文章编号:1004-0609(2014)05-1111-07

基于镁合金 孪生的织构调整及屈服行为演变

孪生的织构调整及屈服行为演变

况新亮,刘天模,何杰军

(重庆大学 材料科学与工程学院,重庆 400030)

摘 要:研究挤压态镁合金沿挤压方向预压缩对随后沿ED方向拉伸以及垂直于ED方向压缩屈服行为的影响。结果表明:在所研究的1%~9%压缩预变形范围内,不同预变形量对随后沿ED方向拉伸的屈服影响几乎一样,都能使沿挤压方向拉伸屈服强度下降到约120 MPa,这几乎与沿挤压方向压缩屈服强度122 MPa一致;沿ED方向预压缩将导致垂直于ED方向压缩屈服强度显著增加, 且不同预变形量对随后沿垂直于ED方向压缩的屈服行为影响几乎一致。造成不同施载方向屈服行为不一样的原因是不同施载方向孪生变体的最大施密特因子值不同。最大施密特因子值越大,孪生启动时的临界剪切应力越小,屈服强度也就越低。

关键词:镁合金;孪生;织构;施密特因子

中图分类号:TG113 文献标志码:A

Evolution of texture and yielding behavior induced by  twinning of magnesium alloy

twinning of magnesium alloy

KUANG Xin-liang, LIU Tian-mo, HE Jie-jun

(College of Materials Science and Engineering, Chongqing University, Chongqing 400030, China)

Abstract: The effects of compressive pre-deformation on subsequent tension along extrusion direction (ED) and compression perpendicular to ED were investigated in an extruded AZ31 Mg alloy. The results show that the subsequent tensile yield stress decreases to about 120 MPa irrespective of the prestrain from 1% to 9%. The tensile yield stresses of about 120 MPa for the samples subjected to pre-compression are nearly equal to that of compression along ED (about 122 MPa) for the sample without any prestrain. However, the pre-compression along ED leads to an obvious increase in the yield stress for subsequent compression perpendicular to ED. Different prestrains exhibit similar effects on the yielding behavior during subsequent compression perpendicular to ED. Because of the difference in the highest Schmid factors for  twinning, the samples exhibit different yielding behaviors under different strain paths. The critical resolved shear stress (CRSS) decreases with the increase of the highest Schmid factor for

twinning, the samples exhibit different yielding behaviors under different strain paths. The critical resolved shear stress (CRSS) decreases with the increase of the highest Schmid factor for  twinning.

twinning.

Key words: magnesium alloy; twinning; texture; Schmid factor

近些年来,镁合金由于在轻质结构元件中有潜在应用,已经引起了学者们广泛的研究兴趣[1-8]。但是,由于其是密排六方(HCP)晶体结构,基面滑移只能提供两个独立滑移系,不能满足Von Mises准则所要求的5个独立滑移系[9-11],这限制了镁合金常温下的变形能力。而镁合金的非基面滑移,即柱面滑移和锥面滑移,需要较大的临界剪切应力,一般认为在室温下很难启动。因此,孪生在镁合金的室温变形中有着非常重要的作用。已报道的镁及其合金中的形变孪生有 、

、 、

、 、

、 、

、 以及二次孪晶等,其中最常见的是

以及二次孪晶等,其中最常见的是 拉伸孪晶、

拉伸孪晶、 压缩孪晶以及

压缩孪晶以及 -

- 二次孪晶。在镁合金的诸多孪生类型中,

二次孪晶。在镁合金的诸多孪生类型中, 孪生被认为是最容易出现的[4-6, 12-16]。大量的研究结果表明,垂直于镁合金的c轴压缩或者平行于c轴拉伸有利于

孪生被认为是最容易出现的[4-6, 12-16]。大量的研究结果表明,垂直于镁合金的c轴压缩或者平行于c轴拉伸有利于 孪晶的产生。

孪晶的产生。

近年来,很多国内外学者对镁合金中 的孪生行为进行了广泛的研究。HONG等[17]认为,不同的施载方向导致6个

的孪生行为进行了广泛的研究。HONG等[17]认为,不同的施载方向导致6个 面的施密特因子存在差异,使得镁合金变形中启动的孪生变体数不一样,因此孪生对镁合金力学行为的影响也不一样。由于孪晶的生成,孪晶界的存在具有细化晶粒的作用,从霍尔-佩奇理论上来说,孪生对材料的力学性能也有一定的影响。WANG等[18]研究了挤压态镁合金中沿ED方向预压缩对随后反向拉伸屈服行为的影响,结果表明压缩预变形使镁合金的取向产生了约86.3°的改变,使得经预变形孪生的区域晶粒的c轴变得几乎与ED方向一致,这有利于随后反向拉伸时

