红土镍矿半熔融还原生产含镍珠铁

潘成,吕学伟,白晨光,郭恩光,陈攀,刘梅

(重庆大学 材料科学与工程学院,重庆,400044)

摘要:针对转底炉处理红土镍矿生产镍珠铁的可行性进行研究。通过控制温度和炉渣高温特性,使炉渣形成半熔融状态,还原后的金属产生聚集和长大,形成含镍铁珠。讨论还原温度、炉渣成分、耐火材料、还原剂配比、球团直径及还原剂种类对生产镍珠铁的影响。研究结果表明:当还原温度为1 400 ℃,还原时间为30 min,SiO2-MgO-CaO三元渣系中CaO的质量分数为15%,球团直径为30 mm时,采用石墨坩埚,可以得到Ni质量分数为11.53%,Fe质量分数为84.16%的镍珠铁,此时,Ni的回收率可以达到98.59%,Fe的回收率为73.27%。

关键词:红土镍矿;半熔融还原;镍珠铁

中图分类号:TF64 文献标志码:A 文章编号:1672-7207(2014)01-0016-09

Ferronickel nugget production from nickel laterite by semi-molten reduction

PAN Cheng, L Xuewei, BAI Chenguang, GUO Enguang, CHEN Pan, LIU Mei

Xuewei, BAI Chenguang, GUO Enguang, CHEN Pan, LIU Mei

(College of Materials Science and Engineering, Chongqing University, Chongqing 400044, China)

Abstract: A novel process was proposed to directly produce ferronickel alloy nugget from nickel laterite by rotary hearth furnace (RHF). By controlling the temperature and slag property, the metal after reduction would separate from the molten slag and agglomerate as ferronickel nugget. In this work, the influences of some factors, such as the temperature, the slag composition, the refractory, the reductants and their dosage, the pellets size, were investigated. The results show that when the temperature is 1 400 ℃, the mass fraction of CaO in SiO2-MgO-CaO ternary system is 15%. When the diameter of pellet is 30 mm, the ferronickel can be achieved successfully by using graphite crucible within 30 min. The nickel content reaches 11.53% and its recovery ratio is 98.59%, while the grade and recovery ratio of Fe is 84.16% and 73.27%, respectively.

Key words: nickel laterite; semi-molten reduction; ferronickel nugget

由于不锈钢具有优良的耐腐蚀性而备受青睐,在军事、工业或民用中都有着广泛的应用。自2006年,中国不锈钢产量达到世界第一,近年来不锈钢产量呈逐年稳定增长趋势。2011年,全国不锈钢产量达到1 250万t,在全球不锈钢产量中的比例增长到30%。镍铁是不锈钢冶炼的重要原料之一,世界镍资源主要分为硫化镍矿和氧化镍矿,随着硫化镍矿资源的枯竭促进了红土镍矿的利用[1-4]。目前世界范围内的红土矿冶炼镍铁工艺,绝大部分采用预还原(造块)—精炼炉或矿热炉工艺(RKEF)[5]。由于红土矿含水量大、品位低,采用现有电炉冶炼镍铁工艺存在原料运输成本高、冶炼效率低、能耗高等缺点。另外,我国是镍资源缺乏国,很多国内企业在菲律宾、印度尼西亚等国投资建厂,但是这些国家的电价很高,不宜采用电能冶炼镍铁。由此可见,红土矿冶炼镍铁工艺亟需一种流程简单、效率较高的“非电”工艺。红土矿直接还原—磁选分离生产高镍铁粉曾经是的“非电”工艺的首选。但是,从目前的实验室研究情况看,该工艺的工业化前景并不乐观[6-14]。因为红土矿中的镍和铁晶粒细小,弥散分布在原矿中,只有经过长时间的高温和还原气氛,金属质点才会通过扩散、碰撞实现聚集长大。即便如此,还原产物的研磨和磁选效率也较低。除工艺过程本身的弊端外,还原产物的使用也存在问题。磁选产物含有较多的金属氧化物和非金属杂质,无法直接进入钢的精炼流程,电炉熔分流程仍然必不可少。故红土矿的直接还原—磁选—熔分工艺并无技术和经济优势。由此可见,仍然需要开发新型的红土矿冶炼镍铁“非电”工艺。为此,本文作者将针对转底炉煤基还原低品位红土矿生产镍珠铁工艺进行研究。在实验室条件下,模拟转底炉的还原条件,控制温度和炉渣高温特性,使炉渣形成半熔融状态,还原后的金属产生聚集和长大,形成含镍铁珠[15]。通过冷却、破碎和分离,直接得到金属产品。重点讨论还原温度、炉渣成分、耐火材料、还原剂配比、球团直径及还原剂种类对还原分离效果的影响。

