Trans. Nonferrous Met. Soc. China 27(2017) 1036-1042

Microstructure and mechanical properties of Ti6Al4V alloy prepared by selective laser melting combined with precision forging

Qi ZHANG, Zheng-long LIANG, Miao CAO, Zi-fan LIU, An-feng ZHANG, Bing-heng LU

School of Mechanical Engineering, Xi’an Jiaotong University, Xi’an 710049, China

Received 26 February 2016; accepted 18 September 2016

Abstract: To improve the mechanical properties of Ti6Al4V alloy prepared by selective laser melting (SLM) process, the precision forging was conducted at 950 °C and different strains and strain rates. The microstructure evolution of as-built samples and forged samples in both horizontal and vertical sections was visualized and analyzed by optical microscope and X-ray diffraction. The microstructure was improved by the precision forging and subsequent water quenching. The porosity in each section was accounted. It can be seen that high strain rate and large deformation result in low porosity, consequently contributing to a better fatigue performance. The micro-hardness was lowered after precision forging and water quenching, while the difference of microhardness between the horizontal and vertical sections became smaller, which illustrated that this process can improve the anisotropy of structural components fabricated by SLM.

Key words: selective laser melting; Ti6Al4V alloy; precision forging; microstructure; anisotropy

1 Introduction

Titanium alloy is widely used in aerospace, biomedical and nuclear industry due to its enticing properties such as high specific strength, low density, excellent corrosion resistance and biocompatibility [1-4]. However, it is usually time-consuming and expensive to produce complex Ti alloy structural components by using conventional manufacturing process. Recently, several additive manufacturing (AM) techniques, such as selective laser sintering, electron beam melting and selective laser melting (SLM) have been proposed and have gained a lot of interest from both industry and academia [5-7]. However, each of the techniques has its inherent advantages and drawbacks. If factors like productivity, geometrical flexibility and equipment availability are taken into account, SLM seems to be an ideal method for additive manufacturing of complex components with high quality and low to medium quantities. Compared to conventional manufacturing methods, SLM offers a wide range of advantages, including shorter time-to-market, near-net forming production without expensive dies, high material utilization, direct production from CAD model, and a high level of flexibility, etc [8]. Thus, SLM has been gradually adopted in the production of Ti alloy components.

However, characterized by high temperature gradient and layer-wise building method, SLM process always results in thermal stress, porosity and inherent staircase effect. LEUDERS et al [9] and EDWARDS and RAMULU [10] indicated that the residual stress, porosity and surface finish greatly affect mechanical properties, especially fatigue strength and fatigue crack growth. Aiming to eliminate the influence of residual stress, two issues should be taken into consideration. One was that the temperature inside the building chamber should be close to the melting point of the forming material as can as possible [11]. However, this was restricted by the peripheral equipment. The other was the heat treatment of post processing. VRANCKEN et al [12] found that heat treatment could improve mechanical properties of SLM parts, but its influence on fatigue performance and porosity was not researched. THIJS et al [8] and LEUDERS et al [9] revealed that the occurrence of porosity was related to laser scan strategy and the purity of powder materials. GALINA and JOACHIM [13] reduced the porosity by optimizing the process parameters, but this optimization was not universal as it was closely related to the SLM equipment. With respect to surface finish, the staircase effect could be avoided with thinner layer thickness. Thus, a trade-off between part quality and production efficiency should be made.

In this research, a new process that combined SLM with precision forging and water quenching was proposed to improve microstructure and decrease porosity. Different forging strains and strain rates were used during the forging process. Aiming at evaluating the influence of this process on part microstructure evolution, metallographic examinations were conducted, using optical microscopy and X-ray diffraction. The porosity and micro-hardness of both as-built samples and forged samples were accounted and measured.

2 Experimental

The material used in this investigation was Ti6Al4V alloy powder, which was gas atomized in argon atmosphere resulting in spherical particles. Its chemical composition is shown in Table 1.

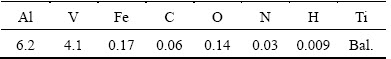

Table 1 Chemical composition of Ti6Al4V alloy (mass fraction, %)

All samples were made on the SPS250J SLM system in National Engineering Research Center of Rapid Manufacturing, Xi’an Jiaotong University, China. This SLM installation is equipped with a fiber laser, with a maximum power of 300 W. The minimum laser spot diameter is 60 μm, the maximum scanning velocity is 6000 mm/s, and the minimum layer thickness is 40 μm. The building chamber was first evacuated and then filled with argon during building phase.

