J. Cent. South Univ. Technol. (2008) 15(s1): 429-433

DOI: 10.1007/s11771-008-393-0

Rheological property of low-damage, ideal packing, film-forming amphoteric/sulfonation polymer drilling fluids

ZHANG Hong-xia(张洪霞), YAN Jie-nian(鄢捷年), SHU Yong(舒 勇), ZHAO Sheng-ying(赵胜英)

(Ministry of Education Key Laboratory of Petroleum Engineering, China University of Petroleum (Beijing),

Beijing 102249, China)

Abstract: Low-permeability dense reservoirs, including micro-fractured reservoirs, are commonly characterized by high content of clay substances, high original water saturation, high sensitivity to invasive fluids, high capillary pressure, complicated structure and anisotropic, high flow-resistance and micro pore throats etc,. Generally they also have lots of natural micro fractures, probably leading to stress sensibility. Main damaging factors in such reservoirs are water-sensibility and water-blocking caused by invasive fluids during drilling and production operations. Once damaged, formation permeability can rarely recovered. Numerous studies have shown that damaging extent of water-blocking ranges from 70% to 90%. Main damaging mechanisms and influencing factors of water-blocking were systematically analyzed. Also some feasible precaution or treating approaches of water-blocking were put forward. In a laboratory setting, a new multi-functional drilling fluid composed mainly of amphion polymer, sulfonation polymer, high effectively preventive water-blocking surfactants, ideal packing temporary bridging agents (TBA) and film-forming agents, etc., were developed. New low-damage drilling fluids has many advantages, such as good rheological properties, excellent effectiveness of water-blocking prevention, good temporary plugging effect, low filtration and ultra-low permeability (API filtration≤5 mL, HTHP filtration≤10 mL, mud cake frictional coefficient≤0.14, permeability recovery>81%), can efficiently prevent or minimize damage, preserve natural formation and enhance comprehensive development-investment effect in TUHA Jurassic dense sandstone reservoir formation with low-permeability, the only one developing integrated condense gas field. Some references can be provided to similar reservoir formations.

Key words: low-permeability dense gas condense reservoir; amphion and sulfonation polymer drilling fluid; damage controlling; water-blocking; ideal packing theory (IPT); film-forming agent; rheological properties

1 Introduction

Low-permeability dense sandstone reservoirs are generally characterized by complicated structure and anisotropic, high flow-resistance, high original water saturation, high sensitivity to invasive fluids, high capillary pressure, etc. Main damaging types in such reservoirs are water sensibility and water-blocking caused by invasive fluids during drilling and production operations. Numerous studies have shown that damaging extent of water-blocking ranges from 70% to 90%[1-5]. Once damaged, formation can rarely be recovered. In this work, geological characteristics and potential damages of target Jurassic formation were analyzed, a new multi-functional drilling fluids system was developed by usage of preventive water-blocking surfactants, ideal packing TBA, film-forming agents etc. Its rheological property, inhibition, compatibility and regained permeability were experimentally evaluated. Both lab-evaluation and field tests have shown that new low-damage amphion, sulfonation polymer drilling fluid are suitable for low-permeability dense gas reservoir in China′s Tuha oilfield.

2 Geological characteristics and potential damages

In target Jurassic formation of Qiudong oil production, main lithology is fine/mid-fine sand; porosity ranges from 11.9% to 13.5%; permeability ranges from 0.08×10-3 to 13.6×10-3 μm2; Radii of pore throat ranges from 0.1 to 1.0 μm, average is 0.28 μm, micro-fine pore throats are main types; many micro fractures play a leading role in seepage flow, basically no capacity of storage, and yet no features of double pore medium. In short, target formation can be distinguished as typical low-permeability, micro-porosity, dense formation. Fracturing is main operation for enhancing oil-gas recovery during production.

