文章编号:1004-0609(2010)12-2307-06

TB6钛合金热变形诱导马氏体转变

欧阳德来1, 2,鲁世强1,崔 霞1,李 鑫1,黄 旭3

(1. 南昌航空大学 材料科学与工程学院,南昌 330063;

(2. 南京航空航天大学 材料科学与技术学院,南京 210016;

(3. 北京航空材料研究院,北京 100095)

摘 要:为研究TB6钛合金在β相区热变形后快冷过程中形变诱导马氏体的转变行为,采用圆柱试样在Thermecmaster-Z型热模拟试验机上进行热压缩试验,并计算β相条件下的稳定系数,观察热变形组织,测试材料的物相结构。结果表明:合金β相条件稳定下系数Kβ为1.06,β相处于机械不稳定状态,在β相区热变形后快冷过程中合金存在形变诱导转变斜方马氏体(α″),β相向斜方马氏体转变时3个点阵方向发生点阵应变为ε1=-7.1%,ε2=7.2%,ε3=1.1%的结果;形变诱导马氏体呈现针状和锯齿状两种形貌,其转变模式是先形成近似平行的细条状或针状主干,后从主干中不断生长成树枝状,且马氏体内部可能存在孪晶。

关键词:TB6钛合金;形变诱导马氏体;稳定系数

中图分类号:TB43 文献标志码:A

Transformation of deformation-induced martensite in TB6 titanium alloy

OUYANG De-lai1, 2, LU Shi-qiang1, cui xia1, li xin1, huang xu3

(1. School of Material Science and Engineering , Nanchang Hangkong University, Nanchang 330063, China;

2. Institute of Materials Science and Technology, Nanjing University of Aeronautics and Astronautics, Nanjing 210016, China;

3. Beijing Institute of Aeronautical Materials, Beijing 100095, China)

Abstract: To study the transformation behavior of deformation-induced martensite in Ti-10Al-2Fe-3V(TB6) alloy during rapid cooling after β hot process,the hot compression experiments adopting cylindrical specimens at constant strain rates were carried out on Thermecmaster-Z simulator. The β stable coefficient (Kβ) of this alloy was calculated and the hot deformation microstructure was observed. The results show that the β stable coefficient (Kβ) is 1.06, the β-phase is of thermomechanical unstability, and the transformation of stress induced orthorhombic martensite from β-phase occurs by transformation strains in three principal lattice directions as ε1=-7.1%, ε2=+7.2%, ε3=+1.1% during rapid cooling after β hot process. The martensite which presents two typical morphologies of transition structure needle-type and serrate-type structure nucleates at pre-existing sub-grain boundaries and grows to laths parallelly.

Key words: TB6 titanium alloy; deformation-induced martensite; stable coefficient

近β钛合金经过适当的固溶处理后,由于β相处于机械不稳定状态,在外加应力甚至内应力作用下,可能导致形变诱导马氏体转变。形变诱导马氏体转变一方面会影响合金的应力-应变曲线特性,另一方面通过控制其转变性质及转变量可调整合金的硬化率以提高合金的塑性,使强度和韧性达到更好的结合[1-4]。早期的研究提出[5-6],钛合金形变诱导马氏体的晶体结构为密排六方[5]、体心立方;但随后的研究[7]表明,其晶体结构应为斜方结构(以α"表示),且这种斜方马氏体形貌一般为针状,其与基体β相之间保持位向关系(111)M//(110)β。

TB6钛合金是在美国Ti-1023合金的基础上国产化的一种近β亚稳型钛合金,其名义成分为Ti-10V-2Al-3Fe。该合金比强度高、断裂韧性好、锻造温度低、淬透性好和抗应力腐蚀能力强,适合于制造高强度的钛锻件[8-10]。该合金在适当的变形条件下也存在形变诱导马氏体转变现象。DUERIG等[7]研究了经不同固溶处理的Ti-10V-2Al-3Fe钛合金在拉伸变形过程中形变诱导马氏体转变的一般规律,并提出了此马氏体为斜方马氏体。BHATTACHARJEE等[11]研究认为,Ti-10V-2Al-3Fe合金固溶处理后的β晶粒尺寸与形变诱导马氏体的转变行为存在密切的关系。沈桂琴和张虹[12]认为Ti-10V-2Al-3Fe合金形变诱导马氏体转变与固溶处理温度和冷却速率密切相关。以上研究证实了TB6钛合金经固溶处理后在室温拉伸应力作用下形变诱导马氏体转变的存在,并获得其转变的一般规律。然而,关于此合金在β相区热变形后快冷是否会出现形变诱导马氏体方面的研究鲜见报道。

