DOI:10.19476/j.ysxb.1004.0609.2018.07.20

含铅玻璃对高铅渣还原性能和熔渣特性的影响

杨洪英,吕建芳,金哲男,佟琳琳,张 勤,王俊鹏

(东北大学 冶金学院,沈阳 110819)

摘 要:采用X射线衍射和原子吸收光谱法研究向高铅渣添加废弃阴极射线管显示器含铅玻璃回收玻璃中铅的可行性,探讨还原煤用量、还原温度、还原时间和钙硅比对铅、锌回收率的影响,分析还原渣的物相变化以及玻璃加入量对还原渣熔融特性和黏度的影响。结果表明:通过该方法可有效地将玻璃中的铅回收,适宜的含铅玻璃加入量为10%~20%(质量分数)。最佳熔炼条件如下:碳氧比0.8、还原温度1230 ℃、还原时间70 min、钙硅比0.7。在此条件下,铅回收率可达96%以上,锌回收率达到83%以上。还原渣中的物相主要为铁氧化物、黄长石和橄榄石。玻璃的加入会使渣的熔点降低,液相比例升高,同时使渣的黏度增加,渣中铅含量升高。

关键词:含铅玻璃;高铅渣;还原熔炼;铅回收;Factsage软件

文章编号:1004-0609(2018)-07-1462-09 中图分类号:TF812 文献标志码:A

随着显示器技术的快速发展,使得越来越多的阴极射线管显示器(Cathode ray tube,CRT)被更为先进的显示器取代,例如液晶显示器(LCDs)、等离子显示器等,从而产生了大量的废弃CRT。据统计,仅在2013年国内就产生了3.2×107件废弃电视机和3.7×107件废弃电脑,所含的CRT玻璃量高达4.3×107 t,报废量巨大[1]。此外,还有大量废CRT通过非法途径从发达国家被转运到我国[2]。废弃CRT的处理已成为我国生活垃圾和电子废弃物处理中的重要问题之一。

CRT中的玻璃含量高达85%,其主要由3部分组成屏玻璃(主要含锶、钡,不含铅)、锥玻璃(含铅量20%~25%(质量分数),占CRT总质量的三分之一)和颈玻璃(含有超过25%的PbO)。如果废弃CRT随意放置,将对水源、土壤和空气产生严重的危害,并危及人类的身体健康[3]。

CRT的回收方式主要有闭环回收和开环回收[4]。但是由于CRT的市场需求下降,闭环回收逐渐失去竞争力,因此,研究主要集中在开环回收上。有研究者将废弃CRT整体作为二次原材料生产泡沫玻璃[5-7]、玻璃陶瓷[8-9]、水泥[10-11]等,但是玻璃中的铅也进入了产品中,使产品存在着潜在的危险,限制了产品的应用。为了从根本上消除含铅玻璃的铅污染问题,研究者围绕含铅玻璃铅回收技术展开了大量研究,主要可分为湿法回收和火法回收。利用湿法冶金回收铅的技术主要有超声波-酸浸[12]、机械活化预处理[13]、氯化焙烧[14-15]等。此类技术的缺点是工艺复杂、处理时间长、条件苛刻,很难应用于实际生产。火法方面,主要有真空碳热还原[16-17]、高温自蔓延[18-20]、添加助剂还原[21-23]、铁粉置换[24]等。相对湿法处理技术,火法处理方式简单高效,还原率高,可直接获得金属铅,但是其缺点也很明显,主要是能耗高,过程中会产生大量烟尘,对环境造成危害,且设备成本也很高。

本文作者提出一种利用铅冶炼技术综合回收CRT的方法,研究通过将CRT含铅玻璃添加到高铅渣中进行碳热还原回收金属铅的可行性。考察熔炼温度、熔炼时间、无烟煤加入量和钙硅比对铅还原效果的影响,得出了最佳的熔炼条件。通过XRD和SEM研究了玻璃加入量对还原渣物相的影响,并利用热力学计算软件FactsageTM 6.4分析了玻璃加入量对熔渣熔融特性及黏度的影响。

