文章编号:1004-0609(2014)02-0387-08

多元氧化物和铝原位反应制备铝基复合材料的组织和性能

王新迎1,于化顺1,王 雷1,万海云1,颜鲁滨2

(1. 山东大学 材料液固结构演变与加工教育部重点实验室,济南 250061;

2. 曲阜金皇活塞股份有限公司,曲阜 273100)

摘 要:采用SEM、EDS、XRD、TEM和拉伸强度测试等研究Al2O3粒子增强的ZL109铝基复合材料。结果表明:多元氧化物和铝原位反应生成的Al2O3粒子尺寸细小,粒径约为0.1 μm,在基体中弥散分布,与基体存在共格关系,(001)α(Al)//(010)α-Al2O3,[110]α(Al) // [001]α-Al2O3。原位反应中生成的金属间化合物经T6处理后,以Al5FeSi、FeCr、Mg2Si、Al3Ni、Al2Cu和Al7Cu4Ni相的形式存在于基体中,使得复合材料在300 ℃的拉伸强度达到163.4 MPa,较基体的提高7.9%。随Al2O3粒子含量的增加,25 ℃时,复合材料断口断裂方式由韧性断裂转变为解理断裂,再到穿晶断裂;而300 ℃时,断口断裂转变方式为脆性断裂到延性断裂。

关键词:铝基复合材料;原位反应;力学性能

中图分类号:TG146.2 文献标志码:A

Microstructure and properties of aluminum matrix composites fabricated by in-situ reaction between multi-oxide and aluminum

WANG Xin-ying1, YU Hua-shun1, WANG Lei1, WAN Hai-yun1, YAN Lu-bin2

(1. Key Laboratory for Liquid-Solid Evolution and Processing of Materials, Ministry of Education,

Shandong University, Ji’nan 250061, China;

2. Qufu Jinhuang Piston Co., Ltd., Qufu 273100, China)

Abstract: Al2O3 particles reinforced ZL109 aluminum matrix composites were investigated by scanning electron microscopy (SEM), energy dispersive spectroscopy (EDS), X-ray diffractometry (XRD), transmission electron microscopy (TEM) and tensile strength test. The results indicate that small size (about 0.1 μm) Al2O3 particles formed by in-situ reaction between multi-oxide and aluminum distribute uniformly in the matrix, and the orientation relation between Al2O3 and matrix is (001)α(Al)//(010)α-Al2O3 and [110]α(Al)//[001]α-Al2O3. After T6 heat treatment, the intermetallic compounds accompany with in-situ reaction uniformly disperse in the matrix and exist in the form of Al5FeSi, FeCr, Mg2Si, Al3Ni, Al2Cu and Al7Cu4Ni phase. Composite tensile strength can reach 163.4 MPa, improves by 7.9% than that of the matrix. With the increase of Al2O3 particles, the fracture mechanism of the composites at 25 ℃ changes from ductile fracture to cleavage fracture, and then to transgranular fracture, while at 300 ℃, the brittle fracture changes to ductile fracture.

