DOI:10.19476/j.ysxb.1004.0609.2018.09.09

机械合金化法制备AlCoNiFeCr高熵合金涂层

蒋 烨,陈 可,王 伟

(南京农业大学 工学院,南京 210031)

摘 要:利用机械合金化原理,在304不锈钢板表面制得AlCoNiFeCr高熵合金涂层。采用XRD、SEM、EDS、显微硬度测试和电化学腐蚀等技术分析涂层的组织结构、显微形貌、力学性能和耐腐蚀性能,并初步探讨合金层的形成机理。结果表明:随着球磨时间的增加,涂层厚度先增大后减小;当球磨时间为9 h时涂层最厚,平均厚度约为110 μm;当球磨时间为12 h时,涂层部分剥落。涂层的硬度明显高于基体的,且从表面到基体硬度呈梯度下降,硬度最高值达590HV0.1约为基体硬度的3倍。电化学腐蚀试验表明,涂层有效增加了基体的耐腐蚀性能。

关键词:机械合金化;高熵合金涂层;显微硬度;耐腐蚀性

文章编号:1004-0609(2018)-09-1784-07 中图分类号:TG174.4 文献标志码:A

高熵效应使高熵合金(High entropy alloy,简称HEA)具备了高强度、高硬度、耐高温、耐腐蚀及高耐磨性等优异性能,而HEA涂层也具备这些性能,有些甚至能得到强化[1]。常用的HEA涂层的制备方法有激光熔覆[2]、钨极气体保护弧焊[3]、电化学沉积[4]、磁控溅射[5]、冷喷涂[6]、等离子熔覆[7]等。而这些方法在不同程度上都存在设备昂贵、工艺复杂等缺点,如何用成本较低的方法制备出性能优异的HEA涂层,一直是研究的焦点。

机械合金化(Mechanical alloying,简称MA)技术是一种将不同的粉末在高能球磨机中球磨,粉末经磨球的碰撞、挤压,重复地发生变形、断裂、焊合,原子间相互扩散或进行固态反应而形成均匀粉末混合物或化合物的固态粉末加工技术[8-9]。MA法常用来制备高熵合金[10]、非晶[11]、纳米晶[12]等新型功能金属材料。在用MA法制作金属粉末的工艺过程中,往往会出现球磨罐内壁和磨球上金属颗粒粘附和沉积的现象[13]。而随后的研究发现粉末的粘附和沉积可应用于涂层的制备。近年来,已经有很多国内学者将机械合金化技术应用于涂层的制备,已成功制备出了合金涂层[14-15]、纳米晶涂层[16]、非晶涂层[17-18]和外加颗粒复合涂层[19-20]等一系列高性能涂层。目前,采用MA法制备高熵合金涂层的研究较为罕见,而MA法具有设备要求简单、大气环境下即可进行、基体和涂层材料选择范围广等特点,在一定程度上克服了其他制备HEA涂层中所存在的设备昂贵、工作环境要求较高和工艺复杂等缺点,为低成本制备HEA涂层提供了新的可能。

本实验采用机械合金化法在304不锈钢板表面制备高熵合金涂层,主要研究工艺参数对涂层的组织结构、形貌及性能的影响,从而获得球磨参数和涂层性能之间的定性关系,同时,还研究了高熵合金涂层的形成机理。

1 实验

采用304不锈钢板作为基体,其尺寸为50 mm×40 mm×3 mm,先后用氧化铝耐水砂纸和金相砂纸打磨,然后放入丙酮中进行超声波清洗。试验原料为纯金属粉末Al(99.9%)、Co(99.9%)、Ni(99.9%)、Fe(99.9%)、Cr(99.9%),按摩尔比为1:1:1:1:1进行配比,称量20 g,球料比为10:1。将原料、不锈钢球连同处理过的304钢板一起装入不锈钢球磨罐中,球磨罐密封后,反复抽真空、通入高纯度氩气(99.9%),然后放入XQM-4L型变频球磨机中进行机械合金化处理。球磨间歇方式为每转30 min停10 min,然后反向运行。球磨转速为400 r/min,球磨时间分别为3、6、9、12 h。