1 实验

1.1 实验原料

本研究所用的红土镍矿及还原剂(研究还原剂种类时,所用煤粉与此不同)化学成分如表1和表2所示,从表1可以看出:Fe主要以Fe2O3的形式存在。

表1 红土镍矿的化学成分(质量分数)

Table 1 Chemical composition of nickel laterite %

表2 煤粉的化学成分(质量分数)

Table 2 Chemical composition of coal %

1.2 实验过程

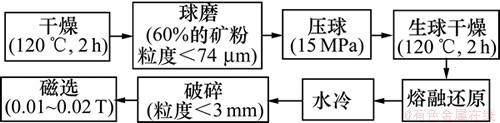

实验过程流程图如图1所示。具体的实验步骤为:(1) 由于红土镍矿含水量较高,球磨前必须在120 ℃干燥2 h;(2) 干燥的红土矿粉经球磨机碾磨至小于74 μm的颗粒占到60%以上;(3) 将矿粉、煤粉、CaO均匀混合后,使用DY-20型电动粉末压片机进行生球压制,成型压力为15 MPa;(4) 由于压球过程中需要添加一定的水,所以必须对生球进行干燥,防止还原过程中发生爆裂;(5) 还原过程中对还原炉充N2保护;(6) 还原后的试样迅速进行水冷,防止再氧化,水冷后的试样发生破裂,大颗粒的金属珠和渣实现了较好的分离;(7) 将水冷后的试样破碎至粒度在3 mm以下,确保小颗粒的金属珠从渣中释放出来;(8) 对破碎的试样进行磁选,磁感应强度为0.01~0.02 T;(9) 对金属和渣进行化学分析。

图1 实验过程流程图

Fig. 1 Flowsheet of experimental process

1.3 实验设备

本文采用电阻炉模拟转底炉的还原条件,探索转底炉生产镍珠铁的可行性。图2所示为实验所用的高温还原炉示意图,还原炉的发热元件为MoSi2,最高温度可以达到1 500 ℃,采用PID控温程序,温度波动范围为±2 ℃。实验过程中球团的放置如图2所示,选用刚玉坩埚时,为了防止坩埚破裂,在刚玉坩埚外加一个石墨坩埚。

1.4 实验方案及内容

在以前的研究中,希望通过提高碳氧比(指碳与氧的摩尔比)来改善金属Ni的还原及聚集长大效果,大量的结果证明,这种方法并未有效改善Ni的富集效果,反而增加了Fe的金属化率,降低了磁选精矿中Ni的含量。本研究期望Ni的回收率能够大于90%,而Fe的回收率小于60%。因此要达到这个目标,只能采用选择性还原,通过控制配碳量降低Fe的金属化率。本文在研究还原温度、炉渣成分、耐火材料、球团直径及还原剂种类对生产镍珠铁的影响时,配碳的原则是保证Ni完全被还原,理论上60%的Fe被还原成金属铁,剩余40%以FeO的形式存在于渣中,此时对应的碳氧比为0.76。

图2 还原炉示意图

Fig. 2 Schematic diagram of furnace

1.4.1 温度及炉渣成分的影响

根据转底炉能够实现的温度条件,还原温度选定为1 340,1 360,1 380和1 400 ℃,熔融还原时间固定为30 min。碱度的选择是根据图3所示的SiO2-MgO- CaO三元渣系液相图进行确定。由图3可以看出:固定w(SiO2)/w(MgO)=7/3(原矿中的含量比)时,随着CaO含量的增加,渣的液相温度逐渐降低,达到一定值后又开始升高。本研究以原矿中CaO的质量分数3%为基础,通过添加CaO,改变SiO2-MgO-CaO三元渣系中CaO的含量来调整渣系的碱度,碱度定义为w(MgO+CaO)/w(SiO2+Al2O3),实验中确定SiO2-MgO- CaO三元渣系中CaO的质量分数分别为3%,6%,9%,12%,15%,18%和21%,对应的碱度为0.40,0.45,0.50,0.55,0.60,0.65和0.70。

