2种浸入式侧吹模式下的熔池搅拌现象

詹树华1,欧俭平1,赖朝彬2,萧泽强3

(1.中南大学 能源与动力工程学院,湖南 长沙,410083;

2.新余钢铁公司,江西 新余,336500;

3.东北大学 冶金和材料学院,辽宁 沈阳,110006)

摘要: 在考虑流股成泡后各分散气泡形阻力的影响以及气液相运动时相间的滑移等条件的基础上,耦合了Sato模型和湍流分散力,建立了欧拉气液两相多流体模型;采用计算流体力学的方法对深侧吹和浅侧吹2种不同浸入式侧吹模式下熔池内两相流动状态和混合特性等进行了计算和比较。研究结果表明:浸入式侧吹能有效吸收气体流股的冲击能量,减少喷溅,熔池中易于形成有利于体系混合的环流;深侧吹比浅侧吹具有更强的搅拌能力和更快的混合速度,相间和相内传质速度更快,可以为高碳锰铁快速脱碳提供更加良好的反应动力学条件。

关键词: 氩氧脱碳; 金属熔池; 计算流体力学; 气液两相流

中图分类号:TF642 文献标识码:A 文章编号: 1672-7207(2005)01-0049-06

Gas Stirring Behaviors in Two Types of Side-blown Metallic Baths

ZHAN Shu-hua1,OU Jian-ping1,LAI Chao-bin2,XIAO Ze-qiang3

(1. School of Energy and Power Engineering, Central South University, Changsha 410083, China;

2. Xinyu Iron and Steel Company, Xinyu 336500, China;

3. School of Metallurgy and Materials, Northeastern University, Shenyang 110006, China)

Abstract: Eulerian multiphase multi-fluid model was formulated to simulate the flow pattern and mixing property in submerged side-blown metallic bath. In the model, the bubble-induced turbulence was integrated with Sato model, and turbulent dispersion force and gas-liquid inter-phase slip were considered. Using computation fluid dynamic method, the mixing properties of two types of submerged side-blown metallic bath, shallow side-blown and deep side-blown were compared. All calculations were done in three dimensions. The results show that the impact energy of in-blowing gas can be effectively absorbed by metallic liquid , splash in bath can be alleviated, and circumfluence flow, which is in favor of systematic mixing, can form easily with gas side-blowing. Metallic bath with deep side-blowing can provide stronger stirring ability, faster mixing rate, faster inter-phase and inner-phase mass transfer rate than that with shallow side-blowing. Therefore, metallic bath with deep gas side-blowing can provide better environment for high-carbon manganese ferrous decarburization.

Key words: argon-oxygen decarburization; metallic bath; computational fluid dynamics; gas-liquid two-phase flow

金属熔池浸入式侧吹已广泛应用于许多金属精炼或提取过程,除应用于氩氧脱碳(argon-oxygen decarburization即AOD)吹炼不锈钢外,20世纪70年代我国许多空气侧吹转炉采用全氧浸入式侧吹技术[1-3]。近年来国内外一些企业研发直接炼铁和连续炼钢新工艺时,也十分注意熔池侧吹技术的应用。

新钢是我国采用高炉生产高碳锰铁最大的冶金企业。由于近代炼钢技术的进步和对钢品种质量要求提高, 高碳锰铁的用户已愈来愈少。 将含碳6%~8%的高炉锰铁处理成含碳1%~2%或更低的中低碳锰铁,可大大改善钢冶炼的脱氧和合金化过程[4-7]。 萧泽强对高碳锰铁吹氧精炼的热力学条件进行了研究和论证[8]。 认为高炉高碳锰铁采用氩氧或氮氧的混氧吹炼,生产中低碳锰铁, 在热力学上是可行的。 因此, 选择合适的反应器, 促进高碳锰铁快速脱碳, 尽可能减少锰的损失, 是高碳锰铁精炼生产中低碳锰铁的关键。 为此, 采用金属熔池浸入式侧吹,供入氩氧混合气体,进行快速脱碳。

