DOI: 10.11817/j.issn.1672-7207.2021.02.002

邯钢LF精炼渣水化特性

李颖1,汪坤1,梁文特2,张思奇1,卢翔宇1,许成文1,倪文1

(1. 北京科技大学 土木与资源工程学院,北京,100083;

2. 河钢股份有限公司 邯郸分公司,河北 邯郸,056015)

摘要:以河钢集团邯钢公司的LF精炼渣为研究对象,研究精炼渣的基本物理化学性质,运用X射线衍射(XRD)、微量热法、热重-差示扫描量热法(TG-DSC)、场发射扫描电镜(FE-SEM)和能量色散谱(EDX)等手段分析精炼渣的水化过程。研究结果表明:在水胶比为0.32的条件下,精炼渣水化活性较好,极早期水化速率和160 h水化累计放热量均比转炉钢渣的高。精炼渣的比表面积对其水化速率、水化放热量和早期净浆强度具有显著影响,但对中后期净浆强度和水化产物类型影响不明显。这种精炼渣的主要水化产物是C4AH13、C3AH6、C-A-S-H凝胶和AH3凝胶,C4AH13、C3AH6与非晶态凝胶产物的复合结构是水化28 d前净浆强度的主要来源。

关键词:精炼渣;基本性质;水化产物;C4AH13;C3AH6

中图分类号:TU526 文献标志码:A OSID:

文章编号:1672-7207(2021)02-0339-11

Hydration characteristics of LF refining slag from Handan Iron & Steel Group

LI Ying1, WANG Kun1, LIANG Wente2, ZHANG Siqi1, LU Xiangyu1, XU Chengwen1, NI Wen1

(1. School of Civil and Resource Engineering, University of Science and Technology Beijing,Beijing 100083, China;

2. Handan Iron & Steel Group Co. Ltd., HBIS Group Co. Ltd., Handan 056015, China)

Abstract: Taking the refining slag of Ladle furnace(LF) from Handan Iron & Steel Group as research target, the basic physical and chemical properties of refining slag were studied. The hydration process of refining slag was analyzed by X-ray diffraction(XRD), microcalorimetry, thermogravimetric-differential scanning calorimetry analysis(TG-DSC), field emission scanning electron microscopy(FE-SEM) and energy dispersive X-ray spectroscopy (EDX). The results show that at the water-binder ratio of 0.32, the hydration activity of refining slag is better, and the hydration rate at the very early stage and the accumulated heat within the first 160 h are higher than that of converter steel slag. The specific surface area of refining slag has a significant effect on its hydration rate, heat release of hydration and early paste strength, but has no significant effect on the middle paste strength, later paste strength and the type of hydration products. The main hydration products of this kind of refining slag are C4AH13, C3AH6, C-A-S-H gel and AH3 gel. The composite structure of C4AH13, C3AH6 and amorphous gel product is the main source of the paste strength in the 28 d hydration.

Key words: refining slag; basic properties; hydration products; C4AH13; C3AH6

2010年,我国钢铁工业精炼比已达到70%,随着市场对钢产品质量要求的提高,精炼比还在不断提高[1]。2017年,我国粗钢产量83 173万t,按照精炼比为70%,一般精炼渣排出量按所处理钢液量的2%~5%来计算,2017年我国的精炼渣年产量约为2 000万t[1-4]。LF(Ladle Furnace)钢包炉是目前我国钢铁企业应用最多的精炼炉型。我国钢铁企业排放的精炼渣中,LF精炼渣占较大比例。LF精炼渣具有易粉化、易水化的特点,随着排渣量的增多,简单的堆存处理占地多,粉尘污染严重,还有可能因渗滤液pH超标导致水环境污染。

国内外针对LF精炼渣的大规模利用开展了广泛的研究。我国的研究大多集中在精炼渣的冶金回用方面,但这种利用方式只能减少精炼渣外排量,不能将其完全利用,并且循环回用的次数一般不超过3次,利用率有限[5-6]。杜昀聪等[7]综述了我国几种典型LF精炼渣的物化特性和综合利用途径,认为精炼渣作为混凝土或砂浆砌块的掺合料,有助于提高材料工作性能、力学性能和耐久性能,并能带来积极的环境效应。GB/T 33813-2017“用于水泥和混凝土中的精炼渣粉”[8]已于2018年11月开始实施,这标志着精炼渣在我国已正式成为继矿渣、粉煤灰、钢渣等材料之后,可大量用于建筑材料的新一代矿物掺合料。

国外对LF精炼渣的水化机理研究得比较深入,NGUYEN等[9-10]认为:LF精炼渣与水混合时首先生成亚稳态的水化产物C2AH8,在水化后7~30 d内,亚稳态水化产物C2AH8会转化为稳态水化产物C3AH6,导致微观结构发生变化,使材料的抗压和抗折强度降低,干缩增大,抗冻融性能下降。ADESANYA等[11]认为:LF精炼渣水化时的水胶比是影响转化率的重要因素,降低水胶比可以适当抑制C2AH8向C3AH6转化,以提高材料性能。这些观点都是以国外某些特定的LF精炼渣为研究基础,国内LF精炼渣的类似研究目前还很少。

河钢集团邯钢公司三炼钢厂精炼渣年产量为(6~7)万 t,其中LF精炼渣占50%以上。采用热焖法处理精炼渣,熔态渣翻渣至焖池中,经打水冷却,充分粉化后实现渣钢分离,再经磁选工序后外排。本文作者研究邯钢LF精炼渣的水化特性,为我国LF精炼渣的综合利用进一步提供基础数据和理论支撑。

