Trans. Nonferrous Met. Soc. China 22(2012) s573-s578

Size effect on indentation depth of oxygen-free high purity copper induced by laser shock processing

HU Yong-xiang1, LI Kang-mei, QI Chen-jie2, YAO Zhen-qiang1, Ramana V. GRANDHI3

1. State Key Laboratory of Mechanical System and Vibration, School of Mechanical Engineering, Shanghai Jiao Tong University, Shanghai 200240, China;

2. School of Materials Science and Engineering, Shanghai Jiao Tong University, Shanghai 200240, China;

3. Department of Mechanical and Material Engineering, Wright State University, Dayton 45435, USA

Received 28 August 2012; accepted 25 October 2012

Abstract: The research was carried out on the sheet metal samples of oxygen-free high purity copper to investigate the size effect on the indentation depth induced by laser shock. Samples were annealed at different temperatures and holding time to obtain microstructures with different grain sizes at the cross-section of thickness. Two spot sizes were used for experiments to obtain different loading sizes with different numbers of grains covered. The depth of indentation was measured to analyze size effects on the deformation at high strain rates. The results show that although the same pulse energy is adopted, the laser shock with the larger laser spot induces deep indentation more easily. The grain size has a notable effect on the indentation depth. It is difficult to generate plastic deformation in material with fine grains. The interactive effect of the thickness, laser spot, and grain sizes are found not to be important for the indentation depth when samples with coarse grains are used for experiments.

Key words: laser shock processing; size effect; indentation; thickness; spot size

1 Introduction

Laser shock processing (LSP) uses high intensity, short duration lasers to induce high shock pressure as an input loading for metallic components processing. It is now commercially available as a competitive alternative process to improve fatigue resistance or to form complex geometry of metallic components [1].

In recent years, much attention has been paid to the application of LSP on small size parts besides conventional parts. WANG et al [2,3] investigated the micro-scale LSP of single crystal aluminium to analyze the residual stress and plastic deformation. WIELAGE et al [4,5] used the TEA-CO2-laser to generate low shock pressure for the high speed forming of extremely thin metal foil. SAGISAKA et al [6] also investigated the feasibility of femtosecond laser peen forming for thin-sheet-metal bending. Although these works have demonstrated that LSP is very useful for the forming and strengthening of small metal parts, size effects such as grain size, sheet thickness, and loading, which commonly exist in some quasi-static forming processes, have not been considered so far. Over the past decade and longer, size effects have been found to have a great affect on the quasi-static forming process. Several research projects for the quasi-static forming process have found that the flow stress decrease can be observed by decreasing specimen thickness in general [7,8]. This phenomenon can also notably be found during the coining forming of micro-features in Type 304 stainless steel [9]. It is known that the metal material is plastically deformed at a very high strain rate of about 106 s-1 during laser shock loading. Unlike in the quasi-static process, strain rate hardening that exists in the high-strain-rate deformation may make the plastic deformation difficult to achieve. This would be quite the contrary to the feature size effect such as thickness, which is expected to make the plastic deformation easier to generate as the sheet thickness or laser spot size continues to decrease. Until now, very limited work is found about the size effect on the plastic deformation of material for the LSP process.

This work presents the research work carried out on the indentation induced by laser shock processing of sheet metal samples of oxygen-free high purity copper (OHFC). Different heat treatment conditions were adopted to obtain different grain sizes in the microstructures of samples. Two spot sizes were also used for experiment to obtain different loading sizes with different grain sizes covered. The indentation depths were measured to analyze size effects on the deformation at high strain rates.

2 Physical process of LSP

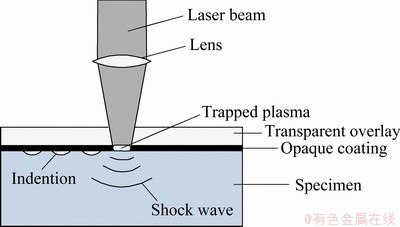

The LSP process originates from the ability to drive a high amplitude shock wave into a material surface with a short-pulsed laser with high power density (several GW/cm2, 1-50 ns). Figure 1 shows a typical application of this process carried out under a confined regime configuration. The metallic surface was first locally coated with an opaque coating and then was covered by a transparent overlay, a dielectric material transparent to the laser beam, such as water. The opaque coating acted as a sacrificial material to prevent the thermal effect from heating the surface by laser irradiation, and a thin layer of the vaporizes upon the absorption of laser energy to generate plasma. The transparent overlay confined the thermally expanding vapour and plasma against the target surface. Thus, a higher amplitude transient pressure was generated, exceeding the yield strength of the material. The high shock pressure caused the target to undergo high strain-rate deformation during a short time and the material to dynamically yield.