1 实验

1.1 实验材料

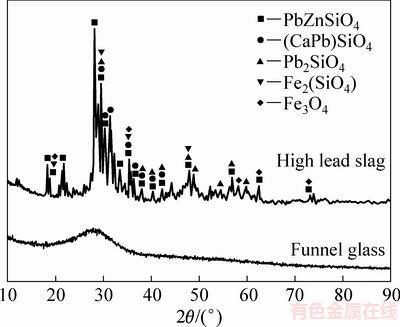

含铅玻璃来自国内某家电拆解企业,高铅渣和无烟煤来自国内某炼铅企业。含铅玻璃化学组成如表1所列,高铅渣化学组成如表2所列。对处理后的含铅玻璃和高铅渣进行XRD分析,其结果如图1所示。

表1 含铅玻璃化学成分

Table 1 Chemical compositions of lead glass (mass fraction, %)

表2 高铅渣化学成分

Table 2 Chemical compositions of high lead slag (mass fraction, %)

图1 含铅玻璃和高铅渣的XRD谱

Fig. 1 XRD patterns of funnel glass and high lead slag

从XRD分析结果可以看出,CRT锥玻璃为无定形组织,在20°~40°之间出现鼓包,呈现出典型的非晶状态。原始高铅渣的物相组成是以硅酸铅2PbO·SiO2为主,同时,PbZnSiO4含量也较高。铅的硅酸盐的熔化温度较低,其熔体的流动性好。与SiO2结合的PbO挥发性要比纯PbO的小。当铅的硅酸盐中SiO2含量越高时,其挥发性越小。与SiO2结合的PbO要比纯的PbO更难于还原,硅酸铅的还原一定要有碱性氧化物如CaO和FeO的参与下才能进行[25]。

实验中使用的氧化钙为分析纯试剂。以无烟煤作为还原剂,其中固定碳含量为84.5%。还原熔炼设备为硅碳棒式竖炉,实验容器采用高纯氧化铝坩埚。

1.2 实验方法

将高铅渣、含铅玻璃、无烟煤经过细磨干燥,根据计算将高铅渣、含铅玻璃、无烟煤和氧化钙配料,并在陶瓷研钵中混匀10 min。将混合物料装入刚玉坩埚中,放置到预先加热的电炉中,进行还原熔炼。到达预定时间后,将坩埚取出,放到空气中进行冷却。待坩埚冷却后,将坩埚称量、破碎,分离渣相和金属相,并称量。还原渣破碎细磨后分析其中的铅锌含量。

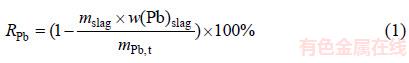

还原熔炼实验中,铅、锌的回收率(RPb、RZn)按式(1)和(2)计算:

式中:mslag为还原渣质量,g;w(Pb)slag为还原渣中铅的含量,%;mPb,t为高铅渣和含铅玻璃中铅的总质量,g。

式中:mslag为还原渣质量,g;w(Zn)slag为还原渣中锌的含量,%;mZn,t为高铅渣和含铅玻璃中锌的总质量,g。

2 结果与讨论

2.1 还原剂量的影响

混合物料中的还原剂量用碳氧摩尔比nC/nO(碳氧比)来表示,其计算公式如下:

式中:mcoal为还原煤粉的质量,g;mmix为混合原料的质量,g;wC为煤粉中固定碳的含量,%;wO, PbO为PbO中氧的含量,%;MC为碳的摩尔质量,g/mol;MO为氧的摩尔质量,g/mol。

考察配碳量对还原熔炼效果影响的实验条件如下:含铅玻璃加入量10%和20%、熔炼温度1200 ℃、还原时间60 min、钙硅比为1。还原剂煤粉用量对还原熔炼中铅、锌回收率及渣中铅含量的影响结果如图2所示。

由图2可以看出,玻璃加入量10%的渣和20%(质量分数)的渣变化趋势相似,随着碳氧比的增加,铅的回收率升高,而还原渣中锌的回收率逐渐降低,这是由于过量的碳与渣中氧化锌反应,生成的锌由于挥发进入烟气使锌回收率下降。同时,玻璃加入量增加使铅回收率下降,并且在碳氧比低时更加明显,但是玻璃增加有利于提高锌的回收率。

