文章编号:1004-0609(2011)11-2775-05

Zn-1.0Cu-0.2Ti合金的静态再结晶行为

肖来荣1, 2, 张喜民1, 3, 王 艳1, 曾德露1, 张宏岭1, 李 威1

(1. 中南大学 材料科学与工程学院,长沙 410083;

2. 中南大学 有色金属材料科学与工程教育部重点实验室,长沙 410083)

摘 要:采用熔铸、轧制的方法制备Zn-1.0Cu-0.2Ti合金,借助扫描电子显微镜(SEM)、透射电子显微镜(TEM)观察合金的显微组织,测定不同退火制度后合金的硬度和再结晶晶粒尺寸,建立了Zn-1.0Cu-0.2Ti合金的再结晶晶粒长大模型,研究退火温度和退火时间对Zn-1.0Cu-0.2Ti合金再结晶行为的影响。利用硬度法测得Zn-1.0Cu-0.2Ti合金的再结晶温度在230 ℃左右。结果表明:随着退火温度的升高和退火时间的延长,合金再结晶晶粒均逐渐长大,但晶粒长大的速度趋于缓慢,合金中弥散分布于基体内的CuZn4和TiZn15相能够抑制再结晶晶粒的长大。

关键词:Zn-1.0Cu-0.2Ti合金;再结晶;退火;显微组织

中图分类号:TG146.2 文献标志码:A

Static recrystallization behavior of Zn-1.0Cu-0.2Ti alloy

XIAO Lai-rong1, 2, ZHANG Xi-min1, 3, WANG-Yan1, ZENG De-lu1, ZHANG Hong-ling1, LI Wei1

(1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. Key Laboratory of Non-ferrous Metal Materials Science and Engineering, Ministry of Education,

Central South University, Changsha 410083, China)

Abstract: Zn-1.0Cu-0.2Ti alloy were prepared by casting and rolling processes. The microstructures of alloy were investigated by SEM and TEM. The recrystallized grain size and Vickers hardness were measured after different annealing processes. The recrystallized grain growth model was founded. The influence of annealing temperature and annealing time on the recrystallization behavior of Zn-1.0Cu-0.2Ti alloy were studied. The recrystallization temperature of Zn-1.0Cu-0.2Ti is about 230 ℃ by measuring the hardness of alloy. The result shows that the recrystallized grain of Zn-1.0Cu-0.2Ti alloys grows with the increase of annealing temperature and time, while the growing rate decreases. The second phases CuZn4 and TiZn15 help to suppress the growth of the recrystallized grains.

Key words: Zn-1.0Cu-0.2Ti alloy; recrystallization; annealing; microstructure

目前,锌合金的研究和应用主要集中在铸造锌合金方面,为了拓展锌合金的使用范围,需要大力发展变形锌合金[1-3]。锌铜钛合金成本低,其密度是Cu的4/5,具有较高的强度、良好的塑性和优良的抗蠕变性能,可用作屋顶材料、下水管道、卫浴、室内装潢等领域[4-6]。

合金的力学性能与其再结晶关系密切,所以再结晶温度是合金加工工艺的重要参考因素[7-8]。纯锌的再结晶温度为10 ℃[9],而对于Zn-Cu-Ti合金的再结晶温度国内外则鲜见报道,因此,研究合金的再结晶行为对于锌合金的加工及相关性能的研究具有重要意义。本文作者以Zn-1.0Cu-0.2Ti合金为研究对象,通过硬度法测定合金的再结晶温度,并观察其不同温度不同退火时间后的微观组织,建立其再结晶晶粒长大模型,以期为优化合金的加工工艺提供参考依据。

1 实验

采用商业用高纯锌(99.995%)、实验室制备的Zn-Ti中间合金和Zn-Cu中间合金为原料,在高纯石墨坩埚中熔炼。熔炼时先加纯锌,控制锌液的温度在550~620 ℃之间,然后加Zn-Ti中间合金和Zn-Cu中间合金,以木炭作覆盖剂,待合金完全熔化后静置 0.5 h,充分搅拌后约500~580 ℃时扒渣浇注。铸锭经均匀化,热轧成厚度约4 mm的板材,冷却后经3个道次冷轧至厚度为1.2 mm,以保证冷变形量为70%。样品经不同热处理制度处理后在HV-10B华银小负荷维氏硬度计上进行硬度测定,载荷为5 N,加载10 s,每个试样测量5次取硬度平均值。