球磨结束后,通过日立S-4800型扫描电镜观测所制备涂层的截面形貌,并利用配置的X射线能谱仪(EDS)表征涂层截面的化学元素分布。合金涂层的相组成通过Panalytical X’Pert Powder型X射线衍射仪检测,入射线为Cu靶Kα射线,步长0.02°。利用HXS1000型显微硬度仪测试涂层显微硬度,载荷0.98 N,保压时间15 s。采用CS350型电化学测试系统,将试样放入50 g/L的NaCl溶液中浸泡30 min,然后以10 mV/s的扫描速度在该溶液中测试样品的阳极极化曲线。

2 结果与分析

2.1 物相分析

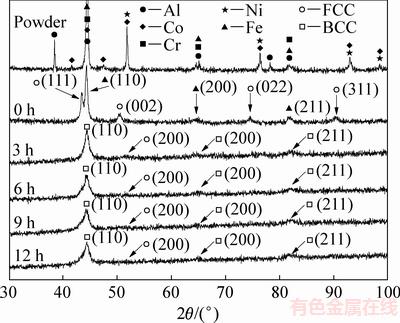

图1所示为原始粉末及304不锈钢板在高能球磨机中球磨不同时间后的XRD谱。从图1可知,304钢板未球磨时(0 h),其中有4个奥氏体衍射峰和3个α-Fe的衍射峰,原始基板中体心立方相的α-Fe居多。从原始粉末的XRD谱中可清晰地观察到Al、Co、Ni、Fe和Cr的衍射峰。球磨时间为3 h时,在2θ=43.473°的奥氏体(1 1 1)衍射峰消失,Al元素的衍射峰基本消失,其他元素的衍射峰变得非常微小,并且随球磨时间的增加,衍射峰的强度持续降低并且有逐渐宽化的趋势,说明此时基体表面已经形成了一定厚度的合金涂层。继续延长球磨时间,涂层的衍射峰角度均不再发生明显变化。球磨时间为6 h时,在XRD谱上已经找不到各对应元素的衍射峰,只留下在2θ=44.338°处的衍射主峰以及晶面指数为(2 0 0)和(2 1 1)的衍射峰,说明此时已经形成了具有BCC和FCC相的简单晶体结构的固溶体。

图1 原始粉末和不同球磨时间下涂层的XRD谱

Fig. 1 XRD patterns of original powder and coatings with different ball milling time

球磨6 h后的涂层BCC相为主相,FCC相为次相。根据YANG等[21]关于高熵合金形成固溶体的研究结果,当合金成分满足Ω≥1.1、δ≤6.6%(Ω为多主元合金系统分子的状态数,δ为多主元合金全部元素的原子尺寸的均方差)的条件时,可以形成固溶体。价电子浓度小于6.87的时候更倾向于形成BCC结构,而大于8的时候有利于形成FCC结构[22]。试验中的AlCoNiFeCr组元的参数满足形成固溶体的条件,而且价电子浓度为7.20,满足形成FCC+BCC双相固溶体结构的条件,实验结果符合这一理论。