图2 碳氧比对铅锌回收率的影响

Fig. 2 Effect of mass ratio of C and O on recovery rate of Pb and Zn

铅回收率随着碳氧比的增加而增加,当碳氧比为0.8、玻璃加入量为10%(质量分数)时,铅的回收率达到93.86%。渣中的铅、锌含量随着碳氧比的增加而逐渐降低,碳氧比由0.6增加至0.8,还原渣中铅含量降低幅度最大,已经达到较好的指标,当增加碳氧比至0.9时,渣中铅含量降低幅度较小,而还原渣中锌的回收率反而降低较多,这对熔炼过程是不利的。随着碳氧比的增加,还原渣中锌的回收率逐渐降低,出现了锌过还原现象,而在实际生产中,铅还原后的低铅渣要进一步进行烟化处理,回收渣中的铅和锌,因此,要控制煤粉加入量,尽可能保证还原渣中锌的高回收率,因此,碳氧比选择为0.8。

2.2 还原温度的影响

在碳氧比0.8、玻璃加入量10%和20%(质量分数)、还原时间60 min、钙硅比为1的条件下探究还原温度对还原效果的影响,实验结果如图3所示。从图3中可以看出,不同玻璃加入量的渣变化趋势相近,与2.1节中的现象相同,玻璃加入对铅还原不利,但是有利于锌的富集。随着还原温度的升高,铅回收率有所提高,这表明高温有利于铅的还原。当加入量10%时,温度由1170 ℃提高到1230 ℃时,铅回收率由91.12%提高到95.47%,这主要是由于在较低温度时,熔渣的黏度较大,形成的阻力较大,不利于铅渣分离;当温度提高时,一方面,使得热传递加快,有利于熔化,另一方面,能使渣黏度大幅降低,金属熔滴在阻力较小的情况下顺利下降,铅的回收率相应提高。温度继续升高铅回收率增加不明显。

锌回收率随着温度升高而降低,这是由于温度的升高加速了锌的挥发,当温度由1230 ℃增加到1260 ℃时,玻璃加入量为10%的还原渣中锌的回收率由84.35%降低至80.59%,降低比较明显,低于指标值。温度在1230 ℃时,各项指标都较优,因此,当碳氧比为0.8时,选择1230 ℃为最佳还原温度。在此条件下,玻璃加入量10%和20%的实验组还原渣中铅含量分别为1.04%和1.13%,铅回收率分别为95.47%和94.43%,还原渣中锌回收率为84.35%和85.61%。

图3 还原温度对铅锌回收率的影响

Fig. 3 Effect of reduction temperature on lead and zinc recovery rate

2.3 还原时间的影响

在碳氧比0.8、玻璃加入量10%和20%(质量分数)、还原温度1230 ℃、钙硅比为1的条件下探究还原时间对还原效果的影响,实验结果如图4所示。相比还原剂量和还原温度,时间对铅锌回收率的影响较小。随着还原时间的延长,铅回收率有所升高,还原渣中锌的回收率却逐渐降低。对于玻璃加入量10%(质量分数),还原时间由60 min增加至70 min,铅回收率由95.47%提高到96.87%,还原渣中锌的回收率由84.35%降至84.17%。随着熔炼时间的延长,还原渣中铅的回收率逐渐下降,这是由于熔炼时间的增加使得锌挥发进入烟气的比例提高,因此,要控制还原时间,还原熔炼的时间为70 min是比较合适的。

图4 还原时间对铅锌回收率的影响

Fig. 4 Effect of reduction time on lead and zinc recovery rate

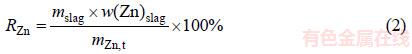

2.4 钙硅比的影响

在碳氧比0.8、玻璃加入量10%和20%(质量分数)、还原温度1230°C、还原时间70 min的条件下探究钙硅比对还原效果的影响,实验结果如图5所示。由图5可以看出,硅钙比对铅还原率的影响较大,而对锌的回收率影响较小。原始高铅渣与锥玻璃的混合物料中钙硅比大约为0.1,SiO2含量很高。大量SiO2会生成结构复杂的络氧阴离子,使炉渣的黏度升高。添加CaO到混合物料中,高温下CaO分解出自由氧,自由氧与桥氧反应产生非桥氧,使复杂的硅氧网状结构解聚,变成小的结构单元,从而降低炉渣黏度。

