Superplastic behavior of Al-Cu-Li based alloy

DU Yu-xuan(杜予晅), ZHANG Xin-ming(张新明), YE Ling-ying(叶凌英), LUO Zhi-hui(罗智辉)

School of Materials Science and Engineering, Central South University, Changsha 410083, China

Received 28 July 2006; accepted 15 September 2006

Abstract: The superplastic behavior was studied in an Al-4Cu-1Li-0.4Mg-0.4Ag-0.1Zr alloy. The alloys were manufactured both by a conventional rolling route and a thermo-mechanical treatment route. The superplastic properties were evaluated as a function of temperature, strain rate, and processing history. Prior to thermo-mechanical processing, the alloys have elevated-temperature ductilities of 94% to 130%, strain rate sensitivities of about 0.25, and activation energies corresponding to lattice diffusion. After thermo-mechanical processing, the alloys have ductilities of 200% to 630%, strain rate sensitivity of about 0.42, and activation energies corresponding to grain boundary diffusion or a mixture of grain boundary diffusion and lattice diffusion. Skipping rapid recrystallization annealing can supply a higher value of elongation-to-failure.

Key words: superplasticity; aluminum-lithium alloy; activation energy; grain boundary diffusion; lattice diffusion; Al-Cu-Li

1 Introduction

The AA2195 Al-Li alloy, which has advantages of high strength, very strong and rapid natural aging capability, good fracture toughness, good weldability and stress-corrosion-cracking resistance, is one of ideal candidates for the application of aerospace and aircraft industry. Applying superplastic forming to produce complex Al-Li alloy sheet-metal components can achieve not only more mass-saving, but also a higher integral rigidity and less number of parts which enables significant time-saving of assembling. Therefore, superplastic forming of Al-Li alloys attracts great interest. Superplastic potential of aluminum alloys critically requires equiaxed grains whose average size is less than 10 ?m and high angular grain boundaries [1] which can be developed by rolling and recrystallization. However, the major efforts of AA2195 are concentrated in the fields of strengthening [2-5], fatigue resistance [6-7], texture [8-10] and welding [11-12]. The investigations [13-16] about superplasticity of some WeldaliteTM 049 Al-Li alloys which are same series of AA2195 have been also reported, but almost none of AA2195 was found. The aim of present paper is to study the superplastic behavior of the AA2195 Al-Li alloy in the rolling-based thermo-mechanically processing condition.

2 Experimental

The AA2195 Al-Li alloy with a chemical composition of Al-3.9Cu-1.1Li-0.38Mg-0.39Ag -0.08Zr (mass fraction, %) was prepared by direct chill casting. The alloy was homogenized and hot rolled to a gauge of 10 mm. Subsequently, the alloy was given a further thermo-mechanical processing treatment. The processing steps were: solution heat treatment, followed by cold water quenching, over-aging at an elevated temperature for 24 and 48 h, deformation by rolling with the reduction of 80%, and rapid recrystallization process at 500 ℃ for 10 min.

EBSD examinations were carried out by means of TSL OIM system attached to an H-3400 scanning electron microscope. For TEM examinations, the samples were thinned to about 0.08 mm. Discs with 3 mm diameter were cut and electropolished to perforation with a twinjet polishing unit using a 30% nitric acid solution in methanol at -20--30 ℃ and 15 V. The thin foils were examined using Tecnai G2 20 TEM at an accelerating potential of 200 kV.

The superplastic characteristics of the alloy were investigated by conducting tests in tension on Instron 8032 servo hydraulic testing system at 400 to 500 ℃ and using initial strain rates from 5×10-4 to 10-2 s-1. Tests were performed on samples in three thermo- mechanically processing and hot-rolling conditions.