面的施密特因子存在差异,使得镁合金变形中启动的孪生变体数不一样,因此孪生对镁合金力学行为的影响也不一样。由于孪晶的生成,孪晶界的存在具有细化晶粒的作用,从霍尔-佩奇理论上来说,孪生对材料的力学性能也有一定的影响。WANG等[18]研究了挤压态镁合金中沿ED方向预压缩对随后反向拉伸屈服行为的影响,结果表明压缩预变形使镁合金的取向产生了约86.3°的改变,使得经预变形孪生的区域晶粒的c轴变得几乎与ED方向一致,这有利于随后反向拉伸时 孪生的启动,从而体现在屈服强度明显的降低,而对于垂直于c轴压缩(即平行于ED方向压缩)与先沿ED压缩预变形再反向拉伸两者的屈服强度一样的结果,WANG等却没有做出合理的解释。

孪生的启动,从而体现在屈服强度明显的降低,而对于垂直于c轴压缩(即平行于ED方向压缩)与先沿ED压缩预变形再反向拉伸两者的屈服强度一样的结果,WANG等却没有做出合理的解释。

然而,关于沿镁合金ED方向预压缩对随后垂直于ED方向压缩屈服行为的影响至今未见文献报道,而且关于施密特因子对镁合金屈服强度的影响的研究报道也较少。因此,本文作者设计了3种不同施载方向和不同晶体取向但都由 孪生主导塑性变形的实验,对比其屈服行为,分析预压缩变形对随后变形屈服行为的影响,并且通过施密特因子分析不同条件下屈服行为差异的原因。

孪生主导塑性变形的实验,对比其屈服行为,分析预压缩变形对随后变形屈服行为的影响,并且通过施密特因子分析不同条件下屈服行为差异的原因。

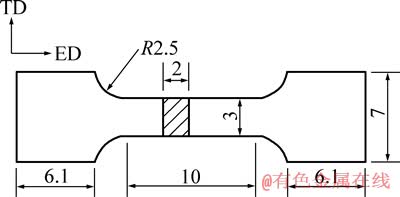

1 实验

本实验所用材料为挤压态AZ31镁合金棒材,平均晶粒尺寸为10 μm。在挤压棒中,沿挤压方向线切割尺寸为d16 mm×32 mm的圆柱形预压缩试样,使预压缩方向与挤压方向一致。在CMT5105材料测试仪上对预压缩样品进行室温下预压缩变形,预压缩变形量分别为1%、3%、5%、7%和9%,变形速率为1.85×10-3 s-1。将经预压缩变形和无预压缩样分成两组进行线切割,使拉伸样拉伸的方向为原挤压棒材的挤压方向,压缩样的压缩方向为垂直于原挤压棒挤压方向,分别制得尺寸为d6 mm×9 mm的压缩样和尺寸标准如图1的拉伸样。

对未变形和不同应变量的试样进行金相组织观察,腐蚀剂为5 mL乙酸、6 g苦味酸,10 mL蒸馏水及100 mL乙醇所配的的溶液;用Dmax/1200型X射线衍射仪对样品的横截面扫描,分析其基面织构变化情况。选取一个未变形试样和一个预压缩量为9%的试样,使用Rigaku D/max-2500 X射线衍射仪,在45 kV和 150 mA条件下用Cu Kα射线(波长λ=0.15406 nm)扫面样品,样品倾斜角变化范围为0~80°,测其极图。对无预变形和预变形量为1%、3%、5%、7%和9%的压缩样品,在CMT5105材料测试仪上进行室温下的单轴压缩实验,变形速率为1.85×10-3 s-1;对无预变形和预变形量为1%、3%、5%、7%和9%的拉伸样品,在型号为Shimadzu AG-X10KN的拉伸机上进行室温下的单轴拉伸实验,应变速率为0.001 s-1。以上力学实验均重复3次,文中样品压缩和拉伸数据若无特殊说明均为3次实验测试结果的平均值。在最终分析时发现,压缩预变形1%~9%的样品之间,屈服阶段的力学特性差异性并无太大的差异,为使图表更加简洁,文中数据只取了无预变形和预变形量为5%,9%进行讨论。

图1 板状拉伸样尺寸

Fig. 1 Schematic diagram of tensile sample in form of sheet (Unit: mm)

