J. Cent. South Univ. Technol. (2008) 15(s1): 467-470

DOI: 10.1007/s11771-008-401-4

Experimental research on characteristic of start-up pressure wave propagation in gelled crude oil by large-scale flow loop

CUI Xiu-guo (崔秀国), AI Mu-yang(艾慕阳), JIANG Bao-liang(姜保良),

HUO Lian-feng(霍连风), ZHANG Li-xin(张立新)

(PetroChina Pipeline R&D Center, Langfang 065000, China)

Abstract: In order to research start-up pressure wave propagation mechanism and determine pressure wave speed in gelled crude oil pipelines accurately, experiment of Large-scale flow loop was carried out. In the experiment, start-up pressure wave speeds under various operation conditions were measured, and effects of correlative factors on pressure wave were analyzed. The experimental and theoretical analysis shows that thermal shrinkage and structural properties of gelled crude oils are key factors influencing on start-up pressure wave propagation. The quantitative analysis for these effects can be done by using volume expansion coefficient and structural property parameter of gelled crude oil. A new calculation model of pressure wave speed was developed on the basis of Large-scale flow loop experiment and theoretical analysis.

Key words: gelled crude oil; start-up pressure wave; propagation characteristic; lager-scale flow loop

1 Introduction

How to ensure safety of shut-down and restart pipelines is a key technical problem of waxy crude oil pipelines operation. The start-up process of waxy crude oil pipelines has close connection with rheological properties of gelled crude oil and start-up pressure wave propagation. Precise prediction to start-up process of crude oil pipelines is very difficult. Previous researchers studied start-up pressure wave by the sound wave propagation mechanism[1-2]. But some experiments showed, pressure wave speed in gelled crude oil decreased remarkably with the increase of its propagation distance[3]. So the mechanism of pressure wave propagation in gelled crude oil is different from that of sound wave propagation. Considering the influence of oil shrinkage with temperature decreasing on start-up pressure wave propagation, ZHANG and AN[4] developed a calculation model of hot oil pipeline start-up pressure wave speed. ZHANG and ZHANG[5] considered that crude oil yield stress could restrict pressure wave propagation in crude oil pipeline; a new model was deduced on the basis of Zhang guo-zhong’s model. Due to the complexity of pressure wave propagation in gelled oils, it is very difficult to determine accurately pressure wave speed by theoretical calculation. LI et al[6] researched start-up pressure wave propagation in gelled crude oil by a small-scale loop, and developed another calculation model of pressure wave speed based on experimental data. Configuration size and operation parameter of small-scale flow loop are different significantly from that of field pipeline, so there are some gaps between experimental data obtained and actual data. In the paper, experiment of large-scale flow loop was carried out to research pressure wave propagation.

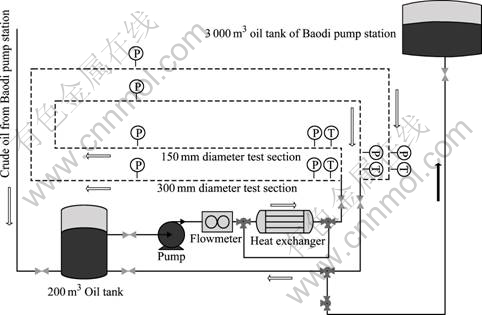

2 Large-scale flow loop

Large-scale flow loop is located in Baodi Pump station of Qinjing crude oil pipeline, and consists of two test sections of different pipe diameters (150 mm and 300 mm). The total length of test sections is 661 m. The test sections are buried and designed for a pressure level of 2.5 MPa. Pressure and temperature sensors with high precision are equipped along the test sections. The configuration of large-scale flow loop system is shown in Fig.1. Oil of the flow loop is fetched from Baodi pump station by pipeline, and is stored in 200 m3 oil tank. Oil flowing through test section goes back to 200 m3 oil tank of flow loop or 3 000 m3 oil tank of Baodi pump station finally.

3 Experimental results and analysis

In the paper, start-up pressure wave propagation process was investigated by these pressure and temperature

Fig.1 Schematic configuration of large-scale flow loop system

sensors equipped along 150 mm diameter test section of large-scale flow loop. The indoor experimental measurements show that, temperatures of freezing point and thixotropic behavior point of crude oil in the flow loop are 28 ℃ and 34 ℃, respectively.