Key words: aluminum matrix composite; in-situ reaction; mechanical property

随着环境污染能源危机等问题的日趋严重,汽车发动机轻量化的发展趋势越来越明显,有研究表明[1-3],汽车质量每减轻10%,其油耗量可降低5%~ 6%。铝合金具有密度低、比强度和比刚度高、散热性好、易回收等优点。此外,铝合金还具有良好的铸造性能和机加工性能。因此,铝合金是汽车轻量化最理想的选择材料。目前,在汽车行业中,铝合金广泛应用于车身、发动机汽缸体、刹车、轮彀等大部零部件[4-6]。铝合金活塞早已代替原来的铸铁活塞。20世纪80年代,日本将氧化铝纤维应用于铝合金活塞局部增强活塞性能,并已达到量化生产[7]。相对于Al2O3纤维,Al2O3粒子增强的铝基复合材料无方向性,具有更低的制作成本,特别是原位Al2O3粒子克服了外加Al2O3粒子尺寸较大、和基体润湿性不好、存在界面反应[8-11]等一系列问题,属较好的活塞用铝基复合材料之一。程和法等[12]在纯铝熔体中加入CuO后发现,原位反应生成的Al2O3粒子尺寸在2~5 μm之间,在基体中分布均匀,复合材料的硬度和耐磨性均显著提高。孙淼等[13]利用CuO和Al在Cu基体中原位反应获得了更小尺寸的Al2O3粒子(0.5 μm)。董鹏等[14]研究了TiO2、B2O3和Al经球磨后原位反应生成Al2O3+ TiB2(2~4 μm)、Al3Ti(5~15 μm)复合增强相,将纯铝的抗拉强度提高到327.4MPa,兰晔峰等[15]则用该工艺将ZL102合金的硬度提高了37.3%。艾桃桃等[16]则采取球磨工艺用Ti+TiO2+Al掺杂Nb2O5的方法制备了Al2O3增强的TiAl基复合材料,增强相Al2O3粒子尺寸在0.5~0.8 μm。多数研究者认为原位Al2O3增强粒子对基体有细化作用,刘慧敏等[17]研究认为,原位Al2O3粒子在合金凝固过程中对基体晶粒的细化作用不明显,需在600 ℃左右通过二次加热才能细化基体晶粒。三元氧化物和铝原位反应制备Al2O3增强复合材料多见于陶瓷复合涂层中,铝基复合材料中则未见报道。基于以上研究背景,本文作者以活塞常用铝合金ZL109为基体,选取Fe2O3、CuO和CrO3这3种常见金属氧化物和Al反应来制备Al2O3和金属间化合物共同增强的铝基复合材料,旨在为开发低成本且力学性能优异的活塞用铝基复合材料提供指导。

1 实验

试验选用的3种金属氧化物均为化学纯,纯度在99%(质量分数)以上,其中CrO3为块状固体,使用前需经粉碎机(XT-100型,25 000 r/min)粉碎,其他均为

粉体。铝粉和镁粉粒度均小于150 μm。将同等质量的Fe2O3、CuO和CrO3粉末和等量Al粉混合均匀后加入3%(质量分数)的反应诱导剂Mg粉,采用千斤顶在直径为50 mm的自制模具中单向压实,经100 ℃预热60 min后加入到ZL109熔体中,待反应完毕后,精炼,除气,除渣,搅拌并静置10 min。按照混合压块加入量0、0.2%、0.4%对熔体分别取样浇注试棒,经T6处理后,对复合材料显微组织和力学性能进行观察分析。拉伸试棒尺寸如图1所示。

图1 拉伸试样示意图

Fig. 1 Schematic diagram for tensile testing samples (Unit: mm)

物相成分利用DMAX-2500PC型X射线衍射仪标定;金相和断口组织观察利用JEOL JEM-7600 F型扫描电子显微镜;显微组织观察利用JEM-2100型高分辨透射电镜。复合材料成分见表1。拉伸试验在WE-30型万能材料试验机上进行,拉伸速度为5 mm/min。室温拉伸在25 ℃时进行,高温拉伸在300 ℃下保温30 min后进行。

2 结果与分析

2.1 原位Al2O3粒子的形貌及分布

表1 ZL109合金的化学成分

Table 1 Chemical compositions of ZL109

文献[18]中指出,Mg粉作为铝热反应的诱导剂能够极大降低起始反应温度,缩短反应时间。图2所示为未添加Mg粉的混合压块在800 ℃的ZL109熔体中保温60 min后的SEM像。能谱分析发现,压块中黑色块状组织为富Fe相,浅灰色网状组织为富Cu相,灰白色组织为富Cr相,反应生成的Al2O3粒子堆积在3种相周围,形成泡沫状多孔组织。

图2 压块在800 ℃保温60 min后的显微组织

Fig. 2 Microstructure of briquetting soaked at 800 ℃ for 60 min

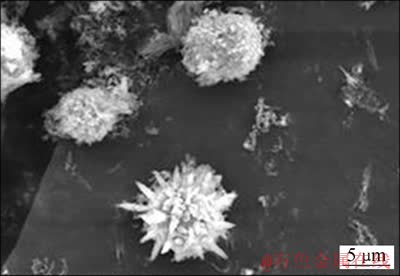

试验发现,将压块在1 000 ℃时放入保温炉中,保温60 min可在其表面得到析出的白色粉末状Al2O3粒子,其宏观形貌如图3所示。保温过程中,压块并未完全熔化,而是烧结成具有金属光泽的块状固体。反应生成的Al2O3粒子尺寸非常细小,吸附能力强,因此,会团聚在一起。将其收集起来在无水乙醇中超声分散,粒子团聚现象消失,用铜网捞取后放到高分辨透射电镜下进行观察。

