Effects of electric field on recrystallization texture evolution in cold-rolled high-purity aluminum sheet during annealing

WU Yan(吴 艳)1, ZHAO Xiang(赵 骧)1, HE Chang-shu(何长树)1,

ZHAO Zhi-peng(赵志朋)1, ZUO Liang(左 良)1, C. ESLING2

1. Key Laboratory for Anisotropy and Texture of Materials (Ministry of Education), Northeastern University,Shenyang 110004, China;

2. LETAM, CNRS-UMR 7078, University of Metz, Ile du Saulcy, 57045 Metz, France

Received 20 July 2006; accepted 14 November 2006

Abstract: The effects of an external DC (direct current) electric field on recrystallization texture evolution in the cold-rolled aluminum sheets with 99.99% purity were investigated by means of X-ray diffraction techniques. The cold-rolled high-purity aluminum sheets were annealed for 60 min at 200, 300 and 400 ℃, respectively with and without an external DC electric field of 800 V/mm. The results show that with DC electric field, the recrystallization cube texture is strengthened at the stage of grain growth. Possible reason for the strengthening of the recrystallization cube texture with the applied electric field may be attributed to both selected nucleation and selected growth of cube oriented crystal nuclei.

Key words: electric field; recrystallization; high-purity aluminum sheet; cube texture

1 Introduction

Owing to the excellent physicochemical properties, high-purity aluminums have been widely used in the modern electronic industry. One of the most important usages is electrolytic capacitor aluminum foils. In order to meet the requirement of diminishing the volume of electric capacitors and reducing their mass, the mechanism leading to the formation of the cube- orientation during recrystallization has become the subject of intense investigations in recent years.

It has been accepted that electric field can affect the mobility of atoms and defects (vacancies, dislocations or grain boundaries) in metals[1-3], thus affecting the evolution of their microstructure and texture. Previous work has shown that the application of an electric field may affect the recovery and recrystallization of various metals, notably the intensity of the cube recrystallization texture. For instance, electric field annealing may retard the recovery and recrystallization process of 3104 aluminum alloy sheet[4-6] and cold-rolled commercial pure copper[7], meanwhile enhance the cube texture component. And research work on 08Al killed steel sheet[8-10] also showed that with the application of an electric field, the recovery and recrystallization process was retarded and the recrystallized γ-fiber texture was strengthened. Besides, the research work of WU et al[11] also showed that electric field treatment decreased the volume fraction of cube texture and the grain size of cube oriented grains in rolled pure nickel.

However, until now, there is very limited report[12] on the study of high-purity aluminum under an external electric field, and further study is certainly necessary and helpful for better understanding the mechanism leading to the formation of the cube-orientation during recrystallization. So in the present work, DC electric field was applied when a cold-rolled high-purity aluminum sheet was annealed, and its effects on the evolution of the recrystallization texture were investigated.

2 Experimental

A high-purity aluminum (99.99%) sheet with chemical composition given in Table 1 was cold rolled at room temperature to 97% reduction, and final thickness was 0.25 mm. Specimens with the dimension of 40 mm (rolling direction, RD)×20 mm (transverse direction, TD) were cut from the sheet and subjected to isothermal annealing at 200, 300 and 400 ℃, respectively. At each temperature the samples were annealed respectively with and without a DC electric field (E=800 V/mm) in a nitrogen atmosphere furnace. The furnace temperature was raised at a rate of 20 ℃/min to the set value. After the furnace temperature remained stable, the specimens were placed into the furnace for isothermal annealing for 60 min, then pulled out and cooled in air.

Table 1 Chemical composition of investigated aluminum sheets (mass fraction, %)

In the case of the electric field annealing,the external electric field was applied as soon as the sample was placed into the furnace by treating the specimens as anode and a stainless steel sheet as cathode. And the experimental equipment has been reported elsewhere[6].

The macro-textures were measured using a X′Pert MRD-type X-ray diffractometer in back reflection method, using Co Kα radiation. Three incomplete pole figures {111}, {200} and {220} were measured,and they were used to calculate the orientation density function (ODF) by the two-step method (Lmax=16)[13]. All the results were shown in the constant φ? sections (Roe’s notation) of the ODF and in orientation intensities w(g).

