文章编号:1004-0609(2007)09-1460-05

Al/Al2O3复合材料伪半固态触变模锻及强韧化

赵祖德1,程远胜2,朱世凤1,黄少东1

(1. 中国兵器工业第五九研究所,重庆 400039;

2. 哈尔滨工业大学 材料科学与工程学院,哈尔滨 150001)

摘 要:在半固态金属加工技术的基础上,提出伪半固态触变成形工艺。对该工艺制备的Al/Al2O3复合材料杯形件进行扫描电镜观察、抗弯强度以及断裂韧性测量。结果表明:伪半固态触变成形的制件具有三维连通的网状结构,界面结合紧密,37%Al/Al2O3(体积分数)复合材料杯形件抗弯强度为570~690 MPa,断裂韧性为8.5~16.8 MPa·m1/2,与其他成形工艺相比,力学性能有所提高;成形温度及压力、金属相体积分数对力学性能具有较大的影响。

关键词:Al/Al2O3复合材料;伪半固态触变成形;力学性能;杯形件

中图分类号:TG 376 文献标识码:A

Thixo-die-forging of Al/Al2O3 composite in pseudo-semi-solid state and toughening-strengthening

ZHAO Zu-de1, CHENG Yuan-sheng2, ZHU Shi-feng1, HUANG Shao-dong1

(1. No.59 Research Institute of China Ordnance Industry, Chongqing 400039, China;

2. School of Materials Science and Engineering, Harbin Institute of Technology, Harbin 150001, China)

Abstract:The thixoforming in pseudo-semi-solid state based on the semi-solid metal forming was proposed. The microstructure of the prepared Al/Al2O3 composite cup shell was observed by SEM, and bend strength and fracture toughness of this alloy were measured. The results show that the cup shell is of three-dimensional network structure and closely bounded interfaces. The bend strength and fracture toughness of 37% Al/Al2O3 (volume fraction) are about 570?690 MPa and 8.5?16.8 MPa·m1/2 respectively. The mechanical properties of the cup shell by this technology are improved compared with other forming technologies. The forming temperature, force and volume fraction of metal phase have great influence on mechanical properties.

Key words: Al/Al2O3 composite; thixoforming in pseudo-semi-solid state; mechanical property; cup shell

金属增韧的Al/Al2O3复合材料,在强度提高的同时塑性却大大降低,难以用普通的成形方法获得形状复杂的零件[1?2]。目前,国内外Al/Al2O3复合材料零件的制备主要采用粉末冶金方法[3?5]。本文作者在传统粉末成形及金属半固态成形工艺的基础上,提出了伪半固态触变模锻成形工艺(PSSP)。该工艺综合了粉末冶金和模锻成形两种工艺的特点,其液相烧结的动力不是来自液相表面张力和固?液界面张力,而是来自外加的机械压力[6?8]。

伪半固态触变模锻工艺的原理是将一定比例的金属微粒和陶瓷粉体均匀混合,在一定的压力作用下成形较致密的坯料,然后二次加热使温度达到基体的固态和增塑体液态区间,最终成形所要求的零件,实现增强(增塑)体体积分数的随意调节[9?10]。目前,对Al/Al2O3复合材料伪半固态触变模锻尚处于原理研究阶段,尤其是其伪半固态触变模锻热力参数对零件力学性能的影响、强韧化行为的研究还是空白[11?13]。为此,本文作者以Al/Al2O3复合材料杯形件为对象,对Al/Al2O3复合材料伪半固态触变模锻及强韧化进行了研究。

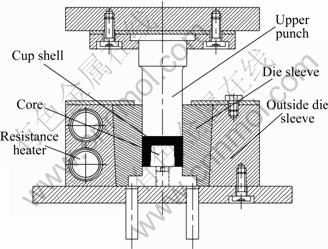

1 实验

实验选用的Al粉末为d 40 μm,粒度为14 mm,Al2O3粉末为d 120 nm,其主要化学成分如表1所示。利用XH?2型三维混粉机制备成形坯料,将37% Al/Al2O3(体积分数)复合粉末均匀混合15 h。然后在1000 kN万能油压机上,通过单向压制工艺制成d 56 mm?60 mm的冷压坯料。将制备好的伪半固态坯料放入电阻炉中二次加热,在伪半固态温度下保温 18 min;将加热的坯料夹持到模具温度为450 ℃的模膛内,选用2 000 kN液压机(实验装置如图1所示),选用30 mm/s成形速度并保压1 min,制备所需零件,如图2所示。

表1 Al2O3的化学成分

Table 1 Chemical composition of Al2O3 (mass fraction, %)