图5 钙硅比对铅锌回收率的影响

Fig. 5 Effect of mass ratio of CaO and SiO2 on lead and zinc recovery rate

当钙硅比由0.2升至0.8时,金属块中铅的回收率提升较大,渣含铅降低明显,这是由于钙硅比升高,熔渣的黏度下降,不仅能促进反应的进行,而且有利于金属液滴的聚集和沉降。而继续增加钙硅比到1.0和1.2时,铅回收率有所下降,这是因为过多的CaO会与SiO2结合生成高熔点物相,提高了熔渣的熔化温度,不利于反应的进行以及金属和渣的分离。还原渣中锌的回收率随着氧化钙加入量的增加而有所升高,这是因CaO的添加促使炉渣熔化温度提高,降低还原渣中锌挥发进入烟气的比例。

综合考虑,本研究中还原熔炼的温度为1230 ℃、时间70 min、碳氧比0.8时,选定钙硅比0.7为最佳。在此条件下,玻璃加入量10%和20%(质量分数)的实验组铅还原率分别为97.36%和96.15%,锌回收率分别为83.38%和83.15%,还原渣中铅含量分别为0.53%和0.59%。

2.5 含铅玻璃对还原渣特性的影响

2.5.1 还原渣物相分析

为了考查含铅玻璃加入量对还原渣特性的影响,增加了含铅玻璃加入量0%和30%(质量分数)的实验组,在1230 ℃、时间70 min、碳氧比0.8时,钙硅比0.7下进行熔炼。通过XRF和定量分析得到还原渣成分,结果如表3所示。由表3可知,还原渣中CaO、SiO2随着玻璃加入量的增加而升高,而ZnO、FeO的含量随之降低,这与高铅渣和含铅玻璃的组分特征相一致。同时,随着含铅玻璃加入量的增加,还原渣中Na、K含量升高,表明锥玻璃中的Na2O和K2O进入渣相,而这两者对熔渣的性质有重要影响,因此,需要更多的研究来明确其作用,以保证铅冶炼正常进行。在含铅玻璃加入量30%(质量分数)时,还原渣中的铅含量升到2.15%,铅还原率有所下降,表明玻璃的加入量有一个适宜的范围,还原率下降的原因可能与熔渣的黏度及液相温度有关。高铅渣冶炼后的还原渣中铅的含量一般要求控制在2%以下,所以玻璃加入量在10%~20%(质量分数)时得到的渣铅含量满足了熔炼指标要求。

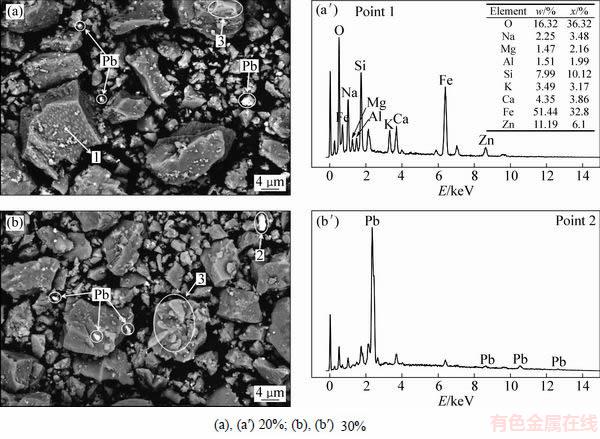

4种还原渣的XRD谱如图6所示。还原渣中的物相主要为铁氧化物、黄长石和橄榄石,渣中已不存在原高铅渣中的含铅物相(如Pb2SiO4、PbZnSiO4等),这说明通过液态还原后高铅渣中的Pb已经被还原为金属Pb进入金属相。随着含铅玻璃加入量的增加,a渣(无玻璃添加)和b渣(添加10%玻璃)中原有的镁黄长石相消失,硅酸铝钾和硅酸钙开始出现,这与还原渣组分变化特征一致。d渣(添加30%玻璃)中出现了金属铅的特征峰,这是可能是由于含铅玻璃加入量升高使熔渣的黏度增加,从而阻碍了还原金属铅的沉降,影响了渣金分离,使渣中含铅量升高。此外,随着含铅玻璃加入量的升高,图谱的峰强减弱,并且在27°~40°之间出现了非晶包,说明还原渣结晶性能变差。4种还原渣的XRD谱中均未出现含Na物相的衍射峰。为了进一步明确还原渣的物相变化,对c渣(添加20%玻璃)和d渣进行扫描电镜分析,结果如图7所示。