The precision forging process was performed on Gleeble-3800 thermal-dynamic system made by the DIS corporation. The as-built samples were machined into cylinders (d8 mm × 12 mm) with finish turning and burnishing; graphite gaskets were used at both ends of the samples to reduce the friction between samples and punches and to ensure homogeneous deformation. Thermocouple wires were welded onto the samples and fixed by high temperature cement to measure the temperature. The forging process was performed at a temperature of 30 to 50 °C lower than the beta phase transition temperature. The beta phase transition temperature range of Ti6Al4V material is from 980 to 1000 °C. Thus, the forging process was conducted at 950 °C. Prior to forging, samples were heated to 950 °C at a heating rate of 10 °C/s , then were held for 30 s. In order to remain their original forging microstructure and to avoid growth of the recrystallized grains, all samples were quenched in water after forging process. Only strain rate ( ) and strain (ε) were changed during the forging experiments. The strain and strain rate used for each sample are shown in Table 2. The deformation chamber was filled with argon atmosphere during forging experiments.

) and strain (ε) were changed during the forging experiments. The strain and strain rate used for each sample are shown in Table 2. The deformation chamber was filled with argon atmosphere during forging experiments.

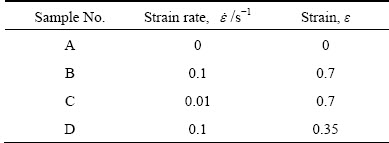

Table 2 An overview of process parameters for different samples

Before microstructural examination, the samples were polished as indicated in the following steps, first with SiC grinding paper up to 3000 grit size, then with diamond powder and polishing solution. To reveal the microstructure, all samples were etched with a 1 mL HF, 2 mL HNO3 and 7 mL H2O solution. Microstructural anisotropy might exist in SLM specimens, therefore two cross sections were examined: vertical view along the building direction (vertical section) and top view (horizontal section) perpendicular to the building direction, as shown in (Fig. 1). A Nikon optical microscope (OM) LV150N and a Hitachi scanning electron microscope (SEM) SU8010 were used for metallography examinations. The phase composition was examined by a Brukers D8 ADVANCE X-ray diffraction. The Vikers micro-hardness tests were performed on a TIME6610A micro-hardness tester and at least five readings were taken for each sample.

Fig. 1 Horizontal view and vertical view

3 Results and discussion

3.1 Microstructure of as-built samples

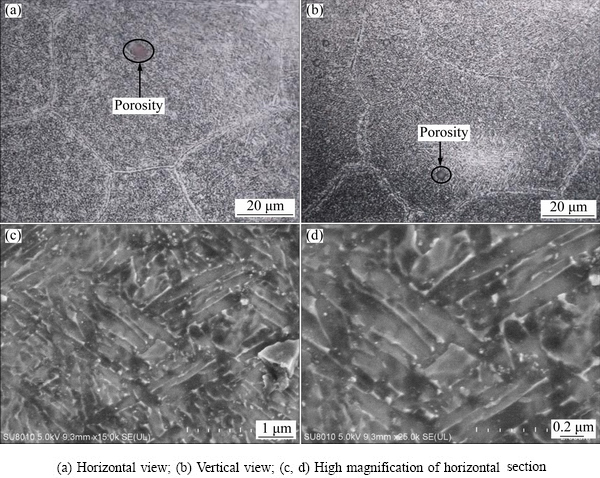

Both the horizontal and vertical views of sample A presented very similar microstructures, as shown in Figs. 2(a) and (b), respectively. Due to the high temperature gradients during the SLM process, the β phase transformed into supersaturated solid solution, namely martensite. The present microstructure of SLM Ti6Al4V was of fine acicular martensite (Figs. 2(c) and (d)). This microstructure was lamellar structure, which was the same as that observed in previous studies on Ti6Al4V [8,10]. As large number of dislocation pile-up would be easily formed at grain boundary in lamellar microstructure that will promote the formation and development of the cavity which can lead to fracture of parts in advance, this lamellar microstructure always is characterized with lower ductility.

