文章编号:1004-0609(2008)07-1185-06

快速凝固/粉末冶金AZ91/SiCp镁基复合材料的

相组成及界面

盛绍顶,陈 鼎,陈振华,陈 刚,严红革

(湖南大学 材料科学与工程学院,长沙 410082)

摘 要:采用双辊雾化法制备快速凝固AZ91镁合金粉末,并用粉末冶金方法制备SiC颗粒增强的镁基复合材料棒材,研究AZ91/SiCp复合材料的微观组织、相组成及增强相与合金基体间的界面结构特点。结果表明:双辊雾化快速凝固AZ91镁合金粉末的相组成为α-Mg固溶体主相和微量细小的T-AlMg2Zn相,尺寸在0.2 mm左右;在后续热挤压过程中合金基体中析出大量的球形b-Mg17Al12,尺寸在0.5 mm左右,而T-AlMg2Zn相的形貌和尺寸无明显变化;复合材料在加热过程中,增强相SiC颗粒表面的SiO2层与合金基体之间发生界面反应。

关键词:镁基复合材料;快速凝固;粉末冶金;界面

中图分类号:TG 156.3 文献标识码:A

Phase composition and interface of rapidly solidified/powder metallurgy AZ91/SiCp Mg-based composite material

SHENG Shao-ding, CHEN Ding, CHEN Zhen-hua, CHEN Gang, YAN Hong-ge

(College of Materials Science and Engineering, Hunan University, Changsha 410082, China)

Abstract: Rapidly solidified (RS) AZ91 magnesium alloy powders and the Mg-based composite material reinforced by SiC particles were produced by twin-roller atomization method and powder metallurgy, respectively. The microstructure, phase compositions and interface characterization between Mg matrix and reinforcing particles of AZ91/SiCp composite material were investigated. The results show that the RS AZ91 magnesium alloy powders are composed of α-Mg and a small quantity of fine T-AlMg2Zn with grain size of about 0.2 μm. A large number of global β-Mg17Al12 with grain size of about 0.5 μm are observed after hot extrusion, but the appearance and grain size of T-AlMg2Zn phase is not changed remarkably during hot extrusion. In the heating process of the composite material, the interface reaction occurs between the layers of SiO2 on the surface of SiC particles and Mg matrix.

Key words: Mg-based composite material; rapidly solidified; powder metallurgy; interface

镁合金是金属结构材料中密度最小的,同时又具有很好的阻尼性能[1?2],在航空、航天和国防工业等领域有着广泛的应用前景。通过在镁合金基体中添加陶瓷颗粒增强相,可以显著提高材料的强度、模量和耐热性能[3?6]。用于制备这种陶瓷颗粒增强镁基复合材料的方法有铸造法、粉末冶金法和喷射共沉积法等3大类型[7],但采用铸造法制备镁基复合材料时存在陶瓷颗粒分散均匀性问题,且由于合金基体的晶粒组织粗大,其力学性能不够理想[8?10];喷射共沉积方法适合于制备大尺寸的镁合金复合材料坯件,但镁合金的喷射沉积过程存在很大的安全隐患,目前很少采用[11?15]。采用粉末冶金法制备的复合材料晶粒组织细小、均匀,陶瓷颗粒分散均匀性很好,且可以避免一些有害的界面化学反应,因此,该方法是制备高性能镁基复合材料的有效方法。若能采用快速凝固的方法制备出晶粒组织微细的合金粉末,则通过粉末冶金工艺有望制备出力学性能优异的复合材料[16?17]。采用快速凝固法制备镁合金的研究工作已有报道[18?19],但尚未见采用快速凝固/粉末冶金法制备镁基复合材料的报道。

本文作者采用自制的雾化双辊甩带制粉装置,制备快速凝固AZ91镁合金粉末,用粉末冶金法制备AZ91/SiCp镁基复合材料,探讨复合材料的相组成及界面结构特点。

1 实验

1.1 实验样品的制备

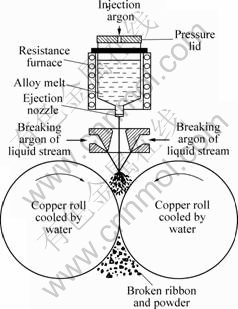

AZ91镁合金的名义成分为Mg-9%Al-1%Zn- 0.2%Mn(质量分数)。按照合金成分配料,在电阻炉中熔炼、精炼后,在如图1所示的自制双辊雾化装置上制备合金粉末。雾化过程在高纯Ar保护下进行。由图1所示,坩埚内的镁合金熔体在Ar压力下沿坩埚下部的小孔喷出合金细流,合金细流经过雾化器雾化成细小的液滴,雾化气体为高纯氩气,雾化后的合金液滴喷在高速旋转的双辊上快速冷却,并甩成碎箔带粉末。在双辊的下方装备一个喷气装置,将刚生成的粉末吹送到粉末收集箱中,喷射气体为高纯氩气。整个过程也在高纯氩气的保护下进行。