表3 最佳工艺条件还原渣成分分析

Table 3 Compositions of residue under optimal conditions

可以明显地看出,两种渣中都含有金属铅,在背散射扫描下其表现为亮白色的金属相,其EDS能谱分析如点2所示。相比c渣,d渣中的铅分布更为广泛且颗粒尺寸更大,说明随着玻璃加入量的增加还原效果变差,渣中的铅升高,这与XRF分析结果相一致。点1的EDS能谱分析中出现了Na和K元素,说明玻璃中的Na和K进入渣相。此外,图中浅色的物相(区域3)主要含有Fe、Si和O元素,可以推测该物相为铁氧化物或铁橄榄石。

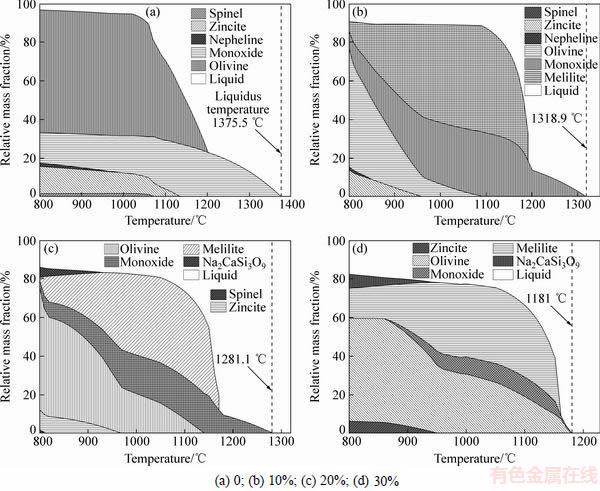

2.5.2 Factsage模拟分析

Factsage是化学热力学领域中世界上完全集成数据库最大的计算系统之一,可用于计算化学反应、热力学平衡和相图等一系列问题[27]。利用热力学计算软件Factsage 6.4的平衡模块对以上4种渣进行平衡冷却计算,为使预测结果与实际生产更接近,将表3还原渣成分中的PbO含量设定为0,并将Fe2O3换算为FeO,其结果如图8所示。从图8中可以看出,随着含铅玻璃加入量由0增加到30%时,熔渣的结晶能力下降,这与XRD分析结果一致,液相线温度由1375.5 ℃降低至1181 ℃,表明含铅玻璃的加入可以降低炉渣熔点,有利于减少实际工业生产的能耗。这主要是由于玻璃中含有的Na和K在熔渣中生成低熔点化合物,增大了熔渣的液相比例,如图8(d)所示,在玻璃加入量达到30%的情况下,熔渣在800 ℃时仍含有18%的液相比例。此外,在所研究的温度区间内,4种渣中只析出了含Na物相(霞石和硅酸钠钙),而没有出现含K物相,说明在该熔渣体系中K比Na降低炉渣熔点的能力更强。a渣中主要含有橄榄石和铁氧化物,随着玻璃加入量的增加,渣中橄榄石量减少,尖晶石相减少并最终消失,生成了大量的黄长石(含Ca2ZnSi2O7)。渣中一部分锌以红锌矿的形式存在,其含量随着玻璃加入量增加而降低。

图6 最佳工艺条件不同玻璃加入量还原渣的XRD谱

Fig. 6 XRD patterns of residue with different glass additions under optimal conditions

图7 玻璃加入量为20%和30%时所得还原渣的SEM像及相应点的EDS能谱图

Fig. 7 SEM images of residues with 20% and 30% glass additions and EDS spectra of corresponding points

图8 不同玻璃加入量还原渣平衡物相的计算结果

Fig. 8 Calculated results of equilibrium phase fractions of reducing slag with different glass additions

