DOI:10.19476/j.ysxb.1004.0609.2017.11.01

固溶时效工艺对2297铝锂合金微观组织和力学性能的影响

李红英1, 2, 3, 4,王小雨1, 2,余玮琛1, 2

(1. 中南大学 材料科学与工程学院,长沙 410083;

2. 中南大学 有色金属材料科学与工程教育部重点实验室,长沙 410083;

3. 中南大学 有色金属先进结构材料与制造协同创新中心,长沙 410083;

4. 轻质高强结构材料重点实验室,长沙 410083)

摘 要:通过扫描电镜(SEM)、透射电镜(TEM)和拉伸性能测试等方法系统研究固溶和时效工艺对2297铝锂合金组织和性能的影响。结果表明:实验合金较为适宜的固溶制度为((535±5) ℃,1.5 h),基体中的第二相得到比较充分的溶解,同时抑制再结晶晶粒长大。T6态的主要强化相为T1相和θ′相,T8态的主要强化相为T1相,时效前的预变形可以促进T1相的形成,提高合金的强度峰值,缩短合金达到峰值的时间,160 ℃时效后,未经预变形的合金的强度峰值为392 MPa,到峰时间为48 h,变形量为7%时,合金的强度峰值最高,达到482 MPa,到峰时间为23 h。

关键词:2297铝锂合金;固溶;时效;微观组织;力学性能

文章编号:1004-0609(2017)-11-2187-08 中图分类号:TG166.2 文献标志码:A

Al-Cu-Li合金具有比强度和比刚度高、疲劳裂纹扩展速率低等优点,其制备成本比复合材料低,因此是很有竞争力的轻质高强结构材料,广泛应用于航空航天飞行器的结构件[1-3]。问世至今,铝锂合金经历了4个发展阶段,相应研制出了4代铝锂合金,目前,航空航天领域正在应用第3代铝锂合金[4-5]。第3代铝锂合金和正在发展的第4代铝锂合金不再片面追求低密度,通过适当的微合金化及固溶时效改善其综合性能,既能实现结构减重,又能达到较好的强韧性平衡及良好的耐损伤性能[6-8]。Al-Cu-Li合金经固溶处理后将合金元素溶解到基体中,淬火后得到过饱和固溶体,合金元素的固溶度和晶粒尺寸等因素对后续的时效行为会产生影响[9-12]。Al-Cu-Li系合金的时效强化相包括δ′(Al3Li)、θ′(Al2Cu)、T1(Al2CuLi)相等[13],其析出顺序受Cu/Li比的影响,其形状、尺寸、数量、分布等对合金的性能产生较大影响。GAO等[14]研究预变形量对铝锂合金的影响时发现,无预拉伸的合金存在δ′和T1两种强化相,随着预变形的增加,合金中出现了少量S′相,拉伸强度逐渐升高。孙刚等[15]研究热处理对2A97铝锂合金组织与性能影响时发现,高温时效初期,细小δ′相的回溶会导致铝锂合金的硬度下降,出现回归现象,随着时效时间继续增加,合金的硬度上升。袁志山等[16]研究2A97合金时效行为时发现,经165 ℃时效18 h后,基体中形成较多的θ′′相、δ′相和分布不均匀的T1相,使得合金强度和塑性较高。2297合金与2A97合金一样属于Al-Cu-Li系合金,是在航空航天领域具有广泛应用前景的第3代铝锂合金,但目前对于2297合金的研究报道较少。因此,本文作者研究固溶时效制度对2297铝锂合金组织和力学性能的影响,探讨其影响机理和确定适宜的固溶时效工艺,为提高合金的综合性能提供理论依据及实验指导。

1 实验

实验材料为2297合金的冷轧板材,化学成分如表1所示。在盐浴炉中进行固溶处理,温度误差在±1 ℃以内,固溶温度分别为505、520、535和550 ℃,保温时间为0.5~2 h,固溶后立即室温水淬,转移时间不超过5 s。分别对实验合金进行T6和T8时效处理,时效温度为160 ℃,时效时间为4~64 h,时效前分别进行2%、5%、7%的预变形。