詹树华等对深浸入式侧吹方式下试验炉内熔池的搅拌现象进行了研究[9],研究中引入浸入式侧吹气流喷入段的物模实测参数,考虑了流股成泡后各分散气泡形阻力的影响以及气液相运动时相间的滑移。结果表明,采用气液两相多流体模型,可以用于描述侧吹熔池内两相流运动和熔池搅动的基本特征。在此基础上,作者采用数值模拟的方法,对深侧吹和浅侧吹2种不同的浸入式侧吹方式下熔池中的两相流动状态、死区的存在和大小及混合特性等进行计算和比较研究,以便为现场工业试验选择合理炉型、侧吹方式和喷吹参数提供依据。

1 侧吹熔池内气液两相流的数值模拟方法

1.1 计算对象及网格

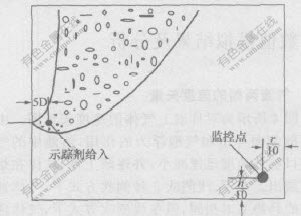

数值模拟的对象为1台锰铁脱碳热模实验炉,其结构简图如图1所示,侧吹入口直径为5.2 mm。计算域为图1所示的浅灰色区域。有2个侧吹入口,深侧吹方式通过深吹入口进行吹气;浅侧吹方式通过浅吹入口进行吹气。

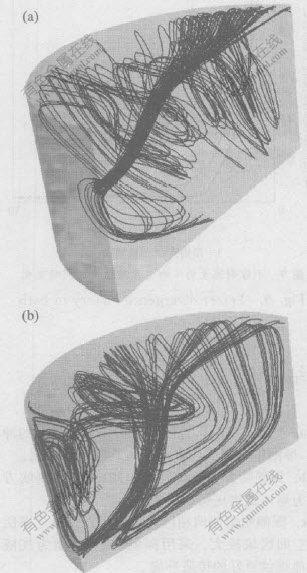

鉴于计算域的对称性,仅计算模型的一半。图2所示为计算网格示意图,网格节点数约为20万。

计算中,取熔池内液体的密度和粘度分别为7.0×103 kg·m-3和5.7×10-3 Pa·s,气液表面张力为1.5 N·m-1,气体的密度和粘度分别为1.27 kg·m-3和1.8×10-5 Pa·s,重力加速度取9.81 m·s-2。不考虑吹入气体与金属熔池内的化学反应,不考虑传热过程及空气的可压缩性。

图 1 计算侧吹熔池简图

Fig. 1 Outline of side-blown bath

(a)—俯视图; (b)—侧视图

图 2 计算网格示意图

Fig. 2 Surface mesh of computational domain

1.2 数学模型

采用气液两相多流体模型对脱碳炉进行计算。两相具有各自的速度场及拥有共同的压力场。连续方程、动量方程控制方程形式与文献[9-12]中的相同。

使用均质模型模拟气液两相湍流。假设 α和β两相的湍动能及湍动能耗散率相等,即kα=kβ=k,εα=εβ=ε,具体传输方程如下[13]:

其中:ρ为平均密度,kg·m-3;U为平均速度,m·s-1;k为湍动能,m2·s-2;ε为湍动能耗散率,m2·s-3;σk为湍动能方程的普朗特数;σε为湍动能耗散率方程的普朗特数;μeff为平均有效粘度,kg·m-1·s-1;Sk为湍动能方程的源项,kg·m-1·s-3;Sε为湍动能耗散率方程的源项,kg·m-1·s-3。

式(1)和(2)中平均量通过式(3)~(11)进行计算:

式中,α为连续相液相,β为离散相气相;r为相体积分数。

根据涡粘假设,并耦合Sato模型,式(3)~(11)中的连续相有效粘度μαeff可表达为[14]:

μαeff=μα+μTα+μTβ。(12)

式中,μα和μTα分别为连续相α的层流和湍流粘度,kg·m-1·s-1,由气泡引起的湍流项μTβ可以表述为:

μTβ=Cμbραrβd|Uβ-Uα|。(13)

式中,d为气泡直径,m;Cμb为常数。离散相粘度由下式给出:

