文章编号:1004-0609(2016)-09-1858-11

Ca含量对Mg-Zn-Gd-Ca系合金轧制板材组织与性能的影响

魏成宾1, 2,闫 宏2,杜兴蒿1,罗 骏2,陈荣石2

(1. 沈阳航空航天大学 材料科学与工程学院,沈阳 110136;

2. 中国科学院 金属研究所材料环境腐蚀研究中心,沈阳 110016)

摘 要:研究Ca含量(0.1%,0.5%(质量分数))对Mg-1.5Zn-0.3Gd-Ca合金铸态组织、轧制板材组织、织构与力学性能的影响,以期通过改善合金组织和织构发展高塑性镁合金板材。结果表明:Mg-1.5Zn-0.3Gd-0.1Ca铸态合金含有细小均匀的第二相,Mg-1.5Zn-0.3Gd-0.5Ca合金中则存在大块状第二相;二者的轧制板材均呈现非基面织构;轧制板材经过退火处理后发生完全再结晶,板材的塑性可大幅度提高,Mg-1.5Zn-0.3Gd-0.1Ca合金经300 ℃退火后,沿横向和轧制方向的伸长率分别可达34.9%和34.1%,且轧制板材沿横向和轧向屈服强度的差异性减小。

关键词:镁合金;轧制板材;织构;力学性能

中图分类号: TG146.2 文献标志码:A

实现变形镁合金板材商业化的前提是提高其室温塑性并改善其各向异性,其中一个主要途径是设计发展弱基面织构或者非基面织构[1-4]。通过等通道挤 压[5]、异步轧制[6]、连续挤压[7]等方式可以获得弱的基面织构,同时也降低了镁合金的力学性能。另一种方式是在镁合金中加入稀土(RE)元素,通过RE元素溶质效应改变变形镁合金的再结晶过程来调控织构形态,同时提高镁合金的力学性能[8-17]。WU等[8]的研究证明,镁合金经热轧变形后,与纯Mg 相比,Mg-1Gd(质量分数,%)合金具有较弱的非基面织构,并且具有较好的力学性能;WANG等[13]通过对挤压态Mg-Zn-Er合金的研究发现,随着合金元素Zn和稀土元素Er含量的增加,合金的织构峰值减小,晶粒尺寸更加均匀,合金也表现出较好的力学性能。

YAN等[14,16]通过稀土合金化方式设计的Mg-Zn- Gd高塑性镁合金板材,由于其较大的伸长率、较高的应变硬化率和较低的各向异性,在室温下表现出较好的成型能力。和稀土元素相似,Ca元素具有较大的原子半径,且其密度和价格都低于稀土元素的,Ca元素还具有阻燃、提高镁合金的耐蚀性等特点,因此,也可以用来作为弱化变形镁合金织构的合金元素之一[18]。LEE等[19]研究表明,与轧制AZ31相比,轧制Mg-3Zn-0.5Ca的强度和延展性更好,并且该合金的各向异性更弱。HANZI等[20]研究表明,在Mg-Zn-Ca(-Zr)系合金中,当Ca的含量为0.2%~0.4%时,合金表现出较高的强度和较好的塑性。因此,本文作者设计了两种低合金化含量的镁合金,即Mg-1.5Zn-0.3Gd-0.1Ca和Mg-1.5Zn-0.3Gd-0.5Ca,探究Ca元素对Mg-Zn-Gd系合金轧制板材的组织及力学性能的影响,开发低成本高塑性的新型镁合金轧制板材。

1 实验

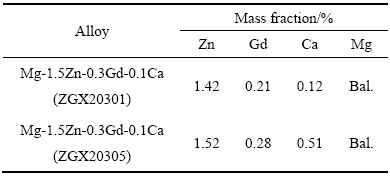

Mg-Zn-Gd-Ca系合金的设计成分分别为Mg-1.5Zn-0.3Gd-0.1Ca、Mg-1.5Zn-0.3Gd-0.5Ca,分别记作ZGX20301和ZGX20305。合金采用纯镁 (99.9%)、纯锌(99.9%)、纯钆(99.9%)和Mg-30%Ca(质量分数,%)中间合金,利用碳钢坩埚在电阻炉中熔化后,浇入尺寸为75 mm×200 mm×200 mm的长方体金属型模具中,浇铸温度为730 ℃,用CO2-SF6(1%,体积分数)气体作为保护气氛。合金化验的化学成分见表1。从铸锭上切取尺寸为200 mm×75 mm×13 mm的轧制坯料,轧制坯料进行400 ℃、10 h均匀化处理,然后在其上取小块试样,观察金相组织。

