镍红土矿加压浸出渣磁化焙烧-弱磁选铁精矿的研究

郭学益,公琪琪,石文堂,李栋,田庆华

(中南大学 冶金科学与工程学院,湖南 长沙,410083)

摘要:以镍红土矿加压酸浸渣为原料(其主要成分是以赤铁矿为主的铁矿物),对其进行磁化焙烧-弱磁选铁精矿的实验研究,确定还原焙烧-弱磁选工艺的优化条件。研究结果表明该工艺的优化条件是:无烟煤质量分数为20%,焙烧温度为750 ℃,焙烧时间为60 min,冷却方式为水冷,弱磁选磁场强度为195 kA/m,在此最优条件下,铁品位和回收率分别为64%和94%,精矿中S质量分数为0.16%,达到了钢铁对铁精矿成分的要求。

关键词:红土镍矿酸浸渣;磁化焙烧;弱磁选;铁精矿

中图分类号:TF802.67 文献标志码:A 文章编号:1672-7207(2012)06-2048-06

Magnetic roasting of pressure leaching residue of nickel laterite and weak magnetic separation of iron concentrate

GUO Xue-yi, GONG Qi-qi, SHI Wen-tang, LI Dong, TIAN Qing-hua

(School of Metallurgical Science and Engineering, Central South University, Changsha 410083, China)

Abstract: An acid leaching residue of nickel laterite with high content of iron minerals which is mainly hematite was chosen as the raw material. The technique of reducing roasting-weak magnetic separation was adopted, and the optimum conditions were determined. The results show that the optimum conditions are as follows: anthracite mass fraction is 20%, roasting temperature is 750 ℃, roasting time is 60 min, cooling to water, and the weak magnetic field strength is 195 kA/m. Under the optimum conditions, the iron concentrate grade and recovery of iron are 64% and 94%, respectively. Moreover, the content of sulfur in iron concentrate is 0.16%, which meets the requirement for iron making.

Key words: acid leaching residue of nickel laterite; magnetic roasting; weak magnetic separation; iron concentrate

全球目前已探明的镍资源大约有1.6亿t,其中硫化镍矿占30%(质量分数,下同),氧化镍矿占70%,镍产品约60%都来自硫化镍矿。我国镍矿储量中,硫化镍占87%,氧化镍占13%。随着硫化镍矿资源的日益枯竭,从氧化矿中提取镍逐渐成为研究的重点[1]。镍红土矿依据所含硅、镁、铁含量的不同,分别采用不同的方法进行处理。本研究采用的红土镍矿为高铁矿,一般采用湿法冶金进行处理,得到的浸出渣含铁量更高。因此,从浸出渣中回收铁,可以减少浸出渣对环境的污染,有效利用矿产资源[2-3]。本文作者对菲律宾某红土镍矿高压酸浸渣中铁矿物回收的工艺进行了研究,采用磁化焙烧-弱磁选工艺回收浸出渣中的铁资源[4-6]。该工艺对原料的适应性强,适于处理各种含铁原料,尤其适用于处理组成复杂的铁矿物,铁的回收率较高,对环境不造成污染。

1 原料及设备

1.1 实验原料

本实验采用的原料是菲律宾某红土镍矿的高压酸浸渣,通过ICP和XRD检测手段分别对渣化学成分(质量分数)进行分析和物相分析,还原剂选用无烟煤,结果分别见表1和图1。

表1 浸出渣的化学成分(质量分数)

Table 1 Chemical composition of leaching residue %

图1 浸出渣的物相分析

Fig.1 XRD pattern of leaching residue

从表1可知:加压酸浸渣可回收利用的主要成分为铁,含量为49.9%,但需进一步富集;主要有害元素为S,含量较高,高达1.56%,需要尽量降低其含量。从图1可知:浸出渣中的Fe主要以Fe2O3的形式存在,而其他杂质金属主要以硅酸盐存在。基于以上分析可知:浸出渣中的铁矿物主要为赤铁矿为主,渣含硫量较高,对于这种非磁性铁矿物,直接强磁选、浮选很难实现铁的回收,最终确定还原焙烧-弱烧磁选方法[7-8]。

1.2 实验设备

实验设备为SX-4-10箱式电阻炉(天津市泰斯特仪器有限公司制造)、SCQS-Φ50型磁选管(厦门市程工矿业设备有限责任公司制造)、瓷坩埚等。

1.3 实验原理及方法

1.3.1 实验原理

磁化焙烧的目的是利用还原剂将弱磁性的Fe2O3还原成强磁性的Fe3O4,使矿物中的铁能够通过磁选工艺进行富集回收。还原焙烧过程中发生的主要反应及对应的吉布斯自由能如下。