1 试验原料与方法

1.1 试验原料

LF精炼渣来自河钢集团邯钢公司三炼钢厂,为LF精炼炉排渣后经打水冷却48 h以上得到的产品。对比样品为P.I 42.5硅酸盐水泥,并采用河钢集团邯钢公司西区炼钢厂生产的转炉钢渣作为辅助研究对象。

1.2 试验方法

将精炼渣和转炉钢渣置于40 ℃烘箱内烘干24 h至恒质量,保证含水率不大于0.2%。烘干后的精炼渣粉化比较彻底,粒径<2 mm的颗粒占总质量70%以上。将精炼渣过孔径2 mm筛,使用球磨机粉磨10 min和20 min,使比表面积分别达到355 m2/kg和564 m2/kg,将2种不同比表面积的精炼渣分别标记为LF3和LF5。转炉钢渣使用球磨机粉磨40 min,使比表面积达到460 m2/kg,标记为SS。硅酸盐水泥按照相关规定储存和使用,标记为PI。

使用李氏瓶法检测精炼渣的干密度。使用水平振荡法[12]获取精炼渣和转炉钢渣重金属离子的浸出液,并将浓度结果与相关国家标准[13]进行比对。在水化热试验和所有净浆试样的制备中水胶比均为0.32,样品制备过程参考相关国家标准[14]进行。净浆浆体放入长×宽×高50 mm×30 mm×30 mm的模具成型后,标准养护24 h脱模,继续标准养护至3 d,7 d和28 d龄期。测试抗压强度后,将试样破碎成直径小于5 mm的颗粒,使用无水乙醇终止水化。随后将各龄期净浆样品在40 ℃条件下烘干至恒质量,并研磨成粉末,进行各项微观分析检测,其中水化热检测温度为20 ℃,热分析检测条件为氮气氛围下升温速率5 ℃/min。

1.3 试验设备和仪器

粉磨精炼渣和转炉钢渣使用SMФ500×500型球磨机,净浆试验使用NJ-160A型水泥净浆搅拌机,净浆抗压强度试验使用BC-100D型电脑恒应力压力试验机。

采用国产LS-POP型激光粒度分布测定仪对精炼渣进行粒度分析,采用日本岛津有限公司XRF-1800扫描型X射线荧光光谱仪(XRF)测定精炼渣和转炉钢渣的化学成分,采用美国安捷伦科技公司7500 a型电感耦合等离子体质谱仪(ICP-MS)测定精炼渣和转炉钢渣浸出液的重金属离子浓度,采用瑞典TAM-Air 8型微量热仪测定精炼渣,硅酸盐水泥和转炉钢渣的水化放热速率和放热量,采用日本理学Ultima Ⅳ X射线衍射仪(XRD)测定精炼渣水化浆体的物相组成,采用德国蔡司SUPRA 55型场发射扫描式电子显微镜(FE-SEM)观察精炼渣及其水化浆体的微观形貌,采用英国Link公司LinkNA1000型能谱仪(EDX)测定精炼渣水化浆体的微区元素种类与原子比例,采用德国NETZSCH STA 409-QMS高温热分析仪(TG-DSC)测定硅酸盐水泥,精炼渣以及它们的水化产物在不同温度区间的失重量和热流量变化。

2 结果与讨论

2.1 精炼渣的基本性质

2.1.1 颜色、密度、比表面积和粒度分析

精炼渣烘干并粉磨后呈浅灰色,干密度为2.88 kg/m3。与转炉钢渣相比,精炼渣经热焖法处理后粉化程度更高,这预示精炼渣具有较好的易磨性,作为建筑材料的矿物掺合料使用时,有助于降低粉磨成本。

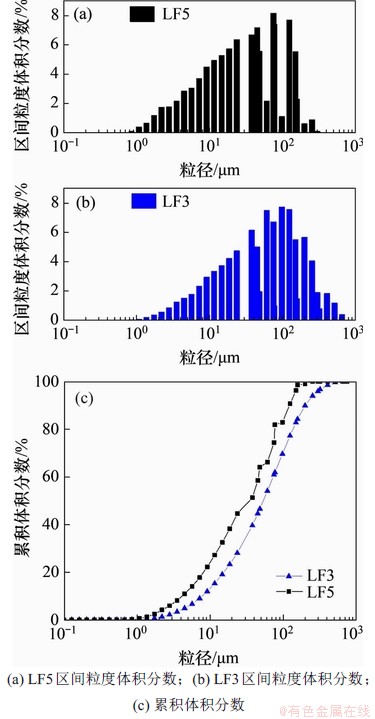

图1所示为不同比表面积精炼渣的粒径分布图,LF3和LF5分别代表比表面积为355 m2/kg和564 m2/kg的精炼渣,对应粉磨时间分别为10 min和20 min。由图1可见:随着粉磨时间增加,精炼渣的整体粒径分布向小粒径方向移动,相比于LF3,LF5在粒径小于25 μm范围的分布有所提高,在大于25 μm粒径范围的分布有所降低,这说明短时间的粉磨可以有效降低精炼渣的粒度。

图1 不同比表面积精炼渣的粒度分布

Fig. 1 Particle size distribution of refining slag with different specific surface areas