2.2 微观形貌与成分分析

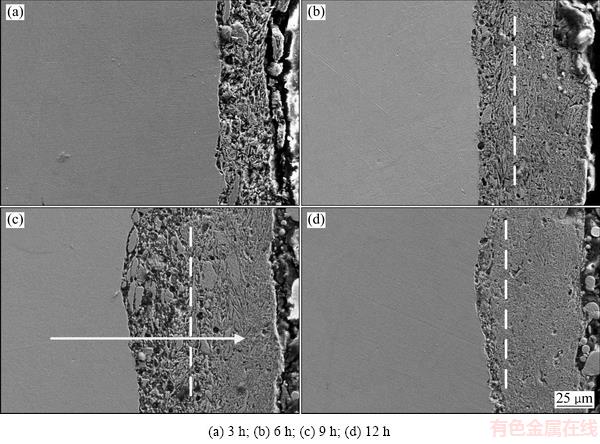

对球磨时间为3~12 h的试样进行横截面形貌观察,结果如图2所示。由图2(a)可以看出,经过3 h球磨后,基体表面形成完整涂层,涂层厚度约为40 μm左右,形成的涂层结构较疏松,有大量的孔洞,涂层中有较大尺寸颗粒存在,基体与涂层界面不整齐。此时,粉末本身形状不规则且容易破碎,基体与涂层之间主要靠物理作用相结合,涂层间结合不牢固。

延长球磨时间至6 h后,试样横截面形貌如图2(b)所示,此时基体表面形成了厚度均匀的合金涂层,涂层厚度大约为70~80 μm,较3 h时有所增加。涂层内部颗粒大小均匀且孔洞明显比3 h时减少,涂层较致密,靠近基体的涂层(虚线左侧)有块状颗粒存在,而外侧涂层(虚线右侧)则呈扁平层状均匀分布。

继续增加球磨时间至9 h时,试样横截面形貌如图2(c)所示,涂层厚度进一步增加,达到110 μm,厚度均匀。此时,涂层与基体之间的界面呈现明显的变形,靠近基体一侧(虚线左侧)的涂层仍为不均匀的块状偏聚,而涂层外表面(虚线右侧)致密度有所提高,孔洞较少且没有明显的裂纹存在,涂层变得更厚且更加致密。

球磨12 h后,试样横截面显微形貌图如图2(d)所示,涂层厚度较球磨9 h的有所减小,约为70~80 μm,涂层仅有靠近基体较薄的一层存在较多孔洞,其他部分变得更加致密。这是由于随着球磨的继续,磨球表面和基体表面都沉积了一定厚度的合金涂层,这样就使得继续参与球磨的粉末量大大降低,合金粉末的冷焊速度小于脱落速度,导致合金涂层厚度有所下降;另外,经过充分细化的粉末颗粒不断被压入涂层孔洞中,使得内侧涂层被不断压实,涂层致密度有所增加,厚度变薄。

图2 不同球磨时间下涂层截面的SEM像

Fig. 2 SEM images of coating cross section with different ball milling time

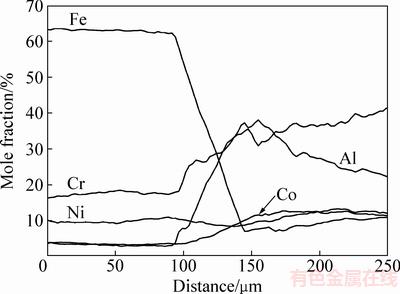

为了探究涂层成分及涂层与基体之间原子的相互扩散情况,对球磨9 h的试样横截面按照图2(c)中箭头的方向进行线扫描能谱分析(因为各个试样的线扫描能谱分析结果相似,故3 h,6 h,12 h不再另外附图),结果如图3所示。从图3中可以看出,涂层表面的Al、Co、Ni、Fe、Cr含量基本均匀。而靠近基体区域Al含量较高,而后呈下降趋势,说明在球磨初期基体表面沉积的涂层多由塑性较好的Al粉末构成[23]。涂层与基体结合处的元素含量在扫描距离上呈现一较长变化区,说明在球磨作用下涂层与基体之间的元素扩散作用比较明显。