1.4.2 耐火材料的影响

不同的耐火材料和熔渣以及金属熔体的润湿性差异较大,而润湿性将直接影响渣和金属与耐材的分离效果,即影响转底炉处理红土镍矿生产镍珠铁工艺中的出料效果。本文分别研究了刚玉及石墨坩埚对还原分离效果的影响。

1.4.3 还原剂配比的影响

还原剂配比不仅影响Ni和Fe金属化率,同时还影响金属中的渗碳量,而渗碳的含量会直接影响金属的熔化温度,最终影响金属聚集长大效果。尤其是采用石墨耐材时,耐火材料也会参加还原反应以及金属中的渗碳。因此,寻找最佳还原剂配比,具有重要的意义。

图3 SiO2-MgO-CaO三元渣系液相图

Fig. 3 Liquid phase diagram of SiO2-MgO-CaO

1.4.4 球团直径的影响

球团直径会影响球团内部的传热效果,最终影响还原分离效果,本文分别研究了直径为20,30和40 mm球团的还原分离效果,并最终确定最佳的球团直径。

1.4.5 还原剂种类的影响

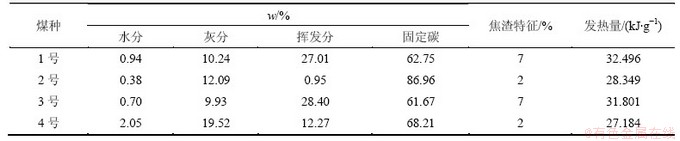

本研究所用的还原剂为煤粉,不同的煤粉固定碳、灰分以及挥发分的含量有所不同,这些因素都会影响镍珠铁的生产,本文分别研究4种还原剂对还原分离效果的影响。

2 结果及讨论

2.1 温度及炉渣成分的影响

改变还原温度及炉渣成分,采用刚玉坩埚得到的还原试样矿相及实物图如图4所示。结合图4(a)及图4(c)可以看出:固定还原温度为1 400 ℃,渣系中CaO质量分数从3%增加到21%,渣中金属的聚集长大效果差异非常明显。当CaO质量分数为3%时,金属仍然以非常小的颗粒弥散分布在渣中;CaO质量分数为6%时,渣中的金属开始发生明显的聚集长大现象;CaO质量分数继续增加到9%以及12%时,渣中金属聚集长大的效果得到很大改善,金属几乎连成一片,不存在弥散分布的金属小颗粒;然而当CaO质量分数达到15%时,如图4(c)所示,出现很好的渣金分离,形成1个3 cm大小的金属块,渣中只有少量的金属颗粒,这样的分离效果与期望目标比较接近;继续增加CaO质量分数到18%及21%,渣与金属的分离效果又开始变差。结合图4(b)及图4(c)可以得出:固定渣中CaO质量分数为15%,温度对金属的聚集长大起着非常关键的作用,当还原温度从1 340 ℃升高到1 400 ℃,金属和渣的分离发生了很大变化;当温度小于1 360 ℃时,渣中金属产生一定程度的聚集,但是,长大效果不够明显,仍然成弥散分布的状态;当温度升高到1 380 ℃时,渣中出现大颗粒的金属,但也存在金属小颗粒;只有在温度达到1 400 ℃,方可形成一个大的金属块,渣和金属完全分离。由此可得:生产镍珠铁的适宜温度为1 400 ℃,最佳的炉渣成分是SiO2-MgO-CaO三元渣系中CaO的质量分数达到15%。

图4 还原试样的矿相图

Fig. 4 Mineralogical observation of reduction sample

2.2 耐火材料的影响

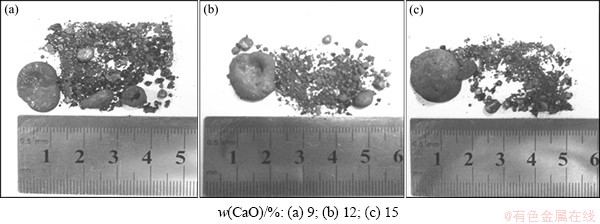

由前面分析可知:用刚玉坩埚进行还原实验,渣和金属能够实现较好的分离,但是渣和坩埚粘结严重,同时不能得到球形的珠铁。由于熔渣与石墨的润湿性较差,本文尝试用石墨坩埚进行还原实验,固定温度为1 400 ℃,改变三元渣系中CaO质量分数,得到的含镍珠铁如图5所示。从图5可以看出:三元渣系中CaO质量分数达到9%时,可以得到珠铁,随着渣系中CaO质量分数的增加,珠铁长大的效果越好,当CaO质量分数达到15%时,最大的珠铁质量占合金总量的75%之多。并且在还原结束后经过水淬极冷,渣及金属与石墨坩埚实现了良好的分离。由此可见,石墨耐材可以实现镍珠铁的生产。