相间动量传递采用Grace模型,并对浓相区使用体积分数进行修正,体积分数修正因子取4.0。

由于高速气流喷入,湍流分散力(Turbulence Dispersion Force)不可忽略,采用下式进行计算[15,16]:

MTDα=-MTDβ=-CTDραkαrα。(15)

式中:CTD为无量纲湍流分散系数,计算时取CTD=0.1。

考虑了浮力的存在,浮力以体积力方式加入动量方程。使用Boussinesq假设,不考虑可压缩性及温度的影响,浮力的计算式为:

Bβ=(ρα-ρβ)g。(16)

式中,Bβ为离散相β的浮力,kg·m-2·s-2;g为重力加速度,m·s-2。

1.3 混合特性分析

1.3.1 示踪剂计算

混合特性分析是在气液两相稳态计算的基础上进行的。计算时,以稳态计算结果为初场,在某一特征点加入示踪剂,将示踪剂加入连续相液相(气相中示踪剂浓度为零),进行瞬态计算和分析。如图3所示,在深侧吹和浅侧吹2种状态下示踪剂的给入位置均为侧吹射流的正前方位置,监控点为与给入点相对应的下方位置。

D—喷嘴直径; r—熔池半径; h—熔池深度

图 3 示踪剂给入位置及监控点位置示意图

Fig. 3 Tracer injection location and

monitor location

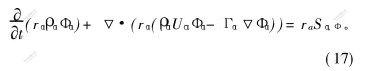

示踪剂浓度控制方程为:

式中:Φα为液相α中示踪剂的无量纲浓度;Γα为有效扩散系数;Sα,Φ为液相α中示踪剂源项(即液相α中示踪剂的产生和消失速率)。

1.3.2 数据处理

为了便于对比2种侧吹方式下熔池的混合特性,对浓度进行无量纲化:

Cnon-d=C/C0。(18)

式中:Cnon-d为无量纲浓度;C0为平衡浓度;C为焙池内某一点的绝对浓度。

用浓度的标准偏差δ来表征熔池内的浓度不均匀度,δ越小,表示熔池内浓度越均匀。计算式如下:

1.4 边界条件

所有控制方程均采用商业软件CFX4.4进行离散和计算,用2种不同侧吹方式计算时采用的边界条件相同。条件如下:

入口上,气体吹入速度均为150 m/s(对应气体流量为2.080×10-3 kg/s),气体体积分数为100%;钢液体积分数为零,速度为零,即没有钢液进入。壁面上,两相采用相同的壁面边界条件。除上表面外,壁面采用无滑移条件,即Ux=Uy=Uz=0,近壁区采用标准壁函数进行处理。对于气体,上表面为脱气表面,即气泡到达上表面后立即逸出(消失);对于液体,上表面为滑移边界,即τx=τy=τz=0。

在对示踪剂进行分析、计算时,设各壁面(包括上表面)示踪剂的通量为零,入口示踪剂浓度为零。

2 数值模拟结果及分析

2.1 气液两相的速度矢量

图4所示为对称面上气体的速度矢量图。由于气流的侧向冲击和气泡浮力的作用,熔池中的气体在喷口前方速度迅速减小,并逐渐上浮,气体在熔池表面溢出。在深、浅侧吹2种侧吹方式下,气体速度衰减的趋势基本相同,但在浅侧吹方式下,气体通过的路径较短,不利于熔池吸收气体能量。

(a)—浅侧吹; (b)—深侧吹

图 4 对称面上气体流动速度矢量

Fig. 4 Gas speed vectors on symmetry plane

图5所示为对称面上的液相流动速度矢量图。可见,气流和气泡周围的液体,受气体流动的驱动,在两相区及其附近向上流动,但速度较气体运动速度略小,相间存在滑移。在整个液相熔池内出现不十分规则环流,喷嘴轴线两侧熔池内出现旋涡流。熔池内的整体搅拌良好。深侧吹熔池内速度较大的区域体积较大,深侧吹能提供比浅侧吹更强的搅拌能。