图3 球磨9 h后涂层截面的元素分布

Fig. 3 Element distribution of coating cross section after ball milling for 9 h

2.3 显微硬度分析

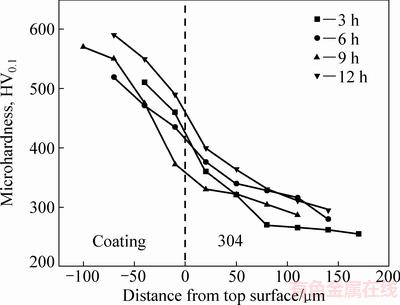

为探究试样表面到基体不同位置的硬度差异,对球磨时间为3~12 h的试样进行显微硬度测试,结果如图4所示。由图4可知:涂层横截面的显微硬度值呈梯度分布,从涂层表面到基体形变强化区,显微硬度呈梯度下降,直至基体原始硬度。涂层表面在磨球的不断撞击下,发生强烈的加工硬化和细晶强化作用[24-25],涂层表面的显微硬度高达590HV0.1,约为基体硬度的3倍。从涂层表面向里延伸,虽然前期也发生了加工硬化,但随着涂层厚度的增加,球磨作用逐渐减弱,涂层的硬度呈下降趋势。而涂层和基体的结合部由于球磨前期磨球的不断撞击造成基体表面一定程度的加工硬化,所以基体与涂层的结合部分硬度相比基体仍有一定程度的提高。随着球磨时间的增加,涂层的显微硬度略有增大,这是因为球磨时间的增加使涂层加工硬化和细晶强化作用更加充分。由图4中可以看出304不锈钢基体的硬度也呈阶梯式分布,导致这一现象的原因是距离表面不同深度基体的加工硬化程度不一样。

2.4 耐腐蚀性能分析

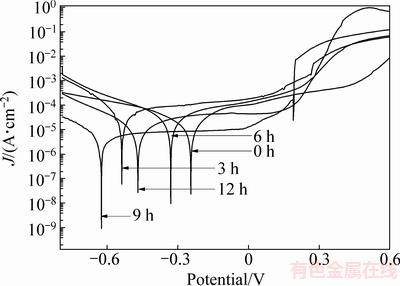

图5所示为不同球磨时间下制备的涂层在50 g/L的NaCl溶液中浸泡30 min后所测得的极化曲线。从图5中可以看出,基体(0 h)与4种不同球磨时间制备的合金涂层,在50 g/L的NaCl溶液中的阳极极化曲线比较接近。极化曲线上不存在过渡态区,而是直接由活性区转变到钝化区。从图5中还可以看出,不同球磨时长得到的HEA涂层的钝化能力与304不锈钢基体相当,钝化区间大约有800 mV,但HEA涂层的致钝电位较304不锈钢的较低,说明当腐蚀电位较小的情况下,HEA涂层可以形成钝化膜,降低腐蚀速率。不同球磨时间形成的涂层钝化区都比较宽,它们的范围介于-0.6 V至+0.6 V之间,当HEA涂层的自腐蚀开始后,有相当一段时间形成防止腐蚀继续发生的钝化膜,有效减缓Cl-离子侵蚀合金的速率。304不锈钢基体的致钝电位和维钝电流基本高于不同球磨时间所得涂层,这也说明HEA涂层在NaCl溶液中的耐腐蚀性能高于基体的。

图4 不同球磨时间下涂层截面的显微硬度分布曲线

Fig. 4 Microhardness distribution curves of coating cross section with different ball milling time

图5 不同球磨时间下涂层的阳极极化曲线

Fig. 5 Anodic polarization curves of coatings at different ball milling time

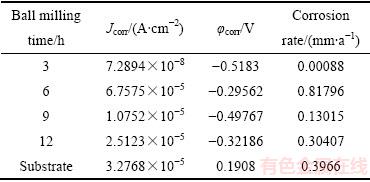

表1所列是利用极化曲线外延法得到各个试样的腐蚀电位(φcorr)、腐蚀电流密度(Jcorr)以及腐蚀速率。由表1可以看出,不同球磨时间形成的HEA涂层的腐蚀电流密度均低于304不锈钢基体,这说明涂层的耐蚀性能优于基体;但腐蚀电位低于304不锈钢基板,这是因为涂层表面由于球磨作用使得活性大于基板的。球磨3 h形成的HEA涂层的腐蚀电流密度较304不锈钢基体的下降3个数量级,说明包覆性涂层对基体的耐腐蚀性能起到了至关重要的作用。