表1 Mg-Zn-Gd-Ca合金的化学成分

Table 1 Chemical compositions of Mg-Zn-Gd-Ca

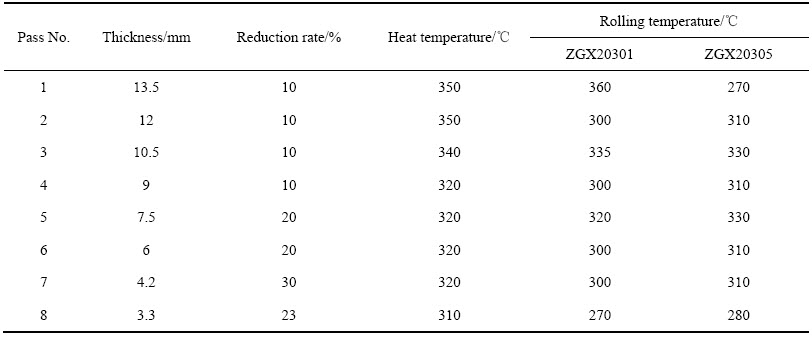

将均匀化处理后的轧制坯料在320 ℃下保温20 min后,进行轧制,得到厚度为3.3 mm的板材。前7道次轧制时,每道次的变形量为20%~30%,最后一道次的变形量为40%。每道次轧制之前将板材重新加热至320 ℃,保温20 min。具体轧制工艺如表2所示。将所得部分轧制板材做退火处理,退火温度分别设为275、300、325和350 ℃,退火时间为90 min。

用金相显微镜(OM)和扫描电镜(SEM)观察合金组织,利用EDS进行能谱分析;取铸态样品,使用D/max-2400型X衍射仪(XRD)对第二相进行分析和鉴定,衍射扫描角度为 10°~90°,扫描速度为1 (°)/min;分别沿轧制及退火板材轧向(RD)和横向(TD)切取标距为10 mm、宽3.5 mm的拉伸试样,在CMT 5105型万能实验机上进行室温拉伸试验,应变速率为1×10-3 s-1,测试轧制态以及退火态板材的力学性能;用Rigaku D/max-2400型X射线衍射仪测量板材织构,采用单一的Cu Kα辐射,织构测量角度范围为0°~70°,扫描的表面为RD-TD面,样品尺寸为12 mm×10 mm;用电子背散射衍射技术(EBSD)表征退火态晶粒取向特征。

2 结果与讨论

2.1 铸态及均匀化处理之后的组织

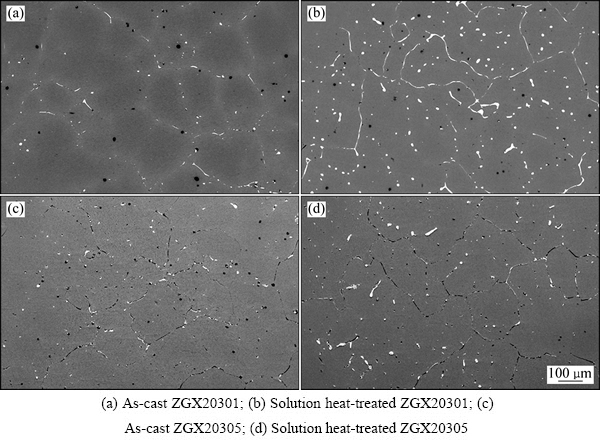

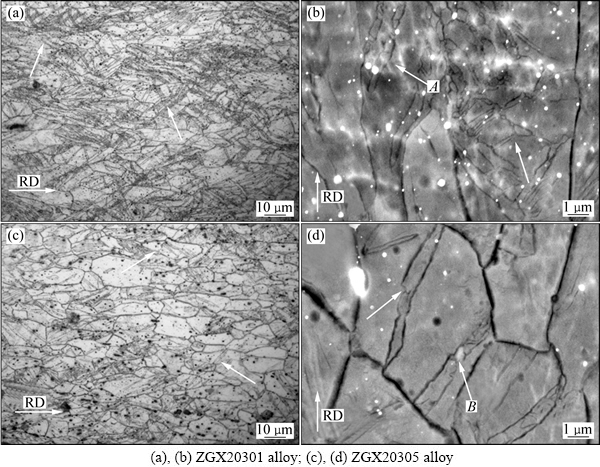

ZGX20301和ZGX20305两种合金的铸态和均匀化处理之后的金相组织如图1所示。图1(a)和(b)所示分别为ZGX20301合金和ZGX20305合金的铸态金相组织。当Ca的含量为0.1%时,晶粒尺寸为等轴晶组织,晶粒尺寸较大约为300 μm,在晶界上存在少量的网状共晶相和颗粒相;当加入0.5%Ca时,晶粒尺寸减小,约为200 μm,晶界上的网状第二相的数量明显增多。前期研究表明[16],Mg-Zn-Gd合金中铸态晶粒尺寸达到毫米级别,且晶粒为柱状晶,影响了合金的轧制性能。这是因为从成本的角度考虑,没有添加晶粒细化剂Zr。从本实验结果可以看到,添加Ca后,明显细化了Mg-Zn-Gd合金的铸态晶粒。研究表明[21],Ca的添加可以使合金产生较多的细小第二相,这些第二相可以作为凝固过程中的形核质点,能够有效细化铸态镁合金晶粒,并且随着Ca含量的增加,细化作用明显。众所周知,晶粒细化有利于提高合金的热加工性能,因而Ca的添加细化了Mg-Zn-Gd合金的铸态晶粒,也将有利于提高该合金的轧制性能。