为了明确TB6钛合金在β相区热变形后快冷过程中形变诱导马氏体的转变行为,本文作者利用Thermecmaster-Z型热模拟试验机进行TB6钛合金在β相区的等温热压缩实验,采用金相显微镜(OM)、扫描电镜(SEM)和X射线衍射分析(XRD)研究TB6钛合金在β相区热变形后快冷过程中形变诱导马氏体的转变行为。

1 实验

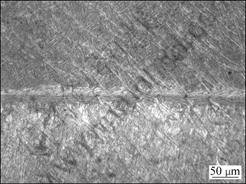

实验材料为铸态TB6钛合金棒材,加工成d8 mm×12 mm圆柱试样。其名义成分(质量分数)如下:V10%,Fe 2%,Al 3%,余量为Ti。原始组织为α+β混合组织(见图1),白色为α相,α+β混合组织的特征呈网篮状结构。

在Thermecmaster-Z型热模拟试验机上进行等温恒应变速率热压缩实验,选择3种变形条件:825 ℃,  =0.01 s-1,ε=0.92;950℃,

=0.01 s-1,ε=0.92;950℃, =0.1 s-1,ε=0.92;1 125 ℃,

=0.1 s-1,ε=0.92;1 125 ℃, =0.001 s-1,ε=0.92。试样采用真空感应加热,升温速率为10 ℃/s,保温时间为4 min,使变形前组织全部由β晶粒组成,试样变形后立即氦气冷却。为考察变形试样中出现的马氏体是否是快速冷却的结果,再将变形条件为825 ℃,

=0.001 s-1,ε=0.92。试样采用真空感应加热,升温速率为10 ℃/s,保温时间为4 min,使变形前组织全部由β晶粒组成,试样变形后立即氦气冷却。为考察变形试样中出现的马氏体是否是快速冷却的结果,再将变形条件为825 ℃, =0.01 s-1,ε=0.92的变形试样分成3块,一起加热到900 ℃,固溶20 min后分别进行水冷、空冷和随炉冷。压缩试样沿压缩轴方向剖开,固溶试样沿中心线剖开,机械抛光后侵蚀。金相组织观察及分析在TG3000型金相显微分析系统上进行,SEM图像分析在JEM-200CX型扫描电镜上进行,物相分析在D8型X射线衍射仪上进行。

=0.01 s-1,ε=0.92的变形试样分成3块,一起加热到900 ℃,固溶20 min后分别进行水冷、空冷和随炉冷。压缩试样沿压缩轴方向剖开,固溶试样沿中心线剖开,机械抛光后侵蚀。金相组织观察及分析在TG3000型金相显微分析系统上进行,SEM图像分析在JEM-200CX型扫描电镜上进行,物相分析在D8型X射线衍射仪上进行。

图1 铸态TB6钛合金的原始组织

Fig.1 As-cast microstructure of TB6 titanium alloy

2 实验结果

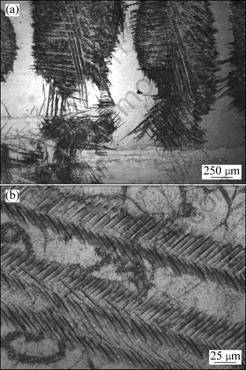

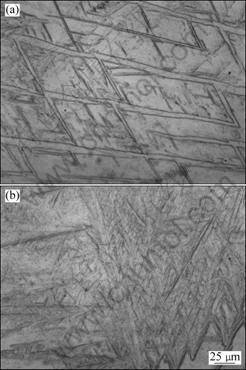

热变形后铸态TB6钛合金组织中两种类型转变产物的形貌如图2所示。图2(a)所示为合金在试验过程中观察到的针状形态转变物,针状物之间纵横交错,并形成外观上的团体,在整个试样中间隔地分布着有限的这种团体。图2(b)所示为合金在试验过程中观察到的锯齿状形态转变物,锯齿状转变物组织是由两组无数个条状物平行排列而成的,锯齿状转变物组织以直线状分布于合金组织中,可能终止于晶内或晶界,有时也能横穿几个晶粒。

