DOI: 10.11817/j.issn.1672-7207.2019.12.005

Co质量分数对FeCuCo预合金粉烧结与力学性能的影响

刘志环,张绍和

(中南大学 地球科学与信息物理学院,湖南 长沙,410083)

摘要:采用共沉淀法制备Co质量分数分别为0,10%和20%的FeCuCo预合金粉,采用SEM,XRD和DSC对这3种合金粉进行微观结构表征、物相分析及热学性能分析,并测定不同配比的预合金粉烧结体的相对密度、洛氏硬度、抗弯强度及耐磨性等物理力学性能,同时研究不同预合金粉胎体对金刚石的包镶性能,采用SEM对不同烧结体断口形貌进行观察。研究结果表明:在烧结温度720~880 ℃范围内,随着烧结温度升高,FeCuCo预合金粉的相对密度、洛氏硬度和抗弯强度都整体呈先增加后减小的趋势;在相同温度下,随Co质量分数增加,FeCuCo预合金粉洛氏硬度和抗弯强度呈逐渐增加趋势,在840 ℃时,Co质量分数为20%的FeCuCo预合金粉烧结体的洛氏硬度和抗弯强度都达到最大值,分别为100.7和1 591 MPa,强度损失率η最小,为19.1%,即包镶金刚石的能力最强;在880 ℃时,Co质量分数为20%的FeCuCo预合金粉烧结体的耐磨性最强,50 N载荷下60 s时的平均磨损量为1.589 8 g。

关键词:FeCuCo预合金粉;金刚石;微观结构;力学性能;包镶性能

中图分类号:TM282 文献标志码:A 文章编号:1672-7207(2019)12-2958-11

Effect of Co content on sintering and mechanical properties of FeCuCo pre-alloyed powders

LIU Zhihuan, ZHANG Shaohe

(School of Geosciences and Info-Physics, Central South University, Changsha 410083, China)

Abstract: FeCuCo pre-alloyed powders with Co mass fraction of 0,10% and 20% were manufactured by co-precipitation method. The microstructure, phase composition and thermal properties of three kinds of powders were characterized by SEM, XRD and DSC. The physical and mechanical properties such as relative density, hardness, bending strength and wear mass loss of the sintering bodies of pre-alloyed powder with different Co mass fractions were measured, and the impregnation properties of different powder matrixs on diamond were studied. The results show that with the increase of sintering temperature in the range of 720-880 ℃, the relative density, hardness and bending strength of FeCuCo sintering bodies first increase and then decrease, and the hardness and bending strength increase gradually with the increase of Co mass fraction at the same temperature.The hardness and bending strength of FeCuCo sintering body with 20% Co mass fraction reach the maximum at 840 ℃, which are 100.7 and 1 591 MPa, respectively, and the strength loss rate is also the smallest,which is 19.1%, so that the holding retention of diamond is the strongest. The wear resistance of FeCuCo sintered body with 20% Co mass fraction is the strongest of all at 880 ℃, and the average wear mass loss is 1.589 8 g for 60 s under 50 N load.

Key words: FeCuCo pre-alloyed powders; diamond; microstructure; mechanical property; impregnation property

目前,预合金粉在粉末冶金制品特别是金属基金刚石制品中普及使用,金属基金刚石制品已被广泛应用于石材、陶瓷、玻璃、混凝土、人工晶体材料等的切割、磨削和钻孔加工等[1-4]。预合金粉在金刚石制品中的使用与单质混合粉末相比,能提高胎体成分的均匀性,减少低熔点成分的偏析,提高产品性能稳定性;同时,预合金化能降低烧结过程中金属原子扩散所需的激活能,显著降低烧结温度和缩短烧结时间,从而提高生产效率并减少对金刚石的热损伤[5-7]。Co由于兼具优异的金刚石把持性能和岩粉匹配磨损性能,一直被认为是优良的金属胎体材料。金刚石制品在开发初期大量采用高Co结合剂或纯Co作为胎体材料,目前金刚石绳锯产品仍采用Co高质量分数的结合剂胎体材料[8-10]。然而,Co是一种稀有而昂贵的金属,全球储量极其有限,因此,研究可替代单质Co的预合金粉体材料成为目前高性能金属基金刚石制品研究与开发的热点方向之一[11-13]。Fe价格低廉、资源丰富,并与Co同处Ⅷ副族,与Co具有许多类似的性能特征;Cu与Fe能实现无限互溶,具有良好的成型性和压制性,且熔点较低,易于调节预合金粉的烧结温度,因此,FeCuCo预合金粉是目前国内外替代Co预合金粉研究的主要方向[14-18],但人们对其相关研究主要集中在FeCuCo预合金粉的制备技术及产品的应用特点上,关于元素质量分数对FeCuCo预合金粉性能影响的研究较少。为此,本文作者采用共沉淀法制备3种不同Co质量分数的FeCuCo预合金粉,研究Co质量分数对FeCuCo预合金粉的烧结性能和力学性能的影响规律,以便为FeCuCo预合金粉在高性能金刚石制品中的应用提供理论依据和实验基础。