3 Results and discussion

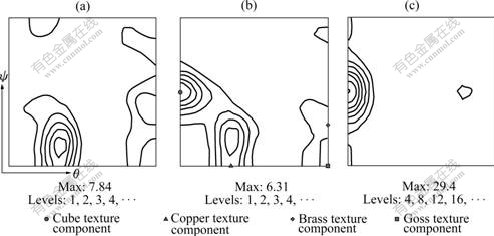

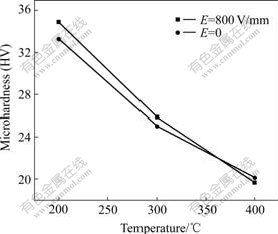

Figs.1 and 2 show the constant φ=45? sections of the ODF for the specimens annealed at 200, 300 and 400℃ without and with the electric field, respectively. From Fig.1(a) and Fig.2(a) it could be seen that when the specimens were annealed at 200 ℃ for 60 min, the recrystallization cube texture did not appear for both specimens with and without electric field annealing, and the textures were still typical cold-rolling ones. When the temperature was raised to 300 ℃, recrystallization cube components began to appear in both the electric field annealed specimen and the conventionally annealed specimen, with intensities of 5.21 mrd (multiples of random density) and 6.31 mrd, respectively. The intensity of cube component in the electric field annealed specimen was significantly lower than that in the conventional specimen. Similarly, the copper and the brass texture components still existed in both the electrical field annealed and conventionally annealed samples, but their intensities were weakened (Fig.1(b), Fig.2(b)). When the annealing temperature was further raised to 400 ℃, the intensity of the recrystallization cube component increased rapidly. The intensity was 29.4 mrd for the specimen annealed without electric field and 37.4 mrd for the specimen annealed with electric field. The electric field annealed specimen exhibited higher cube texture intensity as compared with the conventional annealing specimen. At this stage, other texture components basically disappeared (Fig.1(c), Fig.2(c)). From the above it could be seen that the transition rate from deformation texture to recrystallization texture of the electrical field annealed samples was a little slower compared with the conventionally annealed samples, which indicated that the electric field retarded the recovery and recrystallization of cold-rolled high-purity aluminum sheet. This could also be proved by the result given by Fig.3 that shows the variation of microhardness with the annealing temperature. It was evident that the micro- hardness of electric field annealed specimen was higher than that of the conventionally annealed specimen at the annealing temperature of 200 and 300 ℃. At 400 ℃, since the intensity of cube texture of electric field annealed specimen was higher than that of the conventionally annealed specimen, the microhardness of the former was lower than that of the latter, correspondingly.

Fig.1 Constant φ=45? ODF sections of specimens annealed without electric field at various temperatures for 60 min: (a) 200 ℃; (b) 300 ℃; (c) 400 ℃

Fig.2 Constant φ=45?ODF sections of specimens annealed with electric field at various temperatures for 60 min: (a) 200 ℃; (b) 300 ℃; (c) 400 ℃

Fig.3 Variation of microhardness with annealing temperature

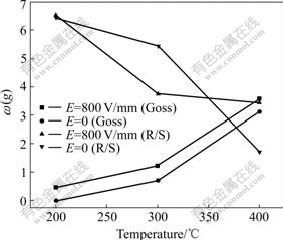

Figs.4-7 show the variation of the orientation intensities ω(g) of some main texture components with and without electric field annealing at various temperatures. With increase of annealing temperature, the intensity of cube texture component and Goss texture component was strengthened, whereas the intensity of S texture component, R/S texture component, copper texture component and brass texture component was weakened. The development trends of the various texture components with and without electric field annealing remained similar. This indicated that electric field did not change the mechanism of recrystallization and recrystallization texture of cold-rolled high-purity aluminum sheet.