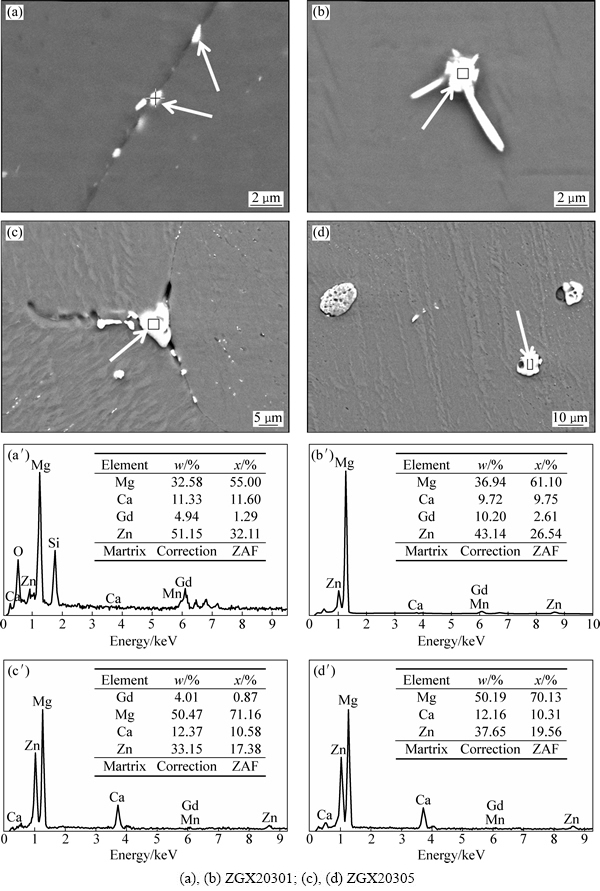

两种合金经过400 ℃、10 h均匀化处理之后的显微组织如图1(c)和(d)所示。由于进行了蚀刻处理,大部分第二相都已经脱落,形成了扫描照片中的黑色斑点。经过均匀化处理后,两种合金中的部分第二相溶入了基体当中,但仍然存在少量第二相。

经过均匀化处理之后,合金中第二相的形貌及能谱如图2所示。EDS结果显示,ZGX20301合金晶界上存在的未溶第二相含有Mg、Zn、Gd、Ca元素,有可能为共存的Mg6Ca2Zn3三元相和Mg3Zn3Gd2相(W相)。由于两者熔点高、热稳定性好,且在镁合金中的溶解度较低,因此均匀化处理之后, 很难完全溶入基体,仍存在于晶界位置(见图2(a))。此外,在晶粒内部还发现了少量形状不规则的第二相,其主要成分含Mg和Gd元素,而ZGX20305合金中残留在晶界和晶内的主要为块状第二相,并且尺寸较大。根据能谱分析,合金晶间第二相含有Mg、Zn、Gd、Ca,而晶内的第二相则为含Mg、Zn、Ca的三元相。

表2 合金ZGX20301和ZGX20305的轧制工艺参数

Table 2 Rolling process parameters of ZGX20301and ZGX20305

图1 合金的铸态及均匀化处理之后的显微组织

Fig. 1 Microstructures of as-cast and solution heat-treated alloys

2.2 轧制板材的显微组织

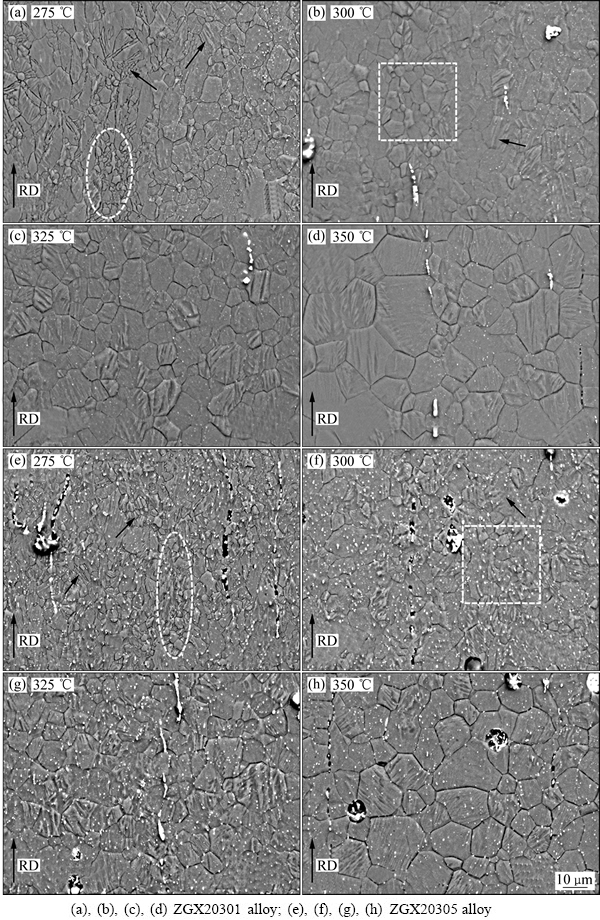

图3所示为两种合金轧制态的光学显微组织图片和扫描电镜图片。两种合金轧制后呈现变形组织,主要包含一些粗大的再结晶晶粒和大量的孪晶,孪晶相互交叉,在交叉处存在细小的动态再结晶晶粒,如图中白色箭头所示。两种合金相对而言,ZGX20301合金的晶粒尺寸更小,孪晶数量较多。从两种合金轧制态的扫描电镜图片可以进一步看出(见图3(b)和(d)),孪晶相互交叉,在孪晶交叉处存在细小的动态再结晶晶粒,如箭头A、B所示。此外, ZGX20301合金的第二相细小、分布均匀,且大部分第二相位于晶内,而ZGX20305合金的第二相尺寸大小不均,分布也不均匀,部分大块第二相分布于晶界处。