1 实验条件与实验方法

1.1 粉末的制备

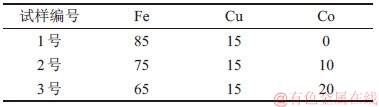

实验采用常规共沉淀法制备预合金粉。按表1中各元素质量配比称取相应的氯化物原材料,分别溶于去离子水中,形成FeCl2·4H2O,CoCl2·6H2O和CuCl2·2H2O等水化合物,混合配制成浓度为1.0 mol/L的水溶液,另外配制浓度为1.0 mol/L的草酸溶液。将金属盐溶液和草酸溶液通过加液釜以相同速率分别加入反应釜中进行共沉淀反应,反应温度为50 ℃,充分搅拌后加入氨水溶液调整反应溶液的pH,使其保持在2左右。反应20 min后再静置沉淀2 h,获得FeCuCo及FeCu复合草酸盐沉淀物,沉淀物经过过滤、清洗、煅烧和还原,得到所需要的预合金粉。

表1 预合金粉中各元素组成(质量分数)

Table 1 Composition of pre-alloyed powders %

1.2 粉末性能检测与表征

采用日本的JSM-6360LV型扫描电子显微镜(SEM)观察粉末形貌并测定晶粒粒径;采用日本 D/max-rA10型X线衍射仪对预合金粉进行物相分析,确定粉末的相结构及组成;采用德国产的STA-449C型热分析仪(DSC)对预合金粉进行热分析(氩气气氛),升温速率为10 ℃/min,升至 1 000 ℃时结束。

1.3 粉末烧结体的制备

分别将3种预合金粉样品按质量要求装入石墨模腔,置于国产真空热压烧结炉中进行热压烧结,得到长×宽×高为30 mm ×12 mm×6 mm的预合金粉烧结体试样。热压炉真空度为0.1 Pa,压力为25 MPa。采用不同烧结温度对3种预合金粉样品的烧结性能进行对比实验,烧结温度分别为720,760,800,840和880 ℃。

分别在3种预合金粉样品中添加体积分数为7.5%、粒度为425~355 μm的金刚石颗粒,并混合均匀,分别采用720,760,800,840和880 ℃的烧结温度及上述相同烧结工艺烧结含金刚石颗粒的复合材料烧结体,研究预合金粉在不同烧结温度下对金刚石的包镶性能。

1.4 烧结体的性能测试与结构表征

采用排水法测试试样的密度,并根据测定的密度与烧结体的理论密度求出相对密度。采用TH300洛氏硬度计测量不含金刚石烧结体试样的洛氏硬度,采用CMT4304万能材料试验机分别测定无金刚石与有金刚石试样的断裂载荷,由此计算各自的三点抗弯强度,并通过日本产的JSM-6700F型扫描电镜观察试样断口形貌。

粉末烧结体对金刚石颗粒的包镶强度用抗弯强度损失率η表示,计算公式如下:

(1)

(1)

式中:σ1为不含金刚石烧结体的抗弯强度;σ2为含体积分数为7.5%的金刚石颗粒烧结体抗弯强度。

采用DHM-1型砂轮磨耗比测定仪检测无金刚石试样的磨损量m。在相同实验条件下,m越小,则试样耐磨损性能越好,反之则越差。标准砂轮的硬度为3.2,线速度为20 m/s,试样加压质量为5 kg,测试时间为60 s,每次测定5个试样并取平均值。试样的磨损量m的计算公式如下:

(2)

(2)

式中:m1为试样与砂轮在对磨前的质量;m2为试样与砂轮对磨后的质量。

2 结果与讨论

2.1 预合金粉SEM分析

图1所示为采用共沉淀法所得3种Co质量分数不同的预合金粉末的SEM形貌。由图1可知:3种预合金粉的形状均为不规则状,粉末颗粒粒度较小且均匀,晶粒相互连接,晶粒表面平滑,颗粒疏松。这种形貌的粉末比表面积大,故活性高,可降低烧结温度;1号试样的颗粒粒径最大,其费氏粒度约为5.23 μm;3号试样的颗粒粒径最小,其费氏粒度约为3.41 μm;2号试样的颗粒费氏粒度居中,约为4.15 μm。造成粉末粒度差异的原因是:在相同条件下,在共沉淀过程中,当以草酸作为沉淀剂时,Fe更容易与沉淀剂反应生产粗大的晶型沉淀,而Cu和沉淀剂反应更易生成细小的无定型沉淀,因此,Fe元素质量分数越高,粉末颗粒粒径越大[19]。