采用小负荷维氏硬度仪测试实验合金时效后的硬度,载荷质量为1 kg,加载时间为30 s,每个试样取5点平均值。采用万能拉伸试验机进行常规拉伸试验,获得实验合金经不同时效处理后的抗拉强度、屈服强度和伸长率数据。采用Sirion200扫描电镜对样品进行二次电子扫描分析,主要观察实验合金拉伸断口形貌。采用TECNAIG220型透射电镜观察时效析出相的形貌、尺寸和分布。

表1 2297合金化学成分表

Table 1 Chemical composition of 2297 alloy (mass fraction, %)

2 结果与分析

2.1 固溶组织

图1所示为实验合金分别在不同固溶温度保温

1.5 h后的显微组织照片,图1(a)、(c)、(e)和(g)为金相照片,图1(b)、(d)、(f)和(h)为SEM像。由金相照片可以看出,几种温度下的合金都发生不同程度的再结晶。经505 ℃固溶处理的实验合金的晶粒较为细小,随着固溶温度的升高,再结晶晶粒逐步长大,当固溶温度超过535 ℃后,再结晶晶粒明显粗化。由SEM像可以看出,随着固溶温度升高,基体中第二相逐渐减少,当固溶温度升高至535 ℃时,残留第二相的数量相对较少,进一步提高固溶温度至550 ℃时,残留第二相的数量及尺寸没有明显的变化。综上可知,实验合金适宜的固溶温度为535 ℃,基体中的第二相得到较充分的溶解,同时合金的晶粒度适中。

OM image SEM image

图1 不同温度下固溶的OM像与SEM像

Fig. 1 OM and SEM images of 2297 alloy after solution treatment at different temperatures

图2所示为实验合金在535 ℃固溶不同时间后的显微组织照片,图2(a)、(c)、(e)和(g)为金相照片,图2(b)、(d)、(f)和(h)为SEM像。由图2(a)可以看出,固溶0.5 h后,晶粒较为细小;随着固溶时间的延长,晶粒尺寸逐渐增大;当固溶时间超过1.5 h后,如图2(e)和(g)所示,晶粒明显粗化。由SEM像可以看出,固溶0.5 h后,实验合金存在较多的残留第二相粒子,随着固溶时间的延长,残留第二相的数量逐渐减少,当固溶时间延长至1.5 h时,残留第二相的数量较少;当固溶时间进一步延长至2 h时,固溶效果没有明显提高。综上可知,在535 ℃固溶保温1.5 h为实验合金适宜的固溶制度。

OM image SEM image

图2 合金经不同固溶时间后的OM像和SEM像

Fig. 2 OM and SEM images of 2297 alloy after solution treatment for different time