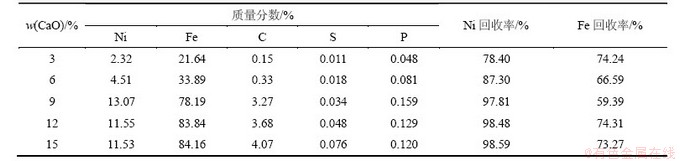

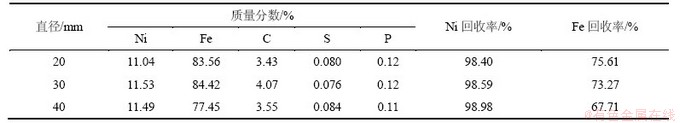

对含镍珠铁进行化学分析,得到合金中Ni,Fe,C,S和P的含量如表3所示。表3中Fe的回收率定义为(Ni的回收率定义与Fe相同):

式中: 为Fe的回收率;m1为试验所得到的金属含Fe质量;m0为还原试样中理论含Fe质量。

为Fe的回收率;m1为试验所得到的金属含Fe质量;m0为还原试样中理论含Fe质量。

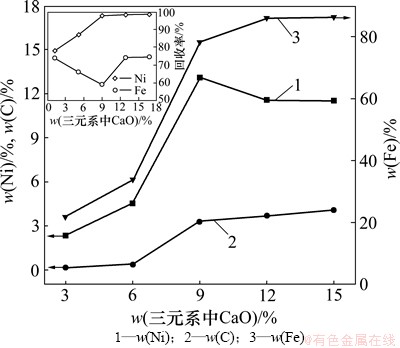

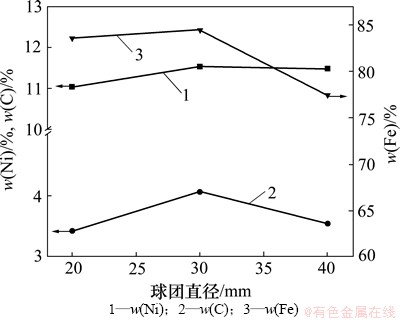

图6所示为用石墨坩埚得到的含镍珠铁中Ni,Fe和C质量分数以及Ni和Fe的回收率。从图6可以看出:合金中Fe和C质量分数随着CaO质量分数的增加而增加,Ni含量在CaO质量分数为9%时达到最高的13.07%,继续增加CaO,合金中Ni质量分数呈现

降低的趋势。这是由于CaO质量分数增加,渣的流动性变好,聚集长大的金属更容易向石墨坩埚底部沉积,Fe被还原的机会增加,合金渗碳更多,由此导致Fe和C质量分数升高的同时,Ni质量分数降低。当CaO质量分数大于9%时,Ni的回收率都可以达到97%以上,而由于石墨坩埚参与了还原反应,致使Fe 的回收率大于期望的60%。由表3可知:S质量分数随着CaO质量分数增加而增加,这是由于分离效果越好,得到合金质量越小,合金中S的质量分数升高。