图1 Co质量分数不同时预合金粉末的SEM图

Fig. 1 SEM images of pre-alloyed powders with different Co mass fractions

2.2 预合金粉XRD分析

图2所示为3种不同配比的预合金粉XRD谱。由图2可知:不同配比的预合金粉不仅有Fe和Cu的单质相,而且存在CoFe15.7,Co3Fe7和FeCu4等金属间化合物,说明Co和Cu进入了Fe的晶胞中,形成了固溶体,在烧结体内能起到固溶强化的作用,能提高烧结体的强度[20]。从图2还可知:由于Cu质量分数相同且占比较少,因此,Cu及FeCu4的衍射峰较弱且基本相同;而随着Fe质量分数降低及Co质量分数增加,Fe及(Co,Fe)合金相的衍射峰强度逐渐减弱,这是Fe质量分数减小而(Co,Fe)质量分数增大的表现;当预合金粉的Co质量分数为10%和20%时,其单质相没有在图谱中显示,是因为Co和Fe属于同族元素,原子半径粒径相近,在共沉淀过程中,Co和Fe易产生原子交换,形成置换固溶体[21]。

图2 不同Co质量分数的预合金粉XRD图谱

Fig. 2 XRD patterns of pre-alloyed powders with different Co mass fractions

2.3 预合金粉DSC分析

图3所示为3种不同配比的预合金粉DSC曲线。由图3可知:不同配比的预合金粉在850 ℃前热流比较稳定,曲线上没有明显的吸热或放热反应,说明在此温度前,预合金粉的组织没有发生太大的变化;1号样品在868.1 ℃时有较明显的吸热峰,Co质量分数为10%的2号样品在896.7 ℃时有明显的吸热峰,Co质量分数为20%的3号样品在933.0 ℃时有明显的吸热峰。结合三者间的二元相图可知[22]:在850 ℃时,发生铁素体α-Fe向奥氏体γ-Fe的共析反应;在912 ℃时,发生α-Fe向(α-Co, γ-Fe)的共析转变。根据相图,在1 096 ℃和 1 112 ℃时,还将发生FeCu的包晶反应和CoCu 的包晶反应。由图3并结合图2中的XRD可以看出:3号试样共析反应的吸热峰相对2号试样更明显,说明3号试样(α-Co,γ-Fe)合金相质量分数更高;1号试样发生明显的α-Fe向γ-Fe的共析反应,而2号和3号试样在此温度时没有明显的吸热峰,说明1号试样有Fe的单质存在,而2号和3号试样Fe单质质量分数较小。

图3 不同Co质量分数的预合金粉DSC曲线

Fig. 3 DSC curves of pre-alloyed powders with different Co mass fractions

2.4 预合金粉烧结体力学性能分析

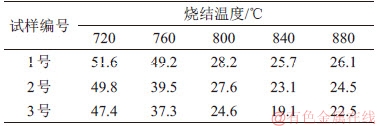

共沉淀法FeCuCo预合金粉替代Co粉末应用于金刚石制品,其相关性能对于制品结合剂的性能具有重要影响。不同元素组成的预合金粉在不同烧结温度下的相对密度见表2。从表2可见:在烧结温度为720~880 ℃时,随着烧结温度升高,不同Co质量分数的FeCuCo预合金粉相对密度整体上呈先增加后减少的趋势,且最低相对密度也达96.5%。这是由于共沉淀法制备的FeCuCo预合金粉的粉末粒度小,粉末比表面积较大,烧结时原子扩散路径较短,烧结所需激活能降低,因此,在较低烧结温度下,试样的烧结相对密度也较高。根据粉末冶金烧结理论,随着烧结温度升高,烧结的过程会进行得更加充分,使得孔隙粒径和孔隙总数量逐渐减少,烧结体逐渐致密化,相对密度逐渐增大。在840 ℃时,3种试样的相对致密度都达到最大值,其中1号试样相对密度最高,为98.6%。这是由于Co元素质量分数越高,粉末粒度越小,有利于晶粒的细化,但理论上也增加了未闭合孔隙的数量,因此,2号和3号试样致密化程度稍低。当温度大于840 ℃时,相对密度略下降,这是由于Cu和FeCu4等的熔点较低,过高的烧结温度会加速低熔点成分流失,因而造成相对密度下降;且在高温烧结时,原子扩散速度加快,晶粒长大速度过快,晶粒内未闭合孔隙数量增加,降低了烧结体的致密化程度。