(1) 对于Fe2O3的还原:

当温度t>570 ℃时,

3Fe2O3+CO=2Fe3O4+CO2

ΔGmΘ=-52 130-41.0t (1)

Fe3O4+CO=3FeO+CO2

ΔGmΘ=35 380-40.16t (2)

FeO+CO=Fe+CO2

ΔGmΘ=-13 160+17.2t (3)

当t<570 ℃时,

3Fe2O3+CO=2Fe3O4+CO2

ΔGmΘ=-52 130-41.0t

Fe3O4+CO=3FeO+CO2

ΔGmΘ=-1 030+2.96t (4)

(2) 布多尔反应:

C+CO2=CO

ΔGmΘ=170 707-174.47t (5)

根据热力学知识可知:式(5)为布多尔反应,高温下CO2易转化为CO;当温度低于1 000 ℃时,Fe2O3的C还原反应通过Fe2O3的CO还原和C的气化2个反应的同时平衡来实现。而且当温度高于570 ℃时,Fe2O3按反应式(1)~(5)的顺序还原,同时,根据热力学的数据可求出Fe3O4的稳定区在650 ℃以下,因此,还原焙烧是可行的[9-10]。且通过选择合适的焙烧温度,既可保证CO的平衡浓度高,又可以尽可能地控制Fe2O3还原成Fe3O4。

1.3.2 实验方法

磁化焙烧实验是在箱式电阻炉中进行的。首先将无烟煤在球磨机中磨至粒度小于180 μm,称取所需一定质量的煤粉和浸出渣,混合均匀后置于坩埚中,待电阻炉的温度升至设定温度后,将装好原料的坩埚加盖后送至炉中进行焙烧。当还原焙烧时间达到后,将坩埚取出,并采用相应的冷却方式对焙烧矿进行冷却。冷却后的还原焙烧渣通过磁选管进行弱磁磁选(选择磁场强度为160 kA/m),采用自来水为磁选介质[11],得到的磁选精矿和尾矿经真空抽滤和干燥后,分别采用ICP进行化学成分分析,并通过式(6)计算Fe的回收率η。

(6)

(6)

其中:w1和w2分别为磁选精矿和原浸出渣中Fe的质量分数,%;m1和m2分别为磁选精矿和原浸出渣的总质量,g。

弱磁选实验在SCQS-Φ50型磁选管中进行。采用焙烧实验中确定的最佳条件进行焙烧,得到的焙砂在不同的磁场强度下进行磁选,通过下式计算磁选率ε:

其中: 为磁选后得到精矿的质量,g;

为磁选后得到精矿的质量,g; 为磁选用焙砂的质量,g。

为磁选用焙砂的质量,g。

2 结果与讨论

2.1 焙烧实验部分

2.1.1 还原剂用量

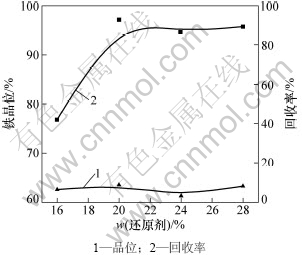

在焙烧温度为750 ℃、焙烧时间为60 min、冷却方式采用水冷的条件下,改变还原剂用量,所得Fe品位和回收率如图2所示。

图2 还原剂用量对Fe品位和回收率的影响

Fig.2 Effect of mass fraction of coal on grade and recovery of Fe

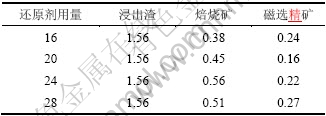

表2 还原剂用量对S质量分数的影响

Table 2 Effect of mass fraction of coal on content of S %

从图2可知:随着还原剂加入量的增加,磁选矿中Fe的品位基本没有变化。这说明在其他条件一定的情况下,增加还原剂加入量只能改变焙砂中磁性产物的含量,而不能改变磁性产物的物相;同时,随着还原剂用量的增加,Fe的回收率逐渐提高。当还原剂用量(质量分数,下同)大于20%时,回收率趋于稳定,达到94%左右,说明增加还原剂用量有利于铁精矿产率的提高。