3.2 Influence of forging process

3.2.1 Effects of strain rate

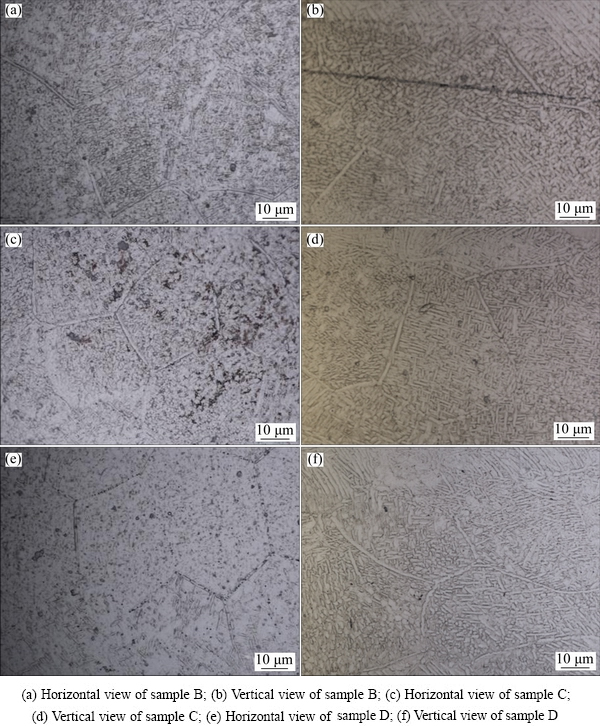

In the horizontal views (Figs. 3(a) and (c)), the grain boundaries were obviously broken and discontinuous and the microstructure had become oval and long strip rather than acicular. At the same time, due to the large deformation along the axial direction of the part, the microstructures observed in the vertical views of samples B (Fig. 3(b)) and C (Fig. 3(d)) also showed grain boundaries broken and fine acicular martensite was transformed into long strips. The main difference between samples B and C was that the microstructure of sample B was shorter and wider. Those microstructures were basketweave microstructure. Compared with lamellar microstructure, basketweave structure had finer microstructure and smaller slipping distance. Thus, those microstructure had more excellent ductility performance than lamellar microstructure [14].

3.2.2 Effects of strain

Compared with the as-built samples, the forged samples have undergone extensive plastic deformation, leading to breaking of initial grain boundaries and recrystallization. That is confirmed by the photographs of horizontal and vertical views of samples B and D. The microstructure became columnar and oval, as presented in Figs. 3(a), (b), (e) and (f).

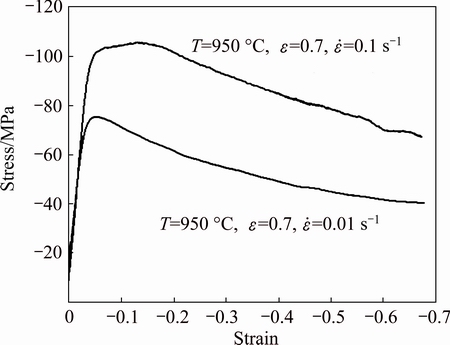

The microstructures of forged samples always characterize with better ductility performance than those of the as-built ones. The compressive stress-strain curves (Fig. 4) obtained from compression tests were conducted to illustrate the influence of forging parameters on mechanical property. It could be observed clearly that the strain hardening phenomenon occurred at the strain below 0.05 and that the strain softening phenomenon occurred at the beginning of yielding. Obviously, there was a notable increase of the flow stress with the increase of strain rate. This is probably because at high strain rate of 0.1 s-1, there is no enough time for dynamic recrystallization softening to occur, and for the slower strain rate of 0.01 s-1, dynamic recrystallization softening become more prevalent [15]. Furthermore, it could be observed that large strain rate may contribute to high yield strength and compressive strength.

Fig. 2 Micrographs of as-built Ti6Al4V specimens

Fig. 3 Micrographs of Ti6Al4V specimens following SLM processing, subsequent forged and water quenching

Fig. 4 Compressive stress-strain curves of Ti6Al4V samples produced by SLM process at different strain rates

In order to investigate the evolution of the α and β phases, XRD measurement was conducted. According to Figs. 2, 3 and 5, the β phase fraction increased obviously after precision forging and water quenching. Therefore, it can be concluded that precision forging and water quenching after SLM could encourage the transition from α phase to β phase. WANG et al [16] found that this transition could improve the creep resistance, fracture toughness and crack propagation resistance.

3.2.3 Influence on porosity

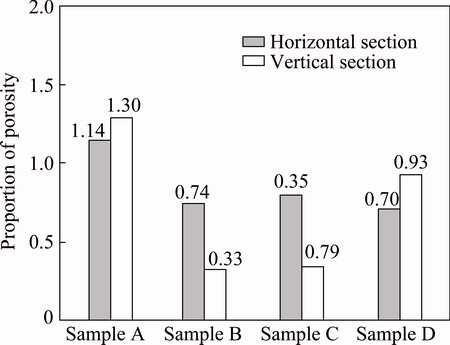

Porosities were observed in both the as-built samples and forged samples. These porosities, which originate from initial powder contaminations, evaporation or local voids after powder deposition, may result in stress concentration and origin sites for fatigue crack initiation, and are likely to be a key contributor to the low fatigue performance of the parts produced by SLM process compared with wrought materials. Therefore, reducing porosity is an efficient method to improve the fatigue performance of the SLM parts. In this research, the forging process is expected to improve the microstructure and to reduce porosity as well. For the samples tested in this study, the size of porosity was measured on both horizontal and vertical faces, and the results are shown in Fig. 6.