表1 不同球磨时间下涂层的腐蚀参数

Table 1 Corrosion parameters of coatings with different ball milling time

3 AlCoNiFeCr高熵合金涂层形成机理探讨

3.1 镶嵌阶段

球磨初期,金属粉末在球磨罐的高速旋转和磨球快速撞击的共同作用下混合均匀,金属粉末颗粒受到磨球的剧烈撞击和摩擦,使得粉末颗粒产生塑性变形和不断细化,球磨罐中部分金属粉末经过合金化作用,形成了简单晶体结构的固溶体。与此同时,基体表面也与磨球产生了剧烈撞击,导致基体表面产生塑性变形,变为凹凸不平,产生众多晶体缺陷,基体此时处于激活状态,有利于基体和粉末冷焊结合。磨球在球磨罐内高速滚动,其携裹着合金粉末与基体发生剧烈撞击,这样就使少量金属粉末砸向基体,嵌入基体表面。但此时形成的合金涂层含有较多塑性较好的金属Al,涂层形貌较差,在基体表面不连续,且厚度较薄,涂层组织疏松,孔洞较多。

3.2 形成连续涂层

继续增加球磨时间,大量的合金粉末被不断地镶嵌在基体表面,伴随着磨球对基体表面的连续撞击,镶嵌在表面的合金粉末不断被压实,合金粉末与基体发生广泛的冷焊作用。与此同时,附着于基体表面的结合力相对较小的合金粉末在磨球的碰撞下也会发生脱落,球磨罐中剩余的自由粉末较多,合金粉末的冷焊速度大于脱落速度,故涂层厚度越来越厚。

3.3 元素扩散形成致密HEA涂层

在进一步的MA过程中,金属粉末由于磨球的不断撞击产生强烈的塑性变形,晶格产生严重畸变和高密度缺陷,如位错、位错管道、层错等[26],这些为金属元素间的快速扩散提供了网络通道,促使球磨罐中的剩余粉末迅速合金化。因为合金粉末的硬度远远大于基体的硬度,当裹挟着粉末的磨球高速撞向基体时,部分合金粉末与基体结合在一起,这一部分合金粉末与处在激活态的基体发生交互作用,基体里的原子与合金粉末中的原子发生扩散,使合金层与基体结合牢固。另一方面,涂层表面受到高速磨球的撞击,发生塑性变形,使涂层内部储存了大量的应变能和非平衡缺陷,为涂层内部合金元素的扩散提供了通道,由于高速球磨给球磨体系输入了较高的能量,其中一部分转化为内能,为涂层内部合金粉末之间的原子扩散提供了能量,促使涂层内部合金化更加完全。

3.4 过度加工硬化涂层脱落

当球磨时间继续增加,磨球以较高速度撞击已经形成的合金涂层,随着大量机械能输入到涂层表面,涂层内部积蓄大量应力,而当应力达到一定程度后,涂层表面开始发生加工硬化,涂层致密度有所增加,厚度有所降低。当加工硬化达到一定阶段后,外侧涂层局部出现裂纹,部分涂层可能会发生剥落现象,而此时球磨罐中剩余粉末量减少,涂层的沉积率降低,涂覆速度小于剥落速度,故涂层开始变薄。

4 结论

1) 采用本实验工艺可在304不锈钢板表面形成具有一定厚度且综合性能较好的AlCoNiFeCr高熵合金涂层,球磨时间在3~12 h范围时,随着球磨时间的增加,涂层厚度先增大后减小。

2) 在球料比为10:1、球磨转速为400 r/min的条件下,球磨9 h所制备的合金涂层的厚度最厚且综合性能最佳,该涂层较为致密,平均厚度约为110 μm。

3) 显微硬度测试表明,涂层的显微硬度最大值能达到590HV0.1,约为基体的3倍,且硬度从表面到基体呈梯度下降。

4) 当高熵合金涂层的自腐蚀开始后,有相当一段时间形成了防止腐蚀继续发生的钝化膜,有效减缓Cl-侵蚀合金的速率。说明机械合金化法制得的AlCoNiFeCr高熵合金涂层的耐腐蚀性在一定程度上较基体有所提高。

REFERENCES

[1] 李 平, 陈金凯, 周晓东, 晁苏全. 高熵合金涂层的研究进展[J]. 材料保护, 2015, 48(4): 44-46.