(a)—浅侧吹; (b)—深侧吹

图 5 对称面上由侧吹气流引起的液相流动速度矢量

Fig. 5 Liquid speed induced by side-blown

gas on symmetry plane

2.2 两相区结构

在采用气体喷吹的金属熔池中,两相区是熔池中的主要搅拌源区,也是冶金过程的重要反应区。5%等值气相分率所包围的空间应该是喷吹熔池内主要反应区域[9]。图6所示为两相区内5%气相分率等值面图。可以看出,在深侧吹方式下,5%等值气相分率所包围的空间区域较大,也就是说,深侧吹能够为冶金过程提供更快速的反应环境,反应更加激烈。

2.3 搅动及混合特性分析

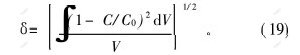

锰铁脱碳速率和程度取决于含碳熔池与两相区供入氧气的反应速度,在高温下,过程的进行速度主要由传递速率控制,因此,液相熔池的搅动和传质是新工艺的关键因素。在高温下,金属熔池内的实际流动是无法观测的。数值计算结果表明,高速气流进入侧吹熔池后速度很快下降,能量被熔池充分吸收,在熔池中形成强有力的大体积循环和局部涡流,为反应所需热量和质量的传递提供了良好的动力学条件。图7所示为熔池内用液体的流线描述的熔池中的流动。可见,在喷嘴的前方熔池存在流经整个熔池的环流,在喷嘴轴线的两侧,出现发展良好的局部涡流。在浅、深侧吹2种情况下,形成的流场结构明显不同。在深侧吹方式下,熔池的搅拌区域更大。

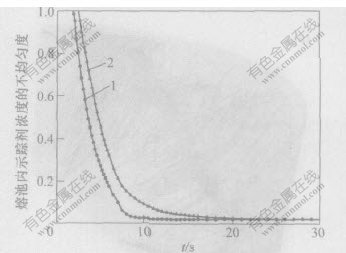

图8所示为浅、深侧吹情况下,熔池内监控点上示踪剂无量纲浓度随时间的变化曲线。可见,在侧吹情况下,监控点上示踪剂无量纲浓度会出现短时间的波动,但很快就能维持在一个平衡的水平上;使用浅侧吹模式时,喷吹前期浓度波动较大,达到平衡浓度的时间比深侧吹的长。图9所示为熔池内示踪剂浓度的不均匀度随喷吹时间的变化曲线。可以看出,侧吹金属熔池内的混匀速度很快,在20 s之内,熔池内基本混匀,也就是说,侧吹方式虽然为单侧喷吹,但传质速度很快,能够促使反应快速进行。深侧吹较浅侧吹混合速度更快,能够提供更好的传质环境。

(a)—浅侧吹; (b)—深侧吹

图 6 两相区内5%气相分率等值面图

Fig. 6 Contours of gas volume fraction at

5% in two phase region

(a)—浅侧吹; (b)—深侧吹

图 7 侧吹熔池中液相流动图线

Fig. 7 Liquid streamline in side-blown bath

1—深侧吹; 2—浅侧吹

图 8 监控点上示踪剂浓度随喷吹时间的变化

Fig. 8 Content of tracer variation

at monitor location with time

1—深侧吹; 2—浅侧吹

图 9 示踪剂浓度的不均匀度随喷吹时间的变化

Fig. 9 Tracer divergence history in bath

3 结 论

a. 浸入式侧吹熔池能有效吸收气体流股的冲击能量,熔池中易于形成有利于体系混合的环流。

b. 深侧吹方式与浅侧吹方式相比,深侧吹方式能够为熔池提供更强的搅拌能力。

c. 深侧吹熔池两相区内5%等值气相分率所包围的空间区域较大。采用深侧吹方式,能为气液两相熔池提供更好的传质环境。

d. 侧吹金属熔池内混合速度快,金属熔池内的反应物和产物能快速扩散,有利于反应过程的进行。

e. 对新钢采用深浸入式氩氧侧吹炉体进行高碳锰铁快速脱碳,可以获得良好的反应`动力学条件,搅拌效率高,脱碳速度快。

参考文献:

[1]韩旭,彭一川,萧泽强. 倾斜侧吹气液射流在熔池中的轨迹[J]. 东北大学学报, 1994,15(2): 145-149.