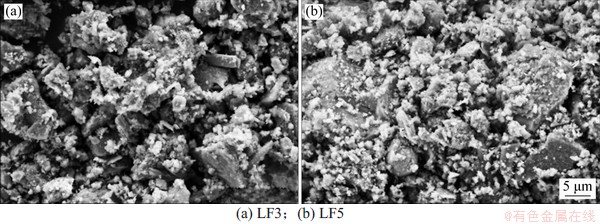

2.1.2 微观结构

图2所示为2种精炼渣的场发射扫描电镜(FE-SEM)图。由图2可见:相比于LF3,LF5含有更多粒径<1 μm的颗粒,说明对精炼渣进行短时间粉磨能够显著增加其中超细粉颗粒的数量,这与图1的粒度分析结果吻合。

2.1.3 成分与重金属含量

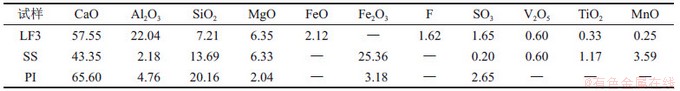

表1所示为精炼渣,转炉钢渣和硅酸盐水泥的化学成分。由表1可见:精炼渣的主要化学成分是氧化钙和氧化铝,这2种成分质量分数之和接近80%,并且含量均比转炉钢渣的高,这预示精炼渣具有比转炉钢渣更好的水化活性。精炼渣中氧化铁的质量分数远比转炉钢渣的低,精炼渣中的氟元素来源于精炼过程中添加的萤石起泡剂(CaF2),硫元素来源于精炼过程中脱硫的产物。

表1 精炼渣、转炉钢渣和硅酸盐水泥的化学成分(质量分数)

Table 1 Chemical compositions of refining slag, converter steel slag and portland cement %

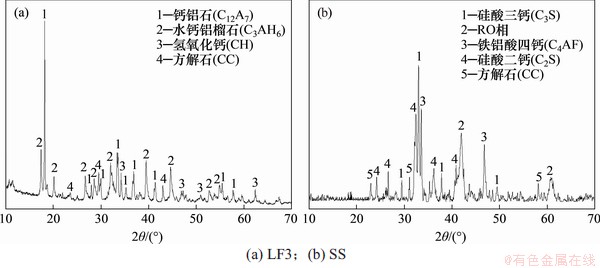

图3所示为精炼渣和转炉钢渣的X射线衍射(XRD)谱。由图3(a)可见:精炼渣主要矿物组成是钙铝石(C12A7)和水钙铝榴石(C3AH6),其中,C3AH6的衍射峰较弱,而C12A7的衍射峰较强,这部分C3AH6应该是精炼渣中的C12A7相在打水冷却过程中水化产生的。钙铝石(C12A7)是水化活性很强的一种矿物成分,这预示这类精炼渣具有良好的水化性能。另外,体系中还存在少量的氢氧化钙(CH)和方解石(CC),这应该是精炼渣所含的游离氧化钙发生水化反应和碳化反应的产物。

由图3(b)可见:转炉钢渣的主要矿物组成是硅酸二钙(C2S)、硅酸三钙(C3S)、铁铝酸四钙(C4AF)、RO相和方解石(CC),与水泥熟料类似,但是富铁矿物相更多。对比图3(a)和图3(b)可见:LF精炼渣和转炉钢渣的矿物组成差别较大。

图2 不同比表面积精炼渣的场发射扫描电镜照片

Fig. 2 FE-SEM images of refining slags with different specific surface areas

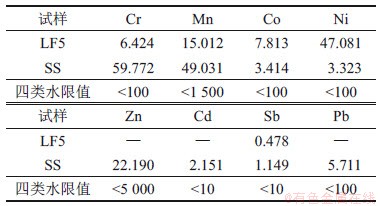

为了最大限度说明精炼渣的重金属浸出毒性,选取比表面积更大的LF5样品进行重金属浸出试验。表2所示为精炼渣和转炉钢渣浸出液的重金属离子浓度。通过与转炉钢渣和相关标准[13]中四类水的重金属离子限值进行对比可知:精炼渣浸出液中除镍元素以外的其他重金属离子浓度均低于转炉钢渣浸出液,所有可检出的重金属离子浓度均低于四类水限值,可以认为精炼渣的浸出液不会对生态环境造成污染。

表2 精炼渣和转炉钢渣浸出液的重金属离子质量浓度

Table 2 Concentration of heavy metal ions in leaching solution of refining slag and converter steel slag μg/L

图3 精炼渣和转炉钢渣的X射线衍射谱

Fig. 3 XRD patterns of refining slag and converter steel slag

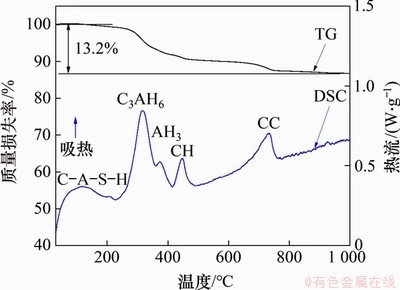

2.1.4 热分析

根据图3可知,精炼渣出厂时就已经存在部分水化和碳化的产物,因此有必要对精炼渣原料进行热分析,以了解这部分水化的程度。图4所示为LF3精炼渣的热重-差示扫描量热法(TG-DSC)曲线。由图4可见:LF3精炼渣在升温至1 000 ℃的过程中,总质量损失率为13.2%,DSC曲线在320 ℃左右的吸热峰对应C3AH6[15],450 ℃和700~750 ℃区间的吸热峰分别对应CH和CC[15-16],这与XRD的分析结果吻合。而380 ℃左右的吸热峰对应非晶态的AH3凝胶[15-17],80~180 ℃区间的弱吸热峰对应非晶态的C-A-S-H凝胶[17],说明精炼渣在打水冷却过程中发生的水化反应还有凝胶类产物。