Fig.4 Variation of orientation intensities ω(g) of cube texture components

Fig.5 Variation of orientation intensities ω(g) of S texture components

From Fig.4 we can see, at 200 and 300 ℃, the intensity of recrystallized cube texture of the specimensannealed with electric field was lower than that of the conventionally annealed specimens. But when the annealing temperature was raised to 400 ℃, the intensity of recrystallized cube texture was higher for the specimen annealed with electric field than that without electric field. The above results suggested that, for cold-rolled high-purity aluminum sheet, the external electric field restrained the development of recrystallized cube texture at the initial stage of recrystallization, but oppositely promoted it at the stage of grain growth.

Fig.6 Variation of orientation intensities ω(g) of copper texture components (C) and brass texture components (B)

Fig.7 Variation of orientation intensities ω(g) of Goss texture components and R/S texture components

It is known that metals are characterized by high electrical conductivity, especially aluminum. The conduction electrons are from valence electrons. Therefore, the metal atoms are actually ions with positive charges. As the crystal structures of metals are built by metal ions, the vacancies create local deficiencies of the positive charges of ions. So vacancies can be considered as electronegative[14]. The sample works as anode, so that the positive surface charges are distributed on the sample surface. Therefore the electric field promotes the vacancies to migrate toward the sample surface, resulting in the decrease of vacancy concentration in the sample interior. As the stored energy of deformed metals is dependent on the concentration of crystal defects, the stored energy or the driving force for recovery and recrystallization is lowered by the application of the electric field. In other words, vacancies play an important role in promoting atom diffusion for polygonization and formation of subgrains in recovery and early stage of recrystallization. The loss of vacancies in the electric field treated samples results in a slow polygonization process and subsequently the nucleation of distortion-free grains and their growth. As a result, the recovery and recrystallization processes are retarded. Yet cube oriented crystals have a better 38.21?<111> orientation relationship with the S-oriented matrix (∑7 CSL grain boundary). In general terms, ∑CSL grain boundaries have lower interface energy than other random grain boundaries. So, at the initial stage of recrystallization, cube orientation nuclei will prefer to nucleate in S-orientation matrix and then grow up into it[15]. This is also in accordance with the development trend of S texture components from 200 ℃ to 300 ℃ shown in Fig.5. Since the electric field decreases the deformation stored energy of S-oriented matrix,cube orientation nuclei have a lower nucleation ratio at the initial stage of recrystallization compared with those in conventionally annealed specimen. So the external electric field restrains the development of recrystallization cube texture at the initial stage of recrystallization.

The full recrystallization texture results from the balance of the initial nuclear content and the competition of the nuclei in the growth stage according to their various growth rates. During recrystallization, S-oriented subgrains have higher average stored energy than other oriented subgrains[16]. When the sample was annealed with the electric field, the electric field decreased the deformation stored energy, so as to make the stored energy of other oriented subgrains decreased below the critical nucleation energy. So at the initial stage of recrystallization, cube orientation nuclei had a higher nucleation rate than other oriented subgrains. At the stage of grain growth, despite the electric field decreased the difference in growth rate between cube oriented and other oriented nuclei, there still existed a predominance of cube oriented nuclei in size and energy. Thus cube oriented nuclei still had a higher growth rate compared with other oriented nuclei, so that the intensity of cube texture was higher in electric field annealed specimen. From the variation trend of cube texture component and copper texture component from 300 ℃ to 400 ℃ as shown in Fig.4 and Fig.6, it could be seen at this stage, cube oriented grains began to grow up into copper oriented matrix mainly and consumed the copper orientated grains, so that the copper oriented grains disappeared in the end. The reason why cube oriented nuclei merged preferentially into copper oriented grains at the stage of grain growth remained unclear, and required further investigation.

4 Conclusions

1) The electric field annealing does not change the mechanism of recrystallization and recrystallization texture of the cold-rolled high-purity aluminum sheet, but it enhances the intensity of recrystallization cube texture at the stage of grain growth.

2) Possible reasons for the intensification of the recrystallization cube texture with the electric field applied may be attributed to both selected nucleation and selected growth of cube oriented crystal nuclei.

Acknowledgements

The Southwestern Aluminum Manufacturer is greatly appreciated for provision of experimental materials.