Based on geological characteristics and lab evaluation, main potential damaging factors or existing problems can be summarized as follows: (1) sensibility evaluation of cores taken from well QD3 (depth 3 105.0-3 141.5 m) shows that main potential sensitivity damages are mid-high flow rate, light salt, acid, alkali sensibility respectively. (2) Permeability and skin factor are high before and after wells are put into production, indicating that formation had been contaminated before wells are put into operation. For instance, well QD3, in the early period and after stabilizing for 20 d, permeabilities are 1.45×10-3 and 2.93×10-3 ?m2, respectively, skin factors are 25.4 and 19.6, respectively. What is more, such damage will not be eliminated during production. (3) Permeability recovery of well-site drilling fluid is evaluated. Experimental results are 56.6% and 51.4%, respectively. However, generally speaking, permeability recovery of drilling fluids is over 70%. (4) Clay content of target formation is 12.74%, among them relative contents of illite/smectite, chlorite, carbonate, kaolinite and illite are 12.6%, 31.9%, 3.5%, 36.1% and 19.4%, respectively. In addition, due to that target formation belongs to low-permeability, micro-pore throat has lots of micro fractures. Water sensibility and water blocking can easily be induced by invasive fluids at micro-pore throats and by seep space with big and small size. As a result, limited seepage flow channels are blocked, and oil-gas production are also restricted.

3 New low-damage, multi-functional drilling fluids

The first step of systemic formation protection is to prevent formation from damaging during drilling operations. Once opened, formations firstly are soaked in drilling fluids, even soaking duration is prolonged because of well depth, circulation loss, drill pipe sticking and well collapse. Consequently water sensibility and water blocking are easily induced by invasive fluids, resulting in big-extent damage. Therefore, drilling fluids should have good properties, such as strong inhibit, low filtration and water-blocking prevention, suitable density (nearly balance/under balance drilling operations).

Based on current drilling technology and known damage factors in low-permeability Jurassic formation[5-9], guidelines to develop new drilling fluids include: (1) selecting effective surfactants to minimize filtration and water-blocking; (2) adopting three kinds of amphion polymer with different molecular masses to substitute macromolecule polymer KPAM so as to further develop drilling fluids property; (3) selecting compound TBA by adopting technology of Ideal Packing Theory (IPT) to form thinner, tighter mud cake and achieve good temporary plugging effect; (4) selecting film-forming agents to further improve inhibition of drilling fluids. The final formulation of drilling fluids formed by above guidelines or techniques should have good rheological property and compatibility with characteristics of target formation, as well as meet requirement of safe density window during drilling operations.

3.1 Optimization of basic formulation

Amphion polymer, FA-367, JT-888 and XY-27, were optimized as main additives in drilling fluids, their concentration were determined by adopting orthogonal experimental method ). Basic formulation of drilling fluids was optimized as follows (formulation 1): 3% bentonite+0.3% FA-367+0.6% JT-888+0.1% XY-27 +1.5% SMP-1+1.5%SPNH, its rheological parameters were measured and shown in Table 1. Experimental results show that relatively reasonable rheological properties are achieved. Next step was to minimize API and HTHP filtration through technology of film-forming and ideal packing TBA.

). Basic formulation of drilling fluids was optimized as follows (formulation 1): 3% bentonite+0.3% FA-367+0.6% JT-888+0.1% XY-27 +1.5% SMP-1+1.5%SPNH, its rheological parameters were measured and shown in Table 1. Experimental results show that relatively reasonable rheological properties are achieved. Next step was to minimize API and HTHP filtration through technology of film-forming and ideal packing TBA.

Table 1 Rheological propertie s under basic formulation 1

3.2 Selection of surfactants

Based on Young-Laplace′s equation and Bennion′s prediction formula, water-blocking damage is mainly related to core permeability, porosity, initial water saturation and oil/gas interface tension, also related to formation lithological characteristics, types and content of cementation substances, porosity structure and property of invasive fluids.

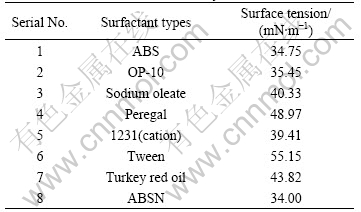

Effective surfactants can markedly minimize surface tension/oil-gas interfacial tension of filtration. Surface tension of eight commonly surfactants were tested and shown in Table 2. Experimental results show that ABSN and OP-10 can effectively reduce surface tension, and were recommended as preventive water- blocking agents in drilling fluids. ABSN may be probably formed precipitation while concentration of Ca2+ is high in formation brine, OP-10 can be used to substitute, concentrations of both surfactants are all recommended as 0.4%.