图3 Al2O3的FESEM像

Fig. 3 FESEM image of Al2O3

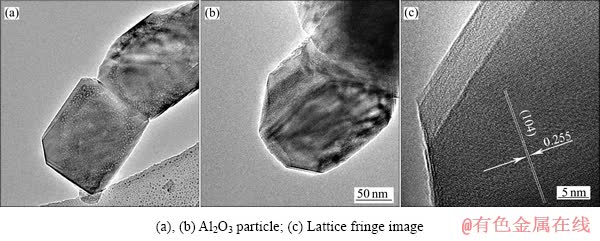

图4所示为原位Al2O3粒子的TEM像和晶格条纹像。观察发现,Al2O3粒子尺寸在0.15 μm左右,其形貌成方块形和椭球形,粒子边界清晰,边角圆滑,有弧形过渡,在图4(b)粒子表面依稀可见层错堆积,这种层错能够为基体合金的形核提供生长平台,降低基体和增强体的界面能,增加粒子在熔体中的运动阻力,因而为Al2O3粒子在合金凝固过程中被凝固前沿吞噬提供了可能。图4(c)所示为图4(a)的晶格条纹像,测量其晶格条纹间距为0.255 nm,正好与α-Al2O3的(104)晶面间距匹配,证明该粒子为α-Al2O3粒子。

图4 Al2O3粒子的TEM像

Fig. 4 TEM images of Al2O3

图5 Al2O3粒子在ZL109中的分布

Fig. 5 Distribution of Al2O3 in ZL109

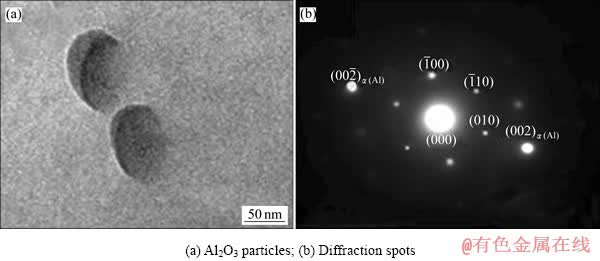

图5所示为合金3中Al2O3粒子在基体中的分布与结合情况,合金成分见表1。观察其尺寸在0.1 μm左右,较图4中粒子尺寸更加细小,形状也更加接近椭球形。对其选区电子衍射斑点进行标定发现,衍射图谱为α-Al2O3的[001]晶带轴衍射斑点。观察发现,图中外围有两个较大的衍射斑点,测算其晶面间距发现d=0.206 1 nm,查阅标准PDF卡片发现,α(Al)的 (002)晶面间距为0.202 4 nm,因此推断此两个衍射斑点为α(Al)[100]晶带轴的衍射斑点,根据这两个斑点和α-Al2O3的(010)晶面衍射斑点的位向关系推断,α-Al2O3的 (010)晶面平行于α(Al)的(002)晶面,也即平行于α(Al)的(001) 晶面,因此判断Al基体和原位反应生成的Al2O3粒子可能存在的位向关系是 ,

, 。

。

依据错配度计算公式如下:

(1)

(1)

计算可得α(Al)(001)晶面和α-Al2O3(010)晶面的错配度约为1.88%。根据Bramfitt得出的经验,非均质形核及δ<6% 时,形核最有效,进一步说明了细小的Al2O3粒子能够作为基体Al的形核衬底,同时Al2O3粒子由于吸附了外来粒子降低了其表面能,从而削弱由于粒子细小表面能高带来的粒子团聚现象,因而有利于Al2O3粒子在基体中的均匀分布。