图1 快速凝固制备镁合金粉末碎带装置的结构示意图

Fig.1 Schematic diagram of twin-roller atomization equipment

将制得的碎箔片粉末在惰性气体保护下破碎过筛,得到120 μm左右的粉末。将过筛后的合金粉末与经煅烧后的SiC粉末(粒度在3~5μm)粉末在“Y”形混料器中机械混合6~8 h,使SiC粉末与镁合金粉末混合均匀。SiC粉末的煅烧温度为900 K、时间为2 h,通过煅烧可以排除颗粒表面吸附的气体、水分,甚至油污等杂质。SiC粉末的加入量分别为15%、20%和25%。在自制的模具中将混合粉末压制成d 50 mm×60 mm的圆柱坯,压制温度为473 K,然后将其挤压成直径为8 mm的棒材,挤压温度为653 K,模具温度为623 K,挤压比为37?1。

1.2 实验样品的检测

采用德国MM?6光学显微镜观察粉末和棒材的金相组织,采用西门子D5000X射线衍射仪对粉末及挤压棒材进行X射线衍射分析(XRD),试样的透射电镜照片和高分辨晶格像采用JEM3010高分辨透射电镜获得,采用JEOM5600扫描电子显微镜对试样进行断口分析。

其中TEM、HRTEM样品的制备是先机械磨成0.05~0.08 ?m的薄片,再用电解双喷法进行减薄制得。在观察前再用离子减薄,除去表面的氧化层。双喷液选择苦味酸5 g+冰醋酸10 mL+乙醇100 mL+蒸馏水10 mL。双喷时温度低于243 K。

2 结果与讨论

2.1 粉末和挤压棒材的相组成

图2所示为快速凝固AZ91合金粉末和AZ91/SiCp复合材料棒材的金相组织照片。由图2(a)可以看出,合金粉末具有细小的等轴晶组织,晶粒大小为1~3 μm,这种组织与单辊甩带材料的组织明显不同。采用单辊甩带法得到的组织一般为分层组织,自由面和贴近铜辊面以及两面之间的组织有明显不同[20]。由图2(b)可知,SiC颗粒在合金基体中的分散较均匀。

图2 快速凝固AZ91碎箔带与相应SiCp/AZ91棒材金相组织照片

Fig.2 Optical microstructures of RS/AZ91 flakes and as- extruded bars of PM/SiCp/AZ91 magnesium alloys: (a) Flake; (b) As-extruded bar of 20%SiCp-d 8 mm

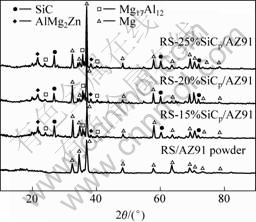

图3所示为基体合金粉末与AZ91/SiCp挤压棒材的XRD谱。由图可见,合金粉末为α-Mg单相固溶体,未见b-Mg17Al12析出相,这是由于采用雾化双辊法制备粉末时的冷速非常高,b-Mg17Al12相来不及从固溶体中析出。根据OHTOSHI的研究结果,采用双辊法制备合金带材时的冷速一般可达3×102 K/s以上[21],本实验采用双辊雾化法制备合金粉末,是一种双级快冷方法,根据二次枝晶间距与冷却速度关系,二次枝晶间距为1~2 mm时,可确定冷却速度为104 K/s左右。但这种单相过饱和固溶体在随后的热挤压过程中发生沉淀相析出反应,生成b-Mg17Al12和T-AlMg2Zn相。

图3 基体粉末与不同SiCp含量的挤压棒材的XRD谱

Fig.3 XRD patterns of AZ91 powder and SiCp-AZ91 bars with different contents of SiCp