2.2 时效组织分析

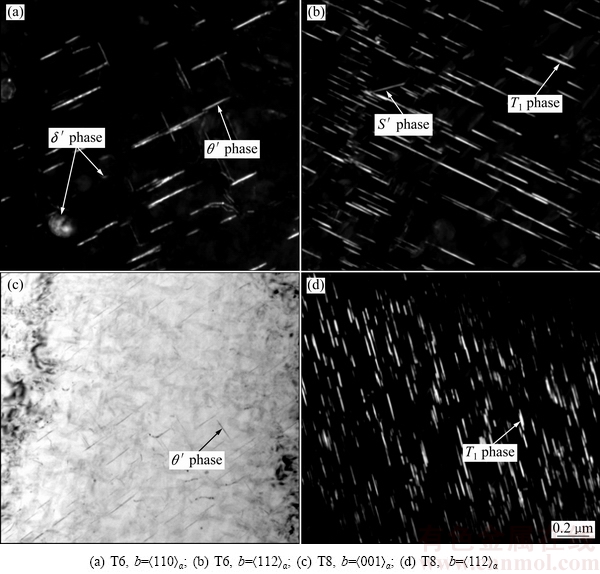

在2297合金中,球状的δ′相与基体共格,具有有序的LI2型超点阵结构,产生有序强化,但容易引起位错塞积,降低合金的韧性。θ′相是一种与基体半共格的亚稳相,形貌通常呈针状或盘片状,其从θ′′相→θ′相→θ相的演变可以使合金出现峰值应力。T1相为不可切割的脆性析出相,呈六角形板条状,通过位错绕过机制使合金强度增加[17-18]。图3所示为实验合金在不同时效状态下的TEM像,图3(a)和(b)对应T6峰值时效态,图3(c)和(d)对应T8状态。T6峰值时效的析出相为δ′相、θ′相、T1相和S′相,其中θ′相和T1相的体积分数较高,而δ′相和S′相的数量较少,表明T1相θ′相有较好的强化效果。在图3(c)和(d)中没有观察到δ′相和S′相,且θ′相数量明显减少,基体中弥散分布了大量细小的T1相,说明实验合金在T8态下的强化相以T1相为主。这是由于实验合金在时效前引入了一定量的冷变形,产生大量的位错和变形带,为T1相提供形核位置和变形储能,增加了T1相的形核率,改善了T1相的析出和分布情况。同时,由于T1相大量形核,消耗了基体中的Cu、Li原子,抑制或减少了δ′相、S′相和θ′相析出。

图3 不同热处理后实验合金的TEM像

Fig. 3 TEM images of 2297 alloy after different heat treatments

图4 实验合金拉伸试样断口形貌

Fig. 4 Fracture surface morphologies of 2297 alloy after different heat treatments

T8态实验合金θ′相的数量明显减少有两个原因:一方面,预变形有促进T1相形核的作用,T1相会优先于θ′相在位错等缺陷处形核;另一方面,由于时效初期θ′相和T1相互相之间争夺Cu原子,峰时效阶段T1相通过消耗θ′相获得Cu原子,从而使θ′相溶解,导致θ′相的体积分数减少[19],因此随着时效时间的延长,合金中的θ′相逐渐减少,且与T6态相比T8态的θ′相数量更少。

图4所示为实验合金在不同时效状态下的拉伸断口形貌。图4(a)和(b)对应T6峰值时效态,断口形貌表现为穿晶断裂和沿晶断裂的混合型断口,可以看到少量的韧窝,但韧窝的深度较浅,尺寸不大。图4(c)和(d)对应T8态,断裂方式主要为穿晶韧性断裂,断口的韧窝数量较多,可以观察到尺寸较大且较深的韧窝,表现出较好的韧性。

2.3 时效性能分析

图5所示为实验合金分别经0(未经过预变形)、2%、5%、7%预变形后在160 ℃时效不同时间的时效硬化曲线。由图5可以看出,随时效时间延长,硬度逐渐升高,达到峰值后逐渐下降。随着预变形量的增加,合金峰值硬度明显提高,且达到峰值的时间逐渐缩短。时效初期,实验合金形成GP区和细小弥散的δ′相,随着时效时间的延长,会析出θ′′相、T1相和少量的θ′相,且含量逐渐升高,合金强度逐渐增大。当合金的硬度达到峰值以后,细小弥散的T1相逐渐粗化,θ′′相会转化为θ′相,最后逐渐转变成平衡θ相[20-21],同时,晶界附近的无沉淀析出带变宽,导致合金硬度下降。

图5 不同预变形量的实验合金在160 ℃的时效硬化曲线

Fig. 5 Aging curves of 2297 alloy with different pre-deformation aged at 160 ℃

图6 实验合金时效后力学性能随时效时间的变化曲线

Fig. 6 Tensile properties of 2297 alloy by heat treatment with different pre-deformation after aging

图6所示为实验合金时效后的力学性能随时效时间的变化曲线。由图6可以看出,随着预变形量的增加,合金的屈服强度和抗拉强度逐渐增加,且达到峰值强度的时间越来越短,伸长率逐渐减小,相比T6态,T8态合金的强度明显提高。不进行预变形处理的合金在160 ℃时效的强度峰值为392 MPa;到峰时间为48 h,当变形量为7%时,合金的强度峰值最高,达到482 MPa,到峰时间为23 h。