Table 2 Surface tension of commonly used surfactants

3.3 Selection of film-forming agents

Ultra low-permeability film-forming agents are key factor of film-forming technology. FLC2000 and CMJ-2, widely used film-forming agents, were selected and used for lab optimizing experiments. These products are mainly composed of plant-derivatives mixture, water-solution or part water-solution compound organic polymer and metal oxide, having relatively high-temperature stability, maintain is simple and environmental pollution is small.

3.3.1 Impact of film-forming agents on drilling fluids

After adding two kinds of film-forming agents into drilling fluids (formulation 1) for 24 h, and aging at 120 ℃ for 16 h, then rheological property was measured and shown in Table 3, indicating that relatively lower filtration can be achieved after adding two film-forming agents to drilling fluids, and has little impact on rheological parameters of drilling fluids.

Table 3 Impact of film-forming agents on drilling fluids

3.3.2 Dynamic filtration tests

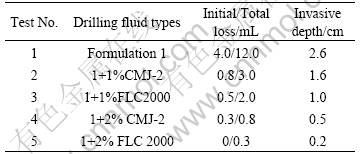

Simulated cores by rustless steel slot plate (width was 50 μm) was set up in clamp holder of HPHT filtration apparatus, filtration change of drilling fluids along with time was measured at 90 ℃ and shown in Table 4. Experimental data show that initial loss and total loss are nearly zero filtration. Considering cost and transportation, CMJ-2 is recommended as film-forming agent in drilling fluids and its concentration is recommended as 2%.

Table 4 Filtration of simulated rustless steel slot plate cores

3.4 Selection of temporary bridging agents (TBA)

Based on relationship between TBA particle size distribution (PSD) and pore throats size distribution, d90 of TBA was determined by adopting IPT[5], d90 rule[6] and corresponding matching intellectualized software, and considering shearing and abrasion of TBA in annulus between drilling string and well bore hole, finally compound ideal packing TBA (different mesh calcium carbonate) was determined, selection result is as follows: 20 μm (10%), 19 μm (40%), 14 μm (50%), shown in Fig.1.

Fig.1 Optimizing curve of ideal packing temporary bridging agents particle size distribution

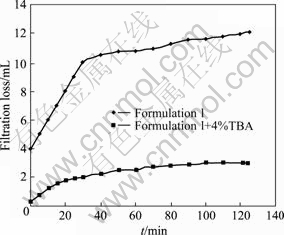

Rheological parameters and dynamic loss of drilling fluids were measured after adding optimizing TBA and shown in Table 5 and Fig.2. As can be seen that rheological parameters are reasonable and filtration is further minimized, total loss is minimized from 12 mL to 4 mL, especially initial instantaneous loss is dramatically reduced, illustrating obvious formation protection effect is achieved. Concentration of ideal packing TBA in drilling fluids is recommended as 4%.

3.5 Evaluation of new low-damage drilling fluids

Based on above optimizing results, new low- damage drilling fluids system (formulation 2) is as follows: 3% bentonite+0.3% FA-367+0.6% JT-888+0.1% XY-27 +1.5%SMP-1 + 1.5% SPNH + 0.4% ABSN + 2% CMJ-2+4% ideal packing TBA (adding 0.5%-1% oil-soluble resin can further improve temporary bridging effect).

Table 5 Ideal packing TBA and its impact on drilling fluids

Fig.2 Dynamic loss of ideal packing TBA drilling fluids

3.5.1 Rheological property

Rheological properties of drilling fluids (weighing and no-weighting by BaSO4 respectively) were evaluated. Experimental results indicate that new drilling fluids system have good high-temperature stability, API and HPHT loss is less than 5 mL and 10 mL, respectively, frictional coefficient is less than 0.141, and lubrification and inhibition can all meet requirement of drilling-in in low-permeability formation.

3.5.2 Compatibility with formation rocks and fluids

Taking certain 2-3.5 mm rock cuttings mixed with new drilling fluids, aged at 120 ℃ for 16 h, then rock cuttings recovery was measured and all is over 99% after screened by 420 μm, illustrating new drilling fluids have good compatibility with formation rock. Also mixing drilling fluids with simulated formation brine in different proportions and no flocculation, chemical reaction and precipitate formed, indicating good compatibility with formation brine is achieved. Shape and size of rock cuttings have no obviously change during above experiments.