LI Ping, CHEN Jin-kai, ZHOU Xiao-dong, CHAO Su-quan. Research progress of high entropy alloy coatings[J]. Materials Protection, 2015, 48(4): 44-46.

[2] 张春华, 单丽娜, 吴臣亮, 张 松, 关 锰, 谭俊哲. Cu单元素基合金表面FeCoCrAlCu激光高熵合金化涂层的制备[J].中国有色金属学报, 2015, 25(5): 1308-1313.

ZHANG Chun-hua, SHAN Li-na, WU Chen-liang, ZHANG Song, GUAN Meng, TAN Jun-zhe. Synthesis of FeCoCrAlCu laser high entropy alloying coating on surface of single-element Cu base alloy[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(5): 1308-1313.

[3] LIN Y C, CHO Y H. Elucidating the microstructural and tribological characteristics of NiCrAlCoCu and NiCrAlCoMo multicomponent alloy clad layers synthesized in situ[J]. Surface & Coatings Technology, 2009, 203(12): 1694-1701.

[4] YAO C Z, ZHANG P, LIU M, LI G R, YE J Q, LIU P, TONG Y X. Electrochemical preparation and magnetic study of Bi-Fe-Co-Ni-Mn high entropy alloy[J]. Electrochimica Acta, 2008, 53: 8359-8365.

[5] 黄纯可, 李 伟, 刘 平, 张 柯, 马凤仓, 刘新宽, 陈小红, 何代华. 磁控溅射法制备AlxCoCrFeNi高熵合金薄膜的微观组织和力学性能研究[J]. 功能材料, 2017, 48(6): 6144-6148.

HUANG Chun-ke, LI Wei, LIU Ping, ZHANG Ke, MA Feng-cang, LIU Xin-kuan, CHEN Xiao-hong, HE Dai-hua. Study on microstructure and mechanical properties of AlxCoCrFeNi high entropy alloy thin films prepared by magnetron sputtering[J]. Journal of Functional Materials, 2017, 48(6): 6144-6148.

[6] 朱 胜, 杜文博, 王晓明, 姚巨坤. 基于高熵合金的镁合金表面防护技术研究[J]. 装甲兵工程学院学报, 2013, 27(6): 79-84.

ZHU Sheng, DU Wen-bo, WANG Xiao-ming, YAO Ju-kun. Research on surface protection technology for magnesium alloys based on high entropy alloy[J]. Journal of Academy of Armored Force Engineering, 2013, 27(6): 79-84.

[7] 张保森, 程江波, 徐滨士. 等离子熔覆(CuCoCrFeNi)95B5高熵合金涂层研[J]. 稀有金属材料与工程, 2014, 43(5): 1128-1132.

ZHANG Bao-sen, CHENG Jiang-bo, XU Bin-shi. (CuCoCrFeNi)95B5 high-entropy alloy coatings prepared by plasma transferred arc cladding process[J]. Rare Metal Materials and Engineering, 2014, 43(5): 1128-1132.

[8] 朱心昆, 林秋实, 陈铁力, 程抱昌, 曹建春. 机械合金化的研究及进展[J]. 粉末冶金技术, 1999(4): 291-296.

ZHU Xin-kun, LIN Qiu-shi, CHEN Tie-li, CHENG Bao-chang, CAO Jian-chun. Research and progress of mechanical alloying[J]. Powder Metallurgy Technology, 1999(4): 291-296.

[9] 唐忠婷, 沈以赴. 机械合金化法制备NiCrAlCoY涂层的研究[J]. 稀有金属与硬质合金, 2011(1): 17-20, 29.