时效前引入一定量的冷变形,可以产生大量位错和形变带,为T1和θ′强化相提供形核位置和变形储能,增加T1相和θ′相的形核率,促进强化相析出并改善其分布情况[22]。随着预变形量从2%增加到7%,实验合金的位错密度逐渐增大,形成的强化相尺寸逐渐变小,分布更加均匀,合金强度峰值越来越高,且到峰时间逐渐缩短,说明时效前的预变形对合金强化有显著作用。析出相的形状和取向都会影响铝合金的强化效果,基体位错柏式矢量在平面{111}α上,板状T1相以{111}α为惯析面析出,引起的临界分切应力较大,盘状θ′相以{100}α为惯析面析出,产生的临界分切应力要小于T1相,因而其强化效果不如T1相的明显[23-25]。从透射电镜照片可以看出,相比T6态,T8态析出了大量的T1相,且随着预变形量从2%增加到7%,合金中T1相的数量逐渐增加,故与前几种实验条件相比,预变形量为7%时合金的强度最高。

3 结论

1) 固溶温度和时间对2297铝合金的组织和性能都有较大的影响,实验合金适宜的固溶工艺为535 ℃保温1.5 h,在该条件下固溶,基体中的第二相数量明显减少,且再结晶晶粒尺寸适中。

2) T6状态的主要强化相为T1相和θ′相,T8状态的主要强化相为T1相,实验合金的断裂形式为混合型断裂,T8态以韧性断裂为主。

3) 时效前的预变形可以缩短2297铝合金达到强度峰值的时间,并提高峰值强度;未经预变形的合金在160 ℃时效达到强度峰值的时间为48 h,强度峰值为392 MPa;相应的预变形量为7%的合金达到强度峰值的时间为23 h,强度峰值为482 MPa,提高了90 MPa。

REFERENCES

[1] 魏修宇, 谭澄宇, 郑子樵, 李劲风, 李 海, 李艳芬. 时效对2195铝锂合金腐蚀行为的影响[J]. 中国有色金属学报, 2004, 14(7): 1196-1200.

WEI Xiu-yu, TAN Cheng-yu, ZHENG Zi-qiao, LI Jin-feng, LI Hai, LI Yan-fen. Influence of aging on corrosion behavior of 2195 Al-Li alloy[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(7): 1196-1200.

[2] LEQUEU P. Advances in aerospace aluminum[J]. Advanced Mater and Processes, 2008, 12(2): 47-49.

[3] 张振强, 许晓静, 宋 涛, 张允康, 罗 勇, 吴 瑶, 邓平安. 2099铝锂合金挤压材的组织与力学性能[J]. 中国有色金属学报, 2013, 23(4): 964-969.

ZHANG Zhen-qiang, XU Xiao-jing, SONG Tao, ZHANG Yun-kang, LUO Yong, WU Yao, DENG Ping-an. Microstructure and mechanical properties of 2099 Al-Li alloy extrusion materials[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(4): 964-969.

[4] 杨守杰, 陆 正, 苏 彬, 戴圣龙, 刘伯操, 颜鸣皋. 铝锂合金研究进展[J]. 材料工程, 2001, 5(4): 44-47.

YANG Shou-jie, LU Zheng, SU Bin, DAI Sheng-long, LIU Bo-cao, YAN Ming-gao. Development of aluminum-lithium alloys[J]. Journal of Materials Engineering, 2001, 5(4): 44-47.

[5] WILLIAMS J C, STARKE J E. Progress in structural materials for aerospace systems[J]. Acta Materialia, 2003, 51(5): 5775-5799.

[6] 范春平, 郑子樵, 贾 敏, 钟继发, 程 彬, 李红萍, 吴秋萍. 2397铝锂合金显微组织、拉伸性能和断裂韧性研究[J]. 稀有金属材料与工程, 2015, 44(1): 92-95.

FAN Chun-ping, ZHENG Zi-qiao, JIA Min, ZHONG Ji-fa, CHENG Bin, LI Hong-ping, WU Qiu-ping. Microstructure, tensile property and fracture toughness of 2397 Al-Li alloy[J]. Rare Metal Materials and Engineering, 2015, 44(1): 92-95.

[7] WARNER T. Recently-developed aluminum solutions for aerospace applications[J]. Materials Science Forum, 2006, 519(521): 1271-1278.

[8] MUKHOPADHYAY A K. High strength aluminum alloy for structural application[J]. Metals Materials and Processes, 2007, 119(1): 1-26.

[9] 刘胜胆, 张新明, 黄振宝, 杜予晅, 周卓平. 固溶处理对高纯7055铝合金组织的影响[J]. 材料热处理学报, 2006, 27(3): 54-59.