Fig. 1 Schematic of laser shock processing

3 Experimental

3.1 Materials

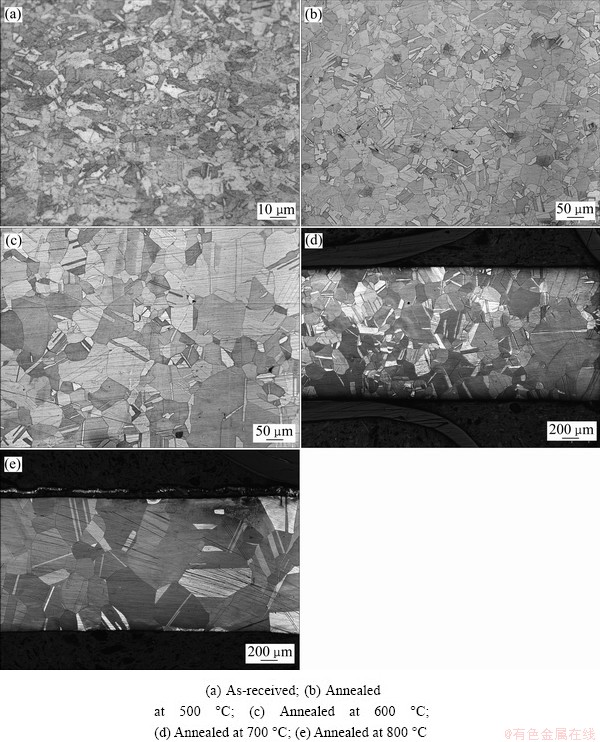

Oxygen-free high purity copper (mass fraction, 99.99% Cu) was selected in this research. A cold-rolled and annealed sheet of 1.46 mm in thickness with a mean grain size of 5.9 μm was subsequently annealed at different temperatures to obtain a wide range of grain sizes. A vacuum tube furnace was used to protect the material from oxidation. Specimens were heat treated at 500 °C, 600 °C, 700 °C, and 800 °C for annealing time of 6 h, respectively. After annealing, the specimens were polished and chemically etched by a mixture of 10 g FeCl3 (anhydrous), 30 mm HCL (analytical grade) and 120 mL H2O. Then, the grain size of the specimens was measured using the optical microscopy based on ASTM-E112-10 standard. The effect of annealling conditions on the grain size is shown in Fig. 2. The average grain diameter after annealing at 500 °C increases from 5.9 μm to 26 μm. The continued increase of annealing temperature to 600 °C, 700 °C, and 800 °C results in grain growth to 60.5, 169.9, and 375.4 μm, respectively.

3.2 LSP experiments

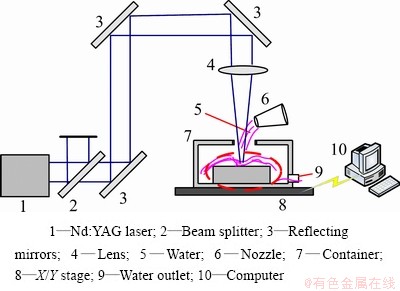

The LSP experiments were conducted with a Q-switched Nd:YAG pulsed laser source in the fundamental transverse electro-magnetic mode (TEM00). The laser was operated at a repetition frequency of 10 Hz and a pulse duration of about 10 ns in FWHM. A wavelength of 532 nm, generated by a second harmonic generator from a fundamental wavelength of 1064 nm, was selected for experiments. Figure 3 illustrates the experimental setup. The laser output pulse energy was controlled using a mirror beam splitter. The laser beam was transmitted by three reflecting mirrors to vertical and then focused onto the target surface with the desired beam diameter. The OFHC sheet specimens, the bottom sides of which were glued to an aluminium alloy plate, were mounted on a motor controlled x-y table stage. One black tape, thick enough to maintain its integrity after the irradiation of laser pulses, was used as the sacrificial overlay. Water was used as the transparent overlay to confine the generated plasma.