与Mg-Zn-Gd合金相比[12],ZGX合金轧制之后产生了更多的孪晶,造成这种现象的原因一方面可能与轧制温度低有关,另一方面可能与Ca有关,但其机理尚难以确定,有待深入研究。KIM等[22]的研究表明,Ca的含量影响镁合金孪晶和位错的临界分切应力,对变形机理产生影响。因此,在Mg-Zn-Gd合金加入一定量的Ca元素之后,并且在较低温度下轧制,可能会促使镁合金产生更多的孪晶。

两种合金分别经过275、300、325和350 ℃退火处理90 min后,其显微组织如图4所示。经过275 ℃退火处理之后,两种合金均发生了局部再结晶,但仍有孪晶存在(见如图4(a)和(e)箭头所示),总体而言,ZGX20301合金的晶粒尺寸大于ZGX20305合金的;当退火温度为300 ℃时(见图4(b)和(f)),再结晶区域增大(见方框区域),此时仍有少量的孪晶存在(见箭头所示);继续升高退火温度至325 ℃(见图4(c)和(g)),部分晶粒开始出现长大,孪晶数目减少;经过350 ℃退火之后(见图4(d)和(h)),晶粒明显长大,此时两者晶粒尺寸相当,表明ZGX20305合金的晶粒长大更为明显。然而,在再结晶组织中,与ZGX20301合金相比,ZGX20305合金中由于第二相数量多,且Ca元素在镁合金中的固溶度极低,因而退火后仍存在较多的在轧制过程中破碎的第二相。

2.3 织构

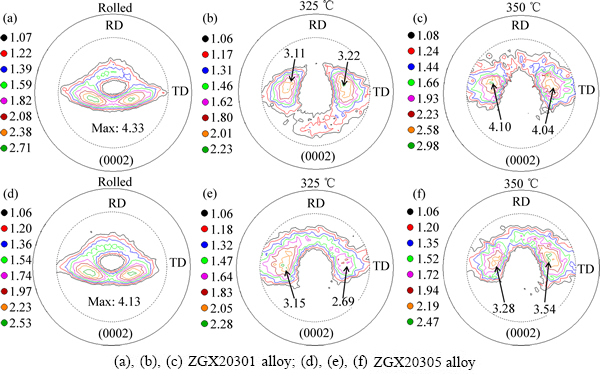

图5所示为两种合金轧制态及不同温度退火态的(0002)极图。由图5(a)和(d)可以看出,轧制之后,两种合金均具有呈横向偏转的非基面织构,两种合金的织构峰值强度接近,说明在一定的成分范围内,Ca含量对合金的织构峰值影响不大。与Mg-Zn-Gd合金不同的是[16],ZGX20301和ZFX20305两种合金中除了存在向横向偏转的两个组分外,还存在一个较弱的向轧制方向偏转的组分。可见, Ca元素并没有影响Gd的织构弱化效果和织构类型,而且形成了一个特殊的织构组分。QI等[10]和BOHLEN等[23]的研究表明,在镁合金中添加适量的稀土元素,可以使热轧后的板材织构更加随机,并且织构沿横向偏转,其织构弱化机理可能与固溶原子偏聚影响再结晶行为有关。同时,研究表明[24-26],Ca、Mn等合金元素也可以起到弱化织构的作用,其织构弱化机理与由含Ca或Mn的第二相粒子诱发再结晶形核机制(PSN)、晶格常数的降低等相关。由显微组织(见图3)可以发现,Ca的添加,造成了组织中的孪生,织构模拟结果表明孪生会导致晶粒向轧制方向偏转。因而,在Mg-Zn-Gd中添加Ca后,可能会有很多的因素使得织构得到弱化,但是Ca元素并不影响Gd原子的固溶度和分布,因而并不影响Gd的织构弱化效果,而Ca元素其本身的织构弱化作用,还对变形方式产生了一定影响,从而影响了轧制后的织构。

图2 合金ZGX20301和ZGX20305均匀化之后的扫描电镜照片及能谱分析

Fig. 2 SEM images ((a), (b), (c), (d)) and corresponding energy dispersive spectra ((a′), (b′), (c′), (d′)) of solution heat-treated alloys