Fig. 5 XRD patterns for specimens A, B, C and D

It can be seen that the porosity after precision forging was obviously decreased in both sections. In the horizontal section, it decreased from a maximum 1.14% of sample A to a minimum of 0.7% of sample D, reduced by about 61.4%. However, there is little difference among samples B, C and D, only 0.09% in the horizontal section. As to the vertical section, the porosity decreased from maximum 1.3% of sample A to a minimum 0.33% of sample B, decreasing by about 74.6%. Thus, it can be concluded that forging process can minimize or eliminate the porosity, and hence improve the mechanical properties, especially the fatigue performance of the SLM components.

Fig. 6 Proportion of porosity at horizontal section and vertical section

3.2.4 Influence on microhardness

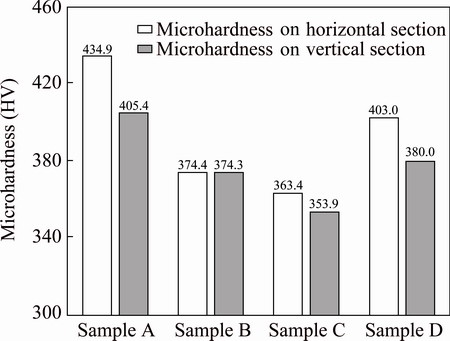

The Vickers microhardness values are shown in Fig. 7. It can be seen from Fig. 7 that the microhardness of vertical sections is lower than that of horizontal section for all samples. Especially for the as-built specimens, the microhardness on horizontal section is about 7.2% larger than that in vertical section, which exhibits obvious anisotropy. The microhardness of the as-built sample is larger than the forged samples, which is similar to the observation in other studies on SLM Ti6Al4V alloy [8]. It is known that strength is positively related to hardness, therefore, the strength may be decreased. On the other hand, we can find that minor strain rate and large deformation may contribute to the low microhardness, but on the other hand, they also reduce the difference between the two sections, namely reducing the anisotropy of the SLM parts. So, it could be accepted that while the precision forging process decreased the microhardness of SLM samples, anisotropy was significantly improved at the same time.

Fig. 7 Microhardness on horizontal section and vertical section

4 Conclusions

1) The original phase of SLM samples is α phase, and the β phase fraction is increased obviously after the precision forging and water quenching. At the same time, the microstructure is improved.

2) The porosity presents a decreasing trend with the increase of deformation and strain rate. The maximum reduction of the average porosity is 74.6%. Large deformation and high strain rate contribute to a better fatigue performance.

3) The forging process can decrease microhardness of the SLM specimens significantly. With strain rate of 0.1 s-1 and strain of 0.7, the difference of microhardness between two sections is reduced to HV 0.1, from which it can be concluded that precision forging after SLM process can improve anisotropy of the SLM parts.

References

[1] XU Jian-wei, ZENG Wei-dong, SUN Xin, JIA Zhi-qiang. Microstructure evolution during isothermal forging and subsequent heat treatment of Ti-17 alloy with a lamellar colony structure [J]. Journal of Alloys and Compounds, 2015, 637: 449-455.

[2] LEE W S, LIN Chi-feng. Plastic deformation and fracture behavior of Ti-6Al-4V alloy loaded with high strain rate under various temperatures [J]. Materials Science and Engineering A, 1998, 241: 48-59.

[3] JAYABTHI P, BINIL S, SHIVAKUMAR R, ANDY C. Mechanical evaluation of porous titanium (Ti6Al4V) structures with electron beam melting (EBM) [J]. Journal of the Mechanical behavior of Biomedical Materials, 2010, 3: 249-259.

[4] REN Hai-shui, TIAN Xiang-jun, LIU Dong, LIU Jian, WANGHua-ming. Microstructural evolution and mechanical properties of laser melting deposited Ti-6.5Al-3.5Mo-1.5Zr-0.3Si titanium alloy [J]. Transactions of Nonferrous Metals Society of China, 2015, 25: 1856-1864.

[5] KRUTH J P, MERCELIS P, VAN V J, FROYEN L, ROMBOUTS M. Binding mechanisms in selective laser sintering and selective laser melting [J]. Rapid Prototyping Journal, 2005, 11: 26-36.