通过ICP分析可得到焙烧-磁选过程中产物中S含量的变化,见表2。从表2可以看出:还原剂加入量对焙砂中硫的含量有一定影响;随着还原剂加入量的增加,焙砂中硫的含量也随之升高,但升高幅度不大。这主要是因为还原剂煤粉中含有一定的硫,随着还原剂加入量的增大,焙砂中未反应完全的煤粉含量也随着增加,从而造成焙砂中硫含量小幅度上升。但是,由于煤粉为非磁性物质,因此,对磁选矿没有影响,且当还原剂用量为20%时,磁选矿S品位最低为0.16%。

根据以上实验结果,确定焙烧实验还原剂用量为20%。

2.1.2 焙烧温度

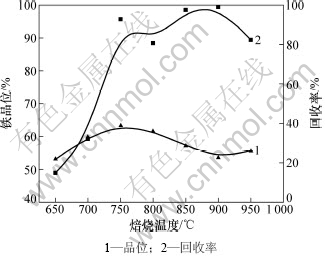

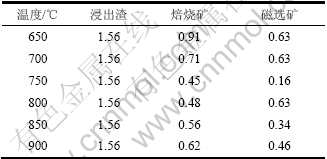

在还原剂用量为20%、焙烧时间为60 min、冷却方式采用水冷的条件下,改变焙烧温度,所得Fe品位和回收率见图3,产物S含量见表3。

图3 焙烧温度对Fe品位和回收率的影响

Fig.3 Effect of roasting temperature on grade and recovery of Fe

表3 焙烧温度S含量的影响

Table 3 Effect of roasting temperature on content of S %

从图3可看出:随着温度的升高,Fe的回收率也随之增高,当温度大于750 ℃时,回收率趋于平衡,略有波动;同时,随着温度增加,铁的品位基本不变。这主要是因为在焙烧温度650~900 ℃时,提高焙烧温度有利于Fe3O4的生成;根据实验原理,当温度超过900 ℃时,式(2)和(3)就容易发生,从而造成铁过还原,矿物中生成部分FeO,从而降低了铁的回收率。从表3可看出:焙烧温度升高,焙烧矿和磁选矿中S品位均有降低趋势,且当温度为750 ℃时,磁选矿S含量最低,有利于炼铁炼钢[12]。

根据以上研究结果,确定焙烧实验温度为750 ℃。

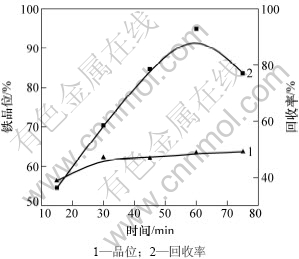

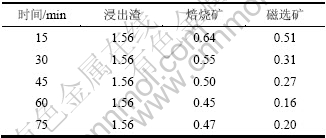

2.1.3 焙烧时间

在还原剂用量为20%、焙烧温度为750 ℃、冷却方式采用水冷的条件下,改变焙烧时间进行实验,所得Fe品位和回收率见图4,产物S含量见表4。

图4 焙烧时间对Fe品位及回收率的影响

Fig.4 Effect of roasting time on grade and recovery of Fe

表4 焙烧时间对S含量的影响

Table 4 Effect of roasting time on content of S %

从图4可知:随着焙烧时间增加,铁的回收率也随之增大,延长时间有利于Fe2O3转化为Fe3O4。这可能是由于还原焙烧时气固反应过程中,CO扩散与生成速度较小,但当焙烧时间大于60 min时,铁回收率略有下降。由于时间过长,副反应影响加大,使铁的磁选率较低,从而降低了铁的回收率。从图4中还可知:焙烧时间对铁的品位影响不大。

从表4可知:随着时间增加,焙烧矿S品位和磁选矿中S品位也均随之下降,这主要是由于延长焙烧时间,有利于硫酸盐的分解,从而降低了S含量,当时间为60 min时,磁选矿S品位可降到最低。

综上所述,确定焙烧实验时间为60 min。

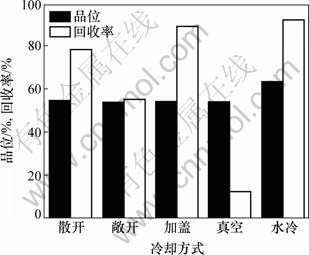

2.1.4 冷却方式

在还原剂用量为20%、焙烧温度为750 ℃、焙烧时间为60 min的条件下,分别采用以下几种冷却方式:(1) 散开,即将焙烧矿平铺开,在空气中冷却; (2) 敞开,即将焙烧矿置于去盖的坩埚中,在空气中冷却;(3) 加盖,即将焙烧矿置于加盖坩埚中,在空气中冷却;(4) 真空,即将焙烧矿置于真空干燥箱中冷却;(5) 水冷,即将焙烧矿置于水中冷却。采用这5种冷却方式进行冷却,得到Fe品位和回收率见图5,S含量见表5。