2.2 Fe、Cu、Cr元素对基体析出相的影响

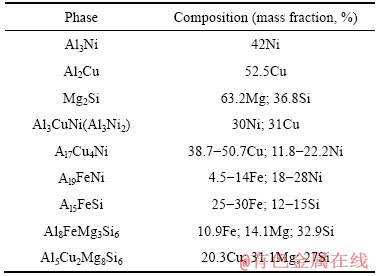

金属间化合物室温下呈现脆性,但其高温时却呈现较高强度,利用其特点可提高活塞的高温性能。表2所列为活塞用Al-Cu-Fe-Mg-Ni-Si系合金中常见的析出相[19]。

表2 Al-Cu-Fe-Mg-Ni-Si合金中的相成分[19]

Table 2 Phase compositions of Al-Cu-Fe-Mg-Ni-Si Alloy[19]

图6所示为图2中压块保温时间延长到120 min后的SEM像和EDS分析结果。能谱分析结果表明,组织中除α(Al)基体外主要含有富Fe相、富Cu相、富Cr相3种组织。Fe元素在铝合金中的作用一直以来褒贬不一,主要是因为Fe虽然对合金的高温性能有利,但过量的Fe会产生针状有害相FeAl3,严重割裂基体,降低合金的室温性能。研究发现[19],Fe含量低于0.6%时,随着Fe含量的增加,Fe相依次以Al8FeMg3Si6、Al9FeNi、Al5FeSi相的形式存在;当Fe含量高于0.5%时,基体中的Si会参与富Fe相的反应,这与图6(b)中富Fe相能谱分析中含有一定量的Si相是一致的,计算Fe和Si的摩尔比,摩尔比接近1:1,因此,该富Fe相的主要的主要成分可能是Al5FeSi,它对Si的吸附作用给初晶硅的细化带来有利影响。文献[19]指出,Cu能够将活塞用Al-Cu-Fe-Mg-Ni-Si系合金的固相线从540 ℃降到505 ℃,这给材料的热处理带来有利影响。此外,Cu还对基体中Al3Ni、Al3CuNi、Al7Cu4Ni、Mg2Si、Al5Cu2Mg8Si6、Al2Cu相的体积分数带来极大影响。图6(c)能谱分析中Al和Cu的摩尔比接近2:1,说明该富铜相的主要成分是Al2Cu相。图6(a)中以较小颗粒并呈团簇状聚集的形状不规则的相为富Cr相,图6(d)富Cr相的能谱分析中氧原子含量较高,分析可能存在Al2O3。消除活塞用铝硅合金中富Fe相给组织带来不利影响的方法除了控制Fe相的含量之外,就是改善富Fe相的形貌,图6(a)中的富Fe相呈短棒状,而且试验中多次能谱分析发现Fe相总是伴随Cr相出现,因此判定Cr元素对富Fe相形貌会产生有利影响。当压块中添加3%的反应诱导剂Mg以后,反应迅速完成,得到表1中所示成分合金。

图6 压块在800 ℃保温120 min的SEM像和EDS分析结果

Fig. 6 SEM image(a) of briquetting soaked at 800 ℃ for 120 min and EDS results of Fe-rich(b), Cu-rich(c) and Cr-rich(d) phases

图7 室温下Cu元素对含13%Si、1%Mg、1%Ni的铝合金中各析出相的影响[19]

Fig. 7 Effect of copper on volume fractions of phases in alloys containing 13%Si, 1%Mg and 1%Ni at room temperature[19]

图7所示为该系合金中Cu元素含量对各析出相体积分数的影响[19]。从图7可以看出,含Cu量较低时,该系合金中的主要存在相是Al3Ni、Al3CuNi和Mg2Si,当Cu含量逐渐增加到1%时,Al3Ni相逐渐消失,Al3CuNi相逐渐增加,而Mg2Si相的含量并没有受到影响,含Cu量进一步增加到3.2%时,Al3CuNi相逐渐消失,Al7Cu4Ni相开始产生并逐渐增加到最大值,Mg2Si相开始出现下降的趋势,Cu含量进一步增加到3.8%时,Mg2Si相完全消失,Al5Cu2Mg8Si6相开始产生并逐渐达到峰值;当Cu含量超过4%后,Al2Cu相开始产生并逐渐增加,Al7Cu4Ni相和Al5Cu2Mg8Si6相含量不再变化。因此,Cu元素在该系合金中最终的存在形式是Al7Cu4Ni相、Al5Cu2Mg8Si6相和Al2Cu相。