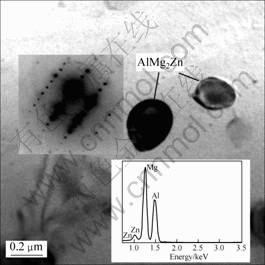

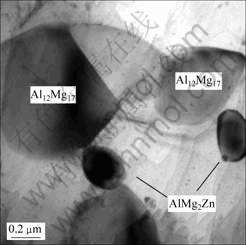

图4和5所示分别为快速凝固AZ91合金粉末和AZ91/20%SiCp复合材料挤压棒材的透射电镜照片。由图4可知,合金粉末中有少量的析出相,根据EDS结果可知,这种析出物是T-AlMg2Zn相。析出相的颗粒尺寸在0.2 mm左右。可能是由于T相的体积分数较小,XRD谱图中未见该相的衍射峰。在图5所示的组织中,T-AlMg2Zn相粒子的尺寸仍在0.2 mm左右,未见长大现象。这说明这种析出相粒子在材料热加工过程中能够保持稳定而不长大。由图5可以看出,复合材料的合金基体中析出了很多的b-Mg17Al12粒子,尺寸在 0.5 mm左右。

图4 快速凝固AZ91镁合金碎箔片的TEM像

Fig.4 TEM micrograph of RS AZ91 foils and EDS patterns

图5 AZ91/20%SiCp复合材料棒材的TEM像

Fig.5 TEM micrograph of AZ91/20%SiCp composite rod

2.2 合金基体与增强相间的界面和界面反应

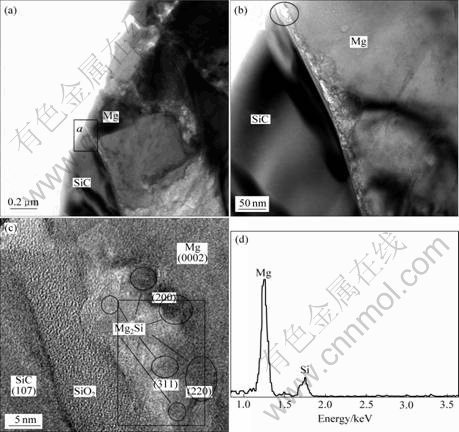

图6所示为AZ91/SiCp的TEM和HRTEM照片以及部分区域的EDS谱,其中图6(b)为图6(a)中a部分的放大像,图6(c)所示为图6(b)图圆圈部分的放大像,图6(d)所示为图6(c)图中方框部分的EDS谱。

图6 复合材料棒材的HRTEM像和EDS谱

Fig.6 TEM and HRTEM micrographs of composite rod and EDS spectrum: (a) TEM micrograph; (b), (c) HRTEM micrographs; (d) EDS specturm

研究表明,SiC在温度低于900 K的镁熔体中不易发生界面反应[ 21],ZHENG等[22]认为SiCw在镁基体中很稳定。因此,采用SiC颗粒作为镁合金的增强相可以避免有害的界面反应。GU等[23]研究了Cu包覆SiC和未包覆SiC颗粒增强的镁合金,发现Cu包覆SiC增强体与基体的结合很好,而由未包覆的SiC增强的复合材料在拉伸过程中有明显的SiC颗粒拔出现象。

由图6可以看出,镁基体与SiC颗粒之间形成反应界面层,呈不规则状(见图6(b))。由图6(c)所示的高分辨电镜照片可以看出,反应界面中存在一些纳米尺寸的颗粒,由EDS结果可知,这种颗粒为Mg2Si相。这些颗粒有些分布在非晶态的反应产物层中,还有一些颗粒分布在Mg基体与非晶反应产物层的界面上。Mg2Si颗粒的形成原因为SiC颗粒在煅烧过程中表面形成了一层SiO2非晶层,厚度约为10 nm左右(见图6(c)),在后续热加工过程中基体合金中的Mg与SiO2非晶层发生化学反应,形成Mg2Si相以及非晶反应产物。

2.3 增强体与基体的界面反应机制

有关镁基复合材料的界面反应问题的研究已有一些报道[9?14]。研究发现,三元系的互扩散引起的固态反应在反应区会形成多种不同结构的反应产物,而这些反应物在界面反应区一般为层状或混合状形态出 现[24],并指出,Si在Si/Mg界面形成Mg2Si时是稳定的。

