Influence of heat treatment on fracture and magnetic properties of radially oriented Sm2Co17 permanent magnets

TIAN Jian-jun(田建军), QU Xuan-hui(曲选辉), ZHANG Shen-gen(张深根),

A. FARID, TAO Si-wu(陶斯武), DU Xue-li(杜学丽)

School of Materials Science and Engineering, University of Science and Technology Beijing, Beijing 100083, China

Received 4 September 2006; accepted 13 March 2007

Abstract: The quenching, fracture and aging treatment of radially oriented Sm2Co17 ring magnets were investigated. The results indicate that the ring magnets have obvious anisotropy of thermal expansion, which easily leads to the splits of the magnets during quenching. The fracture is brittle cleavage fracture. The difference (Δa) of the expansion coefficient reaches the maximum value at 800-850 ℃. So, various quenching processes at different steps are adopted in order to reduce the splits. When the magnets are aged, 1?5 phase precipitates from the 2?17 matrix phase and forms a cellular microstructure with 2?17 phase. BHmax and JHc reach the maximum value 226 kJ/m3 and 2 170 kA/m after being aged at 850 ℃ for 4 h and 8 h, respectively. The aging treatment at 850 ℃ has little influence on remanence(Br), which can always keep a high value (≥1.0 T). Through appropriate heat treatment, the ring magnets have uniform cellular microstructure and excellent magnetic properties: Br≥1.0T, JHc≥2 100 kA/m, BHmax≥220 kJ/m3.

Key words: Sm2Co17 permanent magnets; radially oriented ring magnets; heat treatment; fracture; magnetic properties

1 Introduction

Sm2Co17 permanent magnets have been widely used in industry because of their excellent intrinsic magnetic properties. Recently, Sm2Co17 permanent magnets have attracted considerable attention on high-temperature applications due to their high-Curie temperature (≥800 ℃)[1-5]. Sm2Co17 magnetic products are indispensable in many fields. Among these magnets, radially oriented Sm(Co, Fe, Cu, Zr)z ring magnets are usually applied in airships, satellites, naval ships, and missiles, etc[6-7]. The ring magnets have homogeneous magnetic field lines, which distribute radially along the ring diameter.

Heat treatment is a necessary step in the manufacture process of sintered Sm2Co17 magnets. The heat treatment mainly consists of quenching and aging. After sintering and solution, the Sm2Co17 samples are quenched at rapid cooling rate in order to form supersaturation solid solution. The solid is composed of single 2?17 phase and has low value of coercivity and energy product. After aging, the supersaturation alloy forms multiphase solid and cellular microstructure. Thus the alloy acquires excellent magnetic properties. But radially oriented Sm2Co17 ring magnets are easy to split during quenching because of its thermal expansion[8-9]. In this paper, the thermal expansion, fracture and quenching of the radially oriented Sm2Co17 magnets were studied. Besides, the effect of aging treatment on the magnetic properties of the magnets was also investigated.

2 Experimental

Alloy with nominal composition Sm(Cobal,Fe0.17, Cu0.08,Zr0.03)7.5 were prepared by vacuum induction melting and mold casting with rapid cooling rate. The alloy ingot was milled into powder with an average particle diameter about 4 mm. This process was done in gasoline to prevent oxidation. Alloy powder were aligned and molded into green rings in radially oriented magnetic field. The green compacts were sintered at 1 200-1 220 ℃ and solutionized at 1 160-1 175 ℃, followed by different quenching processes to room temperature. After quenching, the magnets were aged at 850 ℃ for different periods. The sizes of the ring magnets were: inside diameter d18 mm, outside diameter d29 mm and thickness 7 mm.

Magnetic properties, namely, remanence Br, intrinsic coercivity JHc and maximum energy product BHmax, were measured using a hysteresisograph system model NIM-200C. Thermal expansion was measured using a Netzsch Dil 402C measurement equipment. Fracture pattern was studied using a JSM-6301F scanning electron microscope (SEM). Microstructure was studied using a H-800 transmission electron microscope (TEM).

3 Results and discussion

3.1 Quenching and fracture

After sintering and solution, Sm2Co17 alloy must be quenched from high temperature (1 160-1 175 ℃) to room temperature at rapid cooling rate to form supersaturation solid. During quenching, the rapid cooling rate leads to a very high temperature difference (DT), which forms thermal expansion stress in the magnets. The more rapid the cooling rate is, the higher the stress is. When the expansion stress is more than the tensile strength of the ring magnets, the magnets will split. Therefore, we studied the influence of quenching temperature and thermal expansion on the ring magnets in order to acquire an appropriate quenching process.