2 实验结果

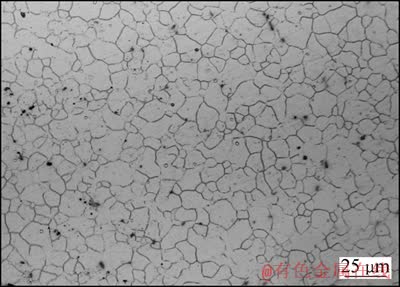

2.1 AZ31镁合金原始组织及挤压态力学性能

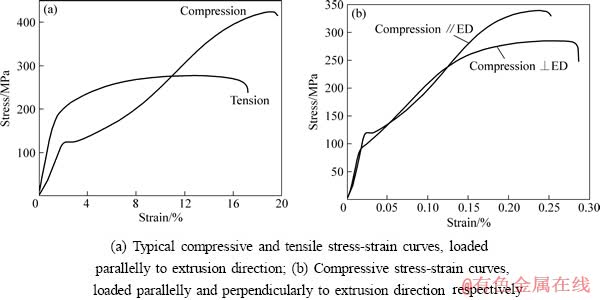

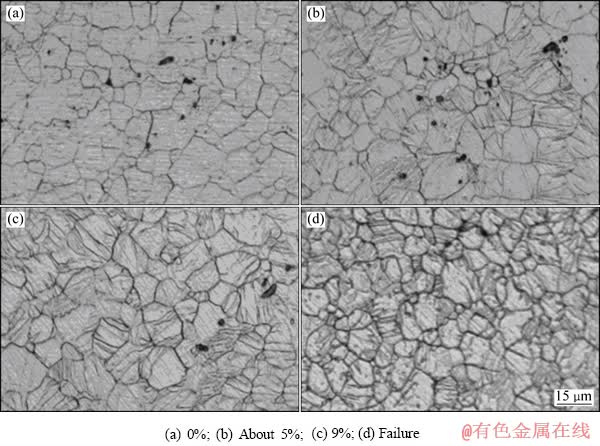

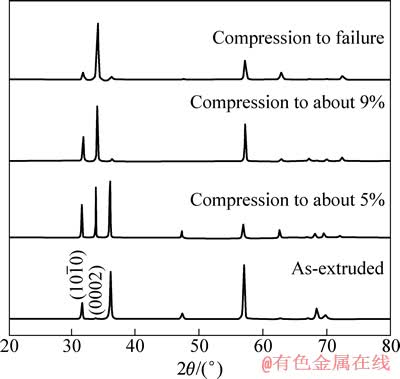

挤压态AZ31镁合金原始组织如图2所示,它是由平均晶粒尺寸为10 μm的等轴细晶组成,在试样晶粒中几乎观察不到有孪晶存在。图3所示为无预应变的挤压态镁合金在不同施载模式下的应力-应变曲线。图3(a)所示为载荷平行于样品挤压方向时的压缩应力-应变曲线和拉伸应力-应变曲线。如表1所列,压缩屈服强度约为122 MPa,拉伸屈服强度约为190 MPa。显然,沿ED方向拉伸相比压缩有着更高的屈服强度,而压缩的加工硬化效应更加明显。图3(b)所示为载荷分别平行和垂直于挤压方向的压缩应力-应变曲线。由表1可知,垂直于ED压缩的屈服强度约为85 MPa,远低于平行于ED压缩的122 MPa。

图2 挤压态AZ31镁合金显微组织

Fig. 2 Microstructure of as-extruded AZ31 alloy

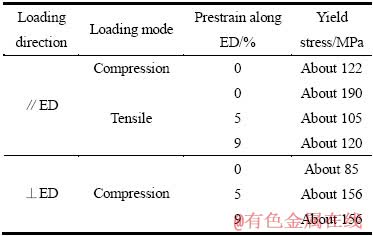

2.2 预变形后样品微观组织观察及XRD分析

图4所示为挤压态镁合金沿ED方向经不同预压缩变形之后的微观组织。由图4可见,随着变形量的增加,镁合金晶粒中孪晶量的数量也不断增加。对样品进行了XRD分析,结果如图5所示。XRD分析可以用来评估各个样品的孪生程度,从而更加清晰地观察样品织构演变。由文献[19]可知,产生 孪生镁合金样品密排六方c轴将发生86.3°的转向。由于开始平行于挤压方向的(0002)面将转至与挤压方向垂直,而

孪生镁合金样品密排六方c轴将发生86.3°的转向。由于开始平行于挤压方向的(0002)面将转至与挤压方向垂直,而 面将转至平行于挤压方向,因此可以用

面将转至平行于挤压方向,因此可以用 值来估计样品的孪生体积分数[20],

值来估计样品的孪生体积分数[20], 比值越大,表示孪生体积分数越高。

比值越大,表示孪生体积分数越高。

图3 挤压态AZ31合金样品的应力-应变曲线

Fig. 3 Stress-strain curves of as-extruded AZ31 alloy samples

图4 挤压态AZ31合金样品的微观组织

Fig. 4 Microstructures of as-extruded AZ31 alloy samples deformed to different pre-strains along ED