图4 LF3精炼渣的热重-差示扫描量热法(TG-DSC)曲线

Fig. 4 TG-DSC curves of LF3 refining slag

2.2 精炼渣水化结果和产物分析

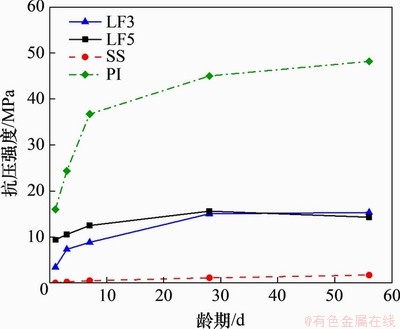

2.2.1 净浆强度

图5所示为精炼渣、转炉钢渣和硅酸盐水泥的净浆抗压强度曲线。由图5可见:硅酸盐水泥的净浆抗压强度最高,而转炉钢渣的净浆抗压强度最低,7 d前强度几乎为0。虽然精炼渣的净浆抗压强度比硅酸盐水泥的低,但是明显比转炉钢渣的高。精炼渣比表面积的差异对其早期的净浆抗压强度影响较大,LF3净浆1 d抗压强度仅为LF5的36.4%,但是这种差距在水化后期逐渐缩小,28 d时,LF3净浆抗压强度为LF5净浆的96.3%,56 d时,LF3净浆的抗压强度比LF5净浆的更大,并且LF5净浆的56 d强度还略低于28 d强度。这说明将精炼渣磨细,有助于提高水化极早期的产物强度,但对于提高后期强度的作用不明显,过细的精炼渣有可能导致水化后期出现强度倒缩现象。

图5 精炼渣、转炉钢渣和硅酸盐水泥净浆的抗压强度曲线

Fig. 5 Paste compressive strength of refining slag, converter steel slag and portland cement

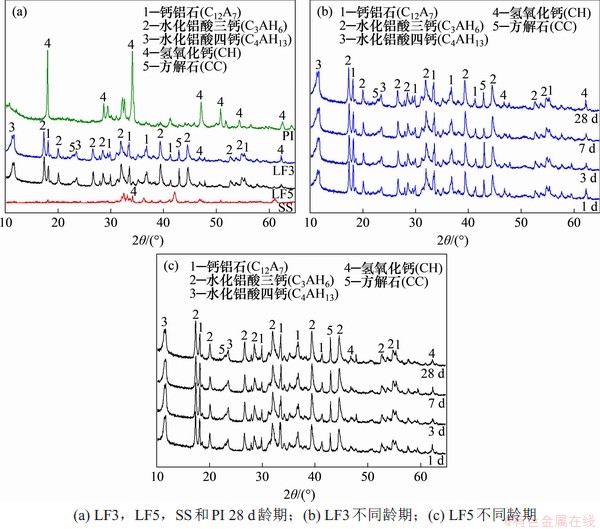

2.2.2 水化产物X射线衍射分析

图6所示为精炼渣、转炉钢渣和硅酸盐水泥净浆的X射线衍射(XRD)谱。由图6(a)可见:在水化28 d时,精炼渣与转炉钢渣、硅酸盐水泥的水化产物明显不同。转炉钢渣除少量CH以外,没有明显的结晶态水化产物,硅酸盐水泥产生了以CH为主的结晶态水化产物,而精炼渣的水化产物就比较丰富。这说明精炼渣、转炉钢渣和硅酸盐水泥主要矿物组成的不同导致三者水化机理有根本的不同,这也是三者净浆强度出现显著差异的原因。

由图6(b)和图6(c)可见:LF3净浆和LF5净浆的水化产物种类一致,并且随着龄期增长,LF3净浆和LF5净浆各自的水化产物种类没有变化。通过与图3进行比较,水化后浆体中的C12A7衍射峰明显降低,说明C12A7参与水化导致含量下降;C3AH6的衍射峰明显增强,并且出现了C4AH13的衍射峰,说明C4AH13和C3AH6是体系中的2种主要水化产物。有研究表明亚稳态的C4AH13在20 ℃左右会逐渐转化成稳态的C3AH6[18],这个过程中会有CH生成,但在前28 d水化过程中CH的衍射峰强度变化不大,这应该是生成的CH又不断参与到C12A7的水化反应所致,因此在标准养护条件下的净浆样品中,很可能存在C4AH13向C3AH6转化的过程。

另外,将图6(b)和图6(c)进行仔细横向比较可见:LF3和LF5样品中C3AH6衍射峰的强度随龄期增长略有升高,LF5各龄期样品中,C3AH6衍射峰强度均比LF3各龄期样品的高,因此可以初步推断:样品养护时间的延长和原料的比表面积的提高都有利于促进C4AH13向C3AH6转化。在XRD谱中并没有出现文献[10]所提到的亚稳态水化产物C2AH8,这可能是不同种类精炼渣的差异导致的。