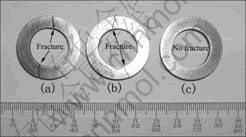

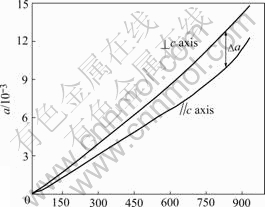

The ring magnets were quenched in water from 1 170, 1 000 and 800 ℃, respectively. The result shows that the ring magnets do not split only at 800 ℃ (shown in Fig.1). Fig.2 shows the thermal expansion curves of the ring magnets in easy magnetization direction and hard magnetization direction. The easy magnetization (c axis) of the ring magnets points to the ring center. It can be seen that the magnets have obvious anisotropy of thermal expansion. When the temperature is below 830 ℃, the difference (Δa) of the expansion coefficient (a) between easy magnetization and hard magnetization direction increases with increasing temperature. Contrary to that, when temperature is above 830 ℃, Δa decreases with increasing temperature. 830 ℃ is the Curie temperature of the magnets. This indicates that the thermal expansion changes to isotropy from anisotropy, when temperature is above Curie temperature. Besides, Δa reaches maximum at 800-850 ℃. During quenching, the anisotropic thermal expansion produces various thermal stresses in different directions. With the growth of Δa, the stress difference (Δa) of different directions increases. So, Δa is up to the maximum at 800-850 ℃. Therefore, the ring magnets are easy to split when the magnets are quenched in water from high temperature (>800 ℃). We adopted different quenching processes at different steps to reduce the splits. The magnets were first quenched in wind from solution temperature (1 160-1 175 ℃) to 800 ℃ (cooling rate of 40-80 ℃/ min), then quenched in water from 800 ℃ to room temperature.

Fig.1 Image of ring magnets quenched in water from high temperature: (a) 1 170 ℃; (b) 1 000 ℃; (c) 800 ℃

Fig.2 Thermal expansion curves of magnets in different directions

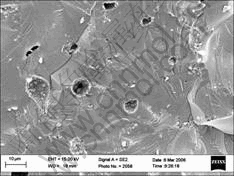

Fig.3 shows the fracture micrograph of the ring magnets. It can be seen that the fracture is brittle cleavage fracture. The fracture surface shows the river pattern and cleavage steps characters of cleavage fracture. Besides, there are some pores in the cleavage plane, which cause great stress concentration during quenching and become the weakest link in the magnets.

Fig.3 Fracture micrograph of ring magnets

3.2 Aging treatment

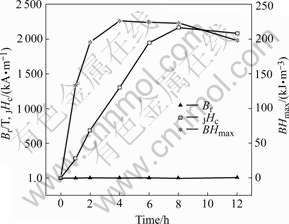

After quenching, Sm2Co17 is supersaturation solid, which must be aged to acquire cellular microstructure and excellent magnetic properties. The supersaturation samples are aged at 850 ℃ for different periods, followed by a slow cooling to 400 ℃ at a cooling rate of 0.7 ℃/min. Fig.4 shows the magnetic properties (Br, JHc and BHmax) of the magnets aged at 850 ℃ for different periods. The results indicate that JHc and BHmax increase drastically with increasing aging time at 850 ℃. BHmax and JHc reach the maximum value 226 kJ/m3 and 2 170 kA/m after aged at 850 ℃ for 4 h and 8 h, respectively. The aging treatment has little influence on Br, which can always keep a high value (≥1.0 T).

Fig.4 Magnetic properties of magnets aged at 850 ℃ for different time

Fig.5 shows X-ray diffraction patterns of the magnets aged at 850 ℃ for 0, 4 and 8 h, respectively. It can be seen that the sample consists of single Sm2(Co, Fe, Cu, Zr)17 phase (2?17 phase) before aging treatment. When the magnets are aged, the diffraction peaks of Sm(Co, Cu)5 phase (1?5 phase) appear. The intensities of the peaks of 1?5 phase grow with increasing aging time at 850 ℃ because the volume fraction of 1?5 phase increases. The magnets are predominantly composed of 2?17 phase and 1?5 phase after aging treatment. 2?17 phase and 1?5 phase form a cellular microstructure. The cell interior of the microstructure is 2?17 phase, which is surrounded by 1?5 phase. 2?17 phase is responsible for the high saturation magnetization, and 1?5 phase for the high intrinsic coercivity by pinning the domain walls[10-14]. Therefore, when the aging time at 850 ℃ prolongs, the volume fraction of 1?5 phase increases, which leads to a higher intrinsic coercivity (JHc) because of higher pinning strength for the domain walls. JHc increases with increasing aging time evidently. But the cellular microstructure of the magnets will be destroyed when the magnets are aged at 850 ℃ for quite a long time[15]. So, JHc starts to decrease when aging time at 850 ℃ is more than 8 h (shown in Fig.4).