图3 合金轧制态的显微组织

Fig. 3 Microstructures of as-rolled alloys

板材分别经过325 ℃、350 ℃退火处理90 min之后,其(0002)极图如图5(b)、(c)、(e)和(f)所示。退火板材的织构与轧制态相比,两种合金织构仍然为双峰非基面织构,但双峰沿横向偏转的程度更大,峰值强度先减小后增加,但是ZGX20301合金的峰值都大于ZGX20305合金的峰值,这可能和Ca元素的含量有关。在退火过程中,随着静态再结晶的发生,由于Ca和Gd的作用,使晶粒的取向更加随机化,形成再结晶织构,从而达到弱化织构的目的。

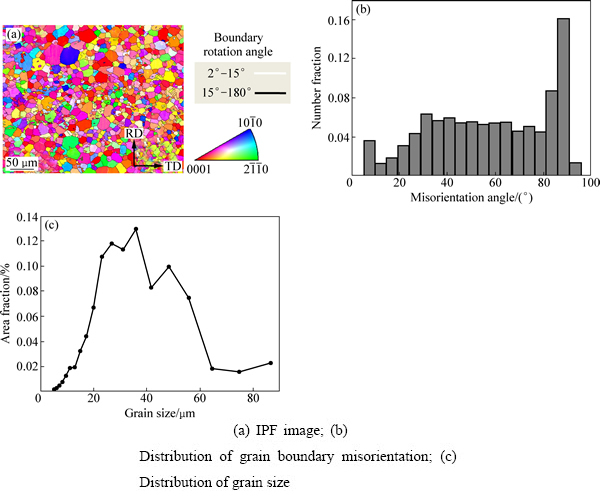

ZGX20301合金经过350 ℃退火之后的EBSD结果如图6所示。退火之后,合金内仍存在因变形产生的细晶区域,并且晶粒取向较为随机,还有部分晶粒出现长大(见图6(a))。图6(b)所示为取向差分布,由于合金发生了静态再结晶,使得合金小角度晶界减少,大角度晶界增多,平均晶粒尺寸为19.2 μm,晶粒尺寸分布如图6(c)所示。

2.4 力学性能

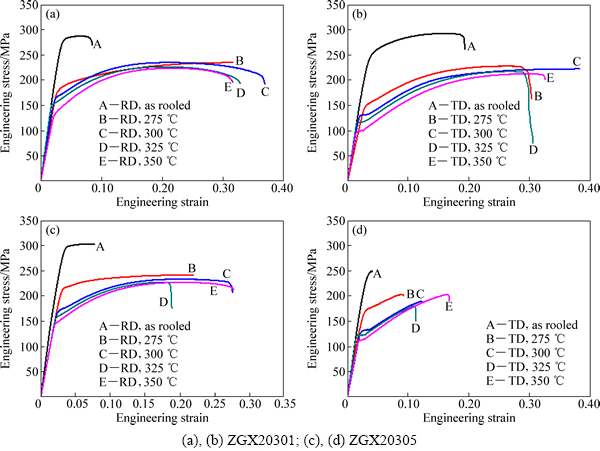

图7所示为ZGX20301合金与ZGX20305合金的轧制态和退火态的应力-应变曲线。两种合金轧制态及退火态的力学性能如表3所列。由图7可以看出,ZGX20301合金轧制态的屈服强度和伸长率沿横向与轧向的差异较大;随退火温度的升高,在伸长率上表现出的这种差异性减小,而屈服强度的差异性变化不大。对于ZGX20305合金而言,这种规律并不明显,与Mg-Zn-Gd合金相比,Mg-Zn-Gd-Ca合金的屈服强度和伸长率沿横向与轧制方向的差异性减弱。

由图7(b)和(c)可以看出,轧制态ZGX20301合金的屈服强度沿横向达到最大值,而ZGX20305 合金的屈服强度沿轧向达到最大值,分别为287.4 MPa和304.2 MPa,但是ZGX20305合金的伸长率比较低,沿横向的伸长率仅为1.1%。这主要是由于在轧制过程中,合金变形量大,位错密度较大,在进一步的变形过程中产生位错塞积,出现较强的加工硬化现象,必须施加更大的力使合金产生变形,这就导致合金产生了较高的屈服强度和较差的塑性。

图4 经不同温度退火90 min后合金的扫描电镜图片

Fig. 4 SEM images of alloys annealed at different temperatures for 90 min

图5 合金轧制态及不同温度退火90 min后的(0002)极图

Fig. 5 (0002) pole figures of rolled and annealed at different temperatures for 90 min