试样经镶样、打磨、抛光后,用浸蚀液(100 g CrO3+ 7.5 g Na2SO4 + 500 mL去离子水)浸蚀3~5 s[10],采用FEI-Sirion 200型场发射扫描电镜(SEM)对样品的微观形貌进行观察分析;将样品机械减薄至70 μm左右,凹坑后在离子减薄仪上进行离子减薄,在TecnaiG220型透射电镜(TEM)下进行形貌观察和电子衍射分析,加速电压为200 kV。

2 结果与分析

2.1 合金的再结晶温度

通常再结晶温度是指经过严重冷变形(变形量≥70%)的金属保温1h再结晶完成95%所对应的温度。测定再结晶温度的实验方法有金相法和硬度法。本研究采用硬度法,测定不同温度退火后试样的硬度,绘制硬度—温度曲线,以硬度值突然急剧下降的温度为再结晶温度[9]。

冷变形及130、170、200、230、260和290℃退火1h后Zn-1.0Cu-0.2Ti合金的维氏硬度如图1所示。从图1可以看出,随着退火温度的升高,合金的硬度逐渐下降,且经230 ℃退火后,硬度突然下降,这是由于退火过程中合金发生了回复和再结晶,消除了冷变形引起的加工硬化。因此,可以判定Zn-1.0Cu-0.2Ti合金的再结晶温度在230 ℃左右。

2.2 不同退火制度后合金的微观组织

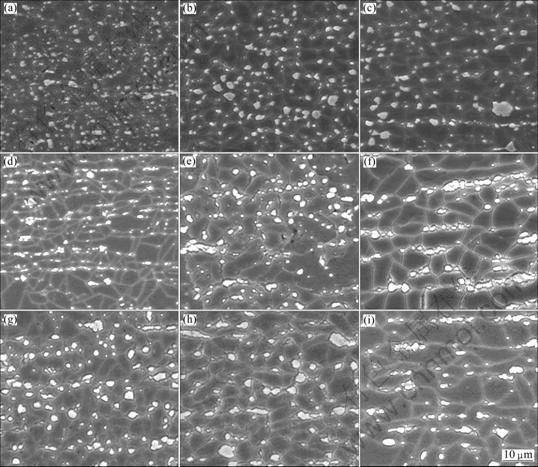

Zn-1.0Cu-0.2Ti合金230、260和290 ℃退火1、2和3 h后的微观组织如图2所示。按照GB/T6394—

2002《金属平均晶粒度测定方法》中的面积法,测得不同温度和时间退火后合金的再结晶晶粒平均尺寸如表1所列。

图1 Zn-1.0Cu-0.2Ti合金不同温度退火1 h后的维氏硬度

Fig.1 Vickers hardness of Zn-1.0Cu-0.2Ti alloy annealed at different temperature for 1 h

表1 Zn-1.0Cu-0.2Ti合金不同退火制度下平均晶粒尺寸D

Table 1 Average grain size of Zn-1.0Cu-0.2Ti after different annealing processes

从图2和表1可以看出,随着退火时间的延长,合金的再结晶晶粒尺寸逐渐增大。经230 ℃退火1 h后,合金的平均晶粒尺寸为(5.7±0.1) μm;2 h后,晶粒尺寸(7.1±0.1) μm;3 h后,晶粒尺寸为(8.4±0.1) μm,晶粒尺寸从1 h到2 h增大了约25%,从2 h到3 h增大了约16%,也就是说晶粒长大的速度逐渐减缓。唐仁正[9]的研究表明,一定温度下金属的再结晶晶粒长大到一定尺寸时不随退火时间的延长而增大。一般而言,晶粒的长大是通过晶界的迁移来完成的,晶界迁移的驱动力之一是晶界自由能差[11]。

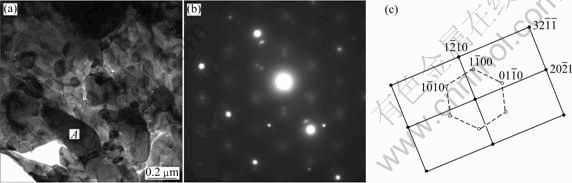

Zn-1.0Cu-0.2Ti合金230 ℃、2 h退火后TEM像及分析如图3所示。图3(a)中A区所示第二相的衍射斑如图3(b)所示,对其进行标定结果如图3(c)所示,表明第二相为ε相,其中基体斑的入射方向为[001],第二相衍射斑的入射方向为 。ε相为CuZn4中间化合物,密排六方结构,硬度为150HV,属硬脆相[12]。文献[13-14] 表明:第二相中还有TiZn15相,但本研究中并未发现,可能是由于其中Ti含量较少。CuZn4和TiZn15这两种第二相不易从形貌和衬度上区分。