图3所示为变形组织中的针状物和锯齿状物的XRD谱。由图3可以看出,在针状物和锯齿状物的XRD谱线上除出现β相特征衍射峰外,还出现了一种相同的马氏体特征衍射峰。由文献[7]中马氏体晶格特征数据可知,这种马氏体为斜方马氏体(α″),晶格常数为a=0.301 nm,b=0.491 nm,c=0.463 nm。合金中观察到的两类马氏体在形貌上存在明显差异,但XRD物相分析表明,合金中只存在一种马氏体相结构(α″),说明TB6钛合金在变形过程中出现的形变诱导马氏体α″在外观上呈现两种形态特征。

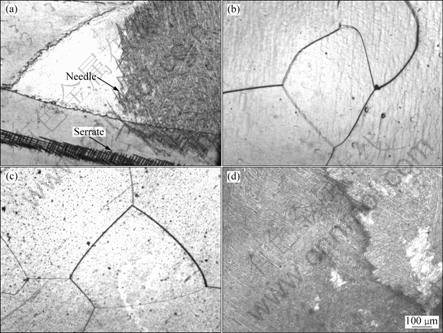

图4所示为合金经825 ℃, =0.01 s-1,ε=0.92变形后的金相组织及该变形试样经900 ℃固溶20 min

=0.01 s-1,ε=0.92变形后的金相组织及该变形试样经900 ℃固溶20 min

图2 热变形后铸态TB6钛合金组织中两种类型转变产物的形貌

Fig.2 Two typical morphologies of transition structures for as-cast TB6 alloy after hot deformation: (a) Needle-type structure (950 ℃,  =0.1 s-1, ε=0.92); (b) Serrate-type structure (1 125 ℃,

=0.1 s-1, ε=0.92); (b) Serrate-type structure (1 125 ℃,  =0.001 s-1, ε=0.92)

=0.001 s-1, ε=0.92)

图3 变形组织中两种转变产物的XRD谱

Fig.3 XRD patterns of two kinds of transition structures: (a) Needle-type structure (950 ℃,  =0.1 s-1, ε=0.92); (b) Serrate-type structure (1 125 ℃,

=0.1 s-1, ε=0.92); (b) Serrate-type structure (1 125 ℃,  =0.001 s-1, ε=0.92)

=0.001 s-1, ε=0.92)

图4 铸态TB6钛合金经825 ℃、 =0.01 s-1、ε=0.92变形后的金相组织及该变形试样经900 ℃固溶20 min后分别进行水冷、空冷和随炉冷的金相组织

=0.01 s-1、ε=0.92变形后的金相组织及该变形试样经900 ℃固溶20 min后分别进行水冷、空冷和随炉冷的金相组织

Fig.4 Microstructures of TB6 titanium alloy taken from samples deformed under conditions of 825 ℃,  =0.01 s-1, ε=0.92 (a) and then sectioned to heat treated at 900 ℃ for 20 min and followed with different cooling rates in water-cooling (b), air-cooling (c) and furnace cooling (d), respectively

=0.01 s-1, ε=0.92 (a) and then sectioned to heat treated at 900 ℃ for 20 min and followed with different cooling rates in water-cooling (b), air-cooling (c) and furnace cooling (d), respectively