TANG Zhong-ting, SHEN Yi-fu. Study of NiCrAlCoY coating prepared by mechanical alloying[J]. Rare Metals and Cemented Carbides, 2011(1): 17-20, 29.

[10] 袁尹明月, 彭 坤, 王海鹏, 汤 灵, 彭 欣. 机械合金化方法制备AlxCoCrCu0.5FeNi高熵合金组织结构和性能研究[J]. 材料导报, 2016, 30(16): 69-73.

YUANYI Ming-yue, PENG Kun, WANG Hai-peng, TANG Ling, PENG Xin. Microstructure and properties of AlxCoCrCu0.5FeNi high-entropy alloy prepared by mechanical alloying[J]. Materials Review, 2016, 30(16): 69-73.

[11] TAN Z, XUE Y F, CHENG X W, ZHANG L, CHEN W W, WANG L, ZHANG H F, FU H M. Effect of element fitting on composition optimization of Al-Cu-Ti amorphous alloy by mechanical alloying[J]. Transactions of Nonferrous Metals Society of China, 2015, 25(10): 3348-3353.

[12] RAJABI M, SEDIGHI R M, RABIEE S M. Thermal stability of nanocrystalline Mg-based alloys prepared via mechanical alloying[J]. Transactions of Nonferrous Metals Society of China, 2016, 26(2): 398-405.

[13] BEWLAY B P, JACKSON M R, LIPSITT H A. The Nb-Ti-Si ternary phase diagram: Evaluation of liquid-solid phase equilibria in Nb-and Ti-rich alloys[J]. Journal of Phase Equilibria, 1997, 18(3): 264-278.

[14] DU H Y, WEI Y H, LIN W M, HOU L F, LIU Z Q, AN Y L, YANG W F. One way of surface alloying treatment on iron surface based on surface mechanical attrition treatment and heat treatment[J]. Applied Surface Science, 2009, 255(20): 8660-8666.

[15] AN Y L, DU H Y, WEI Y H, WANG N, HOU L F, LIN W M. Interfacial structure and mechanical properties of surface iron–nickel alloying layer in pure iron fabricated by surface mechanical attrition alloy treatment[J]. Materials & Design, 2013, 46(4): 627-633.

[16] 韩 忠, 卢 柯. 纯铜纳米晶表层摩擦磨损性能研究[J]. 中国科学G辑: 物理学 力学 天文学, 2008, 38(11): 1477-1487.

HAN ZHONG, LU Ke. Study on friction and wear properties of pure copper nanocrystalline surface[J]. Scientia Sinica Physica, Mechanica & Astronomica, 2008, 38(11): 1477-1487.

[17] 丁润东, 沈以赴, 李 博, 胡永志, 郭 燕. 机械合金化制备Ti-Cu非晶涂层[J]. 中国有色金属学报, 2012, 22(7): 2023-2030.

DING Run-dong, SHEN Yi-fu, LI Bo, HU Yong-zhi, GUO Yan. Preparation of amorphous Ti-Cu coatings by mechanical alloying[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(7): 2023-2030.

[18] CHEN C, DING R D, FENG X M, SHEN Y F. Fabrication of Ti-Cu-Al coatings with amorphous microstructure on Ti-6Al-4V alloy substrate via high-energy mechanical alloying method[J]. Surface & Coatings Technology, 2013, 236(2): 485-499.

[19] WEN L, WANG Y M, JIN Y, SUN D B. Design and characterization of SMAT-MAO composite coating and its influence on the fatigue property of 2024 Al alloy[J]. Rare Metal Materials & Engineering, 2014, 43(7): 1582-1587.

[20] 沈以赴, 邓瑞翔, 陈 成, 冯晓梅, 韩林轩, 田精明, 贺春锋. Cu基表面机械合金化制备W颗粒增强复合层的研究[J]. 稀有金属材料与工程, 2016, 45(4): 940-945.