LIU Sheng-dan, ZHANG Xin-ming, HUANG Zhen-bao, DU Yu-xuan, ZHOU Zhuo-ping. Effect of solution treatment on microstructure of 7055[J]. Transactions of Materials and Heat Treatment, 2006, 27(3): 54-59.

[10] ROBSON J D. Optimizing the homogenization of Zirconium containing commercial aluminium alloys using a novel process model[J]. Materials Science and Engineering A, 2002, 38(1): 219-229.

[11] 陈康华, 刘红卫, 刘允中. 强化固溶对Al-Zn-Mg-Cu合金力学性能和断裂行为的影响[J]. 金属学报, 2001, 37(1): 29-33.

CHEN Kang-hua, LIU Hong-wei, LIU Yun-zhong. Effect of promotively-solutionizing heat treat on the mechanical properties and fracture behavior of Al-Zn-Mg-Cu alloys[J]. Acta Metallurgica Sinica, 2007, 37(1): 29-33.

[12] ROBSON J D, PRANGUELL P B. Predicting the recrystallized volume fraction in AA7050 hot rolled plate[J]. Materials Science and Technology, 2002, 18(6): 607-619.

[13] 赵志龙, 刘 林, 陈 铮. 2090铝锂合金中δ′相和T1相的复合强化作用[J]. 中国有色金属学报, 2006, 16(1): 90-93.

ZHAO Zhi-long, LIU Lin, CHEN Zheng. Co-strengthening contribution of δ′ and T1 phases of Al-Li alloy 2090[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(1): 90-93.

[14] GAO Chong, LUAN Yang, YU Jun-chuan, MA Yue. Effect of thermal-mechanical properties of 2A97 Al-Li alloy[J]. Transaction of Nonferrous Metals Society of China, 2014, 24(7): 2196-2402.

[15] 孙 刚, 苏 海, 高文理, 刘洪波, 陆 政, 冯朝辉, 张显峰. 热处理对2A97铝锂合金轧板微观组织与力学性能的影响[J]. 金属热处理, 2011, 36(2): 75-78.

SUN Gang, SU Hai, GAO Wen-li, LIU Hong-bo, LU Zheng, FENG Zhao-hui, ZHANG Xian-feng. Effect of heat treatment on microstructure and mechanical properties of rolled 2A97 Al-Li alloy plate[J]. Heat Treatment of Metal, 2011, 36(2): 75-78.

[16] 袁志山, 吴秀亮, 陆 政, 谢优华, 戴圣龙, 刘常升. 2A97铝锂合金时效行为研究[J]. 稀有金属材料与工程, 2008, 37(11): 1898-1902.

YUAN Zhi-shan, WU Xiu-liang, LU Zheng, XIE You-hua, DAI Sheng-long, LIU Chang-sheng. The aging behavior of aluminum-lithium alloy 2A97[J]. Rare Metal Materials and Engineering, 2008, 37(11): 1898-1902.

[17] 钟 申, 郑子樵, 廖中全, 蔡 彪. 时效制度对2A97铝锂合金强韧性的影响[J]. 中国有色金属学报, 2011, 21(3): 547-553.

ZHONG Shen, ZHENG Zi-qiao, LIAO Zhong-quan, CAI Biao. Effects of aging treatment on strength and fracture toughness of 2A97 aluminum-lithium alloy[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(3): 547-553.

[18] 林 毅, 郑子樵, 李世晨, 孔 祥, 韩 烨. 2099铝锂合金微观组织及性能[J]. 中国有色金属学报, 2013, 23(7): 1848-1854.

LIN Yi, ZHENG Zi-qiao, LI Shi-chen, KONG Xiang, HAN Ye. Microstructures and properties of 2099 Al-Li alloy[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(7): 1848-1854.

[19] KUMAR K S, BROWN S A, PICKENS J R. Structure and properties of an ultra-high strength Al-Cu-Li-Mg alloy[J]. Scripta Materiallia, 1990, 24(5): 79-84.

[20] 王喜琴, 张贵一, 王业伟. 2195铝锂合金热处理工艺研究[J]. 上海航天, 2014, 31(Z): 53-55.