表1 各种预压缩状态下样品的拉伸压缩屈服强度

Table 1 Tensile and compressive yield stresses of samples subjected to different prestrains

图5 挤压态AZ31合金样品横截面的XRD谱

Fig. 5 XRD patterns of cross-section plane of extruded AZ31samples after compressive deformation to different strains

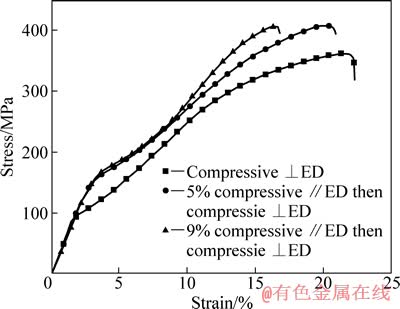

图6 未预变形和预变形挤压态AZ31合金样品垂直于ED方向压缩应力-应变曲线

Fig. 6 Compressive stress-strain curves of as-extruded AZ31 alloy samples after different pre-strains loaded perpendicular to extrusion direction

从图6可以看出,由挤压态、ED5%、ED9%样品到断裂样品, 比值越来越大,因此孪生体积分数越来越高。由图5可知,原始样品基面是平行于挤压方向的,因此预压缩有利于

比值越来越大,因此孪生体积分数越来越高。由图5可知,原始样品基面是平行于挤压方向的,因此预压缩有利于 孪生的产生。图4所示也佐证了这一结论。

孪生的产生。图4所示也佐证了这一结论。

2.3 预变形对随后不同施载模式屈服行为的影响

将未预变形和预变形样品垂直于挤压方向(ED)压缩直至断裂,其应力-应变曲线如图6所示。如表1所列,经压缩预变形后样品垂直于ED方向的压缩屈服强度从约85 MPa提高到约156 MPa,并且无论预压缩变形量为5%还是9%,垂直于ED方向的压缩屈服强度都约为156 MPa,几乎一致。

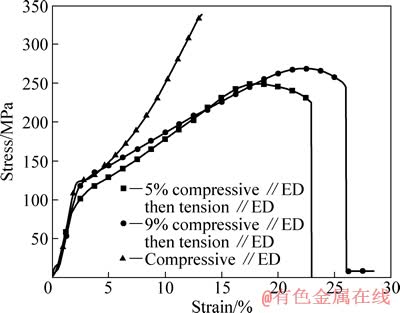

沿未预变形样品ED施加压应力、沿预变形样品ED方向施加拉应力,直至样品断裂,其应力-应变曲线如图7所示。由图7可知,拉伸应力-应变曲线也有着明显的 孪生屈服特征。经ED方向压缩预变形后的样品沿ED方向拉伸时,其屈服强度有着明显的降低,如表1所列,预变形9%后拉伸屈服强度从约190 MPa下降到约122 MPa,而预变形量为5%和9%的样品的屈服强度相差不大。预压缩9%的样品的拉伸屈服强度值,与未预变形样品沿ED方向的压缩屈服强度值(约120 MPa)几乎相等。这表明经压缩预变形后的样品拉伸屈服行为与未经预变形样品的压缩屈服行为是相似的。

孪生屈服特征。经ED方向压缩预变形后的样品沿ED方向拉伸时,其屈服强度有着明显的降低,如表1所列,预变形9%后拉伸屈服强度从约190 MPa下降到约122 MPa,而预变形量为5%和9%的样品的屈服强度相差不大。预压缩9%的样品的拉伸屈服强度值,与未预变形样品沿ED方向的压缩屈服强度值(约120 MPa)几乎相等。这表明经压缩预变形后的样品拉伸屈服行为与未经预变形样品的压缩屈服行为是相似的。

图7 预变形和无预变形样品沿ED载荷应力-应变曲线

Fig. 7 Stress-strain curves of samples after different compressive prestrains along ED direction

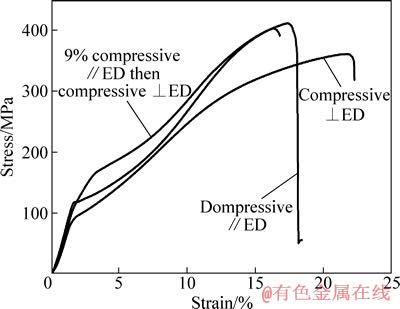

如表1所列,平行于ED压缩屈服强度约为122 MPa,而垂直于ED压缩屈服强度约为85 MPa。两者不同方向施载压缩屈服强度的显著差异表明控制它们屈服行为的机制不一样。经预压缩9%后然后再垂直于ED方向压缩的,屈服强度从~85 MPa增加到~156 MPa,增加了一倍,这甚至超过了沿ED压缩的屈服强度~122 MPa。3种情况下的压缩应力应变曲线如图8所示。