图6 精炼渣、转炉钢渣和硅酸盐水泥净浆的X射线衍射图谱

Fig. 6 XRD patterns of refining slag, converter steel slag and Portland cement

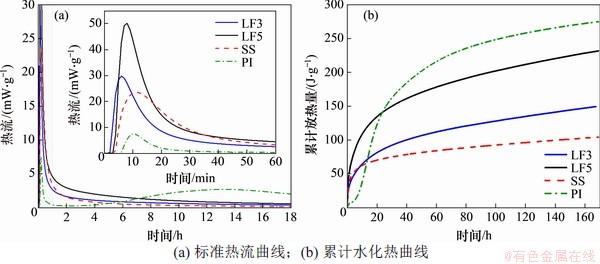

2.2.3 水化热

图7(a)和图7(b)所示分别为精炼渣、转炉钢渣和硅酸盐水泥的标准热流量曲线和累计水化热曲线。由图7(a)可见:转炉钢渣和精炼渣仅在水化30 min之前出现了较为明显的放热峰,精炼渣放热峰比转炉钢渣和硅酸盐水泥的放热峰出现的早,且放热速率更高,LF5的放热速率明显比LF3的大。说明在水胶比0.32的条件下,水化极早期(前30 min)精炼渣比转炉钢渣和硅酸盐水泥水化更快。硅酸盐水泥在水化4~13 h期间进入加速期,在水化13 h后进入减速期,而转炉钢渣和精炼渣则是在水化4~6 h后直接进入稳定期。

图7 精炼渣、转炉钢渣和硅酸盐水泥的水化热曲线

Fig. 7 Hydration heat curves of refining slag, converter steel slag and Portland cement

由图7(b)可见:在水化160 h以内,2种精炼渣的水化累积放热量均比转炉钢渣的大,但小于硅酸盐水泥的水化累积放热量,这说明精炼渣比转炉钢渣的水化放热更剧烈。在水化160 h以内,LF5的水化累积放热量明显比LF3的大,这说明精炼渣的比表面积能够显著影响其放热速率和水化放热量。

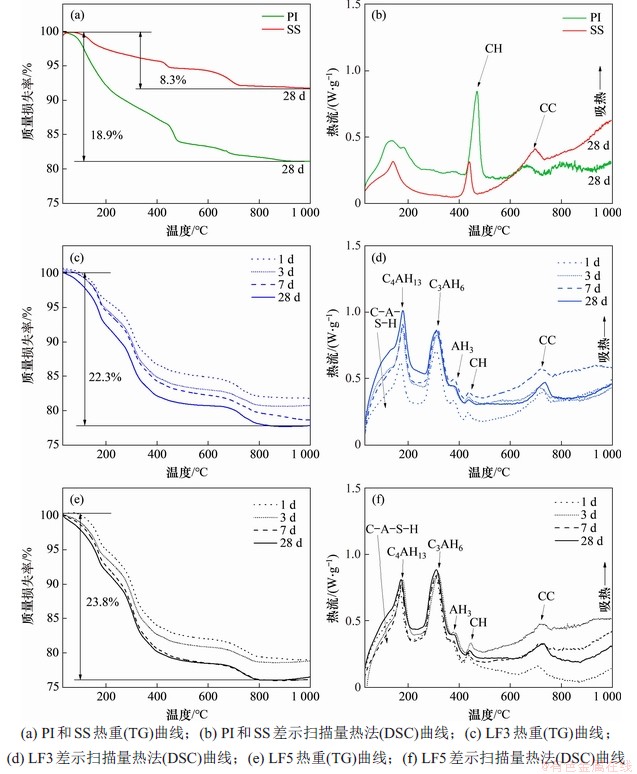

2.2.4 水化产物热分析

图8所示为精炼渣、转炉钢渣和硅酸盐水泥的热重-差示扫描量热法(TG-DSC)曲线。由图8(a)、图8(c)和图8(e)对比可见:LF3水化28 d的质量损失率为22.3%,LF5水化28 d的质量损失率为23.8%,均明显大于同水胶比条件下PI水化28 d的质量损失率为18.9%,这说明精炼渣水化后结合水的增加量大于硅酸盐水泥,具有比硅酸盐水泥更好的水化性能,并且比表面积大的精炼渣在28 d之前生成的水化产物更多。

由图8(c)、图8(e)并结合图4可见:在升温至1 000 ℃的过程中,精炼渣水化后的质量损失大于未水化精炼渣的质量损失,并且随龄期增长,质量损失逐渐增大,这表明精炼渣发生了明显的水化反应,并且在28 d前,这种水化反应是一个持续的过程,这与净浆强度的变化规律吻合。

由图8(b)、图8(d)和图8(f)对比可见:精炼渣的水化产物比转炉钢渣和硅酸盐水泥更加丰富,这与XRD的分析结果吻合。

由图8(d)和图8(f)可见:不同龄期的样品均在180,320,380和450 ℃出现明显的吸热峰。其中180 ℃的吸热峰对应水化产物C4AH13[15],320 ℃的吸热峰对应水化产物C3AH6,450 ℃和700~750 ℃区间的吸热峰分别对应CH和CC[15-16],这与XRD的分析结果吻合。380 ℃的吸热峰对应非晶态的AH3凝胶[15-17],120 ℃左右较弱的肩部吸热曲线对应非晶态的C-A-S-H凝胶[17]。