本实验中挤压态SiCp/AZ91镁基复合材料,其挤压温度为623 K,保温时间一般不超过1 h。由图6(c)可以看出,在SiO2/Mg界面处,有两层反应物存在,分别为非晶态的MgO和混合分布的Mg2Si,最外层则是SiO2和Mg。反应产物的分布状态是:Mg2Si靠近镁基体,还有一些较小颗粒分布在非晶MgO中;MgO分布在Mg2Si和SiO2之间。这说明在623 K的中温区发生了界面反应,反应产物为Mg2Si和MgO。由此,本文作者认为,在623 K的中温区,界面反应没有孕育期或孕育期很短,这与文献[22]中的结果有所不同。

而SiO2/Mg界面的反应方程为:

这就说明界面反应是先生成MgO和Si,然后Si再与Mg反应生成Mg2Si,生成的Mg2Si主要集中在Mg基体附近,这由图6(c)也可以很清楚地看到。

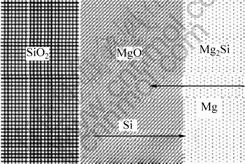

固/固界面反应机制主要是由扩散机制控制[22],本实验所涉及的反应温度为623 K,属于中温扩散。由前面的分析可知,首先是SiO2与Mg反应生成MgO和Si,然后Si扩散至Mg基体附近再与Mg反应生成Mg2Si,同时Mg也通过生成的Mg2Si层不断的扩散至SiO2附近再与SiO2反应生成MgO和Si,最后在反应界面形成反应界面层。该界面反应示意图如图7所示。

图7 界面反应示意图

Fig.7 Abridged general view of interface reaction

3 结论

1) 用雾化双辊快速凝固方法制备出快速凝固SiCp/AZ91镁基复合材料,双辊雾化快速凝固AZ91镁合金粉末主要为α-Mg固溶体,而经挤压后的复合材料棒材含有β-Mg17Al12和T-AlMg2Zn相。

2) 快速凝固合金粉末碎箔带的析出相为T-AlMg2Zn相,并且呈近球形,颗粒大小为200 nm左右,挤压态的析出相较多,主要为β-Mg17Al12相,挤压过程中T-AlMg2Zn相没有长大。

3) 增强体和基体之间发生了界面反应,反应产物呈混合层状分布。

REFERENCES

[1] LIAO Li-hua, ZHANG Xiu-qin, LI Xian-feng. Effect of silicon on damping capacities of pure magnesium and magnesium alloys[J]. Materials Letters, 2007, 61: 231?234.

[2] LIAO Li-hua, ZHANG Xiu-qing, WANG Hao-wei. Influence of Sb on damping capacity and mechanical properties of Mg2Si/Mg-9Al composite materials[J]. Journal of Alloys and Compounds, 2007, 430: 292?296.

[3] HASSAN S F, GUPTA M. Development of high performance magnesium nano-composites using nano-Al2O3 as reinforcement[J]. Mater Sci Eng A, 2005, 392: 163?168.

[4] YUAN Guang-yin, LIU Man-ping, DING Wen-jiang, INOUE A. Microstructure and mechanical properties of Mg-/Zn-/Si-based alloys[J]. Mater Sci Eng A, 2003, 357: 314?320.

[5] LU L, THONG K K, GUPTA M. Mg-based composite reinforced by Mg2Si[J]. Composites Science and Technology, 2003, 63: 627?632.

[6] WANG H Y, JIANG Q C, WANG Y, MA B X, ZHAO F. Fabrication of TiB2 particulate reinforced magnesium matrix composites by powder metallurgy[J]. Materials Letters, 2004, 58: 3509?3513.

[7] 陈振华, 夏伟军, 陈吉华, 严红革, 陈 鼎, 滕 杰, 张 昊, 贺毅强, 盛绍顶. 耐热镁合金[M]. 北京: 化学工业出版社, 2007: 327?345.

CHEN Zhen-hua, XIA Wei-jun, CHEN Ji-hua, YAN Hong-ge, CHEN Ding, TENG Jie, ZHANG Hao, HE Yi-qiang, SHEN Shao-ding. Heat-resisting magnesium alloy[M]. Beijing: Chemical Industry Press, 2007: 327?345.

[8] LEE H S, JEON K Y, KIM H Y, HONG S. Fabrication process and thermal properties of SiCp/Al metal matrix composites for electronic packaging applications[J]. Journal of Materials Science, 2000, 35(24): 6231?6236.