3 Results and discussion

The Al-Cu-Li sheets in the hot-rolling condition show an elongated grain structure (Fig.1(a)) which is typical in the Al-Li based alloys. However, the fine equiaxed grains structure is required in superplastic aluminum alloys [1]. After thermo-mechanical process- ing, a significant grain refinement is achieved, and longer over-aging time produces a finer grain structure and more equiaxed grain shape (see Figs.1(b) and (c)). As previous study [18-19] suggested, the elongation grain structure is caused by being lack of effective recrystallization nucleation site (i.e. coarse second phase particles) and continuous distribution of small particles on the grain boundaries. A long time over-aging can offer more coarse particles as nucleation position and most continuously distributed small particles on the pre-existed grain boundaries are also removed.

Fig.1 Orientation maps of Al-Cu-Li alloy in hot-rolling conditions(a) and thermo-mechanical treating conditions(b), (c) (Over-aging time of samples b and c is 24 h and 48 h, respectively)

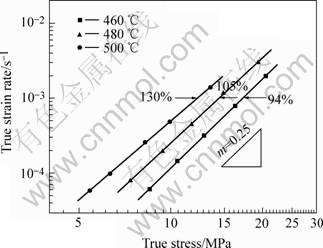

Initially the superplastic properties of the Al-Cu-Li alloy were evaluated for material in the hot-rolling condition. The results on a log true strain rate vs log true stress format for each of the alloys are shown in Fig.2. The strain rate sensitivities are equal to m=0.25 to 0.29 which are a bit higher than the typical value (m≈0.2) of most pure metals and dislocation climb-controlled alloys, but are lower than those typically associated with superplastic metals, i.e. m>0.4. Some of elongation- to-failure values that were recorded at 460, 480 and 500 ℃ are shown in Fig.2. These values of elongation- to-failure ranging from 94% to 130% are certainly high, but they are not as high as those associated with superplastic alloys in which values typically range from over 300% to 1000%. Using strain rate change data from tests carried out over the temperature range of 460 to 500 ℃, activation energies for plastic flow in the alloys were also estimated. The activation energies measured are all found to be close to that measured for lattice self-diffusion in aluminum (about 134 kJ/mol) [19-20].

Fig.2 Strain rate as function of stress for as-rolled Al-Cu-Li alloys over temperature range of 460 to 500 ℃ (The elongation-to-failures are obtained at strain rate of 10-3 s-1)

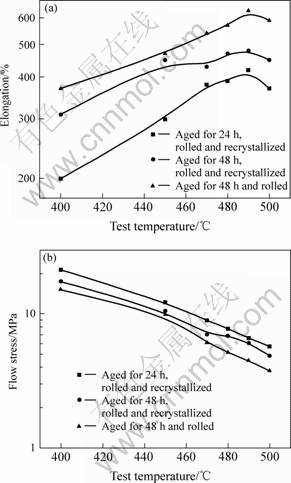

The influence of temperature on superplastic elongation-to-failure and flow stress was determined. The tests were carried out over the temperature range of 400 to 500 ℃ on each thermo-mechanical treated alloy and the results are shown in Fig.3(a). The elongation-to-failure for each alloy shows an enhancement with temperature increasing from 400 to 490 ℃. At temperatures greater than 490 ℃, due to coarsening of grain structure in all of alloy during tension at elevated temperature, the elongation-to-failure shows a little drop. In addition, the alloy whose aging time is 48 h shows a higher elongation-to-failure than that aged for 24 h due to its finer grain structure. In present study, skipping the rapid recrystallization annealing can further improve the ductilities but the statically recrystallized sheets are usually used in commercial production for consideration of stabilization in superplastic forming. The strength of alloy without recrystallization prior to tension is higher than that of statically recrystallized alloy (see Fig.3(b)), which implies that recrystallization is presented during heating to superplastic forming temperature prior to tension.