后分别进行水冷、空冷和随炉冷的金相组织。由图4(a)观察到,在变形试样的金相组织中出现了针状物和锯齿状物(见箭头),此针状物和锯齿状物的组织形态明显与原始材料中的组织形态存在差异。由此判断该针状物和锯齿状物不应是变形前保温时间不足而导致的原始组织未溶物。图4(b)所示为将变形组织经900 ℃固溶20 min后水冷的金相组织,可见,组织中全由β晶粒组成,未见针状物和锯齿状物出现。变形组织经900 ℃固溶20 min后空冷的金相组织(见图4(c))与水冷组织相似,也未出现针状物和锯齿状物。本热变形实验的冷却方式是采用氦气冷却,其冷却速度应是介于水冷和空冷时的冷却速度,在合金经水冷和空冷后的组织中均未观察到针状物和锯齿状物,说明冷却速度与变形组织中针状物和锯齿状物的出现关系不大。图4(d)所示为将变形组织经900 ℃固溶20 min后炉冷的金相组织,可见,该组织与图1中的材料原始组织相似,不同于针状物和锯齿状物形态。因此,变形组织中出现的针状物和锯齿状马氏体不应是未溶或冷却过程中产生的α相,也不应是由于快冷而产生的马氏体,而是形变诱导马氏体组织。

3 讨论

3.1 形变诱导马氏体转变的原因

钛合金的β相之所以能保持至室温是由于合金中加入一定数量的β稳定元素的缘故。含有不同β稳定元素的钛合金中形成的β相的稳定程度采用β相条件稳定系数Kβ表示,采用式(1)计算[13]:

(1)

(1)

式中:wn为合金中元素的质量分数,%;wkn为该合金元素的临界质量分数,%。TB6(Ti-10V-2Fe-3Al)钛合金中的β稳定元素是V和Fe,其临界浓度分别为15%和5%。根据式(1)可以计算出该合金的Kβ为1.06,稍微超过1.0。当合金Kβ值刚好为1.0时,马氏体开始转变温度为室温;当合金Kβ值小于和大于1.0时,马氏体开始转变温度分别为室温以上和室温以下[13]。因此,TB6钛合金在无应力作用下马氏体开始转变温度为室温以下,即在固溶处理及淬火过程中是不能出现马氏体转变的,但β相处于机械不稳定状态,在内应力的作用下可能使马氏体开始转变温度上升到室温以上,促使发生马氏体转变。

3.2 晶体结构的演变

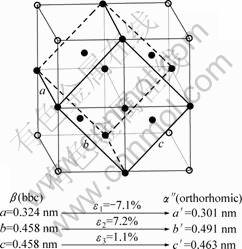

TB6钛合金作为亚稳β钛合金,其过冷β相在应力或应变作用下发生马氏体相变,这种形变诱导马氏体相变必然导致晶体结构之间的相互转变。TB6钛合金形变诱导斜方马氏体α″与基体β相之间保持如下的位向关系: [14],其示意图如图5所示。当基体β相由体心立方结构转变为斜方的α″时,β相的晶胞发生扭曲。相应地,晶胞上的原子发生移动:

[14],其示意图如图5所示。当基体β相由体心立方结构转变为斜方的α″时,β相的晶胞发生扭曲。相应地,晶胞上的原子发生移动:

(0, 0, 0)β→(0, 0, 0)α″

(a/2, b/2, 0) β→(a′/2, b′/2, 0)α″

(0, b/2, c/2) β→(0, 2b′/3, c′/2)α″

(a/2, 0, c/2) β→(a′/2, b′/6, c′/2)α″

图5 TB6钛合金β相转变为斜方α″时的点阵参数和点阵应变的变化

Fig.5 Variation of lattice parameters and lattice strain of β→α″ transformation in TB6 titanium alloy (BBC cell: narrow line and open circles(β), orthorhomic cell: heavy line and closed circles (α″))

原子移动的结果使得沿着3个点阵方向发生点阵应变:ε1=-7.1%,ε2=7.2%,ε3=1.1%。点阵常数也由原来β相的变为斜方α″相的a′=0.301 nm,b′=0.491 nm,c′=0.463 nm[7]。

虽然本实验的条件(合金先β相区热变形后快冷)与文献[7,12]中的实验条件(合金先β相区固溶、快冷后变形)存在一定差异,但是促使马氏体转变的机理应是相同的,即都是在应力的作用下使马氏体开始转变温度升高到室温以上。图3的XRD谱也证实了在本实验条件下变形组织中出现的马氏体晶体结构与文献[7,12,15]的报道是一致的。