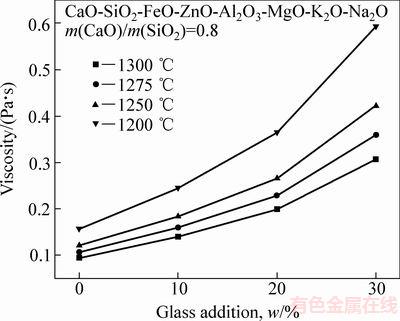

此外,利用Factsage软件黏度计算模块对以上4种渣进行了黏度预测,其结果如图9所示。由图9可以看出,随着含铅玻璃加入量的增加,熔渣的黏度升高,且当玻璃加入量达到20%以上时,黏度变化对玻璃加入量更为敏感,增幅变大。这主要是由于玻璃的加入,降低了FeO和ZnO的含量,而SiO2的含量却大幅升高,在碱度不变的情况下,熔渣中的碱性氧化物含量降低,渣中的自由氧含量降低。大量的SiO2形成复杂的硅酸盐网络结构,增加了炉渣黏度,使渣金分离变难,渣中铅含量升高,造成铅的损失,这与之前的XRF和SEM分析结果一致。

综上,含铅玻璃的引入一方面降低炉渣熔点,另一方面又会增大炉渣的黏度,考虑到玻璃中的铅含量低于高铅渣,其加入会降低铅冶炼生产效率,设定含铅玻璃的加入量在20%以下。

图9 含铅玻璃加入量对熔渣黏度的影响

Fig. 9 Effect of funnel glass addition on viscosity of slag

3 结论

1) 通过将含铅玻璃与高铅渣混合熔炼,可有效地还原玻璃中的铅,适宜的含铅玻璃加入量为10%~20%,最佳熔炼条件为碳氧比0.8、还原温度1230 ℃、还原时间70 min、钙硅比0.7。在最佳熔炼条件下,铅回收率可达96%以上,锌回收率达到83%以上,渣含铅在1%以下。

2) 还原渣中的物相主要为铁氧化物、黄长石和橄榄石。随着含铅玻璃加入量的增加,熔渣的结晶性能变差,出现非晶相;渣中Na、K含量随玻璃加入量的增加而升高,使渣的液相线温度降低、相同温度下的液相比例增加。

3) 含铅玻璃加入量的增加会导致熔渣的黏度升高,且当玻璃加入量超过20%时,黏度增加更为明显,造成渣金分离困难,渣含铅升高;当玻璃加入量达到30%时,渣含铅达到2.15%,还原渣中的金属铅颗粒明显增多。

4) 本研究中提出的含铅玻璃处理方法利用现有的铅冶炼设备,降低了处理成本,具有简单高效的特点,不仅从根本上解决了CRT的铅污染问题,而且易于实现。但在该方法应用前,需要更多的工作来研究还原渣的物理性质变化以及炉壁耐火材料的腐蚀行为。

REFERENCES

[1] GONG Yu, TIAN Xiang-miao, WU Yu-feng, TAN Zhe, Lü Lei. Recent development of recycling lead from scrap CRTs: A technological review[J]. Waste Management, 2015, 57: 176-186.

[2] SHINKUMA T, HUONG N T M. The flow of E-waste material in the Asian region and a reconsideration of international trade policies on E-waste[J]. Environmental Impact Assessment Review, 2009, 29(1): 25-31.

[3] KIDDEE P, NAIDU R, WONG M H. Electronic waste management approaches: An overview[J]. Waste Management, 2013, 33(5): 1237-1250.

[4] XU Qing-bo, LI Guang-ming, HE Wen-zhi, HUANG Ju-wen, SHI Xiang. Cathode ray tube (CRT) recycling: Current capabilities in China and research progress[J]. Waste Management, 2012, 32(8): 1566-1574.

[5] BERNARDO E, CEDRO R, FLOREAN M, HREGLICH S. Reutilization and stabilization of wastes by the production of glass foams[J]. Ceramics International, 2007, 33(6): 963-968.

[6]  F, YOT P, VIENNOIS R, RIBES M. Mechanical behaviour and thermal and electrical properties of foam glass[J]. Ceramics International, 2007, 33(4): 543-550.