Fig.3 Influence of temperature on elongation-to-failure(a) and flow stress(b) of Al-Cu-Li alloy

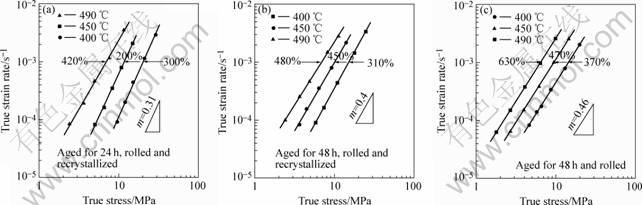

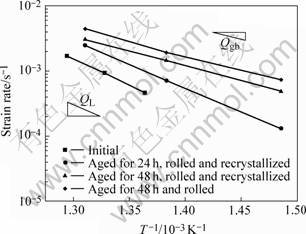

For the thermo-mechanically processed material the strain rate change tests were performed over the temperature range of 400 to 490 ℃ with the resultant data shown in Fig.4(a) for the alloy aged for 24 h and in Fig.4(b) for the one aged for 48 h. A value of strain rate sensitivity of m=0.31 is found at each temperature. Also some elongation-to-failure data are shown in the same figures from samples tested at various temperatures. A value of the activation energy for plastic flow was determined. The activation energy for the alloy aged for 24 h is about 120 kJ/mol(see Fig.5), between those for lattice and grain boundary diffusion. However, for the alloy aged for 48 h, the strain rate sensitivity is equal to 0.4 and the activation energy is about 97 kJ/mol(see Fig.5), close to that for grain boundary diffusion. As shown in Fig.1(b), the 24 h aging is not enough to produce ideal particles for formation of equiaxed fine grains. Although the grain size is much smaller than that of the hot-rolled alloy and some fine equiaxed grains are found, a large amount of grains also show a lath-like shape. Therefore, grain boundary sliding (GBS) can not be dominant part of deformation. In the case of the 48 h-aged alloy, the fine equiaxed grain structure guarantees the prevalence of the GBS.

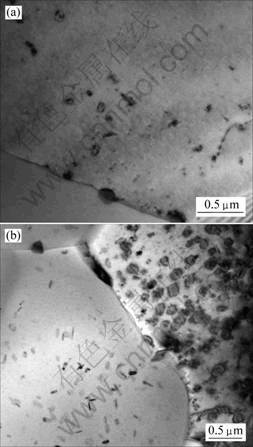

During tension test, large numbers of small particles were observed which ensure the stability of microstructure to a certain extent in the temperature range of 400-490 ℃ as shown in Fig.6.

Fig.4 True strain rate as function of true stress of sample in three thermo-mechanical processing routes showing influences of aging time and recrystallization on superplastic behaviors (The elongation-to-failure are obtained at strain rate of 10-3 s-1)

Fig.5 Determination of activation energies for plastic flow in Al-Cu-Li alloys in both as-rolling and thermo-mechanically processing conditions

Fig.6 TEM photographs showing a large amount of small particles accounting for microstructure stability

4 Conclusions

1) The Al-Cu-Li alloy in the hot-rolling condition shows elongation-to-failure of 94%-130%, strain rate sensitivities of about 0.25, and activation energies corresponding to lattice diffusion.

2) After thermo-mechanical processing, the alloys have ductilities of 200% to 630%, strain rate sensitivities of about 0.42. Longer aging time generates coarser particles to serve as recrystallization nucleation sites and leads to a finer and equiaxed grain structure for which activation energies correspond to grain boundary diffusion.

3) Skipping rapid recrystallization annealing process can supply a higher value of elongation- to-failure.

4) A large amount of small particles presented during tension test at temperature of superplastic forming ensure the stability of microstructure to a certain extent in the temperature range of 400 to 490 ℃.

References

[1] NIEH T G, WADSWORTH J, SHERBY O D. Superplasticity in Metals and Ceramics[M]. United Kingdom: Cambridge University Press, 1997: 1-90.

[2] HUANG B P, ZHENG Z Q, YIN D F, MO Z M. Effects of trace Ag and Mg additions on mechanical properties and microstructures of 2195 alloy[J]. Mater Sci Forum, 1996, 217/222: 1239-1244.

[3] HUANG B P, ZHENG Z Q. Independent and combined roles of trace Mg and Ag additions in properties precipitation process and precipitation kinetics of Al-Cu-Li-(Mg)-(Ag)-Zr-Ti alloys[J]. Acta Mater, 1998, 46(12): 4381-4393.