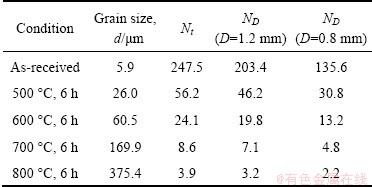

Samples under different heat treatment conditions were polished to Ra=0.08 μm for the accurate assessment of the shock-induced surface indentation. The laser spot size effect was investigated by adjusting the spot diameter to change the number of grains covered by the shock loading. Two spot diameters of 1.2 mm and 0.8 mm with the same energy output of 0.5 J were selected for experiments. To analyze the interactive effect of the thickness, laser spot, and grain size, the number of grains across the thickness and spot diameter was quantified by the ratio of the specimen thickness size and spot size to grain size in the following:

(1)

(1)

(2)

(2)

where t is the thickness size, d is the grain size, and D is the spot size. Three sizes for analysis are listed in Table 1 according to the grain size after heat treatments. By increasing the grain size through temperature control in heat treatments, only a few grains are presented in the specimen cross-section and covered by the laser spot. For example, when the grain size is 375.4 μm, the ratio of sheet thickness to grain size Nt is only 3.9, and the ratio of laser spot size to grain size ND under the spot size of 0.8 mm is only 2.2. The grain size is large enough to perform experiments to analyze the size effect on the indentation induced by the laser shock.

Fig. 2 Microstructures of annealed oxygen- free high purity

Fig. 3 Schematic of experimental setup for laser shock processing

Table 1 Specimen data of OFHC after heat treatments

4 Results and discussion

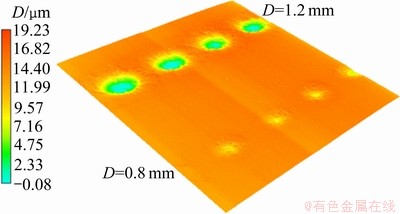

After LSP experiments, profiles of indentations were characterized utilizing a Keyence KS-1100 3D optical surface profilometer. Figure 4 shows one example of 3D indentation profiles of as-received samples with two different spot sizes. It can be found that although the same pulse energy is adopted for each experiment, the indentation depths generated by the 0.8 mm spot size are much shallower than those by the 1.2 mm spot size.

Fig. 4 3D profile of shock indentations for as-received samples

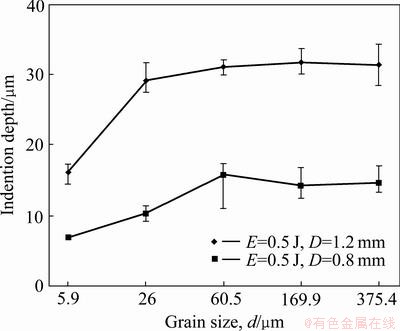

The indentation depth was measured directly from the data of 3D profiles. Figure 5 shows the indentation depths of samples with different grain sizes. Compared with the results induced by different spot sizes but the same pulse energy, the indentation depth with the small spot size is much shallower than that with large spot size. It implies that the pulse energy is not the direct factor for the plastic deformation generated by the laser shock. For the laser shock under the smaller spot size of 0.8 mm, the peak value of the laser power density is 2.25 times of the condition with the 1.2 mm spot size. The shock pressure generated by the laser ablation is affected by the transmission of breakdown plasma because when the laser power density is above a given irradiance, the breakdown plasma occurs in water and partially or fully screens the incident laser pulse. SOLLIER et al [10] theoretically investigated this phenomenon and created a numerical model to compute the characteristics of the laser pulses transmitted through the breakdown plasma, and found that the shock pressure cannot increase when the laser power intensity exceed a threshold [10]. Therefore, the reason for the shallower indentation may be the breakdown of plasma because of high laser power density adopted.