表2 不同烧结温度下3种预合金粉烧结体的相对密度

Table 2 Relative densities of three kinds of pre-alloyed powders sintered at different temperatures %

表3所示为不同烧结温度下3种试样烧结体的抗弯强度与硬度测试结果,图4所示分别为抗弯强度和洛化硬度随温度变化折线图。由图4(a)可知:随着烧结温度升高,3种试样抗弯强度都有逐渐升高的趋势,且总体上Co质量分数越高,试样的抗弯强度也越大;2号和3号试样在烧结温度为800 ℃之前,抗弯强度逐渐升高,800 ℃后则变化幅度不大,且都呈现先升高后小幅度降低的趋势,在840 ℃时都达到最大值,其中,2号试样最大值为1 276 MPa,3号试样最大值为1 591 MPa;1号试样在烧结温度为800 ℃之前,其抗弯强度增加幅度较小,800 ℃以后则快速增加,840 ℃时达到最大值,为1 287 MPa,且稍高于2号试样的最大抗弯强度。经综合分析认为,当Co质量分数越高时,FeCuCo预合金粉中CoFe15.7和Co3Fe7等金属间化合物成分质量分数越高,产生固溶强化作用,因此,在烧结温度为720~880 ℃时,Co质量分数为20%的3号试样抗弯强度远比1号和2号试样的高。当烧结温度大于840 ℃时,2号和3号试样的抗弯强度有小幅度降低,这是由于当到达一定烧结温度时,烧结致密化达到平衡,进一步提高烧结温度,会造成晶粒粒径增大。Hall-Petch公式为

(3)

(3)

式中:σy为试样的强度;d为晶粒粒径;σi和k为常数。由式(3)可知烧结体试样强度与晶粒粒径呈反比,晶粒粒径越大,试样强度越低。1号试样Co质量分数为0,其主要由单质Fe,Cu和少量FeCu4合金组成,在800 ℃低温烧结时,烧结体致密化程度不够,且由于固溶成分组成较少,固溶强化作用不明显,因此,抗弯强度相对较低,由此也验证了2号和3号试样由于Co元素的添加并实现预合金化能够降低烧结温度,使试样在较低的烧结温度下烧结具有较高的强度;当进一步提高1号试样的烧结温度时,单质Fe自身颗粒间原子进一步扩散实现再结晶,晶粒之间烧结颈进一步长大,由此形成大量闭孔隙且继续缩小,使得烧结体孔隙粒径大大减小;孔隙总数大量减少,烧结体密度明显增加,抗弯强度迅速提高;当温度超过840 ℃时,闭孔隙缩小速率减缓,低熔点流失导致烧结体密度降低,抗弯强度反而有所下降。

表3 不同烧结温度下3种预合金粉烧结体的力学性能

Table 3 Mechanical properties of three kinds of pre-alloyed powders sintered at different temperatures

图4 不同烧结温度下预合金粉烧结体的力学性能随Co质量分数的变化

Fig. 4 Changes of mechanical properties of pre-alloyed powders sintered with Co mass fraction at different temperatures

由图4(b)可知:3种烧结体试样的洛氏硬度变化趋势与抗弯强度的变化趋势基本相同;随着烧结温度升高,3种试样抗弯强度都有逐渐升高的趋势;当温度在800 ℃以下时,总体上Co质量分数越高,试样的洛氏硬度也越高;2号和3号试样洛氏硬度在760 ℃之前较低且变化不大,之后随温度提升,洛氏硬度迅速提高,840 ℃时达到最大值,其中3号试样洛氏硬度最大值达100.7,再进一步提高烧结温度,洛氏硬度又有所降低,且3号试样降低幅度较2号试样更大;1号试样在800 ℃之前洛氏硬度变化幅度不大,之后随温度提升,洛氏硬度迅速提高,并超过2号试样洛氏硬度,再进一步提高烧结温度时,洛氏硬度继续提高,但提高幅度减小。经综合分析认为,Co质量分数越高,FeCuCo预合金粉中(Co,Fe)金属间化合物质量分数越高,产生固溶强化作用越强,不但降低了烧结温度,使试样在较低烧结温度下也具有较高的洛氏硬度,而且抵抗外部压入作用的能力越强,因此,洛氏硬度越高;随着烧结温度升高,烧结致密化程度增强,洛氏硬度也迅速提高,但当烧结温度较高时,由于成分流失导致致密化程度降低,洛氏硬度也随之降低。1号试样Co质量分数为0,固溶强化作用较弱;当烧结温度较低时,虽然表2中其致密化程度不低,但由于原子扩散速度缓慢,晶粒再结晶程度有限,其洛氏硬度相对较低;随着烧结温度进一步提升,原子扩散速度迅速增强,致密化程度迅速提高,单质Fe的晶粒内部及晶粒之间再结晶程度迅速增强,因此,其洛氏硬度迅速提高。综合以上分析可知:当烧结温度为840 ℃时,这3种试样综合力学性能最理想,且当Co质量分数为20%时,FeCuCo预合金粉与其他试样相比综合力学性能更优。