图1 Al/Al2O3复合材料杯形件伪半固态的触变模锻装置

Fig.1 Thixotropic die forging device of Al/Al2O3 composite cup shell in pseudo-semi-solid state

图2 伪半固态触变模锻成形Al/Al2O3复合材料杯形件

Fig.2 Al/Al2O3 composite cup shell by thixotropic die forging in pseudo-semi-solid state

2 结果与讨论

2.1 成形温度对力学性能的影响

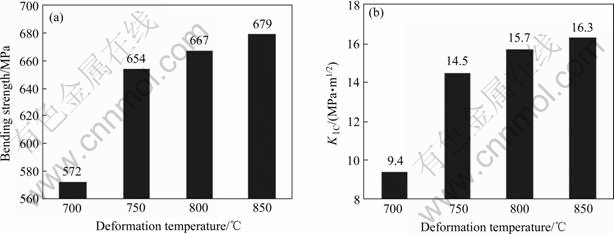

抗弯强度及断裂韧性的测试在Instron?1186电子万能材料试验机上完成。图3所示为成形压力480 MPa时,在不同的成形温度下,37%Al/Al2O3复合材料杯形件的抗弯强度及断裂韧性。从图中可以看出,抗弯强度和断裂韧性随着成形温度的升高而增加。这是因为随着温度的升高,材料的表面能越高,整个体系处在能量不稳定状态,流动单元无序化增大,流动应力减小,充填性增加,坯料容易致密化,提高了抗弯强度和断裂韧性。

图3 不同成形温度下37%Al/Al2O3复合材料杯形件的抗弯强度和断裂韧性

Fig.3 Bending strength(a) and fracture toughness(b) of 37%Al/Al2O3 composite cup shell at different deformation temperatures

Al/Al2O3复合材料低熔点Al相容易相互结合而形成网状结构,包围在高熔点颗粒的周围。随着成形温度的升高,液态金属的活性提高,使延性网状结构更加完整。在材料断裂过程中,裂纹不可能避开这个延性网状结构,因而有利于提高复合材料的断裂韧性。

2.2 成形压力对力学性能的影响

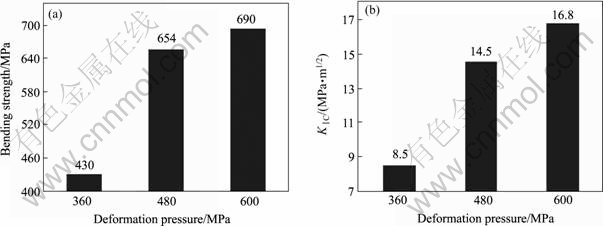

图4所示为成形温度为750 ℃时,37%Al/Al2O3复合材料杯形件在不同的成形压力下的抗弯强度及断裂韧性。可见,伪半固态触变模锻杯形件的抗弯强度和断裂韧性,随成形压力的增加而提高。这是因为成形压力的增加,使固相颗粒的滑动和转动容易进行,坯料中产生的等静压使界面结合也更加紧密,由金属相组成的延性网状结构更加完整,网径减小,提高了抗弯强度和断裂韧性。

图4 不同成形压力下37%Al/Al2O3复合材料杯形件的抗弯强度及断裂韧性

Fig.4 Bending strength(a) and fracture toughness(b) of 37%Al/Al2O3 composite cup shell under different deformation pressures

2.3 金属相体积分数对力学性能的影响

在成形温度为750 ℃,成形压力为480 MPa的条件下,23%、30%和37%Al/Al2O3复合材料杯形件的抗弯强度分别是320、560和654 MPa,断裂韧性分别是6.1、12.6和14.5 MPa·m1/2。可见,伪半固态触变模锻杯形件的抗弯强度及断裂韧性,随金属相体积分数的增加而提高。这是因为金属相体积分数的增加,保压过程中发生塑性变形及补缩的金属相也比较多,界面能提高,促使复合材料致密化和网状结构更加完整,从而提高了抗弯强度和断裂韧性。

2.4 界面润湿性对力学性能的影响

与未经过润湿性改善处理的Al/Al2O3复合材料触变成形零件的抗弯强度相比,经过润湿性改性处理的抗弯强度提高了约40%。在热压致密化温度下,由于Al/Al2O3界面的相互作用而促使润湿性改善。而且润湿性良好的Al/Al2O3复合材料成形坯料在触变模锻过程中,两相的流动协调性增强。润湿性不好的复合材料在触变模锻过程中,由于流动协调性不好而出现偏析,从而影响最终触变模锻成形零件。另外,通过添加合金元素,未参加界面反应的合金元素容易熔于液态金属而形成合金,有利于提高复合材料的力学性能。综上所述,通过改善界面润湿性,对提高复合材料强度的作用是非常明显的。