图5 镍珠铁照片

Fig. 5 Photo of ferronickel nuggets

表3 合金成分及Ni、Fe回收率

Table 3 Chemical composition of alloy and recovery ratio of Ni and Fe

图6 合金中Ni, Fe, C质量分数及Ni, Fe回收率

Fig. 6 Chemical composition of alloy and recovery ratio of Ni and Fe

2.3 还原剂配比的影响

就红土矿而言,真正有经济价值的元素是镍,铁品位只有 15%~25%,不宜将其当作提取铁的“资源”来看待。铁能够起的作用是:通过与镍的合金化作用,在一定空间内,形成具有适宜熔化温度、适宜高温界面特性的金属熔体。一旦追求铁元素的高回收率,反而会带来还原剂用量的增加、生产周期的增长、过程能耗的增大和产品镍品位的降低。综合考虑过程效率和产品等级的情况下,理想的红土矿提取工艺应该是:实现高镍回收率的前提下(>90%),铁的回收率在50%左右为好。本研究固定还原温度1 400 ℃,三元渣系中CaO质量分数固定在15%,研究了改变还原剂配比对红土镍矿还原及渣金分离的影响,分离得到的珠铁形貌、合金成分及Ni和Fe回收率如图7和表4所示。从图7可以看出:随着配碳量的增加,渣金分离效果更好,含镍珠铁的球形度更好。从合金成分的角度看,随着配碳比的增加,合金中Ni的质量分数有所降低,Fe的质量分数基本没有发生变化,C的质量分数有所增加,S和P的质量分数基本维持不变。由此可以得出:增加配碳比对合金成分影响较小,但是对渣金的分离效果影响较为明显,这是由于随着配碳的增加,合金中渗碳量增加,使得合金液相生成量更多,改善了金属的聚集长大及分离效果。

图7 改变还原剂配比对制备镍珠铁的影响

Fig. 7 Effect of carbon dosage on production of ferronickel nugget

2.4 球团直径的影响

改变球团直径,固定还原温度1 400 ℃,三元渣系中CaO质量分数为15%时,得到的合金成分如表5和图8所示。由实验结果可知:当球团直径为30 mm时,合金中Ni,Fe和C的质量分数最高,也就是说在这种球团尺寸下,渣金分离的效果最好。而球团尺寸为20 mm和40 mm时,合金中Ni,Fe和C的质量分数有所降低,这是因为球团的尺寸影响了热传递的效果,直径为40 mm时,在固定的还原时间内,球团中心部分温度达到设定温度值的时间存在延迟,即保持设定温度的时间不足,而导致渣金分离的效果有所降低。当直径为20 mm时,受到坩埚直径的限制,保证还原球团质量相同时,放入的球团个数增加,球团在坩埚内分为两层,又由于电阻炉内恒温段是一定的,因此,上层球团所处的环境会存在一定的温将,从而影响最终的渣金分离。在3种条件下,合金中S和P的质量分数变化不大,Ni的回收率都在98%以上,Fe的回收率有所不同,球团直径为40 mm时,Fe的回收率最低,这是由于渣金分离变差所引起的。

表4 改变碳氧比得到的合金成分及Ni和Fe回收率

Table 4 Chemical composition of alloy and recovery ratio of Ni and Fe

图8 改变球团直径对珠铁成分的影响

Fig. 8 Effect of pellet diameter on chemical composition of ferronickel nugget

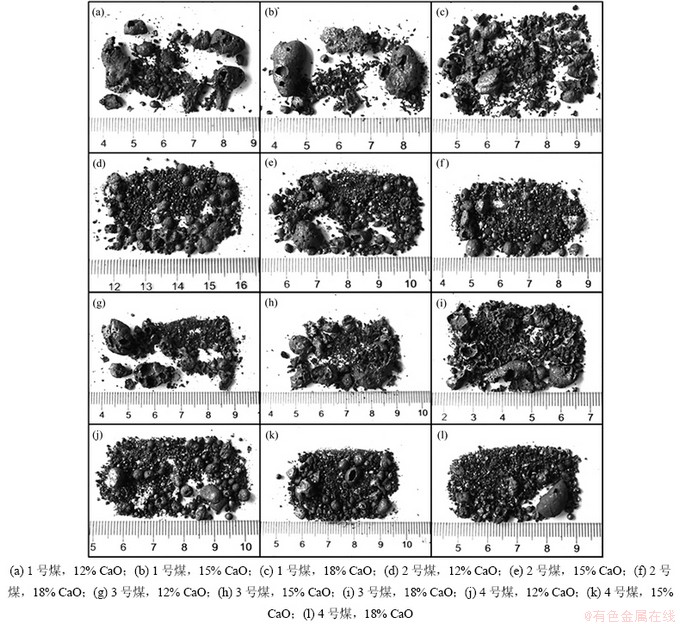

2.5 还原剂种类的影响

不同的煤种因其灰分、挥发分、固定碳、焦渣特征、发热量及水分的差异,分别作为还原剂时,对红土镍矿的还原分离存在不同的影响效果。本研究尝试了4种煤作为还原剂,探索了煤种对红土镍矿熔融态还原分离生产镍珠铁的影响。所用煤的化学成分及特征值如表6所示。