图5 冷却方式对品位和回收率的影响

Fig.5 Effect of methods of cooling on grade and recovery of Fe

表5 冷却方式对S含量的影响

Table 5 Effect of the method of cooling on content of S %

从图5可知:水冷方式的效果最佳,该条件下得到的铁精矿品位以及铁的回收率最高,分别达到63.3%和89.5%,而真空冷却条件下的铁回收率较低。这可能是在真空干燥箱中冷却速度较慢的缘故。同样,比较敞开冷却和散开冷却2种方式可以看出:虽然采用散开冷却方式,焙砂与空气接触较充分,但是,得到铁精矿品位和铁的回收率要比敞开方式的高,这也说明冷却速度是影响焙烧效果的重要因素,冷却速度越快,焙烧-磁选效果越好[13]。

从表5可知:冷却方式对焙砂中硫的含量有一定影响,其中水冷方式得到的焙砂中硫的含量最低。这可能是由于焙烧过程中,部分碱式硫酸盐转化为可溶性硫酸盐,在水冷过程中溶解于冷却水,从而降低焙砂中硫的含量。因此,选择焙砂冷却方式为水冷方式。

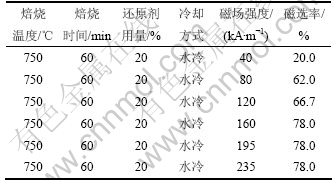

2.2 磁选部分

采用焙烧实验中确定的最佳条件进行焙烧,改变磁选的磁场强度,结果如表6所示。

表6 磁场强度对磁选率的影响

Table 6 Effect of weak magnetic field strength on magnetic ratio

从表6可知:随着磁场强度的增大,磁选率随着增大;当磁场强度大于160 kA/m时,磁选率趋于平衡。为了使磁选达到完全,选取磁选强度为195 kA/m。

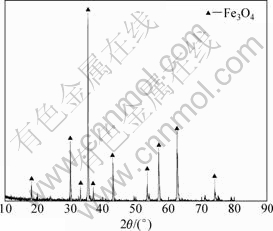

2.3 物相分析

通过对还原焙烧-磁选(均采用了最佳条件)后的磁选矿进行物相分析,结果如图6所示。通过比较图1和图6可知:原浸出渣中存在的物相主要有Fe2O3,CaSiO3和Al2(SiO3)3;而通过对浸出渣进行磁化焙烧-弱磁选处理后,得到的磁选矿物相为Fe3O4。说明磁化焙烧-弱磁选工艺可以将浸出渣中的Fe2O3还原成Fe3O4,从而达到富集铁的目的,以便于铁的回收利用[14]。

图6 磁化焙烧-弱磁选之后浸出渣的XRD物相分析

Fig.6 XRD pattern of leaching residue after magnetic roasting-weak magnetic process

3 结论

(1) 通过对镍红土矿加压酸浸出渣进行磁化焙烧-弱磁选工艺处理,实现了铁的分离回收,得到符合钢铁冶炼要求的铁精矿。

(2) 镍红土矿高压酸浸渣中Fe含量为49.9%,其中Fe主要以Fe2O3的形式存在,S含量较高达到1.56%。同时,渣中还有少量的硅酸盐存在。

(3) 浸出渣通过磁化焙烧-弱磁选工艺处理,原浸出渣中的Fe2O3转化成Fe3O4。

(4) 通过磁化焙烧因素实验的研究,得到最优的工艺条件如下:还原剂(无烟煤)质量分数为20%,焙烧温度为750 ℃,焙烧时间为60 min,冷却方式为水冷,磁选强度为195 kA/m。在此工艺下,磁选矿Fe品位达到64%,回收率达到94%,同时,S含量降低为0.16%,得到的产品达到了钢铁冶炼标准。

参考文献:

[1] 郭学益, 吴展, 李栋. 镍红土矿处理工艺的现状和展望[J]. 金属材料与冶金工程, 2009, 37(2): 3-9.

GUO Xue-yi, WU Zhan, LI Dong. The status and prospects of nickel laterite process[J]. Metal Materials and Metallurgical Engineering, 2009, 37(2): 3-9.