Fig. 5 Indentation depth with different laser spot sizes and heat treatment conditions

The effect of grain size (d) on the flow stress (σ) of metals is generally considered in terms of the Hall- Petch (H-P) equation [11,12]:

(3)

(3)

where σi is the lattice friction stress and KH-P the so-called H-P constant. Good agreement with the H-P equation has reported by a number of investigators, notably by HANSEN et al [13,14]. According to the Hall-Petch equation, the yield stress decreases by the grain size. Because the shock-induced indentation is generated due to the plastic deformation at the surface layer, lower yield stress would make large indentation depth, which means the larger the grain size, the deeper indentation generated will be. As shown in Fig. 5 for the measured data, it can be found that the indentation depth for the as-received sample with very fine grain size is much smaller than those with larger grain sizes after heat-treatment. By increasing the grain size, the OFHC material becomes much easier to plastically deform after laser shock. Therefore, the grain size effect on the indentation depth is very similar to the deformation under the quasi-static condition because the flow stress of material can also decrease by the grain size in the material according to the Hall-Petch equation.

However, the data in Fig. 5 when the feature size, including thickness and laser spot sizes, becomes gradually notable in the material by continually increasing the grain size, the indentation depths for both spot sizes used remain similar, which is not consistent with that from the quasi-static micro forming process.

The feature size effect of thickness which is not dominant here is easy to understand. The surface layer model, commonly used to explain the lower flow stress induced by the thickness effect in the forming of polycrystalline metallic materials, is used to describe the decrease of integral flow stress when the plastic deformation is generated in the whole section. But for laser shock induced indentation of OFHC sheet with a thickness of 1.46 mm, the plastic affect zone is mostly concentrated on the surface layer material. Therefore, the indentation generation is independent of the flow stress in the whole cross section, but mainly related to the material behaviour in the top surface layer.

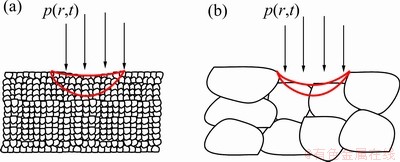

When the grain size is very fine, many grains are included in the plastic affected zone. The material plastic flow behaviour is identical to the integral flow stress as shown in Fig. 6(a). Hence, the increase of indentation depth when the grain size increases from 5.9 μm to 26 μm can be easily explained by the Hall-Petch relationship, which is commonly used to describe the decrease of flow stress by grain size. However, when the grain size increases to be more than 24.1 μm, the deformation is expected to occur predominately within a small number of grains, as shown in Fig. 6(b). The contribution of grain boundaries used as barriers to the flow stress in polycrystalline materials is not notable due to small zone of the plastic deformed material compared with the size of grains. The flow behaviour of material under shock loading is more like the response of single crystal with a few grain boundaries. It is generally assumed that the total dislocation density represents the coupling between the two types of dislocation: statically necessary dislocation (SSD) and geometrically necessary dislocation (GND) [15]. The GNDs are concentrated in the grain boundary region and increase the deformation resistance to the SSDs [16]. Different from the material behaviour of polycrystal, the GNDs for the plastic- deformed surface layer are very little. This makes the indentation depth vary very little for different grains covered by the laser spot when the grain size is large enough.

Fig. 6 Size effect for indentation generation for material with different grain sizes

5 Conclusions

1) Although the same pulse energy is adopted, laser shock with the larger laser spot induces deep indentation more easily.

2) Grains size has a notable effect on the indentation depth. It is difficult to generate plastic deformation in material with fine grains.

3) The interactive effects of the thickness, laser spot, and grain sizes, are found to be not important for the indentation depth for the material with coarse grains.

4) The experimental results presented are only confined to the small deformation generated at the top surface. Further experiments will be performed on the very thin foil to analyze the size effect in the high speed deep draw process induced by laser shock.

References

[1] MONTROSS C S, WEI T, YE L, CLARK G, MAI Y W. Laser shock processing and its effects on microstructure and properties of metal alloys: A review [J]. International Journal of Fatigue, 2002, 24(10): 1021-1036.

[2] WANG Y, FAN Y, KYSAR J W, VUKELIC S, YAO Y L. Microscale laser peen forming of single crystal [J]. Journal of Applied Physics, 2008, 103(6): 063525-8.

[3] VUKELIC S, WANG Y, KYSAR J W, YAO Y L. Dynamic material response of aluminum single crystal under microscale laser shock peening [J]. Journal of Manufacturing Science and Engineering, 2009, 131(3): 031015-10.