2.5 耐磨性分析

不同烧结温度下3种预合金粉烧结体的磨损量见表4。由表4可知:随着烧结温度升高,不同Co质量分数的烧结体试样磨损量呈逐渐减小的趋势,也就是耐磨损能力呈逐渐增强的趋势;在相同烧结温度下,磨损质量损失整体上随Co质量分数增加而逐渐减小。经综合分析认为,当烧结温度较低时,烧结体致密化过程不充分,未闭合孔隙数量较多,烧结体抵抗标准砂轮磨粒压入作用及“犁削”作用能力减弱,被“犁削”材料的质量更高,质量损失越大,耐磨损性能越差;随着烧结温度提高,烧结体致密化程度越高,烧结体试样的洛氏硬度增大,抵抗压入作用与“犁削”作用的能力增强,磨损量减少。在不同烧结温度下,3号试样磨损面的SEM图见图5。由图5可知:随着烧结温度升高,磨损面磨粒擦痕的宽度与深度逐渐减小,说明样品耐磨粒磨损的能力逐渐增强,与磨损量测试结果相符;此外,Co质量分数增加提高了FeCuCo预合金粉烧结体的合金化程度,提高了烧结体的强度和洛氏硬度,增强了烧结体材料抵抗变形的能力,因而,磨损量减少。同时,从表4可以看出,在880 ℃烧结时,磨损量并没有因为烧结体洛氏硬度与强度降低而提高,这是由于在880 ℃烧结产生的晶粒增大,使标准砂轮磨粒的“犁削”作用更多地产生在晶粒内部而非晶界边缘,因而抵抗“犁削”作用的能力更强,磨损量减少。

表4 不同烧结温度下3种预合金粉烧结体的磨损量

Table 4 Wear mass loss of three kinds of pre-alloyed powders sintered at different temperatures g

2.6 预合金粉烧结体断口形貌分析

图6所示为3号试样在不同烧结温度时烧结体断口的SEM图片。由图6可知:3号试样在烧结温度为720~840 ℃时,晶粒粒径较均匀,无异常长大现象;随着烧结温度提高,原子扩散速度增强,晶粒发生再结晶与晶粒长大;在760 ℃之前(如图 6(a)和图6(b)所示),由于烧结温度低,原子扩散不充分,晶粒与晶粒之间的微孔隙数量较多,烧结致密度较低,因此,晶粒间结合强度低,裂纹易在孔隙处沿晶界扩展,烧结体断口主要表现为沿晶断裂特征,伴随着少量的穿晶断裂;当烧结温度高于800 ℃时(如图6(c)和图6(d)所示),试样断口微孔隙数量和粒径都有所降低,且微孔隙主要存在于晶粒的内部,而晶粒之间的微孔隙数量减少,这是由于随着烧结温度升高,晶界移动速度增大,而孔隙迁移或消失的速度比晶界移动速度慢,导致晶界与孔隙发生脱离,因此,孔隙转移到晶粒内部[23],也使烧结致密化程度更加充分。试样断口呈穿晶断裂与沿晶断裂混合特征,主要以穿晶断裂特征为主,这是由于随着晶粒结合强度提高,晶粒间位错运动难度增大,当外部施加应力时,晶粒发生破裂并更易在晶粒内部扩展产生穿晶断裂,这也是试样抗弯强度显著提高的主要原因。当烧结温度提高到880 ℃时(如图6(e)所示),试样断口晶粒粒径明显长大,粗大合金相粒子在晶界处诱发的断口增多,呈现出明显的沿晶断裂的特征,导致试样抗弯强度降低。

图5 不同烧结温度下含质量分数为20% Co的预合金粉烧结体磨损面SEM图

Fig. 5 SEM images of wear face of sintering body containing Co 20% at different sintering temperatures

图6 不同烧结温度下含质量分数为20% Co的预合金粉烧结体SEM图

Fig. 6 SEM images of pre-alloyed powders containing 20% Co sintered at different temperatures