图8所示为表1中合金3的XRD谱,观察发现主要存在的相除基体Al和Si之外,还有Al2O3、Al5FeSi、FeCr、Mg2Si、Al3Ni、Al2Cu和Al7Cu4Ni等相,与前文分析结果相一致。

2.3 复合材料的力学性能

图8 表1中合金3的XRD谱

Fig. 8 XRD patterns of alloy 3 shown in Table 1

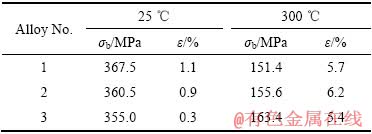

表1中所示合金的室温和高温力学性能测试结果如表3所示。由表3可知, ZL109(表1中合金1)在25和300 ℃的拉伸强度分别为367.5和151.4 MPa;而合金2的室高温拉伸强度分别为360.5和155.6MPa,高温强度上升,室温强度下降,随着复合材料中原位Al2O3粒子和析出相的进一步增多,合金3的高温拉伸强度达到163.4 MPa,较合金1的提高了7.9%,但其室温度强度进一步下降到355 MPa;复合材料25 ℃的伸长率从1.1%下降到0.3%,300 ℃的伸长率从5.7%先上升到6.2%,又下降到5.4%,变化趋势并不明显。可以看出,材料中复合增强粒子在提高高温性能的同时,减弱了部分室温性能,这主要是由于一方面Fe元素的加入可能造成基体局部偏析,在基体局部产生有害铁相,割裂基体,给基体常温力学性能带来不利影响;另一方面,原位反应完成后,基体中生成了大量增强相粒子(Al2O3、Al5FeSi、FeCr、Mg2Si、Al3Ni、Al2Cu、Al7Cu4Ni),这些增强粒子和基体的热膨胀系数不同,在合金凝固过程中,增强相粒子和基体界面处产生内应力,这种应力虽然在T6处理过程中得到部分缓解,但并没有完全消除。高温强度提高的主要原因是一方面基体中原位反应生成了大量高温硬质相(Al2O3、Al5FeSi、FeCr、Al3Ni、Al7Cu4Ni),这些硬质相在高温下起到支撑点的作用;另一方面,基体材料经T6处理以后增强粒子产生的内应力得以消除,而且拉伸过程中细小的原位Al2O3粒子能够有效阻碍位错运动,增加材料的变形抗力,加上T6处理后形成的析出相凭借和基体较高的结合强度,有效阻碍了晶粒间的运动,成为影响复合材料高温力学性能的重要因素。

表3 不同温度时ZL109合金的力学性能

Table 3 Mechanical properties of ZL109 alloy at different temperatures

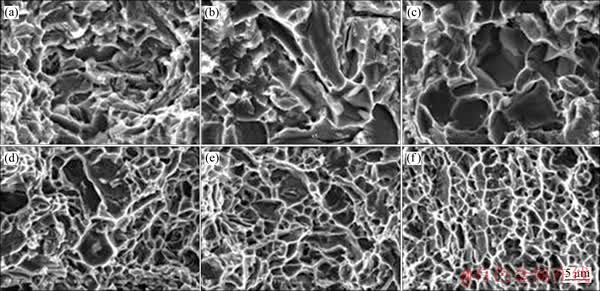

图9所示为原位反应粒子增强的ZL109复合材料的室高温断口形貌。室温下基体合金断口可观察到少量韧窝和撕裂楞,随着增强粒子的加入,断口开始出现河流状解理断面,Al2O3粒子属六方晶系,滑移系较多,材料受力超过极限后,晶粒界面滑移,是造成河流状解理断面的原因;当增强粒子进一步增加时,出现穿晶断裂组织,仔细观察图9(c)可以看到,断裂发生在3个晶界面的交点,在初晶硅断裂小平面上依稀存在一些细小裂纹,这是由于增强粒子在晶界上的偏聚和脱溶造成的。高温拉伸断口呈现相反的趋势,300 ℃下,材料内应力得以消除,断口形貌逐渐由脆性断裂向延性断裂转变,将断口腐蚀后可观察到图3所示分散的絮状组织。