[4] KUMAR K S, BROWN S A, PICKENS J R. Microstructural evolution during aging of an Al-Cu-Li-Ag-Mg-Zr alloy[J]. Acta Mater, 1996, 44(5): 1899-1915.

[5] ZHENG Z Q, HUANG B P, YIN D F. Alloying role of Ag and Mg in 2195 alloy[J]. J Cent South Univ Technol, 1998, 29(1): 42-45. (in Chinese)

[6] HAFLEY R A, WAGNER J A, DOMACK M S. Fatigue crack growth rate test results for Al-Li 2195 parent metal, variable polarity plasma arc welds and friction stir welds[R]. NASA/TM-2000-210098, 2000, 5: 1-43.

[7] DOGLIONE R, MURA L, VERNIANI C, FIRRAO D. Fracture behavior of 2195-T8 aluminium alloy plates[J]. Mater Sci Forum, 2002, 396/402: 1341-1344.

[8] HALES S J, HAFLEY R A. Texture and anisotropy in Al-Li alloy 2195 plate and near-net-shape extrusions[J]. Mater Sci Eng A, 1998, 257: 153-164.

[9] CROOKS R, WANG Z, LEVIT V I, SHENOY R N. Microtexture, microstructure and plastic anisotropy of AA2195[J]. Mater Sci Eng A, 1998, 257: 145-152.

[10] KALU P N, ZHANG L. Texture evolution in Al-Li 2195 alloy during net shape roll forging[J]. Scr Mater, 1998, 39(2): 175-180.

[11] HU W S, MELETIS E I. Corrosion and environment-assisted cracking behavior of friction stir welded Al 2195 and Al 2219 alloys[J]. Mater Sci Forum, 2000, 331/337: 1683-1688.

[12] AIDUM D K, DEAN J P. Effect of enhanced convection on the microstructure of Al-Cu-Li Welds[J]. Welding Research Supplement, 1999, 10: 349s-354s.

[13] SALEM H G, REYNOLDS A P, LYONS J S. Microstructure and retention of superplasticity of friction stir welded superplastic 2095 sheet[J]. Scr Mater, 2002, 46: 337-342.

[14] MAHON G J, RICKS R A. Superplasticity in high strength Al-Cu-Li-Ag-Mg alloys[J]. Scr Metall Mater, 1991, 25(2): 383-386.

[15] KRIDLI G T, EL-GIZAWY A S, LEDERICH R. Development of process maps for superplastic forming of WeldaliteTM 049[J]. Mater Sci Eng A, 1998, 244: 224-232.

[16] SALEM H G, GOFORTH R E, HARTWIG K T. Influence of intense plastic straining on grain refinement, precipitation, and mechanical properties of Al-Cu-Li-based alloys[J]. Metall Mater Trans A, 2003, 34(5): 1153-1161.

[17] DU Y X, ZHANG X M, YE L Y, LIU S D. Evolution of grain structure in AA2195 Al-Li alloy plate during recrystallization[J]. Trans Nonferrous Met Soc China, 2006, 16: 321-326.

[18] DU Y X, ZHANG X M, YE L Y, LUO Z H. Investigation of over-aging in superplastic treatment of an AA2195 Al-Li alloy[J]. Trans Mater Heat Treatment, 2006, 27(6): 52-56.

[19] SHERBY O D, BURKE P M. Mechanical behavior of crystalline solids at elevated temperature[J]. Progr Mater Sci, 1967, 13: 325-390.

[20] LUNDY T S, MURDOCK J F. Diffusion of Al26 and Mn54 in aluminum[J]. J Appl Phys, 1962, 33: 1671-1677.

(Edited by YUAN Sai-qian)

Foundation item: Project (2005CB623706) supported by the National Basic Research Program of China

Corresponding author: DU Yu-xuan; Tel: +86-731-8830265; Email: yuxuandu@gmail.com