3.3 马氏体的形核及亚结构

形变诱导马氏体一般优先在预先存在的晶界和亚晶界形核,并不断生长成近似平行的细条状或针状,后生长成树枝状[15] 。试验观察发现,在TB6钛合金中的形变诱导马氏体也存在这种形核和生长模式。在马氏体转变初期,在β相基体中形成条状马氏体主干,主干之间近似平行(见图6(a))。随着马氏体转变的进一步发展,马氏体枝干不断从主干中生长出来,马氏体枝干之间可能发生交合、重叠,但主干仍能清楚呈现其相互平行的特点(见图6(b))。

图6 形变诱导马氏体的金相组织

Fig.6 Microstructures of stress-induced martensite: (a) Early stage of transition (825 ℃,  =0.01 s-1, ε=0.92); (b) Final stage of transition (950 ℃,

=0.01 s-1, ε=0.92); (b) Final stage of transition (950 ℃,  =0.1 s-1, ε=0.92)

=0.1 s-1, ε=0.92)

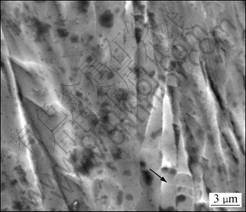

一般来说,孪晶是形变诱导马氏体内部亚结构的主要形式。DUERIG[7]等认为,Ti-10V-2Fe-3Al钛合金形变诱导马氏体内部存在á111?{112}类型的孪晶。而一些学者在Ti-Ni-Nb合金形变诱导马氏体内部观察到了(111)型孪晶体[16]。MENG等[17]研究认为,Ti-Ni-Hf合金形变诱导马氏体的亚结构主要为(001)型孪晶。孪晶的特点是在切应力的作用下晶体一部分相对另一部分发生以孪晶面为面对称的共格切变,而发生孪晶部分与未发生孪晶部分保持面对称关系。在本实验条件下产生的形变诱导马氏体内部也可能存在孪晶亚结构。图7所示为形变诱导马氏体的SEM像。可见,某些马氏体内部晶体的某一部分与相邻之间在形貌上保持一定的对称关系,存在孪晶形貌的一般特征。

图7 形变诱导马氏体(950 ℃,  =0.1 s-1, ε=0.92)的SEM像

=0.1 s-1, ε=0.92)的SEM像

Fig.7 SEM micrograph of stress-induced martensite (950 ℃,  =0.1 s-1, ε=0.92)

=0.1 s-1, ε=0.92)

4 结论

1) TB6钛合金β相条件稳定系数Kβ为1.06,β相处于机械不稳定状态,一定应力作用下将发生马氏体转变。

2) 在β相区热变形后快冷过程中合金存在形变诱导斜方马氏体相变,其晶格常数为a′=0.301 nm,b′=0.491 nm,c′=0.463 nm。这种形变诱导马氏体相变是通过β相沿着3个点阵方向发生点阵应变ε1=-7.1%,ε2=7.2%,ε3=1.1%而实现的。

3) 形变诱导马氏体呈现针状和锯齿状两种形貌,其转变模式是先形成近似平行的细条状或针状主干,后从主干中不断生长成树枝状,枝干之间可能发生交合、重叠,马氏体内部可能存在孪晶。

References

[1] DATTA K, DELHEZ R, BRONSVELD P M. A low-temperature study to examine the role of [epsilon]-martensite during strain-induced transformations in metastable austenitic stainless steels[J]. Acta Materialia, 2009, 57(11): 3321-3326.

[2] STANCIU S, BUJOREANU L G. Formation of β′1 stress-induced martensite in the presence of [gamma]-phase, in a Cu-Al-Ni-Mn-Fe shape memory alloy[J]. Materials Science and Engineering A, 2008, 481/482: 494-499.

[3] GOLLERTHAN S, YOUNG M L, NEUKING K. Direct physical evidence for the back-transformation of stress-induced martensite in the vicinity of cracks in pseudoelastic NiTi shape memory alloys[J]. Acta Materialia, 2009, 57(19): 5892-5897.

[4] LIU W B, WEN Y H, LI N. Effects of electropulsing treatment on stress-induced martensite transformation of a pre-deformed Fe17Mn5Si8Cr5Ni0.5NbC alloy[J]. Materials Science and Engineering A, 2009, 507(1/2): 114-116.