图9 ZL109合金不同温度拉伸断口SEM像

Fig. 9 Tensile fracture SEM images of ZL109 alloy 1(a), alloy 2(b), alloy 3(c) at 25 ℃ and alloy 1(d), alloy 2(e), alloy 3(f) at 300 ℃

3 结论

1) 液态环境中原位Al2O3粒子(0.1 μm)较空气中反应得到的Al2O3粒子尺寸更加细小(0.15 μm),形状更加接近椭球形。与基体的位相关系是

,

, 。

。

2) 原位颗粒增强的复合材料中增强相有Al2O3、Al5FeSi、FeCr、Mg2Si、Al3Ni、Al2Cu和Al7Cu4Ni等相,使得25 ℃的拉伸强度和伸长率略有下降,300 ℃的拉伸强度提升了7.9%,伸长率先升后降,变化幅度不大。

3) 随增强相粒子的增加,ZL109的室温拉伸断裂方式由韧性断裂向解理断裂,再向穿晶断裂转变;高温拉伸断裂方式由脆性断口向韧性断口转变,韧窝变得更加细小。

REFERENCES

[1] EDGAR R L. Magnesium alloys and their application[M]. France: KU Kainer Pub, 2000: 3-8.

[2] LUO A A. Magnesium: Current and potential automotive applications[J]. JOM, 2002, 54(2): 42-48.

[3] MORDIKE B L, EBERT T. Magnesium properties applications potential[J]. Materials and Engineering A, 2001, 302(1): 37-45.

[4] MEJER G, XIA Z, ELLYIN F. Biaxial cyclic analysis of Al2O3p-6061 Al composite[J]. Acta Materialia, 1997, 45(8): 3237-3249.

[5] MIKUCKI B A, MERCER W E Ⅱ, GREEN W G. Extruded magnesium alloy reinforced with ceramic particles[J]. Light Metal Age, 1990, 48(6): 12-14

[6] XIA Z, ELLYIN F, MEIJER G. Mechanical behavior of Al2O3-particle reinforced 6061 aluminum alloy under uniaxial and multiaxial cyclic loading[J]. Composites Science and Technology, 1997, 57(2): 237-248

[7] 周彼德, 陈跃飞, 安阁英, 彭德林. 氧化铝短纤维增强铝合金活塞性能的研究[J]. 铸造, 1991(8): 5-9.

ZHOU Bi-de, CHEN Yue-fei, AN Ge-ying, PENG De-lin. A study of properties of reinforced aluminium alloy pistons with short-fiber alumina[J]. Foundry, 1991(8): 5-9.

[8] 张 强, 姜龙涛, 陈国钦, 武高辉. 无压浸渗法制备Al2O3颗粒增强铝基复合材料[J]. 稀有金属材料与工程, 2011, 40(S2): s525-s528.

ZHANG Qiang, JIANG Long-tao, CHEN Guo-qin, WU Gao-hui. Al2O3 particles reinforced aluminum matrix composite fabricated by pressureless infiltration technique[J]. Rare Metal Materials and Engineering, 2011, 40(S2): s525-s528.

[9] 李新梅, 刘 炳, 董晓锋. Al2O3颗粒增强Al-Mn合金基复合材料的制备及摩擦学性能[J]. 材料热处理学报, 2011, 32(7): 6-11.

LI Xin-mei, LIU Bin, DONG Xiao-feng. Fabrication and friction and wear behavior of Al2O3 particulates reinforced Al-Mn alloy matrix composites[J]. Transactions of Materials and Heat Treatment, 2011, 32(7): 6-11.

[10] JIANG Lan, CUI Yan-zhou, SHI Yu-juan, DING You-dong, YUAN Fang-lan. Preparation and mechanical properties of in situ Al2O3/Al composites by adding NH4AlO(OH)HCO3[J]. Transactions of Nonferrous Metals Society of China, 2011(21): 2181-2185.

