GF set theory[J]. Chinese Journal of Mechanical Engineering, 2013, 26(2): 264-274.

[10] WU Chao, LIU Xinjun, WANG Liping, et al. Dimension optimization of an orientation fine-tuning manipulator for segment assembly robots in shield tunneling machines[J]. Automation in Construction, 2011, 20(4): 353-359.

[11] WANG Lintao, GONG Guofang, YANG Huayong, et al. The development of a high-speed segment erecting system for shield tunneling machine[J]. ASME Transactions on Mechatronics, 2013, 18(6): 1713-1723.

[12] WADA M. Automatic segment erection system for shield tunnels[J]. Advanced Robotics, 1990, 5(4): 429-443.

[13] TANAKA Y. Automatic segment assembly robot for shield tunneling machine[J]. Computer-Aided Civil and Infrastructure Engineering, 1995, 10(5): 325-337.

[14] HIRASAWA Y, HASHIMOTO H, WORI Y, et al. Development of automatic segment assembly robot for shield tunnelling machine[C]// BRILAKIS I. Proceedings of International Symposium on Automation and Robotics in Construction. Tokyo: ISARC, 1996: 813-820.

[15] MAKOTO S, FUMIO T,TERUYUKI M, et al. Assembly method for erector controller and lining work member:Japan,2004131979A [P].2004-04-30.

[16] 崔晋征. 拼装机液压系统仿真与拼装轨迹的能耗分析[D]. 上海: 上海交通大学机械与动力工程学院, 2014: 10-11.

CUI Jinzheng. Design and simulation of segment erector hydraulic control system and energy saving analysis of system assembly path[D]. Shanghai: Shanghai Jiaotong University. School of Mechanical Engineering, 2014: 10-11.

[17] SHI Hu, GONG Guofang, YANG Huayong. Drive system design and error analysis of the 6 degrees of freedom segment erector of shield tunneling machine[J]. Frontiers of Mechanical Engineering, 2011, 6(3): 369-376.

[18] 张龙, 王海波, 范曙远. 盾构机管片拼装自动控制传感检测系统的设计[J]. 机械制造, 2018, 56(2): 74-77.

ZHANG Long, WANG Haibo, FAN Shuyuan. Design of automatic control, sensing and detection system for segment assembly of shield machine[J]. Machinery, 2018, 56(2): 74-77.

[19] YAO Jili, XU Yufei, XIAO Wei. Applications of lodrigues matrix in 3D coordinate transformation[J]. Geo-Spatial Information Science, 2007, 10(3): 173-176.

[20] BAJD T, MIHELJ M, MUNIH M. Introduction to robotics[M]. Dordrecht, Netherlands: Springer, 2013: 21-26.

(编辑 杨幼平)

收稿日期: 2019 -03 -29; 修回日期: 2019 -06 -10

基金项目(Foundation item):国家重点研发计划项目(2017YFB1302601);上海隧道工程有限公司专项研究科研项目(2017-SK-08) (Project(2017YFB1302601) supported by the Natioal Key R&D Program of China; Project(2017-SK-08) supported by the Special Scientific Research Program of Shanghai Tunnel Engineering Co. Ltd)

通信作者:陶建峰,博士,副教授,从事机械电子工程研究;E-mail:jftao@sjtu.edu.cn