图6 合金ZGX20301经350 ℃退火90 min的EBSD表征

Fig. 6 EBSD characterization of ZGX20301 after annealed at 350 ℃ for 90 min

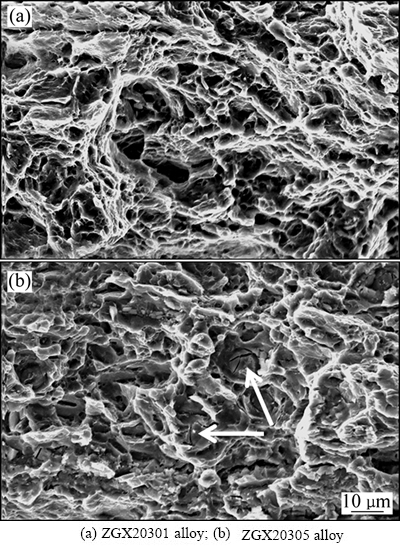

板材在275 ℃退火时,由于退火温度比较低,合金中发生再结晶的比例较少,伸长率不高,但强度下降明显;当退火温度为300 ℃时,塑性增加明显, ZGX20305合金沿轧向的伸长率达到最大值24.8% ,而ZGX20301合金沿横向的伸长率达到最大,为34.9%;继续升高退火温度,再结晶晶粒开始长大,晶粒尺寸不均匀,合金的力学性能开始下降;当退火温度为350 ℃时, ZGX20301合金沿横向的伸长率减小为29.7%, ZGX20305合金沿横向的伸长率减小为13.6%。合金经适当温度退火后表现出的高塑性可能和合金中的第二相有关,根据合金的扫描电镜图片(见图3(b)),ZGX20301合金的第二相数量少,尺寸也比较小,且大部分位于晶内,分布较为均匀,在变形过程中不易产生开裂;而ZGX20305合金的第二相尺寸较大,且多位于晶间位置,在变形过程中,容易在晶间处产生裂纹,导致合金的塑性较差。两种合金沿横向的屈服强度都低于沿轧向的屈服强度,并且随退火温度的升高,屈服强度依次降低;经350 ℃退火时, ZGX20301合金沿横向的屈服强度仅为98.3 MPa。这种现象可能与合金的织构有关,AGNEW等[27]对AZ31B进行等通道挤压也发现了这一现象。根据表3,与ZGX20301合金相比,ZGX20305合金的伸长率沿横向与轧制方向表现出的差异性更加明显,但这种差异性小于Mg-Zn-Gd合金。经300 ℃退火90 min后的拉伸断口形貌如图8所示,两种合金的断口都出现大量的韧窝,属于准解理断裂的特征,但ZGX20305合金的断口还有二次裂纹出现(见图8(b)白色箭头所示),并且断口上存在块状的第二相。而ZGX20301合金的断口中韧窝的数量相对较多,并且在大韧窝中有一些小韧窝,属于韧性断裂。这也证明了ZGX20301合金的伸长率大于ZGX20305合金的。

图7 合金轧制态、不同退火温度下的应力-应变曲线

Fig. 7 Stress-strain curves of as-rolled and annealed two alloys along RD and TD

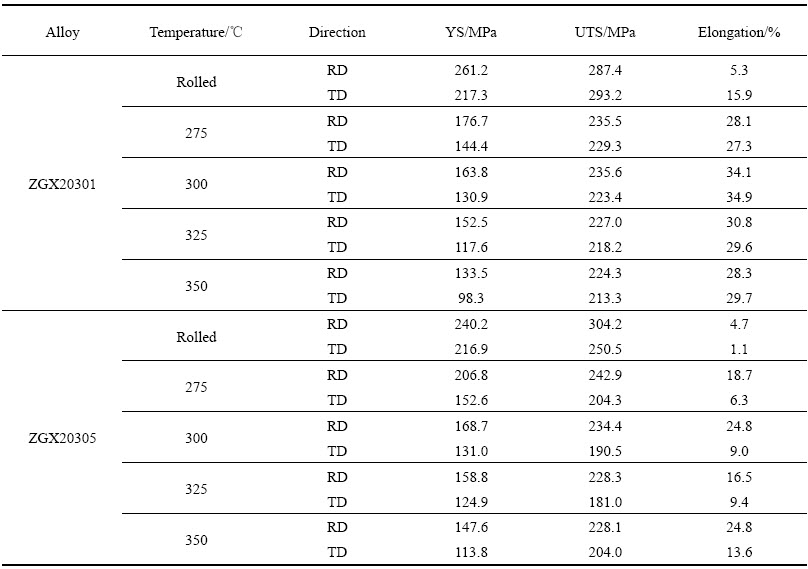

表3 合金轧制态及退火态的力学性能

Table 3 Mechanical properties of rolled and annealed alloys

图8 300 ℃退火90min后的断口的SEM像

Fig. 8 SEM image of fracture surface morphologies of alloys annealed at 300 ℃ for 90 min: (a) ZGX20301 alloy; (b) ZGX20305 alloy

3 结论

1) Mg-1.5Zn-0.3Gd-0.1Ca 铸态合金含有细小均匀的第二相,随着Ca含量增加,铸态晶粒尺寸有所减小,但第二相的数量增多,并呈现大块状;均匀化处理之后,部分第二相溶入基体内。

2) 经轧制之后,板材组织中存在许多孪晶,同时还有少量的再结晶晶粒,轧制板材呈现双峰非基面织构;退火处理之后,再结晶比例增加;织构更加随机化和弱化,峰值都小于轧制态的织构峰值。

3) 经过退火处理之后,合金Mg-1.5Zn-0.3Gd- 0.1Ca的轧制板材表现出很好的拉伸塑性,并且沿轧制方向和横向的差异性较小,轧向和横向的伸长率分别达到34.1%和34.9%;随退火温度的升高,两种合金的屈服强度依次降低,抗拉强度也呈现下降趋势。

REFERENCES

[1] 丁文江. 镁合金科学与技术[M]. 北京: 科学出版社,2007.