根据磁选得到的金属可以看出:球形度越好的颗粒基本不夹带渣,而没有成为球型的小金属颗粒通常和渣包裹在一起,即磁选分离得到的小颗粒越多,金属中夹带的渣越多。基于此,结合图9可以看出:1号煤和3号煤作为还原剂,得到的金属中,大颗粒的金属珠所占的比例较大,还原分离的明显效果优于2号煤和4号煤。对比4种煤的区别可以得出:1号煤和3号煤的挥发分含量较高,经分析可知,挥发分的产生可以促进金属的还原,同时挥发分在溢出的过程中对熔体产生搅拌作用,可以加速金属的扩散、聚集、长大,从而改善了渣金分离效果。

考虑到煤中灰分对渣系成分的影响,针对每一种煤,研究了3种CaO含量,期望找到适宜每个煤种的最佳渣系组成。从图9可以看出:当三元渣系中CaO的质量分数达到18%,分离的效果开始变差,而CaO质量分数为12%和15%时,分离效果没有明显的差异。从节约成本的角度出发,应尽量减少添加剂的使用量,因此,4种煤的适宜CaO质量分数应为12%。由此可见,煤中灰分的含量对红土镍矿半熔融还原生产镍珠铁的影响较小。

表5 球团直径得到的合金成分及Ni、Fe回收率

Table 5 Chemical composition of alloy and recovery ratio of Ni and Fe

表6 4种不同还原剂的成分表

Table 6 Chemical composition of four kinds reducing agent

图9 改变还原剂种类对制备镍珠铁的影响

Fig. 9 Effects of reducing agent on production of ferronickel nugget

3 结论

(1) 还原温度和三元渣系中CaO含量对制备镍珠铁的影响较大,适宜还原温度为1 400 ℃,渣中最佳CaO质量分数为15%。

(2) 耐火材料会影响金属颗粒的形状,采用刚玉坩埚能够得到金属块,不能形成球状的珠铁,而石墨耐材可以很好地实现含镍珠铁的制备。

(3) 球团直径会影响渣金分离的效果,从而影响合金的成分,适宜的球团直径为30 mm。

(4) 配碳比对合金成分影响不大,但是对渣金分离效果影响较大,配碳比越高,分离效果越好。

(5) 还原剂中挥发分含量对渣金分离影响较大,挥发分越高,分离效果越好。

(6) 转底炉处理红土镍矿生产镍珠铁工艺具有一定的可行性,可以进行工业扩大试验。

参考文献:

[1] L Xuewei, BAI Chenguang, HE Shengping, et al. Mineral change of Philippine and Indonesia nickel lateritic ore during sintering and mineralogy of their sinter[J]. ISIJ International, 2010, 50(3): 380-385.

Xuewei, BAI Chenguang, HE Shengping, et al. Mineral change of Philippine and Indonesia nickel lateritic ore during sintering and mineralogy of their sinter[J]. ISIJ International, 2010, 50(3): 380-385.

[2] L Xuewei, BAI Chenguang, QIU Guibao, et al. Dehydrating and sintering of Philippine nickel laterite[J]. Canadian Metallurgical Quarterly, 2011, 50(1): 20-27.

Xuewei, BAI Chenguang, QIU Guibao, et al. Dehydrating and sintering of Philippine nickel laterite[J]. Canadian Metallurgical Quarterly, 2011, 50(1): 20-27.

[3] 潘成, 白晨光, 吕学伟, 等. 菲律宾红土镍矿液态还原研究[J]. 钢铁, 2011, 26(1): 24-28.

PAN Cheng, BAI Chenguang, L Xuewei, et al. Study on liquid reduction of Philippines nickeliferous laterite ore[J]. Iron and Steel, 2011, 26(1): 24-28.

Xuewei, et al. Study on liquid reduction of Philippines nickeliferous laterite ore[J]. Iron and Steel, 2011, 26(1): 24-28.

[4] 潘成, 白晨光, 吕学伟, 等. 硅镁型红土镍矿球团焙烧固结机制研究[J]. 稀有金属, 2011(6): 916-921.

PAN Cheng, BAI Chenguang, L Xuewei, et al. Roasting and consolidation mechanism of nickeliferous laterite ore pellets[J]. Chinese Journal of Rare Metals, 2011(6): 916-921.