图8 不同加载模式下的应力-应变曲线

Fig. 8 Stress-strain curves of samples under different loading modes

3 分析与讨论

3.1  孪生系统的施密特因子分析

孪生系统的施密特因子分析

施密特因子定义为: ,其中

,其中 为应力与孪生面法向之间的夹角,

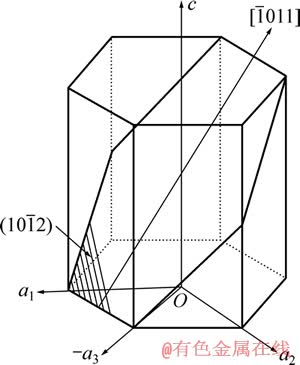

为应力与孪生面法向之间的夹角, 为应力与孪生方向之间的夹角[21]。图9所示为镁合金中

为应力与孪生方向之间的夹角[21]。图9所示为镁合金中 拉伸孪生系。镁合金六方晶格有6个等同的

拉伸孪生系。镁合金六方晶格有6个等同的 孪生面,本文下面计算了在应力垂直或平行镁六方晶格c轴时这6个孪生系的施密特因子值。

孪生面,本文下面计算了在应力垂直或平行镁六方晶格c轴时这6个孪生系的施密特因子值。

图9 镁 拉伸孪生系

拉伸孪生系

Fig. 9  tensile twinning system of HCP-Mg metal

tensile twinning system of HCP-Mg metal

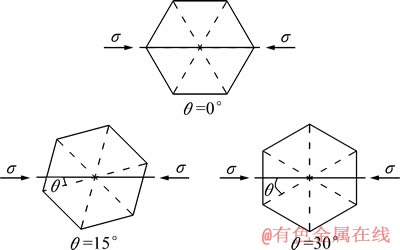

图10所示为应力垂直于镁六方晶格c轴时应力与基面的相对角度,θ为应力与镁六方晶格a轴的夹角。从图10可知,当θ分别处于0°~30°、30°~60°和60°~90°范围时,其所对应的孪生系施密特因子情况是重复的,因此只需将θ变化范围设为0°~30°。在θ=0°时,此时外应力为 方向,6个孪生变体所对应的施密特因子值(M)分别0.374、0.374、0.374、0.374、0和0,M值最大为0.374;在θ=15°时,此时外应力介于

方向,6个孪生变体所对应的施密特因子值(M)分别0.374、0.374、0.374、0.374、0和0,M值最大为0.374;在θ=15°时,此时外应力介于 和

和 晶向之间,6个孪生变体所对应的M值分别为0.465、0.249、0465、0.249、0.033和0.033,M值最大为0.465;在θ=30°时,此时外应力为

晶向之间,6个孪生变体所对应的M值分别为0.465、0.249、0465、0.249、0.033和0.033,M值最大为0.465;在θ=30°时,此时外应力为 方向,6个孪生变体所对应的M值分别为0.499、0.125、0.499、0.325、0.125和0.125,M值最大为0.499。当应力平行于c轴时,显然,6个孪生变体的M值都相同,为0.499。

方向,6个孪生变体所对应的M值分别为0.499、0.125、0.499、0.325、0.125和0.125,M值最大为0.499。当应力平行于c轴时,显然,6个孪生变体的M值都相同,为0.499。

通过现有的相关文献可知,具有最大施密特因子值的孪生体系更容易被激活。因此,可猜想镁合金屈服强度跟其孪生系的施密特因子有关。4.2节的分析也验证了这一猜想。

图10 应力垂直于镁六方晶格c轴时与基面取向示意图

Fig. 10 Schematic diagrams showing orientation of stress and basal plane

3.2 屈服行为分析

镁合金中主要有3种滑移系:基面滑移、柱面滑移和锥面滑移。一般来讲,镁及镁合金在室温下变形时,主要是滑移和孪生相互协调进行的,滑移和孪生启动时所需的临街剪切应力(CRSS)存在着比较大的差别。据文献[22]报道,镁基面滑移时的CRSS值在室温下为0.6~0.7 MPa,棱柱面滑移室温时的CRSS值则高达40 MPa以上;而镁合金中 拉伸孪生启动所需的临界剪切应力约为2~2.8 MPa[23]。从图11(a)中(0002)极图可以看出,在预变形以前,样品存在(0002)面法向(即c轴)垂直于ED方向的基面织构,而c轴在垂直于ED方向为随机分布。因此,当沿ED方向压缩时,基面滑移系的施密特因子值几乎为零,基面滑移很难启动,此时,