WANG Xi-qin, ZHANG Gui-yi, WANG Ye-wei. Heat treatment process of 2195 aluminum-lithium alloy[J]. Aerospace Shanghai, 2014, 31(Z): 53-55.

[21] 陈永来, 李劲风, 张绪虎, 朱瑞华, 杨 柯. 2195铝锂合金搅拌摩擦焊接头组织[J]. 中国有色金属学报, 2016, 26(5): 964-972.

CHEN Yong-lai, LI Jin-feng, ZHANG Xu-hu, ZHU Rui-hua, YANG Ke. Structure of friction-stir wielding joint of 2195 Al-Li alloy[J]. The Chinese Journal of Nonferrous Metals, 2016, 26(5): 964-972.

[22] 游 文, 呙永林. 预变形量对2297合金组织与性能的影响[J]. 铝加工, 2015, 12(4): 21-25.

YOU Wen, GUO Yong-lin. Effects of pre-deformation on microstructure and properties of 2297 alloy[J]. Aluminum Fabrication, 2015, 12(4): 21-25.

[23] KUMAR K S, HEUBAUM F H. The effect of Li content on the natural aging response of Al-Cu-Li-Mg-Ag-Zr alloys[J]. Acta Materialia, 1997, 45(6): 2317-2327.

[24] 魏修宇, 郑子樵, 潘峥嵘, 陈圆圆, 李世晨, 陈秋妮. 预变形对2197铝锂合金显微组织和力学性能的影响[J]. 稀有金属材料与工程, 2008, 37(11): 1996-1999.

WEI Xiu-yu, ZHENG Zi-qiao, PAN Zheng-rong, CHEN Yuan-yuan, LI Shi-chen, CHEN Qiu-ni. The role of plastic deformation on microstructure and mechanical properties of 2197 AI-Li alloy[J]. Rare Metal Materials and Engineering, 2008, 37(11): 1996-1999.

[25] 张 健, 朱瑞华, 李劲风, 马云龙, 刘德博, 郑子樵. 时效前处理对新型Al-Cu-Li-X合金力学性能和显微组织的影响[J]. 中国有色金属学报, 2015, 25(12): 3300-3308.

ZHANG Jian, ZHU Rui-hua, LI Jin-feng, MA Yun-long, LIU De-bo, ZHENG Zi-qao. Effect of heat treatment before aging on tensile properties and microstructures of new Al-Cu-Li-X alloy[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(12): 3300-3308.

Effect of solid solution and aging process on microstructure and mechanical properties of 2297 Al -Li alloy

LI Hong-ying1, 2, 3, 4, WANG Xiao-yu1, 2, YU Wei-chen1, 2

(1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. Key Laboratory of Nonferrous Metal Materials Science and Engineering, Ministry of Education, Central South University, Changsha 410083, China;

3. Nonferrous Metal Oriented Advanced Structural Materials and Manufacturing Cooperative Innovation Center, Central South University, Changsha 410083, China;

4. Science and Technology on High Strength Structural Materials Laboratory, Changsha 410083, China)

Abstract: The effects of solid solution and aging process on structure and properties of 2297 Al-Li alloy were investigated by SEM, TEM and tensile tests systematically. The results show that the optimum solution treatment is determined as ((535±5) ℃, 1.5 h), and in this case, second phases can be more fully dissolved in the Al matrix and the sizes of recrystallized grains are moderate. The dominant strengthening phases during T6 are T1 phase and θ′ phase. Pre-deforming before aging can promote the nucleation of T1 phase, enhance the peak-aged strength and shorten the time to reach peak. The peak strength of the alloy under T6 state at 160 ℃ is 392 MPa after 48 h. The peak strength of the alloy at 7% pre-deformation is the highest strength which can reach 482 MPa after 23 h.

Key words: 2297 Al-Li alloy; solid solution; aging; microstructure; mechanical property

Received date: 2016-10-12; Accepted date: 2017-04-17

Corresponding author: LI Hong-ying; Tel: +86-731-88879341; E-mail: lhying@csu.edu.cn

(编辑 何学锋)

收稿日期:2016-10-12;修订日期:2017-04-17

通信作者:李红英,教授,博士;电话:0731-88879341;E-mail:lhying@csu.edu.cn