图7所示为1号和2号试样在840 ℃时烧结体断口SEM图片。由图7和图6(d)可知:在840 ℃烧结时,1号和2号试样断口形貌与3号试样的断口形貌明显不同,两者都具有韧窝断裂和穿晶断裂的混合断裂特征,晶粒粒径小且均匀,与3号试样的脆性断裂特征相比,理论上应具有更高的强度,但由图3(a)可知实际结果却相反,由此可知材料的力学性能不仅与断口形貌、晶粒粒径相关,而且与材料本身的成分、晶体结构等因素有较大关系。由图2检测结果并经综合分析认为:随着Co质量分数增加,CoFe15.7和Co3Fe7等金属间化合物质量分数明显增加,同时也减少了单质Fe在预合金粉中的质量分数,合金相增加及单质颗粒减少能大大降低预合金粉末的烧结温度,因此,3号试样特征更接近于液相烧结的特征,晶粒之间的结合强度有较大提高,而1号和2号试样合金相成分质量分数减少,断口主要表现为合金相包覆单质Fe的晶粒,因此,其试样强度相对3号试样大大减少,这与力学性能检测结果相对应。

2.7 金刚石/预合金粉烧结性能

在不同烧结温度下,3种含金刚石烧结体试样的抗弯强度损失率见表5。从表5可知:随着烧结温度升高,3种试样抗弯强度损失率η整体上都呈逐渐减小的趋势,在840 ℃时达到最小值,到880 ℃时η又有所增大;另外,整体而言,在相同温度下,η随预合金粉中Co质量分数增大整体上呈逐渐变小的趋势,3号试样烧结体在840 ℃时的强度损失率η最小,为19.1%。强度损失率η越小,金刚石颗粒阻碍胎体断裂的能力越强,换而言之,胎体对金刚石包镶能力越强[24]。

表5 金刚石/预合金粉烧结体不同烧结温度下的强度损失率

Table 5 Strength loss rate of pre-alloyed powders containing diamond sintered at different temperatures %

图7 840 ℃时Co质量分数不同时预合金粉烧结体的SEM图

Fig. 7 SEM images of pre-alloyed powders containing different mass fractions of Co sintered at 840 ℃

图8所示为3种含金刚石烧结体试样在840 ℃时的SEM照片。由图8可知:3种预合金粉胎体对金刚石的包镶界面都存在一定缝隙,所以,3种预合金粉胎体对金刚石的包镶都属于机械包镶作用,没有发生元素与金刚石的反应而产生冶金结合;3种试样的金刚石表面光滑,无其他物质黏连,说明试样中Co元素完全与其他金属元素形成了合金相,因为若存在单质Co,则由于其对金刚石表面具有良好的亲和性,会沿着金刚石表面铺展,形成薄薄的Co膜,甚至在一定温度下与金刚石反应生成Co3C[25]。3种预合金粉胎体对金刚石颗粒的包镶能力主要依靠胎体对金刚石颗粒的支撑力,这种支撑力与预合金粉胎体的强度、洛氏硬度相关联,强度和洛氏硬度越高,金刚石颗粒在受到外力作用时包镶金刚石的胎体越不容易产生界面裂纹,也不容易产生胎体的压缩与变形,因而,胎体对金刚石的包镶能力也就越强。这就是含金刚石烧结体强度损失率变化规律与不含金刚石的预合金粉烧结体的抗弯强度及洛氏硬度变化规律基本接近的原因。

图8 840 ℃时含金刚石预合金粉烧结体的SEM图

Fig. 8 SEM images of pre-alloyed powders containning diamond sintered at 840 ℃

综合以上分析认为:在综合成本提高不大的条件下,在840 ℃烧结时,Co质量分数为20%的 3号预合金粉末不仅具有较高的抗弯强度、洛氏硬度、致密度等,而且具有较好的耐摩擦磨损特性以及最佳的包镶金刚石磨粒性能,作为高性能金刚石制品的胎体材料或改性成分将具有广阔的应用前景。

3 结论

1) 不同配比的共沉淀法FeCuCo预合金粉在一定程度上实现了合金化。当Co质量分数为10%和20%时,存在CoFe15.7,Co3Fe7和FeCu4等金属间化合物,不含Co 的FeCu预合金粉则存在FeCu4固溶体。当Fe元素质量分数越低而Co质量分数越高时,粉末粒度越小,当Co质量分数为20%时,FeCuCo预合金粉费氏粒度最小,约为3.41 μm。FeCuCo预合金粉在912 ℃时发生α-Fe向(α-Co, γ-Fe)的共析转变,Co质量分数越高,共析转变过程越显著。