拉伸孪生启动所需的临界剪切应力约为2~2.8 MPa[23]。从图11(a)中(0002)极图可以看出,在预变形以前,样品存在(0002)面法向(即c轴)垂直于ED方向的基面织构,而c轴在垂直于ED方向为随机分布。因此,当沿ED方向压缩时,基面滑移系的施密特因子值几乎为零,基面滑移很难启动,此时, 拉伸孪生主导塑形变形;而垂直于ED方向压缩时,基面在垂直于ED方向并没有确定的取向,它是随机分布的,换句话说,此时应力与镁六方晶格c轴的夹角是不确定的,因此此时基面滑移的施密特因子值相对于前者能够取得较大的值。在这种情况下,CRSS较小的基面滑移将启动,屈服阶段变形由基面滑移主导。这也就是图3中垂直于ED方向的压缩屈服强度只有85 MPa,而沿ED方向的压缩屈服强度却达到122 MPa的主要原因。

拉伸孪生主导塑形变形;而垂直于ED方向压缩时,基面在垂直于ED方向并没有确定的取向,它是随机分布的,换句话说,此时应力与镁六方晶格c轴的夹角是不确定的,因此此时基面滑移的施密特因子值相对于前者能够取得较大的值。在这种情况下,CRSS较小的基面滑移将启动,屈服阶段变形由基面滑移主导。这也就是图3中垂直于ED方向的压缩屈服强度只有85 MPa,而沿ED方向的压缩屈服强度却达到122 MPa的主要原因。

图11 无预变形和预压缩量9%的样品的极图

Fig. 11 Pole figures of samples with 0% (a) and ~9% (b) strain along ED direction

在沿样品ED预压缩的过程中,挤压态镁合金产生 拉伸孪生(此时压应力⊥c轴),孪生部分取向相对于基体发生了86.3°的旋转,即原来样品晶粒中镁六方晶格c轴垂直于ED方向,预压缩后晶格旋转至c轴与ED方向平行,这可以从图10所示的样品预压缩前后的极图(见图1(b))看出。因此,对经预变形的样品,沿ED方向拉伸(此时拉应力∥c轴),将产生

拉伸孪生(此时压应力⊥c轴),孪生部分取向相对于基体发生了86.3°的旋转,即原来样品晶粒中镁六方晶格c轴垂直于ED方向,预压缩后晶格旋转至c轴与ED方向平行,这可以从图10所示的样品预压缩前后的极图(见图1(b))看出。因此,对经预变形的样品,沿ED方向拉伸(此时拉应力∥c轴),将产生 孪生。由文献[24]可知,在挤压态镁合金中,主要存在ED∥

孪生。由文献[24]可知,在挤压态镁合金中,主要存在ED∥ 和ED∥

和ED∥ 两种丝织构。因此,当沿ED方向压缩时,此时就相当于图10中θ=30°的情形。由4.1节可知此时

两种丝织构。因此,当沿ED方向压缩时,此时就相当于图10中θ=30°的情形。由4.1节可知此时 孪生系的施密特因子值最大为0.499。经过预变形,c轴∥ED,由4.1节知此时沿ED方向拉伸时

孪生系的施密特因子值最大为0.499。经过预变形,c轴∥ED,由4.1节知此时沿ED方向拉伸时 孪生系的施密特因子值最大也为0.499。从图7可知,样品经沿ED方向预压缩9%再沿ED方向拉伸的屈服强度与直接沿ED方向压缩的屈服强度都约为120 MPa,因此,可认为此时两者最大施密特因子值相同是两种情况下屈服强度相近的主要原因。据此可推测,当晶体中存在一定量相同取向的晶粒,材料塑形变形时将产生明显的屈服,并且屈服强度高低与发生孪生的孪生系的施密特因子值大小有关,其值越大,屈服强度就越低。在样品经9%预变形后再垂直于c轴压缩的过程中,虽然预变形导致晶粒旋转86.3°角,使几乎所有晶粒的c轴都平行于原来的挤压方向,但是由于原来的ED∥