F, YOT P, VIENNOIS R, RIBES M. Mechanical behaviour and thermal and electrical properties of foam glass[J]. Ceramics International, 2007, 33(4): 543-550.

[7] 田英良, 张友良, 田 晖, 许 军. 利用废显像管研制泡沫玻璃[J]. 玻璃与搪瓷, 2003, 31(4): 44-47.

TIAN Ying-liang, ZHANG You-liang, TIAN Hui, XU Jun. Research on foam glass by using waste kinescope[J]. Glass & Enamel, 2003, 31(4): 44-47.

[8] BERNARDO E. Micro-and macro-cellular sintered glass- ceramics from wastes[J]. Journal of the European Ceramic Society, 2007, 27(6): 2415-2422.

[9] ZHANG Wei-yi, GAO Hong, XU Yu. Sintering and reactive crystal growth of diopside-albite glass-ceramics from waste glass[J]. Journal of the European Ceramic Society, 2011, 31(9): 1669-1675.

[10] LING Tung-chai, POON Chi-sun. Utilization of recycled glass derived from cathode ray tube glass as fine aggregate in cement mortar[J]. Journal of Hazardous Materials, 2011, 192(2): 451-456.

[11] LING Tung-chai, POON Chi-sun. Effects of particle size of treated CRT funnel glass on properties of cement mortar[J]. Materials and Structures, 2013, 46(1/2): 25-34.

[12] SATERLAY A J, WILKINS S J, COMPTON R G. Towards greener disposal of waste cathode ray tubes via ultrasonically enhanced lead leaching[J]. Green Chemistry, 2001, 3(4): 149-155.

[13] YUAN Wen-yi, LI Jin-hui, ZHANG Qi-wu, SAITO F. Innovated application of mechanical activation to separate lead from scrap cathode ray tube funnel glass[J]. Environmental Science & Technology, 2012, 46(7): 4109-4114.

[14] ERZAT A, ZHANG Fu-shen. Detoxification effect of chlorination procedure on waste lead glass[J]. Journal of Material Cycles and Waste Management, 2014, 16(4): 623-628.

[15] ERZAT A, ZHANG Fu-shen. Evaluation of lead recovery efficiency from waste CRT funnel glass by chlorinating volatilization process[J]. Environmental Technology, 2014, 35(22): 2774-2780.

[16] CHEN Meng-jun, ZHANG Fu-shen, ZHU Jian-xin. Lead recovery and the feasibility of foam glass production from funnel glass of dismantled cathode ray tube through pyrovacuum process[J]. Journal of Hazardous Materials, 2009, 161(2): 1109-1113.

[17] XING Ming-fei, ZHANG Fu-shen. Nano-lead particle synthesis from waste cathode ray-tube funnel glass[J]. Journal of Hazardous Materials, 2011, 194(5): 407-413.

[18] CHEN Meng-jun, ZHANG Fu-shen, ZHU Jian-xin. Detoxification of cathode ray tube glass by self-propagating process[J]. Journal of Hazardous Materials, 2009, 165(1): 980-986.

[19] WANG Yu, ZHU Jian-xin. Preparation of lead oxide nanoparticles from cathode-ray tube funnel glass by self-propagating method[J]. Journal of hazardous materials, 2012, 215: 90-97.

[20] 王 昱, 谢毅君, 高 雅, 朱建新. CRT 玻璃高温自蔓延反应过程中铅的挥发及纳米晶化规律研究[J]. 无机材料学报, 2012, 27(10): 1084-1088.

WANG Yu, XIE Yi-jun, GAO Ya, ZHU Jian-xin. Lead evaporation from CRT glass and nanocrystallization mechanism in the high-temperature self-propagating process[J]. Journal of Inorganic Materials, 2012, 27(10): 1084-1088.

[21] YOT P G,  F O. Lead extraction from waste funnel cathode-ray tubes glasses by reaction with silicon carbide and titanium nitride[J]. Journal of hazardous materials, 2009, 172(1): 117-123.

F O. Lead extraction from waste funnel cathode-ray tubes glasses by reaction with silicon carbide and titanium nitride[J]. Journal of hazardous materials, 2009, 172(1): 117-123.