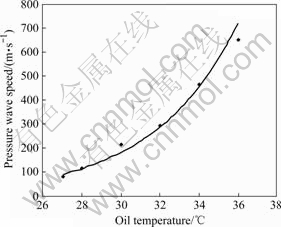

3.1 Effect of start-up oil temperature

Fig.2 shows that pressure wave speed in crude oil decreases significantly with crude oil temperatures dropping, and the decreasing trend can be described as exponential form. As an example, although oil temperature decreasing range is only 6 ℃ from 34 ℃ to 28 ℃, pressure wave speed decreases 75% from 467.1 m/s to 116.8 m/s. The analysis for crude oil properties shows, variety of crude oil temperature can lead to changes of volume and structure of crude oil. It is

Fig.2 Experimental curve of pressure wave speed in different temperatures crude oil

these changes that bring about great effects on pressure wave propagation in gelled crude oil.

On one hand, gelled crude oil has remarkable shrinkage property with the decrease of temperature, which leads to emerge some voids in pipeline. The compression to these voids can remarkably restrict pressure wave propagation during pipeline start-up. The experiment of small-scale flow loop[6] also verified the above opinion. Crude oil shrinkage with the decrease of temperature can be quantitatively described by volume expansion coefficient of crude oil. So voidage parameter M may be determined by the following equation.

(1)

(1)

where M is voidage parameter relating to thermal shrinkage of gelled crude oil in pipe; ε is the volume expansion coefficient; ?T is the temperature difference of crude oil.

On the other hand, as a nonideal elasticity substance, lower temperature can lead to the increase of structure strength of gelled crude oil. Researches[7-8] on the gelling properties of crude oil showed that, small structural deformation of gelled crude oil could also bring about lager energy dissipation, which restricted pressure wave propagation .

So the effect of gelled crude oil structure properties need to be considered in the research of pressure wave propagation.

3.2 Effect of start-up flow rate

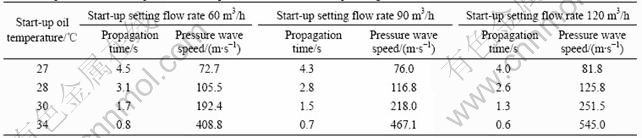

Experimental data of pressure wave speed under various restart flow rates are shown in Table 1. These

Table1 Experimental data of pressure wave speed under various start-up setting flow rates

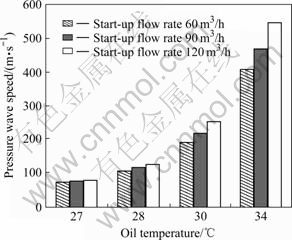

data of pressure wave speed are obtained by the length of flow loop divided by the time of pressure wave propagation from the inlet to the outlet of flow loop. Some researchers[4-5] considered, pressure wave speed of hot-oil pipeline was dependent on start-up flow rate, besides crude oil and pipe properties. It can be found from Table 1 that, for 28 ℃ crude oil, when start-up setting flow rate increases from 60 m3/h to 120 m3/h, the increasing range of pressure wave speed is from 105.5 m/s to 125.8 m/s. And the difference of pressure wave propagation time under 60 m3/h and 120 m3/h is 0.5 s .For 34 ℃ crude oil, the difference of pressure wave propagation time under 60 m3/h and 120 m3/h is only 0.2 s. Considering for measure precision of pressure sensors and additional measure errors, it is obvious that pressure wave speed slightly increases with the increase of start-up setting flow rate, which is shown more visibly in Fig.3. Therefore, under the presently operation mode of large–scale flow loop, variety of start-up setting flow rate only has a little effect on pressure wave speed.

Fig.3 Histogram of pressure wave speed in different temperature crude oil

4 A new calculation model

It is known by the above experimental analysis that thermal shrinkage and structural properties of gelled oil are key factors of influencing pressure wave propagation, and pressure wave speed decreases according to exponential form with the decrease of crude oil temperature. A new model of restart pressure wave speed is developed by the combination with experimental data and theoretical analysis.