孪生系的施密特因子值最大也为0.499。从图7可知,样品经沿ED方向预压缩9%再沿ED方向拉伸的屈服强度与直接沿ED方向压缩的屈服强度都约为120 MPa,因此,可认为此时两者最大施密特因子值相同是两种情况下屈服强度相近的主要原因。据此可推测,当晶体中存在一定量相同取向的晶粒,材料塑形变形时将产生明显的屈服,并且屈服强度高低与发生孪生的孪生系的施密特因子值大小有关,其值越大,屈服强度就越低。在样品经9%预变形后再垂直于c轴压缩的过程中,虽然预变形导致晶粒旋转86.3°角,使几乎所有晶粒的c轴都平行于原来的挤压方向,但是由于原来的ED∥ 和ED∥

和ED∥ 两种丝织构却因9%预变形而消失了(图11(b)的

两种丝织构却因9%预变形而消失了(图11(b)的 极图可说明),因此,这时大多数晶粒(样品中有很多晶粒)的

极图可说明),因此,这时大多数晶粒(样品中有很多晶粒)的 方向在横截面内是随机分布的,最终导致很多晶粒的

方向在横截面内是随机分布的,最终导致很多晶粒的 孪生面的施密特因子小于0.499。这可能就是后来垂直ED方向压缩时,其屈服强度比前两者的要高的原因。

孪生面的施密特因子小于0.499。这可能就是后来垂直ED方向压缩时,其屈服强度比前两者的要高的原因。

4 结论

1) 沿挤压方向的预压缩将导致沿挤压方向屈服强度的下降和垂直于挤压方向压缩屈服强度的显著升高。

2) 镁合金在不同施载情形下的屈服强度不同,其原因可以通过 孪生系的施密特因子值进行解释,即孪生变体所对应的施密特因子值越高,它就更容易被激活,因而屈服强度也就越低。

孪生系的施密特因子值进行解释,即孪生变体所对应的施密特因子值越高,它就更容易被激活,因而屈服强度也就越低。

REFERENCES

[1] WANG Xing, HU Lian-xi, LIU Kai, ZHANG Yin-ling. Grain growth kinetics of bulk AZ31 magnesium alloy by hot pressing[J]. Journal of Alloys and Compounds, 2012, 527(25): 193-196.

[2] NIE J F, ZHU Y M, LIU J Z, FANG X Y. Periodic segregation of solute atoms in fully coherent twin boundaries[J]. Science, 2013, 340(6135): 957-960.

[3] JIAN Wei-wei. Ultrastrong Mg-alloy via nano-spaced stacking faults[J]. Materials Research Letter, 2013, 1(2): 61-66.

[4] YUAN Xin-jian, SHENG Guang-min, LUO Jun, LI Jia. Microstructural characteristics of joint region during diffusion-brazing of magnesium alloy and stainless steel using pure copper interlayer[J]. Transactions of Nonferrous Metals Society of China, 2013, 23(3): 599-604.

[5] 余 琨, 黎文献, 王日初, 马正青. 变形镁合金的研究、开发及应用[J]. 中国有色金属学报, 2003, 13(2): 277-288.

YU Kun, LI Wen-xian, WANG Ri-chu, MA Zheng-qing. Research, development and application of wrought magnesium alloys[J]. The Chinese Journal of Nonferrous Metals, 2013, 13(2): 277-288.

[6] 丁雪征, 刘天模, 陈 建, 张 瑜, 卢立伟. 孪晶界对AZ31镁合金静态再结晶的影响[J]. 中国有色金属学报, 2013, 23(1): 1-8.

DING Xue-zheng, LIU Tian-mo, CHEN Jian, ZHANG Yu, LU Li-wei. Effect of twin boundary on static recrystallization of AZ31 magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(1): 1-8.

[7] LI X,YANG P, WANG L N, MENG L, CUI F. Orientational analysis of static recrystallization at compression twins in a magnesium alloy AZ31[J]. Material Science and Engineering A, 2009, 517: 160-169.

[8] 张丁非, 张红菊, 兰 伟. 高强镁合金的研究进展[J]. 材料热处理学报, 2012, 33(6): 1-8.

ZHANG Ding-fei, ZHANG Hong-ju, LAN Wei. Some research progress of high-strength magnesium alloy[J]. Transactions of Materials and Heat Treatment, 2012, 33(6): 1-8.

[9] 陈振华, 刘俊伟, 陈 鼎, 严红革. 镁合金超塑性的变形机理、研究现状及发展趋势[J]. 中国有色金属学报, 2008, 18(2): 103-202.

CHEN Zhen-hua, LIU Jun-wei, CHEN Ding, YAN Hong-ge. Deformation mechanisms, current status and development direction of superplastic magnesium alloys[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(2): 103-202.

[10] 余 琨, 黎文献, 王日初. 塑性变形机制[J]. 中国有色金属学报, 2005, 15(7): 1081-1086.