Xuewei, et al. Roasting and consolidation mechanism of nickeliferous laterite ore pellets[J]. Chinese Journal of Rare Metals, 2011(6): 916-921.

[5] Bergman R A. Nickel production from low-iron laterite ores: Process descriptions (vol 96, pg 137, 2003)[J]. Cim Bulletin, 2003, 96(1073): 67.

[6] 曹志成, 孙体昌, 杨慧芬, 等. 红土镍矿直接还原焙烧磁选回收铁镍[J]. 北京科技大学学报, 2010, 32(6): 708-712.

CAO Zhicheng, SUN Tichang, YANG Huifen, et al. Recovery of iron and nickel from nickel laterite ore by direct reduction roasting and magnetic separation[J]. Journal of University of Science and Technology Beijing, 2010, 32(6): 708-712.

[7] Zhu D Q, Cui Y, Vining K, et al. Upgrading low nickel content laterite ores using selective reduction followed by magnetic separation[J]. International Journal of Mineral Processing, 2012, 106: 1-7.

[8] LI Guanghui, SHI Tangming, RAO Mingjun. et al. Beneficiation of nickeliferous laterite by reduction roasting in the presence of sodium sulfate[J]. Minerals Engineering, 2012, 32: 19-26.

[9] PAN Cheng, BAI Chenguang, L Xuewei, et al. Gaseous reduction of pellets of laterite ore containing carbon[J]. Metalurgia International, 2011, 16(1): 5-9.

Xuewei, et al. Gaseous reduction of pellets of laterite ore containing carbon[J]. Metalurgia International, 2011, 16(1): 5-9.

[10] LI Bo, WANG Hua, WEI Yonggang, et al. The reduction of nickel from low-grade nickel laterite ore using a solid-state deoxidisation method[J]. Minerals Engineering, 2011, 24(14): 1556-1562.

[11] 刘志宏, 马小波, 朱德庆, 等. 红土镍矿还原熔炼制备镍铁的试验研究[J]. 中南大学学报(自然科学版), 2011, 42(10): 2905-2910.

LIU Zhihong, MA Xiaobo, ZHU Deqing, et al. Preparation of ferronickel from laterite ore in reduction smelting process[J]. Journal of Central South University (Science and Technology), 2011, 42(10): 2905-2910.

[12] 林重春, 张建良, 黄冬华, 等. 红土镍矿含碳球团深还原-磁选富集镍铁工艺[J]. 北京科技大学学报, 2011, 33(3): 270-275.

LIN Chongchun, ZHANG Jianliang, HUANG Donghua, et al. Enrichment of nickel and iron from nickel laterite ore/coal composite pellets by deep reduction and magnetic separation[J]. Journal of University of Science and Technology Beijing, 2011, 33(3): 270-275.

[13] 李艳军, 李淑菲, 韩跃新, 等. 红土镍矿深度还原-磁选富集镍铁实验研究[J]. 东北大学学报(自然科学版), 2011, 32(5): 740-744.

LI Yanjun, LI Shufei, HAN Yuexin, et al. Deep reduction/magnetic separation of laterite for concentration of Ni and Fe[J]. Journal of Northeastern University (Natural Science), 2011, 32(5): 740-744.

[14] 李东海, 吕学伟, 白晨光, 等. 红土镍矿含碳球团还原焙烧-磁选试验[J]. 钢铁研究学报, 2011, 23(10): 9-14.

LI Donghai, L Xuewei, BAI Chenguang, et al. Reduction roasting and magnetic separation of nickel laterite pellets bearing carbon[J]. Journal of Iron and Steel Research, 2011, 23(10): 9-14.

Xuewei, BAI Chenguang, et al. Reduction roasting and magnetic separation of nickel laterite pellets bearing carbon[J]. Journal of Iron and Steel Research, 2011, 23(10): 9-14.

[15] Tsuji H. Behavior of reduction and growth of metal in smelting of saprolite Ni-ore in a rotary kiln for production of ferro-nickel alloy[J]. ISIJ International, 2012, 52(6): 1000-1009.

(编辑 杨幼平)

收稿日期:2012-12-21;修回日期:2013-01-31

基金项目:国家自然科学基金重点项目资助计划(51234010)

通信作者:吕学伟(1982-),男,山东莱芜人,博士研究生,副教授,从事炼铁新技术及铁合金冶炼研究;电话:023-65112631;E-mail: lvxuewei@163.com