[6] GORNY B, NIENDORF T, LACKMANN J,  T, MAIER H J. In situ characterization of the deformation and failure behaviour of non-stochastic porous structures processed by selective laser melting [J]. Materials Science and Engineering A, 2011, 528: 7962-7967.

T, MAIER H J. In situ characterization of the deformation and failure behaviour of non-stochastic porous structures processed by selective laser melting [J]. Materials Science and Engineering A, 2011, 528: 7962-7967.

[7] FU Tao, LI Hong-wei, SUN Jian-min, LI Gang, LI Wen, ZHANG Hong-mei. Facile hydrothermal synthesis of TiO2-CaP nano-films onTi6Al4V alloy [J]. Transactions of Nonferrous Metals Society of China, 2015, 25: 1122-1127.

[8] THIJS L, VERHAEGHE F, CRAEGHS T, VAN H J, KRUTH J P. A study of the micro structural evolution during selective laser melting of Ti-6Al-4V [J]. Acta Materialia, 2010, 58: 3303-3312.

[9] LEUDERS S,  M, RIEMER A, NIENDORF T,

M, RIEMER A, NIENDORF T,  T, RICHARD H A, MAIER H J. On the mechanical behavior of titanium alloy TiAl6V4 manufactured by selective laser melting: Fatigue resistance and crack growth performance [J]. International Journal of Fatigue, 2013, 48: 300-307.

T, RICHARD H A, MAIER H J. On the mechanical behavior of titanium alloy TiAl6V4 manufactured by selective laser melting: Fatigue resistance and crack growth performance [J]. International Journal of Fatigue, 2013, 48: 300-307.

[10] EDWARDS P, RAMULU M. Fatigue performance evaluation of selective laser melted Ti-6Al-4V [J]. Materials Science and Engineering A, 2014, 598: 327-337.

[11] SHIOMI M, OSAKADA K, NAKAMURA K, YAMASHITA T, ABE F. Residual stress within metallic model made by selective laser melting process [J]. CIRR Annals—Manufacturing Technology, 2004, 53: 195-198.

[12] VRANCKEN B, THIJIS L, KRUTH J P, HUMBEECK J V. Heat treatment of Ti6Al4Vproduced by selective laser melting: microstructure and mechanical properties [J]. Journal of Alloys and Compounds, 2012, 541:177-185.

[13] GALINA K, JOACHIM H. Improvement of fatigue resistance and ductility of Ti6Al4V processed by selective laser melting [J]. Journal of Materials Processing Technology, 2015, 220: 202-214.

[14] ZHU Zhi-shou. Research and development of new-brand titanium alloys of high performance for aeronautical application [M]. 2nd ed. Beijing: Aviation Industry Press, 2013. (in Chinese)

[15] YANG Liu-qing, YANG Yan-qing. Deformed microstructure and texture of Ti6Al4V alloy [J]. Transaction of Nonferrous Metals Society of China, 2014, 24: 3103-3110.

[16] WANG Tao, GUO Hong-zhen, TAN Li-jun, YAO Ze-kun, ZHAO Yan, LIU Peng-hui. Beta grain growth behavior of TG6 and Ti17 titanium alloys [J]. Materials Science & Engineering A, 2011, 528: 6375-6380.

选择性激光熔覆与精密锻造联合成形工艺对Ti6Al4V合金显微组织与力学性能的影响

张 琦,梁正龙,曹 苗,刘梓璠,张安峰,卢秉恒

西安交通大学 机械工程学院,西安 710049

摘 要:为提高合金的力学性能,在温度950 °C不同应变和应变速率条件下对SLM成形的Ti6Al4V合金试样进行精密锻造处理,使用光学显微镜和X射线衍射仪分析原试样和锻造处理试样在水平和竖直截面内显微组织的演化,并计算了每个截面的孔隙率。结果表明,大应变速率以及大变形量可以改善显微组织并降低孔隙率,进而提高材料的疲劳性能。精密锻造处理后的试样显微硬度小于SLM成形原件的显微硬度;同时,精密锻造处理试样在水平截面和竖直截面的显微硬度差小于SLM成形原件在两个截面的显微硬度差。这说明精密锻造工艺可以改善SLM成形零件的各向异性。

关键词:选择性激光熔覆;Ti6Al4V合金;精密锻造;显微组织;各向异性

(Edited by Yun-bin HE)

Foundation item: Project (50975222 ) supported by the National Natural Science Foundation of China; Project (2014ko8-34) supported by the Industrial Research Project of Shaanxi Province, China

Corresponding author: Qi-ZHANG; Tel: +86-29-82668607; E-mail: henryzhang@mail.xjtu.edu.cn

DOI: 10.1016/S1003-6326(17)60121-3