YU Kun, LI Wen-xian, WANG Ri-chu. Plastic deformation mechanism of magnesium alloys[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(7): 1081-1086.

[11] 唐伟琴, 张少睿, 范晓慧, 李犬永, 彭颖红. AZ31镁合金的织构对其力学性能的影响[J]. 中国有色金属学报, 2010, 20(3): 371-377.

TANG Wei-qin, ZHANG Shao-rui, FAN Xiao-hui, LI Quan-yong, PENG Ying-hong. Texture and its effect on mechanical properties of AZ31 magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(3): 371-377.

[12] SHAHZAD M, WAGNER L. Influence of extrusion parameters on microstructure and texture development, and their effect on mechanical properties of the magnesium alloy AZ80[J]. Materials Science and Engineering A, 2009, 506(1): 141-147.

[13] 刘 筱, 娄 燕, 李落星, 朱必武, 何凤亿. AZ31镁合金热压缩过程中晶粒取向和织构的演变[J]. 中国有色金属学报, 2012, 22(8): 2141-2147.

LIU Xiao, LOU Yan, LI Luo-xin, ZHU Bi-wu, HE Feng-yi. Grain orientation and texture evolution of AZ31 magnesium alloy during hot compression[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(8): 2141-2147.

[14] 路 君, 靳 丽, 董 杰, 曾小勤, 丁文江, 姚真裔. 等通道角挤压变形 AZ31镁合金的变形行为[J]. 中国有色金属学报, 2009, 19(3): 424-432.

LU Jun, JIN Li, DONG Jie, ZENG Xiao qin, DING Wen jiang, YAO Zhen yi. Deformation behaviors of AZ31 magnesium alloy by equal channel angular extrusion[J]. The Chinese Journal of Nonferrous Metals, 2009, 19(3): 424-432.

[15] 刘天模, 刘世宇, 彭天成. AZ31镁合金变通道角挤压工艺[J]. 材料热处理学报, 2009, 30(5): 64-67.

LIU Tian-mo, LIU Shi-yu, PENG Tian-cheng. Change channel angular extrusion process of AZ31 magnesium alloy[J]. Transactions of Materials and Heat Treatment, 2009, 30(5): 64-67.

[16] LUO A A, MISHRA R K, SACHDEV A K. High ductility magnesium zinc cerium extrusion alloys[J]. Scripta Materialia, 2011, 64(5): 410-413.

[17] HONG S G, SUNG H P, CHONG S L. Role of {10-12} twinning characteristics in the deformation behavior of a polycrystalline magnesium alloy[J]. Acta Materialia, 2010, 58(18): 5873–5885.

[18] WANG Y N, HUANG J C. The role of twinning and untwinning in yielding behavior in hot-extruded Mg–Al–Zn alloy[J]. Acta Materialia, 2007, 55(3): 897-905.

[19] Barnett M R. Twinning and the ductility of magnesium alloys Part I: “Tension” twins[J]. Materials Science and Engineering A, 2007, 464(1): 1-7.

[20] HE Jie-jun, LIU Tian-mo, XU Shun, ZHANG Yin. The effects of compressive pre-deformation on yield asymmetry in hot-extruded Mg-3Al-1Zn alloy[J]. Materials Science and Engineering A, 2013, 598(1): 1-8.

[21] WANG H, WU P-D, WANG J, TOME C N. A crystal plasticity model for hexagonal close packed (HCP) crystals including twinning and de-twinning mechanisms[J]. International Journal of Plasticity, 2013, 49(1): 36-52.

[22] 陈振华. 镁合金[M]. 北京: 化学工业出版社, 2004: 224-253.

CHEN Zhen-hua. Magnesium alloy[M]. Beijing: Chemical Industry Press, 2004: 224-253.

[23] 刘 庆. 镁合金塑性变形机理研究进展[J]. 金属学报, 2010, 11(46): 1458-1472.

LIU Qing. Research progress on plastic deformation mechanism of Mg alloys[J]. Acta Metall Sin, 2010, 46(11): 1458-1472.

[24] KADIRI H E, KAPIL J, OPPEDAL A L, HECTOR L G, AGNEW S R, CHERKAOUI M, VOGEL S C. The effect of twin–twin interactions on the nucleation and propagation of {10-12} twinning in magnesium[J]. Acta Materialia, 2013, 61(10): 3549-3563.

(编辑 何学锋)

基金项目:科技部国际合作项目(2011DFR50010);重庆大学大型仪器设备开放基金资助项目(2012121513)

收稿日期:2013-06-05;修订日期:2013-03-14

通信作者:刘天模,教授,博士;电话:023-66650011;E-mail:tmliu@cqu.edu.cn