图8 精炼渣、转炉钢渣和硅酸盐水泥净浆的热重-差示扫描量热法(TG-DSC)曲线

Fig. 8 TG-DSC curves of refining slag, converter steel slag and portland cement

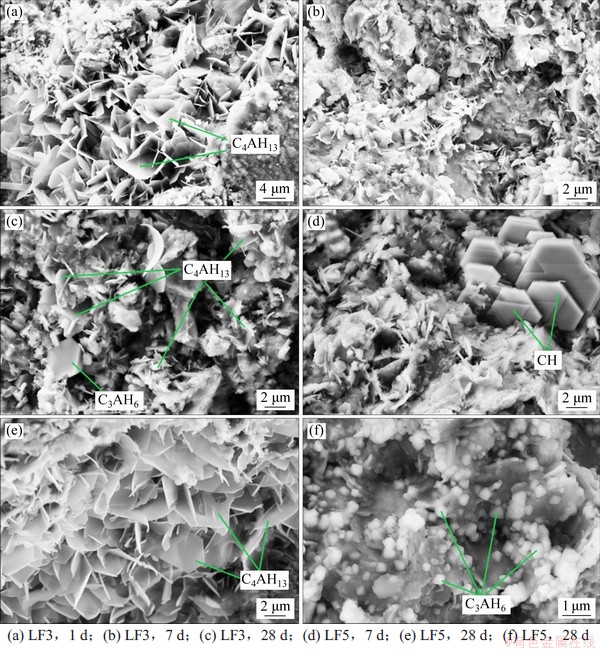

2.2.5 水化产物微观形貌

图9所示为不同水化龄期精炼渣的场发射扫描电镜(EF-SEM)图。由图9(a)可见:在水化极早期阶段(1 d),LF3水化生成了大量六方片状的晶体,结合EDX结果可知,为C4AH13晶体。这种结构在碱性介质的室温环境下能稳定存在,还能够阻碍体系中粒子的相对移动,使浆体发生瞬时凝结[18]。因此将精炼渣用于胶凝材料中作为矿物掺合料,必须注意用量以防止胶凝材料出现瞬凝现象,同时也可以加入适量石膏,促使水化产物向钙矾石方向转化[18-19]。

由图9(b)和图9(d)可见:水化7 d,精炼渣呈现密集片状产物和无定形凝胶产物交织的状态,结合EDX结果可知,片状产物应为C4AH13晶体,无定形凝胶产物可能是非晶态的C-A-S-H凝胶和AH3凝胶,这与XRD和DSC曲线的分析结果一致。结合净浆强度的数据,可以认为这种片状C4AH13晶体和非晶态凝胶的复合结构对净浆强度起主要支撑作用。另外,相比于LF3的水化产物,LF5的水化产物中更多见较大尺寸的CH晶体,这可能是由于粉磨有利于暴露精炼渣中的游离氧化钙,使之能够在水化早期与水接触充分反应。

由图9(c)、图9(e)和图9(f)可见:在精炼渣水化28 d的产物中,除大量六方片状C4AH13晶体外,还观察到八面体形状的晶体,结合EDX数据结果分析,应为C3AH6晶体。对比图9(c)和图9(f)可知:LF5水化产物中的C3AH6晶体更多,这与XRD的分析结果吻合,表明精炼渣的比表面积增大对C4AH13晶体向C3AH6晶体转化很可能有促进作用。这种转化会伴随CH的生成,这也可能是精炼渣LF5的水化产物中更多见较大尺寸CH晶体的原因。文献[20]认为:C4AH13向C3AH6的转化可能会导致硬化体强度的损失,这与本文中LF5的净浆强度在龄期28~56 d区间出现倒缩相呼应,因此有必要对精炼渣长期水化产物进行跟踪分析,明确这种精炼渣作为矿物掺合料使用,是否会影响胶凝材料的长期强度。

图9 不同水化龄期精炼渣净浆的场发射扫描电镜照片

Fig. 9 FE-SEM images of refining slag at different hydration times

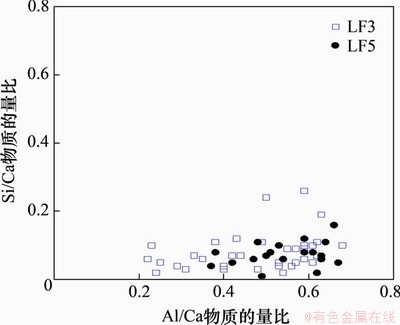

图10所示为28 d龄期精炼渣净浆中非晶态产物的Al/Ca和Si/Ca物质的量比。在SEM下,对2种精炼渣水化样品的非晶态凝胶产物聚集位置(如图9(b)和图9(d)左下角)进行不少于20个点的EDX点扫描,得出的不同元素的摩尔分数。由图10可见:从元素构成上看,LF3和LF5水化生成的非晶态产物中主要含有钙、铝、硅、氧等元素,结合图8(b)的DSC曲线和经典的水泥化学研究成果进行分析[21]:由于C12A7快速水化生成C4AH13,必然引起局部钙离子浓度下降,只有生成AH3凝胶才能够平衡,LF3和LF5水化产生的非晶态产物应为C-A-S-H凝胶和AH3凝胶的混合体。

图10 28 d龄期精炼渣净浆中非晶态产物的Al/Ca和Si/Ca物质的量比

Fig. 10 Al/Ca and Si/Ca molar ratio of amorphous products in different pastes at 28 d