2.5 强韧化分析

目前,制备Al/Al2O3复合材料的工艺主要是高温直接氧化工艺和原位反应工艺等,与之相比,伪半固态触变模锻成形工艺制备的复合材料有很好的强度和断裂韧性。图5所示为不同成形工艺制备的37%Al/ Al2O3复合材料的力学性能比较[14?15]。伪半固态触变模锻工艺具有如此高的力学性能,是由其成形工艺特点决定的。

图5 不同工艺条件下制备的37%Al/Al2O3复合材料的力学性能

Fig.5 Mechanical properties of 37%Al/Al2O3 composites by different technologies: (a) Bending strength; (b) Fracture toughness (R—In situ reaction; L—High temperature oxidation; P—Pseudo semisolid)

1) 伪半固态触变模锻由于高压作用以及液态金属的存在,加强了高熔点颗粒材料的转动和滑动运动能力,坯料具有很好的流动充填能力,提高了复合材料的致密性。液态金属在高压作用下充填模腔并凝固结晶,晶粒比较细小,并产生压力补缩,致密性提高。而且,触变模锻成形过程中始终都有力的作用,界面结合紧密。

2) 金属铝将陶瓷粒子包围,形成了包围着陶瓷粒子的网状结构。微观裂纹在扩展通过三维连通的塑性网状金属相时,随着裂纹的扩展,金属相将发生塑性变形,在材料内部产生大量的裂纹桥连,消耗大量的断裂功,从而有利于提高Al/Al2O3复合材料的强度和断裂韧性。

2.6 组织分析

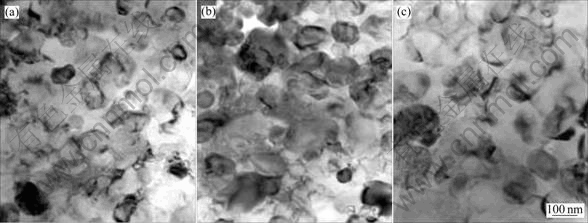

图6所示为成形温度为750 ℃,成形压力为480 MPa的条件下,37%Al/Al2O3复合材料伪半固态触变模锻成形杯形件,在CM12透射电子显微镜下不同位置处的微观组织。从图中可以看出,Al2O3固相颗粒约为d 120 nm,说明触变成形中的高熔点纳米相没有出现长大。Al2O3固相颗粒包裹着由Al组成的网状结构延性相,这一网状结构的形成,对提高复合材料的强度以及韧性十分有利。同时可以看出,微观组织中熔点较高的Al2O3固相颗粒与熔点较低的Al相之间结合比较紧密,致密性很好。

图6 37%Al/Al2O3复合材料杯形件不同位置处的微观组织

Fig.6 Microstructures of 37%Al/Al2O3 composite cup shell at different positions: (a) Upper; (b) Centre; (c) Underside

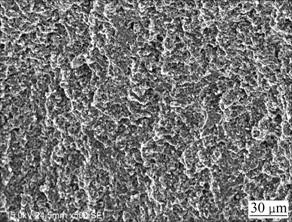

图7所示为成形温度为750 ℃,成形压力为480 MPa条件下,37%Al/Al2O3复合材料触变成形杯形件在S570扫描电子显微镜下的弯曲断口形貌。由金属相作为粘结相的Al/Al2O3复合材料断口的微观组织形貌,很显然为脆性断裂特征。同时,弯曲断口可以很清晰地观察到大量的微小韧窝和棱脊,说明复合材料存在一定的塑性。

图7 37%Al/Al2O3复合材料杯形件的断口形貌

Fig.7 Fracture surface of 37%Al/Al2O3 composite cup shell

3 结论

1) 在伪半固态触变模锻的Al/Al2O3复合材料的微观组织中,Al2O3颗粒没有发生长大现象,界面结合紧密且界面比较平滑,没有界面反应物出现,属于典型的脆性断裂。

2) 随着触变模锻成形温度、成形压力及金属铝相体积分数的升高,Al/Al2O3复合材料构件的抗弯强度及断裂韧性随之提高,复合材料的网状结构有利于提高成形件的力学性能。

3) 伪半固态触变模锻的Al/Al2O3复合材料相对其他成形工艺,具有较高的抗弯强度和断裂韧性。

REFERENCES

[1] 程晓敏, 周世权, 方华斌. Al2O3颗粒增强铝基复合材料的半固态搅熔复合[J]. 中国有色金属学报, 2001, 11(6): 61?64.