DING Wen-jiang. Science and technology of magnesium alloys[M]. Beijing: Science Press, 2007.

[2] 陈振华, 夏伟军, 程永奇, 傅定发. 镁合金织构与各向异性[J]. 中国有色金属学报, 2005, 15(1): 1-11.

CHEN Zhen-hua, XIA Wei-jun, CHEN Yong-qi, FU Ding-fa. Texture and anisotropy in magnesium alloys[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(1): 1-11.

[3] JUNG I H, SANJARI M, KIM J, YUE S. Role of RE in the deformation and recrystallization of Mg alloy and a new alloy design concept for Mg-RE alloys[J]. Scripta Materialia, 2015, 102: 1-6.

[4] CHINO Y, LEE J S, SASSA K, KAMIYA A, MABUCHI M. Press formability of a rolled AZ31 Mg alloy sheet with controlled texture[J]. Materials Letters, 2006, 60(2): 173-176.

[5] YUAN Y C, MA A B, GOU X F, JIANG J H, LU F M, SONG D, ZHU Y T. Superior mechanical properties of ZK60 mg alloy processed by equal channel angular pressing and rolling[J]. Materials Science and Engineering A, 2015, 630: 45-50.

[6] GONG X B, KANG S B, CHO J H, LI S Y. Effect of annealing on microstructure and mechanical properties of ZK60 magnesium alloy sheets processed by twin-roll cast and differential speed rolling[J]. Materials Characterization, 2014, 97: 183-188.

[7] TONG L B, LI X H, ZHANG H J. Effect of long period stacking ordered phase on the microstructure, texture and mechanical properties of extruded Mg-Y-Zn alloy[J]. Materials Science and Engineering A, 2013, 563: 177-183.

[8] WU W X, JIN L, WANG F H, SUN J, ZHANG Z Y, DING W J, DONG J. Microstructure and texture evolution during hot rolling and subsequent annealing of Mg-1Gd alloy[J]. Materials Science and Engineering A, 2013, 582: 194-202.

[9] 丁文江, 靳 丽, 吴文祥, 董 杰. 变形镁合金中的织构及其优化设计[J]. 中国有色金属学报, 2011, 21(10): 2371-2381.

DING Wen-jiang, JIN Li, WU Wen-xiang, DONG Jie. Texture and texture randomization of wrought Mg alloy[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(10): 2371-2381.

[10] QI Fu-gang, ZHANG Ding-fei, ZHANG Xiao-hua, PAN Fu-sheng. Effect of Y addition on microstructure and mechanical properties of Mg-Zn-Mn alloy[J]. Transactions of Nonferrous Metals Society of China, 2014, 24: 1352-1364.

[11] WU B L, ZHAO Y H, DU X H, ZHANG Y D, WAGNER F, ESLING C. Ductility enhancement of extruded magnesium via yttrium addition[J]. Materials Science and Engineering A, 2010, 527: 4334-4340.

[12] YAN H, XU S W, CHEN R S, KAMADO S, HONMA T, Han E H. Twins, shear bands and recrystallization of a Mg-2.0%Zn- 0.8%Gd alloy during rolling[J]. Scripta Materialia, 2011, 64(1): 141-144.

[13] WANG Q F, LIU K, WANG Z H, LI S B, DU W B. Microstructure, texture and mechanical properties of as-extruded Mg-Zn-Er alloys containing W-phase[J]. Journal of Alloys and Compounds, 2014, 602: 32-39.

[14] YAN H, CHEN R S, HAN E H. Room-temperature ductility and anisotropy of two rolled Mg-Zn-Gd alloys[J]. Materials Science and Engineering A, 2010, 527: 3317-3322.

[15] 余 琨, 黎文献, 王日初, 马正青. 变形镁合金的研究、开发及应用[J]. 中国有色金属学报, 2003, 13(2): 277-288.

YU Kun, LI Wen-xian, WANG Ri-chu, MA Zheng-qing. Research, development and application of wrought magnesium alloys[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(2): 277-288.

[16] YAN H, CHEN R S, ZHENG N, LUO J, KAMADO S, HAN E H. Effects of trace Gd concentration on texture and mechanical properties of hot-rolled Mg-2Zn-xGd sheets[J]. Journal of Magnesium and Alloys, 2013, 1(1): 23-30.

[17] 王 军, 朱秀荣, 徐永东, 王 荣, 聂景江, 张立君. 稀土Ce和Y对AZ80镁合金组织和力学性能的影响[J].中国有色金属学报, 2014, 24(1): 25-35.

WANG Jun, ZHU Xiu-rong, XU Yong-dong, WANG Rong, NIE Jing-jiang, ZHANG Li-jun. Effects of rare-earth Ce and Y on microstructure and mechanical properties of AZ80 Mg alloys[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(1): 25-35.