[9] HU Lian-xi, WANG Er-de. Fabrication and mechanical properties of SiCw/ZK51A magnesium matrix composite by two-step squeeze casting[J]. Mater Sci Eng A, 2000, 278: 267?271.

[10] HU H. Grain microstructure evolution of Mg(AM50A)/SiCp metal matrix composites[J]. Scripta Materialia, 1998, 39(8): 1015?1022.

[11] SCHRODER J, KAINER K U. Characterization of P/M magnesium-SiCp-compsites processed by spray forming. Powder Forging and Extrusion of Composite Powder Mixtures[C]// ALDINGER F. Materials by Powder Technology. PJM193. Oberursel: DGM-Infornation Syesellschatf, 1993: 739?740.

[12] EBERT T, MOLL F, KAINER K U. Spray forming of magnesium alloys and composites[J]. Powder Metallurgy, 1997, 40(2): 126?127.

[13] NOGUCHI A, EZAWA I, KANEKO J, SUQAMATA M. SiCp/Mg-Ce and Mg-Ca alloy composites obtained by spray forming[J]. Journal of Japan Institute of Light Metals, 1995, 45(2): 64?69.

[14] VEROORT P J, DUSZCZYK J. Extrusion of spray deposited magnesium alloys and composites[C]//WOOD J V. Proceedings of the Second International Conference on Spray Forming. Cambridge: Woodhead Publishing Ltd, 1993: 409?425.

[15] HASSAN S F, HO K F, GUPTA M. Increasing elastic modulus, strength and CTE of AZ91 by reinforcing pure magnesium with elemental copper[J]. Materials Letters, 2004, 58(16): 2143?2146.

[16] WATANABE H, MUKAI T, NIEH T G, HIGASHI K. The low temperature superplasiticity of magnesium matrix composites[J]. Scripta Materialia, 2000, 42(3): 249?255.

[17] JIANG Q C, WANG H Y, MA B X, WANG Y, ZHAO F. Fabrication of B4C participate reinforced magnesium matrix composite by powder metallurgy[J]. Journal of Alloys and Compounds, 2005, 386(1/2): 177?181.

[18] SHENG S, CHEN Z, CHEN D, YAN H. The microstructures and mechanical properties of rapidly solidified and powder metallurgy AZ91 alloy[J]. Metall, 2008, 1/2: 47?50.

[19] SHIBATA T, KAWANISHI M, NAGAHORA J, INOUE A, MASUMOTO T. High specific strength of extruded Mg-Al-Ga alloys produced by rapid solidification processing[J]. Mater Sci Eng A, 1994, 179/180: 632?636.

[20] 徐锦锋, 翟秋亚, 袁 森. AZ91D镁合金的快速凝固特征[J]. 中国有色金属学报, 2004, 14(6): 939?944.

XU Jin-feng, ZHAI Qiu-ya, YUAN Sen. Rapid solidification characteristics of melt-spun AZ91D magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(6): 939?944.

[21] GUTMAN I, GOTMAN I, SHAPIRO M. Kinetics and mechanism of periodic structure formation at SiO2/Mg interface[J]. Acta Materialia, 2006, 54: 4677?4684.

[22] ZHENG Ming-yi, WU Kun, YAO Cong-kai. Effect of interfacial reaction on mechanical behavior of SiCw/AZ91 magnesium matrix composites[J]. Mater Sci Eng A, 2001, 318: 50?56.

[23] GU Jin-hai, ZHANG Xiao-nong, QIU Yong-fu. Damping behaviors of magnesium matrix composites reinforced with Cu-coated and uncoated SiC particulates[J]. Composites Science and Technology, 2005, 65: 1736?1742.

[24] URENA A, GOMEZ J M, ESCALERA M D. Influence of metal-ceramic interfaces on the behavior of metal matrix composites and their joints[J]. Key Eng Mater, 1997, 127/131: 687?694.

基金项目:教育部新世纪优秀人才支持计划资助项目(NCET-06-0701);教育部博士点基金资助项目(20070532087)

收稿日期:2008-03-27;修订日期:2008-05-12

通讯作者:陈 鼎,教授,博士;电话/传真:0731-8821648;E-mail: shaodings@yahoo.com.cn

(编辑 龙怀中)