由于精炼渣中硅元素的含量较低,这种混合体整体上Al/Ca物质的量比较高,而Si/Ca物质的量比较低。LF3净浆在28 d龄期所产生非晶态产物比LF5净浆在28 d龄期所产生非晶态产物的成分分布范围更加分散,说明在EDX所测量的范围内,LF5净浆中C-A-S-H凝胶和AH3凝胶的混合体更加均匀,这与LF5的颗粒更细、水化速度更快、胶体分异聚集和结晶趋势更弱密切相关。同时,与LF3净浆相比,LF5净浆在28 d龄期的非晶态产物更加富铝贫钙,这说明LF5净浆的非晶态产物中AH3凝胶所占比例更大,这是因为LF5比LF3水化速度更快,AH3迁移出凝胶体与其他成分结合形成结晶态化合物的过程受到了致密凝胶体的抑制。

所有EDX结果中Si/Ca物质的量比都远远低于水化(铝)硅酸钙的正常比例,这是由于测量视域附近的CH晶体及其他富钙物相的成分叠加造成的。

2.3 精炼渣水化机理

精炼渣水化反应如下:

C12A7+51H→3C4AH13+4AH3(1)

C12A7+33H→4C3AH6+3AH3(2)

3C4AH13→3C3AH6+3CH+18H(3)

C12A7+4CH+57H→4C4AH13+3AH3(4)

在水胶比为0.32的条件下,水化早期精炼渣中的C12A7按照反应式(1)和(2)水化生成C4AH13晶体、C3AH6晶体和AH3凝胶。其中,C4AH13晶体是一种在常温下处于介稳状态的产物,在温度较高时,有按照反应式(3)向等轴晶体C3AH6转化的趋势[18]。精炼渣LF5的水化放热速率和放热量比LF3的更大,因此更容易发生这种转化。转化发生后,体系中CH的浓度逐渐升高,较高的CH浓度一方面会抑制C4AH13向C3AH6转化,保持C4AH13的稳定存在,另一方面也会按照反应式(4)与未水化的C12A7继续反应生成C4AH13,因此在较长的一段龄期内,C4AH13,C3AH6和AH3都是主要的水化产物。

当水化进行到后期,或者在精炼渣最初打水冷却的阶段,由于体系中的自由水逐渐减少,C12A7会更倾向于按照反应式(2)直接水化生成C3AH6,而且介稳状态的C4AH13缓慢向C3AH6转化,体系中的C3AH6可能会越来越多。由于C4AH13的密度小于C3AH6,并且C4AH13的晶体结构是类似蜂窝结构的片状,C3AH6的晶体结构是紧凑的八面体形状[22-23],越来越多的C3AH6晶体势必会导致体系整体强度增速减缓甚至强度下降,这与LF5净浆强度的变化规律吻合,将精炼渣应用于实际工程中必须要注意这一点。

3 结论

1) 邯钢LF精炼渣粉化程度高,易于粉磨,其浸出液的重金属离子浓度符合我国地下水质量标准中四类水的标准。在水胶比为0.32的条件下,粉磨10 min和20 min的精炼渣均有较好的水化活性,其极早期水化速率和160 h水化累计放热量均高比转炉钢渣的高。

2) 邯钢LF精炼渣的比表面积对其水化速率、水化放热量和早期净浆强度具有显著影响,比表面积大的精炼渣水化更快,更剧烈,早期净浆强度更高。

3) 邯钢LF精炼渣主要含有水化活性很高的钙铝石(C12A7),其水化过程与转炉钢渣和硅酸盐水泥明显不同,其主要水化产物具有由C4AH13、C3AH6、C-A-S-H凝胶、AH3凝胶组成的复合结构,该复合结构是精炼渣水化硬化体强度的主要来源。

4) 比表面积对于邯钢LF精炼渣的中后期净浆强度和水化产物类型影响不明显,但在水化的中后期,比表面积大的精炼渣产物中更容易发生C4AH13晶体向C3AH6晶体转化的现象,并伴随强度增速减缓甚至强度下降。

参考文献:

[1] 张亮亮, 张瑞艳, 郑云, 等. 钢铁厂冶炼渣分类及矿物组成分析[J]. 中国建材科技, 2014, 23(2): 59-62.

ZHANG Liangliang, ZHANG Ruiyan, ZHENG Yun, et al. Classification and mineral composition of smelting slag in iron and steel plant[J]. China Building Materials Science & Technology, 2014, 23(2): 59-62.

[2] 中华人民共和国国家统计局. 2017年经济运行稳中向好、好于预期[EB/OL]. [2018-01-18]. http: //www.stats.gov.cn/tjsj/zxfb/201801/t20180118_1574917.html.

National Bureau of statistics of the people's Republic of China. In 2017, the economic operation was stable, positive and better than expected[EB/OL]. [2018-01-18].http: //www.stats.gov.cn/tjsj/zxfb/201801/t20180118_1574917.html.

[3] 何环宇, 曾昭志, 刘吉刚, 等. 钢包炉废渣水热浸出去硫反应机理研究[J]. 武汉科技大学学报, 2010, 33(1): 6-9.

HE Huanyu, ZENG Zhaozhi, LIU Jigang, et al. Mechanism of sulfur removal from LF slag by hydrothermal reaction[J]. Journal of Wuhan University of Science and Technology, 2010, 33(1): 6-9.

[4] The world steel association. World steel in figures 2018 now available [EB/OL]. [2018-06-25]. https: //www.worldsteel.org/zh/media-centre/press-releases/2018/world-steel-in-figure-2018.html.