SHEN Yi-fu, DENG Rui-xiang, CHEN Cheng, FENG Xiao-mei, HAN Lin-xuan, TIAN Jing-ming, HE Chun-feng. Fabrication of W particle reinforced composite layer on copper substrate via mechanical alloying[J]. Rare Metal Materials and Engineering, 2016, 45(4): 940-945.

[21] YANG X, ZHANG Y. Prediction of high-entropy stabilized solid-solution in multi-component alloys[J]. Materials Chemistry & Physics, 2012, 132(2/3): 233-238.

[22] GUO S, NG C, LU J, LIU C T. Effect of valence electron concentration on stability of fcc or bcc phase in high entropy alloys[J]. Journal of Applied Physics, 2011, 109(10): 213.

[23] 郭 燕, 张 俊. 球磨时间对304不锈钢表面Al-Al2O3-ZrO2涂层的影响[J]. 特种铸造及有色合金, 2016(11): 1129-1133.

GUO Yan, ZHANG Jun. Effect of ball-milling time on Al-Al2O3-ZrO2-Y2O3 composite coatings fabricated on surface of 304 stainless steel[J]. Special-cast and Non-ferrous Alloys, 2016(11): 1129-1133.

[24] 黄 真, 沈以赴, 朱永兵, 顾冬冬. 低碳钢表面Cr合金层的低温高能球磨制备[J]. 兵器材料科学与工程, 2008, 31(2): 000054-57.

HUANG Zhen, SHEN Yi-fu, ZHU Yong-bing, GU Dong-dong. Preparation of Cr coating on low carbon steel by high-energy ball milling[J]. Ordnance Material Science and Engineering, 2008, 31(2): 000054-57.

[25] REVESZ A, TAKACS L. Coating metals by surface mechanical attrition treatment[J]. Journal of Alloys & Compounds, 2007, 441: 111-114.

[26] RAWERS J, COOK D. Influence of attrition milling on nano-grain boundaries[J]. Nanostruc Mater, 1999, 11(3): 331-342.

Preparation of AlCoNiFeCr high entropy alloy coating by mechanical alloying

JIANG Ye, CHEN Ke, WANG Wei

(College of Engineering, Nanjing Agricultural University, Nanjing 210031, China)

Abstract: AlCoNiFeCr high entropy alloy coating was prepared successfully on the surface of 304 stainless by mechanical alloying. The microstructure, mechanical properties and corrosion resistance of the coating were analyzed by XRD, SEM, EDS, microhardness test and electrochemical etching. The formation mechanism of the alloy layer was also discussed. The results show that with milling time increasing, the thickness of the coating increases at first and then decreases. The coating prepared by milling for 9 h is the densest with average thickness of 110 μm. When the milling time is prolonged to 12 h, part of the coating is peeled off. The micro-hardness of coating is significantly higher than that of the substrate, and declines gradually from the top surface to inner substrate. The maximum micro-hardness of the coating is up to 590HV0.1, about three times that of the substrate. Electrochemical corrosion tests show that the coating effectively increases the corrosion resistance of the matrix.

Key words: mechanical alloying; high entropy alloy coating; microhardness; corrosion resistance

Foundation item: Project(KYZ201657) supported by the Fundamental Research Funds for the Central Universities, China; Project(HGAMTL-1710) supported by the Opening Fund of the Key Laboratory of Advanced Manufacturing Technology of Jiangsu Province, China

Received date: 2017-08-24; Accepted date: 2018-04-26

Corresponding author: CHEN Ke; Tel: +86-18751909360; E-mail: ckyf@njau.edu.cn

(编辑 何学锋)

基金项目:中央高校基本科研业务费专项自主创新重点项目(KYZ201657);江苏省先进制造技术重点实验室开放基金资助项目(HGAMTL-1710)

收稿日期:2017-08-24;修订日期:2018-04-26

通信作者:陈可,讲师,博士;电话:18751909360;E-mail:ckyf@njau.edu.cn