。ε相为CuZn4中间化合物,密排六方结构,硬度为150HV,属硬脆相[12]。文献[13-14] 表明:第二相中还有TiZn15相,但本研究中并未发现,可能是由于其中Ti含量较少。CuZn4和TiZn15这两种第二相不易从形貌和衬度上区分。

图2 合金不同温度、不同时间退火后的显微组织

Fig.2 Microstructures of alloy annealing at different temperatures for different times: (a) 230 ℃, 1 h; (b) 230 ℃, 2 h; (c) 230 ℃, 3 h; (e) 260 ℃, 2 h; (f) 260 ℃, 3 h; (g) 290 ℃, 1 h; (h) 290 ℃, 2 h; (i) 290 ℃, 3 h

图3 Zn-1.0Cu-0.2Ti合金经230 ℃、2 h退火后的TEM像和SAED衍射谱

Fig.3 TEM image and corresponding SAED patterns of Zn-1.0Cu-0.2Ti alloy after annealing at 230 ℃ for 2h: (a) TEM image; (b) SAED pattern of area A; (c) Diffraction spot diagram of (b)

Zn-1.0Cu-0.2Ti合金中的第二相在加工的过程中破碎成细小晶粒,弥散分布于基体内。第二相对再结晶的影响主要表现在两个方面:1) CuZn4和TiZn15相粒子附近可能作为再结晶形核位置,提高形核率。Zn-1.0Cu-0.2Ti合金塑性变形时位错在基体内移动遇到CuZn4和TiZn15相粒子又不能切过它们,便会在第二相周围留下一个位错环,随着变形量的增加,

第二相附近的位错环的积累逐渐增多,从而在变形组织中的第二相附近形成高密度位错区和高的取向梯度。这些高密度畸变区增大了合金再结晶储能,为再结晶提供了更多的形核位置,进而使合金形核率得到提高,从而细化再结晶晶粒。2) 弥散分布的第二相钉扎晶界,阻碍晶界迁移。当亚晶界迁移到第二相粒子最大界面处后,亚晶界继续移动会增大晶界面积,即增加了总的界面能量,这时第二相粒子对晶界移动产生拖曳力,即钉扎作用。从图2中可以看出,第二相分布多的区域再结晶晶粒的尺寸小于第二相分布少的区域,这说明晶界上存在的第二相粒子阻碍晶界运动,对晶界运动起到了良好的钉扎所用,能够抑制再结晶晶粒的长大。

2.3 合金再结晶晶粒长大模型

再结晶晶粒长大的动力学模型一般用下式描 述[15]:

(1)

(1)

式中:D为平均晶粒尺寸;D0为t=0时的平均晶粒尺寸,即再结晶恰好完成时的平均晶粒尺寸;t为等温退火时间;K0为热激活过程常数;Q为晶粒长大过程中的热激活能;T为等温退火温度;R为摩尔气体常数。

由式(1)两边取对数可得:

(2)

(2)

将表1中的D与t的数值代入式(2),得D2同t的关系曲线如图4(a)所示,线性拟合得出3条直线的斜率m1、m2和m3(不同退火温度下合金的D2-t斜率)。将m代入式(2)得到:

(3)

(3)

将m1、m2和m3的值取对数得到lnm1、lnm2和lnm3,并作ln m与1/T关系曲线如图4(b)所示。图4中曲线的斜率为-Q/R,计算出蠕变激活能Q=49.9 kJ/mol。

将Q代入式(3)中,计算出常数K0值, K0=5.338 51×105,将Q、K0及各退火态下的数据代入式(1)中得D0值。至此得出230~290 ℃范围内Zn-1.0Cu-0.2Ti合金的再结晶晶粒长大动力学模型为

。

。

图4 合金再结晶退火晶粒尺寸与退火时间和温度的关系

Fig.4 Relationships among grain size and annealing time and annealing temperature

3 结论

1) Zn-1.0Cu-0.2Ti合金的再结晶温度为230 ℃ 左右。

2) Zn-1.0Cu-0.2Ti合金冷变形量为大于70%时,在230~290 ℃退火过程中,随着退火温度的升高和退火时间的延长,合金的晶粒逐渐长大。

3) 合金中第二相能够抑制再结晶晶粒的长大。合金的再结晶晶粒长大动力学模型如下:

REFERENCES

[1] 郭天立, 杨如中, 陈 锐, 郭 杰. 锌合金发展现状述评[J]. 有色矿冶, 2001, 17(5): 37-40.