[5] KOUL M K, BREEDIS J F. Phase transformations in beta isomorphous titanium alloys[J]. Acta Metallurgica, 1970, 18(6): 579-588.

[6] BLACKBURN M J, WILLIAMS J C. Phase Transformations in Ti-Mo and Ti-V alloys[J]. Transactions of TMS-AIME, 1968, 242: 2461-2469.

[7] DUERIG T W, ALBRECHT J, RICHTER D. Formation and reversion of stress-induced martensite in Ti-10 V-2 Fe-3Al[J]. Acta Materialia, 1982, 30(12): 2161-2172.

[8] 刘 彬, 黄 旭, 黄利军, 齐立春. TB6 钛合金多重固溶时效热处理工艺研究[J]. 稀有金属, 2009, 33(4): 489-493.

[9] Liu Bin, Huang Xu, Huang Li-jun, QI Li-chun. Efect of multiple solution and aging treatment on microstructure and mechanical property of TB6 titanium alloy[J]. Chinese Journal of Rare Metals, 2009, 33(4): 489-493.

[10] 李 骋, 何玉怀, 黄利军, 苏 彬. TB6 钛合金疲劳及裂纹扩展性能研究[J]. 失效分析与预防, 2008, 3(3): 17-22.

[11] LI Cheng, HE Yu-huai, HUANG Li-jun, SHU Bin. Study on fatigue property and crack growth behavior of TB6 titanium alloy[J]. Failure Analysis and Prevention, 2009, 3(3): 17-22.

[12] 吕逸帆, 孟祥军, 李士凯. TB6合金β斑研究概述[J]. 稀有金属材料与工程, 2008, 37(增刊3): 544-548.

[13] L? Yi-fan, MENG Xiang-jun, LI Shi-kai. An overview of β fleck in TB6 alloy[J]. Rare Metal Materials and Engineering, 2008, 37(supplement 3): 544-548.

[14] BHATTACHARJEE A, BHARGAVA S, VARMA V K. Effect of β grain size on stress induced martensitic transformation in β solution treated Ti-10V-2Fe-3Al alloy[J]. Scripta Materialia, 2005, 53(2): 195-200.

[15] 沈桂琴, 张 虹. Ti-10V-2Fe-3Al 合金的应力诱发马氏体转变[J]. 航空材料学报, 1997, 53(2): 26-31.

[16] Sheng Gui-qin, zhang Hong. Stress induced formation of martensite in Ti-10V-2Fe-3Al[J]. Journal of Aeronautical Materials, 2005, 53(2): 195-200.

[17] 王金友, 葛志明, 周彦邦. 航空用钛合金[M]. 上海: 上海科学技术出版社, 1985: 199-203.

[18] WANG Jin-you, GE Zhi-ming, ZHOU Yan-bang. Titanium alloys in aviation applications[M]. Shanghai: Scientific and Technical Press, 1985: 199-203.

[19] DUERIG T W, MIDDLETON R M, TERLINDE G T. Stress assisted transformation in Ti-10V-2Fe-3Al[C]//Proceedings of the 4th International Conference on Titanium. 1980, 2: 1503-1512.

[20] ZHANG L C, ZHOU T, AINDOW M. Nucleation of stress-induced martensites in a Ti/Mo-based alloy[J]. Journal of Materials Science, 2005, 40(11): 2833-2836.

[21] ZHENG Y F, CAI W, ZHANG J X. Microstructural development inside the stress induced martensite variant in a Ti-Ni-Nb shape memory alloy[J]. Acta Materialia, 2000, 48(6): 1409-1425.

[22] MENG X L, CAI W, ZHENG Y F. Stress-induced martensitic transformation behavior of a Ti-Ni-Hf high temperature shape memory alloy[J]. Materials Letters, 2002, 55(1/2): 111-115.

(编辑 龙怀中)

基金项目:国家重点基础研究发展计划资助项目(2007CB613803);国家自然科学基金资助项目(51005112);航空科学基金资助项目(2009ZE56014);江西省自然科学基金资助项目(2008GZC0041);江西省教育厅科技资助项目(GJJ08203)

收稿日期:2009-12-17;修订日期:2010-04-28

通信作者:鲁世强,教授,博士;电话:0791-3863039;E-mail:niatlusq@126.com