References

[1] KOCH C C. Experimental evidence for magnetic or electric field effects on phase transformations [J]. Materials Science and Engineering A, 2000, 287(2): 213-218.

[2] LIU W, LIANG K M, ZHENG Y K, CUI J Z. Effect of an electric field during solution treatment of 2091 Al-Li alloy [J]. Journal of Materials Science Letters, 1996, 15: 1327-1329.

[3] LIU W, CUI J Z. The mechanisms of nonequilibrium segregation of solute atoms with an electric field [J]. Materials Research Bulletin, 1997, 32(10): 1411-1417.

[4] HU Z C, ZHAO X, ZUO L, WANG F, CLAUDE E. Effects of electric field annealing on microstructure and recrystallization texture of 3104 aluminum alloy sheets [J]. The Chinese Journal of Nonferrous Metals, 2004, 14(8): 1366-1371. (in Chinese)

[5] HU Z C, LIU Y D, ZHAO X, ZUO L, WANG F, CLAUDE E. Microstructure and texture variation of Al-Mn-Mg alloy sheets under external electric field [J]. Chinese Journal of Materials Research, 2004, 18(5): 477-484.

[6] HU Z C, ZHANG Y D, ZHAO X, ZUO L, WANG F, CLAUDE E. Electric field annealing on 3104 aluminum alloy sheets:Evolution of microstructure and texture [J]. Solid State Phenomena, 2005, 105: 169-174.

[7] WANG Y N, HE C S, ZHAO X, ZUO L, ZHI Q Z, LIANG Z D. Effect of electric field annealing on the recrystallization and recrystallization texture of cold-rolled commercial pure copper [J]. Acta Metallurgica Sinica, 2000, 36: 126-130.

[8] HU Z C, HE C S, ZHAO X, ZUO L. Effects of external electric field on recrystallization texture and microstructure of 08Al killed steel sheet [J]. Journal of Materials Science, 2004, 39: 4231-4234.

[9] HU Z C, HE C S, ZHAO X, ZUO L. Effects of electric field recovering on the microstructure and recrystallization texture of deep-drawing 08Al killed steel sheet [J]. Journal of Northeastern University (Natural Science), 2002, 23(7): 663-666.

[10] HU Z C, ZHAO X, ZUO L. Effects of electric field on annealing texture of 08Al killed steel sheets [J]. Journal of Iron and Steel Research, 2004, 16(1): 57-61.

[11] WU T K, LIU W, Li X L, LIU Q. Effects of an external electric field on cube texture development of rolled pure nickel during recrystallization [J]. Materials Letters, 2005, 59(11): 1365-1368.

[12] JIANG Qi-wu, WANG Cun-sheng, WANG Fu, ZUO Liang, WANG Zhi-guo. Recrystallization textures of high-purity aluminum foil annealed with an electric field [J]. The Chinese Journal of Nonferrous Metals, 2001, 11(4): 598-602. (in Chinese)

[13] LIANG Z D, XU J Z, WANG F. Three Dimensional Orientation Analysis of Textured Materials—ODF Analysis [M]. Shenyang: Northeastern University of Technology Press, 1986: 108-109.

[14] BALLUFI R W. Grain Boundary Structure and Kinetics [M]. Ohio: Milwaukee American Society for Metals, 1979: 125.

[15] DUGGAN B J, LEE C S. Deformation banding original grain size and recrystallization in FCC intermedia to high sfe metals [J]. Scripta Metall Mater, 1992, 27: 1503-1507.

[16] VATNE H E, DAALAND O. On the formation of cube texture in aluminum [J]. Materials Science Forum, 1994, 157/162: 1087-1094.

Foundation item: Project(50374028) supported by the National Natural Science Foundation of China and Shanghai Bao Steel Group of China; Project(PRA MX04-02) supported by Sino-French Cooperation Program

Corresponding author: ZHAO Xiang; Tel: +86-24-83681723; Fax: +86-24-83681758; E-mail: zhaox@mail.neu.edu.cn

(Edited by YANG Bing)