GUO Tian-li, YANG Ru-zhong, CHEN Rui, GUO Jie. Review of development of zinc alloy[J]. Nonferrous Mining and Metallurgy, 2001, 15(5): 37-40.

[2] 谭 兵. 锌铜钛合金板带材的试制与性能[J]. 冶金丛刊, 1999(2): 37-39.

TAN Bing. Trial preparation and properties of Zn-Cu-Ti alloy [J]. Metallurgical Collections, 1999(2): 37-39.

[3] 孙连超, 田荣璋. 锌及锌合金物理冶金学[M]. 长沙: 中南工业大学出版社, 1994: 409-454.

SUN Lian-chao, TIAN Rong-zhang. Zinc and zinc alloy physical metallurgy [M]. Changsha: Central South University, 1994: 409-454.

[4] 彭曙光. 锌铜钛合金及其产业前景分析[J]. 湖南有色金属, 2003, 19(2): 35-37.

PENG Shu-guang. Zn-Cu-Ti alloy and its industry prospects [J]. Hunan Nonferrous Metals, 2003, 19(2): 35-37.

[5] ZHANG Xiao-ge Gregory. Corrosion and electrochemistry of zinc [M]. New York: Plenum Press, 1996: 7-20.

[6] 沈保罗. 锌基合金的性能特点及其在冶金行业中的应用[J]. 四川冶金, 1996(1): 63-65.

SHEN Bao-luo. Properties of Zinc-based alloy and its usage in Metallurgical industry [J]. Metallurgy of Sichuan, 1996(1): 63-65.

[7] DONALD R, ASKELAND P, PHULE P. The science and engineering of materials [M]. 4th ed. Beijing: Tsinghua University Press, 2005: 315-357.

[8] HIMMEL L. Recovery and recrystallization of metals[M]. New York: Interscience Publishers, 1963: 199-223.

[9] 唐仁正. 物理冶金基础[M]. 北京: 冶金工业出版社, 1997: 149-270.

TANG Ren-zheng. The basis of physical metallurgy [M]. Beijing: Metallurgical Industry Press, 1997: 149-270.

[10] BOS C B , SCHNITGER H C, ZHANG X, et al. Influence of alloying elements on the corrosion resistance of rolled zinc sheet[J]. Corrosion Science, 2006, 48(9): 1483-1499.

[11] 宋余九. 金属的晶界与强度[M]. 西安: 西安交通大学出版社, 1986: 85-87.

SONG Yu-jiu. The grain boundary and strength of metals [M]. Xi’an: Xi’an Jiaotong University Press, 1986: 85-87.

[12] MA D, LI Y, NG S C. Unidirectional solidification of Zn-rich peritectic alloy—I. Microstructure selection [J]. Acta Materialia, 2000, 48(2): 419-431.

[13] 张喜民, 肖来荣, 温燕宁, 耿占吉, 张宏岭, 孙泉胜. 挤压Zn-Cu-Ti合金组织及其力学性能[J]. 材料科学与工程学报, 2010, 28(4): 1-7.

ZHANG Xi-min, XIAO Lai-rong, WEN Yan-ning, GEN Zhan-ji, ZHANG Hong-ling, SUN Quan-sheng. Microstructure and mechanical properties of extruded Zn-Cu-Ti alloy[J]. Materials Science and Engineering, 2010, 28(4): 1-7.

[14] WEGRIA J, FOCT J. Structural aspects of the bendability of zinc-copper-titanium alloys[J]. Mem Sci Rev Metall, 1984, 81(3): 145-155.

[15] 毛卫民, 赵新兵. 金属的再结晶与晶粒长大[M]. 北京: 冶金工业出版社, 1997: 181-195.

MAO Wei-min, ZHAO Xin-bing. Recrystallization and grain growth of metal [M]. Beijing: Metallurgical Industry Press, 1997: 181-195.

(编辑 龙怀中)

基金项目:国家科技支撑计划资助项目(2009BAE71B00)

收稿日期:2010-08-25;修订日期:2010-11-22

通信作者:肖来荣,教授,博士;电话:0731-88830137;E-mail: xiaolr@mail.csu.edu.cn