[11] 杨 真, 卢德宏, 陈飞帆, 魏绍生, 周 明. 纳、微米Al2O3颗粒混杂增强铝基复合材料的磨损性能[J]. 润滑与密封, 2011, 36(2): 87-91.

YANG Zhen, LU De-hong, CHEN Fei-fan, WEI Shao-sheng, ZHOU Ming. Wear resistance of nanometer and micron Al2O3 particles reinforced aluminum matrix hybrid composites[J]. Lubrication Engineering, 2011, 36(2): 87-91.

[12] 程和法, 黄笑梅, 苏 勇. 固液原位反应生成Al2O3(P)/Al复合材料的研究[J]. 热加工工艺, 2001(1): 34-35.

CHENG He-fa, HUANG Xiao-mei, SU Yong. Study on Al2O3(P)/Al composites fabricated by in-situ oxidation reaction between solid and molten Al[J]. Hot Working Technology, 2001(1): 34-35.

[13] 孙 淼, 郝 斌, 刘克明, 杨 滨. 原位Al2O3颗粒增强铜基复合材料的制备及微观组织[J]. 金属热处理, 2006(S1): 88-90.

SUN Miao, HAO Bin, LIU Ke-ming, YANG Bin. Fabrication and microstructure of Cu matrix composite strengthened by in-situ Al2O3 particulate[J]. Heat Treatment of Metals, 2006(S1): 88-90.

[14] 董 鹏, 严 彪, 陈 兴. TiB2-Al2O3-TiAl3颗粒增强铝基复合材料的制备方法[J]. 特种铸造及有色合金, 2009, 29(6): 553-556.

DONG Peng, YAN Biao, CHEN Xing. Preparation of TiB2-Al2O3-TiAl3 particulate reinforced aluminum matrix composites[J]. Special Casting and Nonferrous Alloys, 2009, 29(6): 553-556.

[15] 兰晔峰, 张宝林, 王国斌. (TiB2+Al2O3)增强铝基复合材料的组织分析与硬度测试[J]. 兰州理工大学学报, 2009, 35(4): 19-22.

LAN Ye-feng, ZHANG Bao-lin, WANG Guo-bin. Analysis of microstructure and hardness test of Al-based composite with (TiB2+Al2O3) strengthened[J]. Journal of Lanzhou University of Technology, 2009, 35(4): 19-22.

[16] 艾桃桃, 王 芬, 冯小明, 郭从盛. 原位合成Al2O3颗粒增强双相TiAl基复合材料的组织与性能[J]. 中国有色金属学报, 2007, 17(11): 1849-1854.

AI Tao-tao, WANG Fen, FEGN Xiao-ming, GUO Cong-sheng. Microstructure and mechanical properties of in situ Al2O3 particles reinforced two-phase TiAl-based composites[J]. The Chinese Journal of Nonferrous Metals, 2007, 17(11): 1849-1854.

[17] 刘慧敏, 张复懿, 吴宏明. 原位Al2O3颗粒对Al-Cu合金二次加热组织的影响[J]. 材料热处理学报, 2011, 32(4): 38-42.

LIU Hui-min, ZHANG Fu-yi, WU Hong-ming. Effect of in-situ Al2O3 particles on reheating microstructure of Al-Cu alloy[J]. Transactions of Materials and Heat Treatment, 2011, 32(4): 38-42.

[18] 黄赞军, 胡敦芫, 杨 滨, 张济山. 原位Al2O3颗粒强化铝基复合材料的研究[J]. 金属学报, 2002, 38(6): 568-574.

HUANG Zan-jun, HU Dun-yuan, YANG Bin, ZHANG Ji-shan. Study on in situ Al based composites reinforced by Al2O3 particles[J]. Acta Metallurgica Sinica, 2002, 38(6): 568-574.

[19] BELOV N A, ESKIN D G, AVXENTIEVA N N. Constituent phase diagrams of the Al-Cu-Fe-Mg-Ni-Si system and their application to the analysis of aluminium pison alloys[J]. Acta Materialia, 2005, 53: 4709-4722.

(编辑 龙怀中)

收稿日期:2013-05-13;修订日期:2013-11-06

通信作者:于化顺,教授,博士;电话:0531-88395639;E-mail: yuhuashun2002@aliyun.com