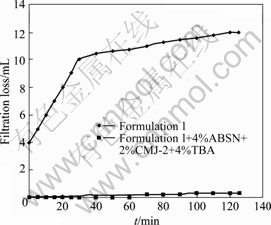

3.5.3 Evaluation of formation damage of new drilling completion fluids

JHMF-2 dynamic damage experimental apparatus and cores taken from low-permeability target formation, well was QD-3, well depth was 3 105.0-3 141.5 m, were used for dynamic damage evaluation of new drilling fluids, experiment was conducted at simulated well-site formation conditions, temperature was 90 ℃, contaminated differential pressure was 3.5 MPa, shearing rate was 150 s-1, experimental results are shown in Table 6 and Fig.3. Experimental results illustrate that dynamic permeability recovery is obviously improved and can reach 82.8% and 81.0%, respectively (well-site drilling fluids formulation are 56.6% and 51.4%, respectively) after adding optimizing film-forming and ideal packing TBA in drilling fluids, dynamic loss is low, initial loss is nearly zero loss and good film-forming effect is basically achieved.

Table 6 Dynamic damage of new low-damage drilling fluids

Fig.3 Dynamic damage curve of low-damage drilling fluids

4 Conclusions

1) Water blocking is main damaging factor for low-permeability reservoir formation, damaging extent ranges from 70% to 90%. Once damaged, formation permeability can rarely recovered, low-permeability formation with low-pressure can be even more badly damaged.

2) Main influencing factors of water blocking include core permeability, porosity, original water saturation and oil/water interfacial tension, and lithology characteristics, types and content of cementing substances, pores structure, and properties of invasion fluids, etc.

3) New multifunctional low-damage drilling fluids composed of ideal packing TBA, film-forming agents, water-blocking prevention surfactants have many advantages, such as good compatibility with target formations, high permeability recovery, low filtration (nearly zero loss), small friction coefficient, reasonable rheological parameters etc.

References

[1] LIN Guang-rong, SHAO Chuang-guo, XU Zheng-feng. Fluid damage and solution method study of low permeability gas reservoir [J]. Petroleum Exploration and Development, 2003, 30(6): 117-118.

[2] REN Xiao-juan, ZHANG Ning-sheng, ZHANG Xi-feng, et al. Damage of residual water on permeability of tight gas reservoir [J]. Natural Gas Industry, 2004, 24(11): 106-108.

[3] BENNION D B, THOMAS F B, MA T. Formation damage processes reducing productivity of low permeability gas reservoirs [J]. SPE, 60325.

[4] ERWOM M D, RIERSOM C R, BENNION D B. Brine imbibition damage in the Colville River Field, Alaska [J]. SPE, 84320.

[5] BENNION D B, THOMAS F B, BIETZ R F, et al. Remediation of Atr and hydrocarbon phase trapping problems in low permeability gas reservoirs [J]. Journal of Canadian Petroleum Technology, 1999, 38(8): 39-48.

[6] CUI Ying-chun, ZHANG Yan. Characteristic of formation damage in low permeability reservoir [J]. Drilling Fluid and Completion Fluid, 1998, 15(2): 11-13.

[7] ZHANG Qian, DU Jian-fen, CUI Li-chun, et al. Study on stress sensibility of the reservoir rock in Sulige gas oilfield [J]. Drilling Fluid and Completion Fluid, 2006, 23(5): 29-30.

[8] ZHANG Jin-bo, YAN Jie-nian. New theory and method for optimizing the particle size distribution of bridging agents in drilling fluids [J]. Acta Petrolei Sinica, 2004, 25(6): 88-91.

[9] PU Xiao-lin, LEI Gang, LUO Xing-shu, et al. Study on membrane theory and film-forming drilling fluid [J]. Drilling Fluid and Completion Fluid, 2005, 22(6): 1-4.

(Edited by YANG Hua)

Foundation item: Project(50574061) supported by the National Natural Science Foundation of China

Received date: 2008-06-25; Accepted date: 2008-08-05

Corresponding author: ZHANG Hong-xia, Doctor candidate; Tel: +86-10-83793893; E-mail: zhanghongxia919@sina.com