CHENG Xiao-min, ZHOU Shi-quan, FANG Hua-bin. Melt-stirred composing in semi-solid for Al2O3 particulate reinforced aluminium matrix composites[J]. The Chinese Journal of Nonferrous Metals, 2001, 11(6): 61?64.

[2] 栾佰峰, 姜龙涛, 孔海宽, 武高辉. 热挤压变形对亚微米Al2O3p/Al复合材料组织性能的影响[J]. 中国有色金属学报, 2003, 13(2): 55?59.

LUAN Bai-feng, JIANG Long-tao, KONG Hai-kuan, WU Gao-hui. Effect of hot extrusion deformation on microstructure and mechanical properties of sub-micro Al2O3p/Al composite[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(2): 55?59.

[3] 唐靖林, 曾大本. 半固态加工技术的发展和应用现状[J]. 兵器材料科学与工程, 1998, 21(3): 56?58.

TANG Jing-lin, ZENG Da-ben. Development and applications of semisolid metal forming[J]. Ordnance Material Science and Engineering, 1998, 21(3): 56?58.

[4] 郭瑞松, 崔一强, 杨正方, 袁启明, 陈玉如. 氧化铝复合陶瓷烧结工艺研究与力学性能改善[J]. 无机材料学报, 1998, 13(2): 239?242.

GUO Rui-song, CUI Yi-qiang, YANG Zheng-fang, YUAN Qi-ming, CHEN Yu-ru. Sintering and properties improvement of alumina composites[J]. Journal of Inorganic Materials, 1998, 13(2): 239?242.

[5] 张希华, 张建华, 刘长霞. 氧化铝基陶瓷材料增韧研究现状及其发展方向[J]. 山东大学学报(工学版), 2004, 34(5): 14?17.

ZHANG Xi-hua, ZHANG Jian-hua, LIU Chang-xia. An overview and prospect of toughening research on alumina matrix ceramic material[J]. Journal of Shandong University (Engineering Science), 2004, 34(5): 14?17.

[6] DU Zhi-ming, CHENG Yuan-sheng, ZHAO Jiu-zhou. Thixoforming of spray deposited AlZn12Cu2Mg2 wrough aluminum alloy in semi-solid state[J]. Trans Nonferrous Met Soc China, 2005, 15(S2): 152?156.

[7] LUO Shou-jing, CHENG Yuan-sheng, DU Zhi-ming. Ceramics matrix composite thixoforming in pseudo-semisolid state[J]. Trans Nonferrous Met Soc China, 2004, 14(8): 1286?1294.

[8] LUO Shou-jing, ZU Li-jun. Influence of strain rate, volume fraction of liquid and liquid viscosity on the force of semi-solid metal forming[J]. Trans Nonferrous Met Soc China, 2000, 10(6): 192?197.

[9] CHENG Yuan-sheng, DU Zhi-ming, LUO Shou-jing. Rheological behavior of Al2O3n/Alm composites in pseudo-semi-solid state[J]. Trans Nonferrous Met Soc China, 2005, 15(S2): 142?146.

[10] LUO Shou-jing, CHENG Yuan-sheng, DU Zhi-ming. Thixoforming of SiC ceramic matrix composites in pseudo-semi-solid state[J]. Trans Nonferrous Met Soc China, 2005, 15(5): 1062?1066.

[11] CHENG Yuan-sheng, LUO Shou-jing, DU Zhi-ming. Pseudo-semi-solid thixoforming of ceramic matrix composite[C]//Proceedings of the 8th Esaform Conference on Material Forming. Roumania: Cluj-Napoca, 2005: 1091?1094.

[12] DU Zhi-ming, CHENG Yuan-sheng, LUO Shou-jing. High volume fraction Al2O3/Al composites thixoforming in pseudo-semi-solid state[J]. Solid State Phenomena, 2006, 116/117: 725?729.

[13] LUO Shou-jing, CHENG Yuan-sheng, WANG Peng-xiang. Pseudo-semi-solid thixoforming of cup shell with Al/Al2O3 [J]. Trans Nonferrous Met Soc China, 2006, 16(4): 772?775.

[14] Sigl S L, Mataga P A, Dalgleish B J, Meeking R M, Evans A E. On the toughness of brittle materials with a ductile phase[J]. Acta Metall, 1988, 36(4): 945?953.

[15] Flinn B, Ruhle M, Evans A G. Toughening in composites of Al2O3 reinforced with Al[J]. Acta Metall, 1989, 37(4): 3001?3006.

基金项目:国家自然科学基金资助项目(50375035)

收稿日期:2007-01-10;修订日期:2007-04-17

通讯作者:赵祖德,研究员;电话:023-68792238;E-mail: cqzzd@163.com

(编辑 李向群)