Fig.5 Typical X-ray diffraction patterns of magnets aged at 850℃ for different periods

3.3 Magnetic properties and microstructure

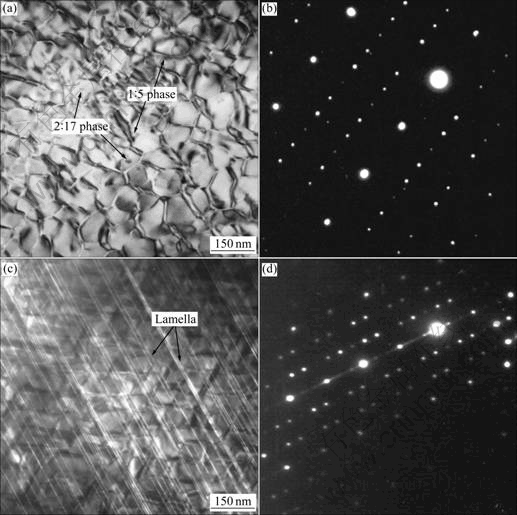

Fig.6 shows the demagnetization curve of the ring magnets. It is clear that the magnets have excellent magnetic properties: Br=1.08 T, JHc=2 170 kA/m, BHmax=224 kJ/m3. Fig.7 shows TEM microstructure and typical diffraction pattern of the ring magnets. Fig.7(a) gives the TEM micrograph perpendicular to the c aixs, which shows the homogeneous celleular microstructure of the magnets. The cell interior is a rhombohedral Sm2(Co, Fe)17 phase, which is surrounded by a hexagonal Sm(Co, Cu)5 cell boundary phase. Sm2(Co, Fe)17 phase is responsible for the high saturation magnetization, and Sm(Co, Cu)5 phase for the high coercivity by pinning the domain walls[10-14]. Fig.7(b) shows the lamella phase of the magnets. The microstructure is parallel to the c axis. The lamella phase is a Zr-rich hexagonal 2?17 phase, which is superimposed on the cellular microstructure. Lamella phase helps to form a uniform Sm(Co, Cu)5 cell boundary phase by providing easy diffusion paths for Cu segregation [16-19].

Fig.6 Demagnetization curve of ring magnets

Fig.7 TEM microstructures and typical diffraction patterns of radially oriented Sm(Co, Fe, Cu, Zr)z ring magnets: (a) Perpendicular; (b) Parallel to c axis of magnets

4 Conclusions

1) Radially oriented Sm2Co17 ring magnets have obvious anisotropy of thermal expansion, which easily leads to the splits of the magnets during quenching. The fracture is brittle cleavage fracture. The difference (Δa) of the expansion coefficient (a) reaches maximum at 800-850 ℃. Therefore, the magnets are first quenched in wind from solution temperature (1 160-1 175 ℃) to 800 ℃ (cooling rate of 40-80 ℃/min), then quenched in water from 800℃ to room temperature.

2) When the magnets are aged, 1?5 phase precipitates from 2?17 matrix phase. BHmax and JHc increase evidently with increasing aging time. BHmax and JHc reach the maximum value 226 kJ/m3 and 2 170 kA/m after aged at 850 ℃ for 4 h and 8 h, respectively. The aging treatment has little influence on Br, which can always keep a high value (≥1.0 T).

3) Through appropriate heat treatment, the ring magnets have excellent magnetic properties: Br≥1.0 T, JHc≥2 100 kA/m, BHmax≥2 200 kJ/m3. The micro- structure of the magnets consists of a mixture of uniform cellular and lamella structures.

References

[1] Schobinger D, Gutfleisch O, Hinz D, Müller K H, Schultz L, Martinek G. High temperature magnetic properties of 2?17 Sm-Co magnets [J]. J Magn Magn Mater, 2002, 242/245: 1347-1350.

[2] Zhang Y, Corte-Real M, Hadjipanayis G C, Liu J F, Walmer M S, Krishnan K M. Magnetic hardening studies in sintered Sm(Co, Cux, Fe, Zr)z 2?17 high temperature magnets [J]. J Appl Phys, 2000, 87(9): 6722-6724.