2) 在烧结温度为720~880 ℃时,随着烧结温度升高,不同配比的FeCuCo预合金粉烧结体的相对密度整体上呈先增加后减少的趋势,在840 ℃时达到最大值;洛氏硬度和抗弯强度也呈现先升高后降低的趋势,且在相同烧结温度时,总体上呈随Co质量分数升高而升高的趋势。随着烧结温度提高,不同配比的FeCuCo预合金粉烧结体的耐摩擦磨损能力呈逐渐增强的趋势。

3) 在840 ℃时,Co质量分数为20%的FeCuCo预合金粉烧结体断口为穿晶断裂为主;在相同温度下,Co质量分数为0或10%的预合金粉烧结体断口呈韧窝断裂和穿晶断裂的混合断裂特征,主要表现为合金相包覆单质Fe晶粒的断口形貌特征。

4) 在烧结温度为720~880 ℃内,随着烧结温度升高,含金刚石复合材料烧结体试样的抗弯强度损失率η呈先减小后增大的趋势,且在相同温度下,η随预合金粉中Co质量分数增加而变小。不同配比的预合金粉胎体对金刚石的包镶都属于机械包镶作用,Co质量分数越高,FeCuCo胎体对金刚石的机械支撑作用越强。

参考文献:

[1] ERSOY A, ATICI U. Performance characteristics of circular diamond saws in cutting different types of rocks[J]. Diamond and Related Materials, 2004, 13(1): 22-37.

[2] WRIGHT D N, ENGELS J A. The environment and cost benefits of using diamond wire for quarrying and processing of natural stone [J]. Industrial Diamond Review, 2003, 63(4): 16-24.

[3] MARTIN J. Dry cutting of concrete parapets with a diamond wire saw[J]. Industrial Diamond Review, 2005, 65(1): 44-45.

[4] ZHAI Fugang, ZHANG Yanling, LI Juan, et al. Influences of magnetic treatment on microstructure densification of diamond saw segments[J]. Journal of Central South University of Technology, 2008, 15(S2): 267-272.

[5] ZHANG Shizhong, GAN Xueping, CHENG Jinjuan, et al. Effect of applied load on transition behavior of wear mechanism in Cu–15Ni–8Sn alloy under oil lubrication[J]. Journal of Central South University, 2017, 24(8): 1754-1761.

[6] CHU Zhiqiang, GUO Xueyi, LIU Donghua, et al. Application of pre-alloyed powders for diamond tools by ultrahigh pressure water atomization[J]. Transactions of Nonferrous Metals Society of China, 2016, 26(10): 2665-2671.

[7] 张绍和, 丁星妤, 杨仙, 等. 金刚石工具胎体预合金粉末制取与应用[J]. 金刚石与磨料磨具工程, 2006, 26(6): 22-27.

ZHANG Shaohe, DING Xingyu, YANG Xian, et al. Preparation of pre-alloyed powder and it's application in diamond tools[J]. Diamond & Abrasives Engineering, 2006, 26(6): 22-27.

[8] 孙毓超, 宋月清. 对结合剂中钴的再认识[J]. 人工晶体学报, 2002, 31(6): 608-615.

SUN Yuchao, SONG Yueqing. Recongnizance to cobalt in the matrix[J]. Journal of Synthetic Crystals, 2002, 31(6): 608-615.

[9] 郭桦, 苏钰, 陈剑章, 等. Co基金刚石串珠胎体中W添加剂的作用[J]. 中国工程机械学报, 2007, 5(1): 108-112.

GUO Hua, SU Yu, CHEN Jianzhang, et al. Effect of W in Co-based matrix of diamond beads[J]. Chinese Journal of Construction Machinery, 2007, 5(1): 108-112.

[10] AN K. Pressure assisted master sintering surface of Co, Cu and Fe powder mixture[J]. Powder Technology, 2013, 234: 117-122.

[11] DAI He, WANG Limin, ZHANG Jingguo, et al. Iron based partially pre-alloyed powders as matrix materials for diamond tools[J]. Powder Metallurgy, 2015, 58(2): 83-86.

[12] ROMANSKI A, KONSTANTY J. Ball-milled Fe-Ni and Fe-Mn matrix powders for sintered diamond tools[J]. Archives of Metallurgy and Materials, 2014, 59(1): 189-193.

[13] 谢德龙, 万隆, 刘志环, 等. 共沉淀法制备Fe-Cu基预合金粉的低温热压烧结[J]. 粉末冶金材料科学与工程, 2015, 20(1): 93-98.