HAN Xun, PEN Yi-chuan, XIAO Ze-qiang. The Track of Inclined Side-blown Gas Liquid Jet in Bath[J]. Journal of Northeastern University, 1994, 15(2):145-149.

[2]朱苗勇,萧泽强. 钢的精炼过程数学物理模拟[M]. 北京: 冶金工业出版社, 1998.

ZHU Miao-yong, XIAO Ze-qiang. Mathematical and Physical Modeling in Steel Refining Process[M]. Beijing: Metallurgical Industry Press, 1998.

[3]杨天钧,刘述临. 熔融还原技术[M]. 北京: 冶金工业出版社, 1991.

YANG Tian-jun, LIU Shu-lin. Smelting Reduction Technology[M]. Beijing: Metallurgical Industry Press, 1991.

[4]DRESLER W. Oxygen Refining of High-carbon Ferromanganese[J]. Canadian Metallurgical Quarterly, 1989, 28(2): 109-115.

[5]SCHURMANN E. Ferromangan-Affine-Erzeugung nach dem TBM-Verfahren[J]. Stahl und Eisen, 1993, 113(3): 77-82.

[6]YOU B D. Oxygen Refining of Molten High-carbon Ferromanganese[J]. Metals and Materials, 1999, 5(4): 395-399.

[7]YOU B D. Manganese Loss During the Oxygen Refining of High-carbon Ferromanganese Melts[J]. Metals and Materials, 1999, 5(5): 497-502.

[8]萧泽强.利用混氧侧吹转炉生产中、低碳锰铁的可行性分析[D].沈阳:东北大学冶金与材料学院,1999.

XIAO Ze-qiang. Analyze on the Feasibility of Producing Medium-carbon Ferromanganese and Low-carbon Ferromanganese Using Mixed-oxygen Side-blowing Converter[D]. Shenyang: School of Metallurgy and Materials, Northeastern University, 1999.

[9]詹树华, 赖朝斌, 萧泽强. 侧吹金属熔池内的搅动现象[J]. 中南工业大学学报(自然科学版),2003, 34(2):148-151.

ZHAN Shu-hua, LAI Chao-bin, XIAO ze-qiang. CFD Analysis of Gas Stirring Behavior in Side-blown Metallic Bath[J]. Journal of Central South University of Technology (Natural Science), 2003, 34(2): 148-151.

[10]PFLEGER D, BECKER S. Modeling and Simulation of the Dynamic Flow Behaviour in a Bubble Column[J]. Chemical Engineering Science, 2001, 56(4): 1737-1747.

[11]KRISHNA R, VAN BATEN J M. Eulerian Simulations of Bubble Columns Operating at Elevated Pressures in the Churn Turbulent Flow Regime[J]. Chemical Engineering Science, 2001, 56(21-22): 6249-6258.

[12]van BATEN J M, KRISHNA R. Eulerian Simulations for Determination of the Axial Dispersion of Liquid and Gas Phases in Bubble Columns Operating in the Churn-turbulent Regime[J]. Chemical Engineering Science, 2001, 56(1): 503-512.

[13]AEA Technology PLC. CFX 4.4 User Documentation[M]. Harwell: AEA Technology, 1999.

[14]SATO Y, SEKOGUCHI K. Liquid Velocity Distribution in Two-phase Bubble Flow[J]. International Journal of Multiphase Flow, 1975, 2(1): 79-95.

[15]LOPEZ de BERTODANO M A. Turbulent Bubbly Flow in a Triangular Duct[D]. New York:Rensselaer Polytechnic Institute, 1991.

[16]LOPEZ de BERTODANO M A. Two Fluid Model for Two-Phase Turbulent Jet[J]. Nuclear Engineering and Design,1998,179(1): 65-74.

收稿日期:2004-06-20

作者简介:詹树华(1973-),男,江西崇仁人,博士,从事化工冶金新工艺的开发与仿真研究

论文联系人: 詹树华,男,博士;电话:0731-8830897(O); E-mail:Zhan_shuhua@hotmail.com, Zhanshuhua@263.net