[18] DING Han-lin, ZHANG Peng, CHENG Guang-ping, KAMADO S. Effect of calcium addition on microstructure and texture modification of Mg rolled sheets[J]. Transactions of Nonferrous Metals Society of China, 2015, 25: 2875-2883.

[19] LEE J Y , YUN Y S, SUH B C, KIM N J, KIM W T, KIM D H. Comparison of static recrystallization behavior in hot rolled Mg-3Al-1Zn and Mg-3Zn-0.5Ca sheets[J]. Journal of Alloys and Compounds, 2014, 589: 240-246.

[20] HANZI A C, SOLOGUBENKO A S, GUNDE P, SCHINHAMMER M, UGGOWITZER P J. Design considerations for achieving simultaneously high-strength and highly ductile magnesium alloys[J]. Philosophical Magazine Letters, 2012, 92(9): 417-427.

[21] 漆振华, 林晓娉, 代兆立, 柳士强, 李小芳. Ca及时效处理对ZA102镁合金组织和力学性能的影响[J]. 材料热处理学报, 2011, 32(5): 105-109.

QI Zhen-hua, LIN Xiao-pin, DAI Zhao-li, LIU Shi-qiang, LI Xiao-fang. Effects of addition of Ca and aging treatment on microstructure and mechanical properties of ZA102 casting magnesium alloy[J]. Transactions of Materials and Heat Treatment, 2011, 32(5): 105-109.

[22] KIM D W, SUH B C, SHIM M S, BAE J H, KIM D H, KIM N J. Texture evolution in Mg-Zn-Ca alloy sheets[J]. Metallurgy Materials Transactions A, 2013, 44: 2950-2961.

[23] BOHLEN J, NURNBERG M R, SENN J W, LETZIG D, AGNEW S R. The texture and anisotropy of magnesium-zinc-rare earth alloy sheets[J]. Acta Materialia, 2007, 55(6): 2101-2112.

[24] BORKAR H, HOSEINI M, PEKGULERYUZ M. Effect of strontium on flow behavior and texture evolution during the hot deformation of Mg-1wt% Mn alloy[J]. Materials Science and Engineering A, 2012, 537: 49-57.

[25] TONG B L, ZHENG M Y, CHENG L R, ZHANG D P, KAMADO S, MENG J, ZHANG H J. Influence of deformation rate on microstructure, texture and mechanical properties of indirect-extruded Mg-Zn-Ca alloy[J]. Materials Characterization, 2015, 104: 66-72.

[26] ROBSON J D, HENRY D T, DAVIS B. Particle effects on recrystallization in magnesium-manganese alloys: Particle- stimulated nucleation[J]. Acta Materialia, 2009, 57(9): 2739-2747.

[27] AGNEW S R, HORTON J A, LILLO T M, BROWN D W. Enhanced ductility in strongly textured magnesium produced by equal channel angular processing [J]. Scripta Materialia, 2004, 50(3): 377-381.

Effects of Ca concentration on microstructures and properties of rolled Mg-Zn-Gd-Ca alloys

WEI Cheng-bin1, 2, YAN Hong2, DU Xing-hao1, LUO Jun2, CHEN Rong-shi2

(1.School of Materials Science and Engineering, Shenyang Aerospace University, Shenyang110136, China;

2. Environmental Corrosion Centre, Institute of Metal Research, Chinese Academy of Sciences, Shenyang110016, China)

Abstract: The effects of Ca content (0.1%, 0.5% (mass fraction)) on the microstructure, texture and mechanical properties of rolled Mg-1.5Zn-0.3Gd-Ca sheets were investigated aiming to develop high ductile Mg base alloys by improving the microstructure and texture. The results show that the as-cast microstructure of the Mg-1.5Zn-0.3Gd-0.1Ca alloy includes uniform and fine second phase, while in the as-cast microstructure of the Mg-1.5Zn-0.3Gd-0.5Ca alloy, the big-block second phases can be observed. The rolled sheets show non-basal texture with double peaks. The sheets show equiaxed grain after annealing treatment, and the ductility of the sheets can be improved significantly. After being annealed at 300 ℃ for 90 min, the room-temperature elongations of the Mg-1.5Zn-0.3Gd-0.1Ca alloy along the transverse direction and the rolling direction are 34.9% and 34.1%, respectively. And the difference of the yield tensile strength between the rolling and transverse direction is shown to be lower due to the static recrystallization during annealing treatment at certain temperature.

Key words: magnesium alloy; rolling sheet; texture; mechanical property

Foundation item: Project(51601193, 51301173, 51531002) supported by the National Natural Science Foundation of China; Project(2013CB632202) supported by the National Basic Research Program of China

Received date: 2015-07-22; Accepted date: 2016-01-24

Corresponding author: YAN Hong; Tel: +86-24-23893116; E-mail: hyan@imr.ac.cn

(编辑 龙怀中)

基金项目:国家自然科学基金资助项目(51601193, 51301173, 51531002);国家重点基础研究发展计划资助项目(2013CB632202)

收稿日期:2015-07-22;修订日期:2016-01-24

通信作者:闫 宏,副研究员,博士;电话:024-23893116;E-mail:hyan@imr.ac.cn