[4] WIELAGE H, VOLLERTSEN F. Classification of laser shock forming within the field of high speed forming processes [J]. Journal of Materials Processing Technology, 2011, 211(5): 953-957.

[5] VOLLERTSEN F, NIEHOFF H, WIELAGE H. On the acting pressure in laser deep drawing [J]. Production Engineering, 2009, 3(1): 1-8.

[6] SAGISAKA Y, KAMIYA M, MATSUDA M, OHTA Y. Application of femtosecond laser peen forming to sheet metal bending [J]. Journal of Laser Micro/Nanoengineering, 2012, 7(2): 158-163.

[7] GEIGER M, KLEINER M, ECKSTEIN R, TIESLER N, ENGEL U. Microforming [J]. CIRP Annals-Manufacturing Technology, 2001, 50(2): 445-462.

[8] LEU D K. Modeling of size effect on tensile flow stress of sheet metal in microforming [J]. Journal of Manufacturing Science and Engineering, 2009, 131(1): 011002-8.

[9] KIM G Y, KOC M, NI J. Experimental and numerical investigations on microcoining of stainless steel 304 [J]. Transactions of ASME, Journal of Manufacturing Science and Engineering, 2008, 130(4): 041017.

[10] SOLLIER A, BERTHE L, FABBRO R. Numerical modeling of the transmission of breakdown plasma generated in water during laser shock processing [J]. The European Physical Journal Applied Physics, 2001, 16(2): 131-139.

[11] HALL E O. The deformation and aging of mild steel: III Discussion of results [J]. Proceedings of the Physical Society. Section B, 1951, 64(9): 747-753.

[12] PETCH N J. The cleavage strength of polycrystals [J]. Journal of the Iron and Steel Institute, 1953, 174(4): 25-28.

[13] HANSEN N, RALPH B. The strain and grain size dependence of the flow stress of copper [J]. Acta Metallurgica, 1982, 30(2): 411-417.

[14] CONRAD H. Grain-size dependence of the flow stress of Cu from millimeters to nanometers [J]. Metallurgical and Materials Transactions A, 2004, 35(9): 2681-2695.

[15] ASHBY M F. The deformation of plastically non-homogeneous materials [J]. Philosophical Magazine, 1970, 21(170): 399-424.

[16] THOMPSON A, BASKES M, FLANAGAN W. The dependence of polycrystal work hardening on grain size [J]. Acta Metallurgica, 1973, 21(7): 1017-1028.

OFHC铜高应变率激光冲击微坑的尺寸效应

胡永祥1,李康妹1,齐晨洁2,姚振强1,Ramana V. GRANDHI3

1. 上海交通大学 机械与动力工程学院 机械系统与振动国家重点实验室,上海 200240;

2. 上海交通大学 材料科学与工程学院,上海 200240;

3. Department of Mechanical and Material Engineering, Wright State University, Dayton 45435, USA

摘 要:采用高温无氧铜材料,实验研究激光冲击压力作用下铜材料表面微坑的几何特征以及尺寸效应作用规律。通过控制热处理温度与保温时间,在厚度截面方向获得多种不同晶粒粒径的试样,结合2种不同光斑大小的实验,研究激光冲击表面高应变率塑性变形的大小效应作用特征。实验结果表明:在相同激光能量条件下,大光斑冲击产生的微坑深度较大。晶粒粒径对微坑深度有较大的影响,小晶粒条件下,产生的坑深较小;大晶粒条件下,光斑大小与晶粒粒径对于坑深的影响较为显著。

关键词:激光冲击强化;尺寸效应;微坑;厚度;光斑尺寸

(Edited by DENG  -xiang)

-xiang)

Foundation item: Projects (50905109, 51075271) supported by the National Natural Science Foundation of China; Project (20090073110039) supported by the Doctoral Fundation of Ministry of Education, China; Project supported by the Young Faulty Research Foundation of Shanghai Jiao Tong University, China

Corresponding author: HU Yong-xiang; Tel: +86-21-34206554; E-mail: huyx@sjtu.edu.cn

DOI: 10.1016/S1003-6326(12)61763-4