[5] 刘航航, 刘朝阳, 邵伟. LF精炼废渣资源循环利用综述[J]. 炼钢, 2015, 31(2): 73-78.

LIU Hanghang, LIU Zhaoyang, SHAO Wei. The resource recycling of LF refining slag[J]. Steelmaking, 2015, 31(2): 73-78.

[6] 林路, 侯中晓, 包燕平, 等. LF精炼渣的气化脱硫及资源化利用[J]. 工程科学学报, 2018, 40(S1): 154-160.

LIN Lu, HOU Zhongxiao, BAO Yanping, et al. Gasification desulfurization and resource utilization of ladle furnace refining slag[J]. Chinese Journal of Engineering, 2018, 40(S1): 154-160.

[7] 杜昀聪, 伊元荣, 何秉宇. LF精炼渣物化特性及综合利用[J]. 环境科学与技术, 2019, 42(4): 88-94.

DU Yuncong, YI Yuanrong, HE Bingyu. Physicochemical properties of LF refining slag and comprehensive utilization of slag[J]. Environmental Science & Technology, 2019, 42(4): 88-94.

[8] GB/T 33813—2017. 用于水泥和混凝土中的精炼渣粉[S].GB/T 33813—2017. Refining slag powder used for cement and concrete[S].

[9] NGUYEN H, ADESANYA E, OHENOJA K, et al. Byproduct-based ettringite binder: a synergy between ladle slag and gypsum[J]. Construction and Building Materials, 2019, 197: 143-151.

[10] ADESANYA E, OHENOJA K, KINNUNEN P, et al. Properties and durability of alkali-activated ladle slag[J]. Materials and Structures, 2017, 50(6): 1-10.

[11] ADESANYA E, SREENIVASAN H, KANTOLA A M, et al. Ladle slag cement-Characterization of hydration and conversion[J]. Construction and Building Materials, 2018, 193: 128-134.

[12] HJ 557—2010. 固体废物 浸出毒性浸出方法 水平振荡法[S].

HJ 557—2010. Solid waste-Extraction procedure for leaching toxicity-Horizontal vibration method[S].

[13] GB/T 14848—2017. 地下水质量标准[S].

GB/T 14848—2017. Standard for groundwater quality[S].

[14] GB/T 1346—2011. 水泥标准稠度用水量、 凝结时间、 安定性检验方法[S].

GB/T 1346—2011. Test methods for water requirement of normal consistency, setting time and soundness of the portland cement[S].

[15] COLLOER N C. Transition and decomposition temperatures of cement phases: a collection of thermal analysis data[J]. Ceramics-Silikaty, 2016, 60(4): 338-343.

[16] STEPKOWSKA E T, BLANES J M, REAL C, et al. Hydration products in two aged cement pastes[J]. Journal of Thermal Analysis and Calorimetry, 2005, 82(3): 731-739.

[17] 杨南如, 岳文海. 无机非金属材料图谱手册[M]. 武汉: 武汉工业大学出版社, 2000: 206-251.

YANG Nanru, YUE Wenhai. The handbook of inorganic metalloid materials atlas[M]. Wuhan: Wuhan Industrial University Press, 2000: 206-251.

[18] 林宗寿. 水泥工艺学[M]. 2版. 武汉: 武汉理工大学出版社, 2017: 150-156.

LIN Zongshou. Cement technology[M]. 2nd ed. Wuhan: Wuhan University of Technology Press, 2017: 150-156.

[19] NGUYEN H, KINNUNEN P, CARVELLI V, et al. Strain hardening polypropylene fiber reinforced composite from hydrated ladle slag and gypsum[J]. Composites Part B: Engineering, 2019, 158: 328-338.

[20] ADOLFSSON D, ROBINSON R, ENGSTROM F, et al. Influence of mineralogy on the hydraulic properties of ladle slag[J]. Cement and Concrete Research, 2011, 41(8): 865-871.

[21] 倪文, 李建平, 方兴, 等. 矿物材料学导论[M]. 北京: 科学出版社, 1998: 343.

NI Wen, LI Jianping, FANG Xing, et al. Introduction to Mineral materials[M]. Beijing: Science Press, 1998: 343.

[22] RAMACHANDRAN V S, PAROLI R M, BEAUDOIN J J, et al. Handbook of Thermal Analysis of Construction Materials[M]. Amsterdam: Elsevier, 2002: 355-402.

[23] MAJUMBAR A J, SINGH B, EDMONDS R N. Hydration of mixtures of C12A7 and granulated blastfurnace slag[J]. Cement and Concrete Research, 1989, 19(6): 848-856.

(编辑 赵俊)

收稿日期: 2020 -02 -25; 修回日期: 2020 -06 -24

基金项目(Foundation item):国家重点研发计划重点专项项目(2019YFC1900603) (Project(2019YFC1900603) supported by the Key Project of National Key Research and Development Plan)

通信作者:倪文,博士,教授,从事固体废弃物资源化和矿物材料研究;E-mail: niwen@ces.ustb.edu.cn

引用格式: 李颖, 汪坤, 梁文特, 等. 邯钢LF精炼渣水化特性[J]. 中南大学学报(自然科学版), 2021, 52(2): 339-349.

Citation: LI Ying, WANG Kun, LIANG Wente, et al. Hydration characteristics of LF refining slag from Handan Iron & Steel Group[J]. Journal of Central South University(Science and Technology), 2021, 52(2): 339-349.