XIE Delong, WAN Long, LIU Zhihuan, et al. Low-temperature hot press sintering of Fe-Cu based pre-alloyed powder manufactured by co-precipitation method[J]. Materials Science and Engineering of Powder Metallurgy, 2015, 20(1): 93-98.

[14] 谢志刚, 刘心宇, 秦海青, 等. 金刚石制品用FeCoCu胎体的烧结与力学性能研究[J]. 中南大学学报(自然科学版), 2010, 41(6): 2178-2183.

XIE Zhigang, LIU Xinyu, QIN Haiqing, et al. Sintering and mechanical properties of FeCoCu fetal body applied for diamond tools[J]. Journal of Central South University(Science and Technology), 2010, 41(6): 2178-2183.

[15] XIE Delong, WAN Long, SONG Dongdong, et al. Low-temperature sintering of FeCuCo based pre-alloyed powder for diamond bits[J]. Journal of Wuhan University of Technology:Material Science Edition, 2016, 31(4): 805-810.

[16] DE PAULA BARBOSA A, BOBROVNITCHII G S, SKURY A L D, et al. Structure, microstructure and mechanical properties of PM Fe-Cu-Co alloys[J]. Materials & Design, 2010, 31(1): 522-526.

[17] LI Wensheng, ZHAN Jie, WANG Shucai, et al. Characterizations and mechanical properties of impregnated diamond segment using Cu-Fe-Co metal matrix[J]. Rare Metals, 2012, 31(1): 81-87.

[18] PALUMBO M, CURIOTTO S, BATTEZZATI L. Thermodynamic analysis of the stable and metastable Co-Cu and Co-Cu-Fe phase diagrams[J]. Calphad, 2006, 30(2): 171-178.

[19] 向波, 谢志刚, 贺跃辉, 等. 金刚石制品用Fe-Co-Cu预合金粉末的制备及其粒度控制[J]. 粉末冶金材料科学与工程, 2007, 12(2): 123-128.

XIANG Bo, XIE Zhigang, HE Yuehui, et al. Preparation and granularity control of Fe-Co-Cu prealloyed powder[J]. Materials Science and Engineering of Powder Metallurgy, 2007, 12(2): 123-128.

[20] 谢德龙, 万隆, 宋冬冬, 等. 金刚石工具用FeCoCu预合金粉组成对烧结特性的影响[J]. 中国有色金属学报, 2016, 26(3): 577-585.

XIE Delong, WAN Long, SONG Dongdong, et al. Effect of composition of FeCoCu pre-alloyed powders on sintering characters used for diamond tools[J]. The Chinese Journal of Nonferrous Metals, 2016, 26(3): 577-585.

[21] 孙毓超,刘一波,王秦生. 金刚石工具与金属学基础[M]. 北京: 中国建材工业出版社, 1999: 105-106.

SUN Yuchao, LIU Yibo, WANG Qinsheng. Basis of diamond tools and metallographic[M]. Beijing: Chinese Building Materials Industry Press, 1999: 105-106.

[22] 陈树江, 田凤仁, 李国华, 等. 相图分析及应用[M]. 北京: 冶金工业出版社, 2007: 126-128.

CHEN Shujiang, TIAN Fengren, LI Guohua, et al. Analysis and application of phase diagram[M]. Beijing: Metallurgical Industry Press, 2007: 126-128.

[23] 黄培云. 粉末冶金原理[M]. 北京: 冶金工业出版社, 2011: 288-289.

HUANG Peiyun. Powder metallurgy principle[M]. Beijing: Metallurgical Industry Press, 2011: 288-289.

[24] 戴秋莲, 徐西鹏, 王永初. 金属结合剂对金刚石把持力的增强措施及增强机制评述[J]. 材料科学与工程, 2002, 20(3): 465-468.

DAI Qiulian, XU Xipeng, WANG Yongchu. Measures used to improve bonding of diamond to matrix and bonding mechanisms[J]. Materials Science and Engineering, 2002, 20(3): 465-468.

[25] 汤东华, 洪跃生. 钴基结合剂对金刚石把持力的研究[J]. 华侨大学学报(自然科学版), 1994, 15(3): 353-357.

TANG Donghua, HONG Yuesheng. A study on the retention of cobalt base bonding agent to diamond[J]. Journal of Huaqiao University(Natural Science), 1994, 15(3): 353-357.

(编辑 陈灿华)

收稿日期: 2019 -03 -25; 修回日期: 2019 -05 -26

基金项目(Foundation item):国家自然科学基金资助项目(41872186)(Project(41872186) supported by the National Natural Science Foundation of China)

通信作者:张绍和,博士,教授,博士生导师,从事超硬材料和地质工程等研究;E-mail: zhangshaohe@163.com