(2)

(2)

where a is the pressure wave speed in gelled crude oil; These constants of B and C are determined by the flow loop experiment; βy is a structural property parameter of gelled crude oil; af is pressure wave speed in usual fluid, and can be determined by Eqn.(3).

(3)

(3)

where ρ is the density of crude oil; D is the inner diameter of pipe; E is the elastic modulus of pipe; δ is the thickness of pipe; C1 is the restriction coefficient; F is the compression coefficient of fluid, which is determined by the following Eqn.(4). Eqn.(4)[9] is provided by Hebei Provincial Institute of Metrology.

ln(F×1010) = 0.51992+0.0023662T

+846596/ +2 366.67T/

+2 366.67T/ (4)

(4)

where T is the temperature of crude oil; ρ0 is the density of 20 ℃ crude oil.

For crude oil with high temperature, its structure strength is very weak. When crude oil temperature is close to or higher than abnormal point, the structural property parameter can be taken as zero. In the case, Eqn.(2) transforms to an equation with the combination of pressure wave speed in usual fluid (Eqn.(3)) and voidage parameter. For low temperature crude oil, the structural property parameter βy need to be considered to calculate pressure wave speed accurately.

In the paper, yield stress of gelled crude oil is used instead of the structural property parameter βy in Eqn.(2). These parameters B and C are determined by experimental data of large-scale flow loop, and Eqn.(2) can be written as:

(5)

(5)

5 Conclusions

1) The experiment of large-scale flow loop shows that thermal shrinkage and structural properties of gelled crude oil are important factors influencing on pressure wave propagation.

2) A new model of start-up pressure wave speed in gelled crude oil is developed by the combination with experimental data and theoretical analysis. The volume expansion coefficient and a structural property parameter (yield stress) of gelled crude oil are considered in the model.

References

[1] CAWKWELL M G, CHARLES M E. An improved model for start-up of pipelines contained gelled crude oil [J]. Journal of Pipelines. 1987, 7(1): 41-52.

[2] WYLI E B, STREETER V H. Fluid transients [M]. Michigan: Ann Arbor, 1983: 35-38.

[3] LI Cai, ZHANG Xiao-ping, SU Zhong-xun, QIAO Ming-qian, LUO Shi-jin, CHENG Qing-lin, QIN Yu-cheng, WEI Ming-jing. The restarting pressure research of a hot waxy crude pipeline [J]. Oil and Gas Storage and Transportation, 1998, 17(1): 10-14. (in Chinese)

[4] ZHANG Guo-zhong, AN Jia-rong. Calculation of pressure wave speed of initial restart for hot-oil pipeline [J]. Journal of the University of Petroleum, 1999, 23 (1): 72-73. (in Chinese)

[5] ZHANG Zu-bin, ZHANG Guo-zhong. Calculation of pressure wave speed in cooled crude oil pipelines [J]. China Offshore Oil and Gas, 2000, 12(5): 33-36. (in Chinese)

[6] LI Cai, ZHANG Xiao-ping, SU Zhong-xun. The researches in the pressure propagation velocity of start-up a waxy crude pipeline [J]. Oil and Gas Storage and Transportation, 1998, 17(2): 6-10. (in Chinese)

[7] LI Chuan-xian, LU Qing-liang. Discussion on the gelling properties of waxy crude oil [J]. Oil and Gas Storage and Transportation, 2005, 24(2): 23-26. (in Chinese)

[8] HOU Lei, ZHANG Jin-jun. Status and analysis of low temperature viscoelasticity of waxy crude oil [J]. Journal of the University of Petroleum, 2006, 28(6): 140-144. (in Chinese)

[9] ZHANG Guo-zhong. The analysis of fluid transients in pipeline [M]. Dongying: University of Petroleum Press, 1994: 15-16. (in Chinese)

(Edited by ZHAO Jun)

Foundation item: Project(2008B-2901) supported by China National Petroleum Corporation

Received date: 2008-06-25; Accepted date: 2008-08-05

Corresponding author: CUI Xiu-guo, PhD; Tel: +86-316-2076109; E-mail: xgcui@petrochina.com.cn