[22] OKADA T, YONEZAWA S. Energy-efficient modification of reduction-melting for lead recovery from cathode ray tube funnel glass[J]. Waste Management, 2013, 33(8): 1758-1763.

[23] OKADA T, YONEZAWA S. Reduction-melting combined with a Na2CO3 flux recycling process for lead recovery from cathode ray tube funnel glass[J]. Waste Management, 2014, 34(8): 1470-1479.

[24] LU Xing-wen, SHIH K, LIU Cheng-shuai, WANG Fei. Extraction of metallic lead from cathode ray tube (CRT) funnel glass by thermal reduction with metallic iron[J]. Environmental Science & Technology, 2013, 47(17): 9972-9978.

[25] 李卫锋, 杨安国, 陈会成, 张传福. 液态高铅渣直接还原试验研究[J]. 有色金属(冶炼部分), 2011(4): 10-13.

LI Wei-feng, YANG An-guo, CHEN Hui-cheng, ZHANG Chuan-fu. Technology study on direct reduction of lead-rich slag[J]. Nonferrous Metals (Extractive Metallurgy), 2011(4): 10-13.

[26] 陈 霖, 杨天足, 刘伟锋, 张杜超, 宾 舒, 宾万达. 高铅渣液态还原过程中有价金属分布[J]. 中国有色金属学报, 2014, 24(4): 1056-1062.

CHEN Lin, YANG Tian-zu, LIU Wei-feng, ZHANG Du-chao, BIN Shu, BIN Wan-da. Distribution of valuable metals in liquid high lead slag during reduction process[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(4): 1056-1062.

[27] 帅 航, 尹洪峰, 袁蝴蝶, 陈金学. 煤气化炉渣的高温物相组成演变与黏温特性[J]. 煤炭转化, 2015, 38(3): 44-48.

SHUAI Hang, YIN Hong-feng, YUAN Hu-die, CHEN Jin-xue. Phase composition evolution and viscosity-temperature characteristics of gasification slags at high temperature[J]. Coal Conversion, 2015, 38(3): 44-48.

Effect of lead glass on reducing property and slag characteristics of high lead slag

YANG Hong-ying, Lü Jian-fang, JIN Zhe-nan, TONG Lin-lin, ZHANG Qin, WANG Jun-peng

(School of Metallurgy, Northeastern University, Shenyang 110819, China)

Abstract: The feasibility of lead extraction from waste cathode ray tubes (CRTs) funnel glass by introducing lead glass high lead slag was investigated by X-ray diffraction and atomic absorption spectroscopy. The influences of carbon addition, reducing temperature, reducing time and Ca-Si mass ratio on Pb and Zn recoveries were determined. Also, the phase changes of the residue, the effects of glass addition on the melting behavior and the viscosity of the slag were studied. The results show that the proposed method is an effective approach for extracting lead from funnel glass. The suitable glass addition is 10%-20% (mass fraction), and the optimum conditions are mole ratio C and O of 0.8, reducing temperature 1230 ℃, reducing time 70 min and Ca-Si mass ratio of 0.7. Under these conditions, Pb and Zn recovery rates reach up to 96% and 83%, respectively. The main phases of the residue are iron oxide, melilite and olivine. Meanwhile, the melting point of the slag can be lowered by the addition of funnel glass, resulting in the increase of the liquid phase ratio in the slag. However, it can also cause an increase of the slag viscosity, thereby, increasing the lead content in slag.

Key words: lead glass; high lead slag; reduction smelting; lead recovery; Factsage software

Foundation item: Project(2014BAC03B07) supported by the National Key Technology Research and Development Program of China during the 12th Five-year Plan Period

Received date: 2017-02-27; Accepted date: 2017-10-28

Corresponding author: JIN Zhe-nan; Tel: +86-18604021970; E-mail: jinzn@smm.neu.edu.cn

(编辑 李艳红)

基金项目:国家“十二五”科技支撑计划资助项目(2014BAC03B07)

收稿日期:2017-02-27;修订日期:2017-10-28

通信作者:金哲男,副教授,博士;电话:18604021970;E-mail:jinzn@smm.neu.edu.cn