[2] McDonald R G, Whittington B I. Atmospheric acid leaching of nickel laterites review. Part I: Sulphuric acid technologies[J]. Hydrometallurgy, 2008, 91: 35-55.

[3] LI Chao, SUN Heng-hu. Innovative methodology for comprehensive utilization of iron ore tailings. Part 1: The recovery of iron from iron ore tailings using magnetic separation after magnetizing roasting[J]. Journal of Hazardous Materials, 2010, 174: 71-77.

[4] Prakash S, Das B, Mohanty J K. The recovery of fine iron minerals from quartz and corundum mixtures using selective magnetic coating[J]. Int J Miner Process, 1999, 57: 87-103.

[5] 张欧邦, 邓强, 刘文全. 贵州某难选褐铁矿磁化焙烧弱磁选试验研究[J]. 现代矿业, 2009, 5(5): 18-20.

ZHANG Ou-bang, DENG Qiang, LIU Wen-quan. Study on magnetic roasting and weak magnetic separation of limonite in Guizhou[J]. Modern Mining, 2009, 5(5): 18-20.

[6] 张汉泉, 任亚峰, 管俊芳. 难选赤褐铁矿焙烧-磁选试验研究[J]. 中国矿业, 2006, 15(5): 44-50.

ZHANG Han-quan, REN Ya-feng, GUAN Jun-fang. Study on roasting-magnetic separation of limonite[J]. China Mining Magazine, 2006, 15(5): 44-50.

[7] Bahgat M, Khedr M H. Magnetic behavior and morphological changes during reduction of magnetite single crystal[J]. Mater Science Engineering, 2007, 1988(3): 251.

[8] LI Ke-qing, NI Wen. Iron extraction from Oolitic iron ore by a deep reduction process[J]. Journal of Iron and Steel Research, 2001, 18(8): 9-13.

[9] 王海峰, 王芹. 高铁赤泥还原磁化焙烧的热力学分析[J]. 中国稀土学报, 2008, 26(1): 79-83.

WANG Hai-feng, WANG Qin. Thermodynamic analysis on the reduction magnetic roast of red mud with high iron[J]. Chinese Rare Earths, 2008, 26(1): 79-83.

[10] 邓强, 陈文祥, 余红林, 等. 贵州某难选褐铁矿选矿试验研究[J]. 金属矿山, 2009(2): 56-72.

DENG Qian, CHEN Wen-xiang, YU Hong-ling. Study on mineral separation of limonite in Guizhou[J]. Metal Mines, 2009(2): 56-72.

[11] ZHOU Jian-jun, ZHU Qing-hua, WANG Hua-jun, et al. Magnetic roasting of an Oolitic hematite and limonite ore in a fluidized bed reactor[J]. The Chinese Journal of Process Engineering, 2009, 9(2): 307.

[12] 薛伟, 罗琳, 关欣. 关于江西某褐铁矿选矿工艺的探讨[J]. 中国矿业, 2007, 16(6): 20-22.

XUE Wei, LUO Ling, GUAN Xin. Investigate on the process of dressing of limonite in Jiangxi[J]. China Mining Magazine, 2007, 16(6): 20-22.

[13] 宋海霞, 徐德龙, 酒少武, 等. 悬浮态磁化焙烧菱铁矿及冷却条件对产品的影响[J]. 金属矿山, 2007(1): 52-57.

SONG Hai-xia, XU De-long, JIU Shao-wu, et al. Suspend magnetic roasting of siderite and the impact of cooling condition on production[J]. Metal Mines, 2007(1): 52-57.

[14] 罗立群, 余永富, 张泾生. 闪速磁化焙烧及铁矿物的微观相变特征[J]. 中南大学学报: 自然科学版, 2009, 40(5): 1174-1179.

LUO Li-qun, YU Yong-fu, ZHANG Jin-sheng. Flash magnetic roasting and micro-phase change characteristics of iron minerals[J]. Journal of Central South University: Science and Technology, 2009, 40(5): 1174-1179.

(编辑 陈灿华)

收稿日期:2011-06-15;修回日期:2011-09-01

基金项目:青海省科技计划重大专项(2010-G-118A)

通信作者:郭学益(1966-),男,湖南长沙人,博士,教授,博士生导师;从事资源循环与环境材料、有色冶金等研究;电话:0731-88836207;E-mail:xyguo@csu.edu.cn