[3] Liu J F, Chui T, Dimitrov D, Hadjipanayis G C. Abnormal temperature dependence of intrinsic coercivity on Sm(Co, Fe, Cu, Zr)z powder materials [J]. Appl Phys Lett, 1998, 73(20): 3007-3009.

[4] Gjoka M, Panagiotopoulos I, Niarchos D, Matthias T, Fidler J. Temperature-compensated Sm1-xGdx(Co0.74Fe0.10Cu0.12- Zr0.04)7.50 permanent magnets (x=0, 0.2, 0.4, 0.6, 0.8) [J]. J Alloy Compd, 2004, 367: 262-265.

[5] LI Li-ya, YI Jian-hong, HUANG Bai-yun, PENG Yuan-dong, DU Juan. Microstructure of Sm2Co17 magnets and its influence on coercivity [J]. Trans Nonferrous Met Soc China, 2004, 14(4): 790-793.

[6] ZHANG Shen-gen, TIAN Jian-jun, QU Xuan-hui, TAO Si-wu. Research on the sintering process of 2?17 type Sm-Co radially oriental integral magnetic ring [J]. J Funct Mater, 2006, 37(2): 200-203. (in Chinese)

[7] GUO De-sen, LI Hui. Application and development of multi-pole ring magnet [J]. J Magn Mater Devices, 2005, 36(2): 31-34. (in Chinese)

[8] Paladino A E, Weihrauch P F, Newborn H A. Application of hot pressing in fabricating radial polarized Sm-Co magnets [J]. IEEE Trans Magn, 1975, 11(5): 1455-1457.

[9] SUN Tian-duo, ZHU Jing-han, WANG De-wen. Anisotropic thermal expansion and fracture of radially oriented toroids of RE-Co permanent magnets [J]. Acta Metallurgica Sinica, 1979, 15(1): 58-68. (in Chinese)

[10] Fidler J, Skalicky P. Microstructure of precipitation hardened cobalt rare earth permanent magnets [J]. J Magn Magn Mater, 1982, 27: 127-130.

[11] Rabenberg L, Mishra R K, Thomas C. Microstructures of precipitation-hardened SmCo permanent magnets [J]. J Appl Phys, 1982, 53: 2389-2391.

[12] Yan A, Handstein A, Gemming T, Müller K H, Gutfleisch O. Coercivity mechanism of Sm2(Co, Cu, Fe, Zr)17-based magnets prepared by melt-spinning [J]. J Magn Magn Mater, 2005, 290/291: 1206-1209.

[13] Gopalan R, Ohkubo T, Hono K. Identification of the cell boundary phase in the isothermally aged commercial Sm(Co0.725- Fe0.1Cu0.12Zr0.04)7.4 sintered magnet [J]. Scripta Materialia, 2006, 54: 1345-1349.

[14] GUO Z H, PAN W, LI W. Sm(Co, Fe, Cu, Zr)z sintered magnets with a maximum operating temperature of 500 ℃ [J]. J Magn Magn Mater, 2006, 303: e396-e401.

[15] ZHOU Shou-zeng. Rare Earth Permanent Magnets and Application [M]. Beijing: Metallurgy Industry Press, 1995. (in Chinese)

[16] Tang W, Zhang Y, Hadjipanayis G C. Effects of Zr on the microstructure and magnetic properties of Sm(CobalFe0.1Cu0.088Zrx)8.5 magnets [J]. J Appl Phys, 2000, 87(1): 399-402.

[17] Camposa M F, Neiva A C, Romeroc S A, Rechenberg H R, Missell F P. Impurity phases in Sm(CoFeCuZr)z magnets: The role of Zr [J]. J Alloy Compd, 2005, 403: 329-334.

[18] PENG Yuan-dong, YI Jian-hong, LI Li-ya, LI Yun-qing, DU Juan. Design principles of high temperature Sm(Co, Fe, Cu, Zr)z permanent magnets [J]. Journal of Central South University: Natural Science, 2002, 33(1): 60-62. (in Chinese)

[19] LI Li-ya, YI Jian-hong, PENG Yuan-dong, ZENG Qin-ling, FU Ying-sheng. High temperature Sm2(Co, Cu, Fe, Zr)17 permanent magnets [J]. Journal of Central South University: Natural Science, 2001, 32(6): 608-611. (in Chinese)

Foundation item: Project(20040008015) supported by the Specialized Research Fund for the Doctoral Program of Higher Education; Project supported by the Program for New Century Excellent Talents in University, China

Corresponding author: TIAN Jian-jun; Tel: +86-13261216081; E-mail: twbky@163.com

(Edited by YANG Hua)