文章编号:1004-0609(2008)03-0409-05

Ti对Mo-Ti合金拉伸强度及显微组织的影响

卢明园,范景莲,成会朝,刘 涛,田家敏,黄伯云

(中南大学 粉末冶金国家重点实验室,长沙 410083)

摘 要:采用粉末冶金方法制备Mo-Ti合金,研究合金元素添加方式及添加量对材料拉伸强度和显微组织的影响。结果表明,添加TiH2粉末所制备的合金的拉伸强度及相对密度均较添加纯Ti粉末的合金高,当添加量(质量分数)为0.8%时合金拉伸强度最高。显微组织分析结果表明,一部分Ti固溶到Mo基体,提高材料的拉伸强度,另一部分则与Mo及合金中的氧结合形成MoxTiyOz复合氧化物第二相粒子,起到细化晶粒及净化晶界的作用。

关键词:Mo-Ti合金;拉伸强度;相对密度;固溶强化;第二相粒子

中图分类号:TG146.4 文献标识码:A

Effects of Ti on tensile strength and microstructure of Mo-Ti alloy

LU Ming-yuan, FAN Jing-lian, CHENG Hui-chao, LIU Tao, TIAN Jia-min, HUANG Bai-yun

(State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China)

Abstract: Mo-Ti alloy were fabricated by powder metallurgy process. The effects of adding forms and content of Ti on the tensile strength and microstructure of molybdenum were studied. The results indicate that the tensile strength of Mo-Ti alloy with TiH2 addition is much higher than that with pure Ti. The tensile strength achieves the highest value when the content of TiH2 is 0.8%. The microstructure analysis reveals that a part of the alloying element Ti solves into the Mo matrix, which enhances the tensile strength of the alloys, while the other part of Ti is combined with Mo and O in alloy to form second phase compounding oxide particles MoxTiyOz, which refines the grains and purifies the grain boundaries.

Key words: Mo-Ti alloy; tensile strength; relative density; solid solution; second phase particles

金属Mo具有熔点高,导电、导热性好,膨胀系数低,抗热震性能以及耐热疲劳性能好等特点,被广泛用作高温材料。然而,Mo存在再结晶温度低和室温强度低、脆性大等缺陷,严重制约了其在高温领域中的应用[1-3]。合金元素的固溶强化是提高金属Mo性能最为典型的方法,其中Ti又是最为有效和常用的添加元素之一。添加合金元素Ti,可改善Mo的使用性能:微量Ti的固溶,可以提高Mo的低温延展性,降低其韧-脆转变温度(DBTT);Ti在Mo中形成氧化物粒子,对晶界迁移起钉扎作用,提高了Mo的再结晶温度[4-7],使Mo的使用温度范围和领域得以拓宽。

电弧熔炼法是目前制备Mo合金大多采用的方 法[8-10],但这种方法工艺复杂,合金显微组织粗大,成品率较低,加工量大,生产成本高[11]。粉末冶金方法不仅可以用于制备形状复杂的零部件,且合金显微组织均匀,晶粒较细小,因此,越来越引起人们的重视。为此,本文作者采用粉末冶金工艺制备Mo-Ti合金,研究了合金元素Ti的两种添加方式及添加量对合金性能和显微组织的影响。

1 实验

按一定质量分数配比(0%、0.3%、0.4%、0.5%、0.55%、0.6%、0.7%、0.8%、0.9%、1.0%)将合金元素以纯金属和氢化物两种形式添加到Mo粉中,在球磨机中进行混合,混合粉末在25 t油压机上压制,压制压力为350 MPa。压坯在氢气下进行预烧结,预烧温度为1 000 ℃,保温2 h。然后,在氢气气氛下进行高温烧结,在1 890~1 950 ℃保温3 h。

采用LJ-3000A型机械式拉力实验机检测样品的拉伸性能;采用JSM-5600LV型扫描电镜观察样品断口形貌,并采用EDX能谱仪进行选区或定点成分分析;采用MeF3A型金相显微镜进行样品显微组织观察。

2 结果与讨论

2.1 Ti的添加方式及添加量对合金性能的影响

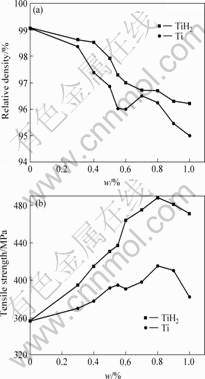

图1所示为Ti的添加方式对合金相对密度和拉伸强度的影响。由图可见,无论是相对密度还是拉伸强度,添加TiH2的样品基本上都较添加纯Ti的样品要高。

图1 Ti的添加方式对Mo-Ti合金相对密度和拉伸强度影响 (1 920 ℃烧结)

Fig.1 Effect of adding forms of Ti on relative density and tensile strength of Mo-Ti alloy (sintered at 1 920 ℃): (a) Relative density; (b) Tensile strength

由于Ti与O的亲和力较大,添加纯Ti的粉末,在球磨混合、存放、压制及预烧等过程中已被严重氧化。晶界处的孔隙与预烧样的O含量呈正比[12],因此,高O含量的预烧样经高温烧结后相对密度较低。Ti颗粒外部的氧化膜,阻碍其向Mo中扩散,削弱了固溶强化的效果,同时,由于氧化物使晶界的强度降低,容易产生脆性沿晶断裂[13],因此,样品的拉伸强度较低。TiH2脆性比Ti的大,球磨过程中TiH2颗粒较Ti颗粒粉碎程度大,故经球磨后其粒度较细,经脱氢后形成的Ti原子活性较高,更容易被氧化。由于Ti在882 ℃时和Mo形成的是连续固溶体[12],易于向Mo基体中扩散,而活性提高、接触面积增大等因素使Ti向Mo基体扩散的速度显著加快,强化效应加强,同时生成的氧化物相对较少,因此,添加TiH2的合金强度较高。

图2所示为TiH2添加量对合金拉伸强度的影响。由图可见,添加了TiH2后,所得合金样品的拉伸强 度明显比纯Mo样品的高,且在TiH2添加量为0.8%时,合金拉伸强度最高。由于金属Ti容易被氧化,脱氢后得到的Ti活性较高,一方面有利于Ti向Mo基体扩散,另一方面也加速了其与合金中的少量氧结合。但随着TiH2添加量升高,脱氢后形成的Ti量增大,固溶进Mo基体的Ti增多,强度增加。而与此同时,被氧化的Ti也增加。氧化物存在于晶界处影响合金强度,使得材料的性能削减。当氧化物含量达到一定程度时,其对材料力学性能的恶化作用将会严重地抵消Ti的固溶强化作用,使得强度曲线下降。

图2 TiH2添加量对Mo-Ti合金拉伸强度的影响

Fig.2 Effect of addition amount of TiH2 on tensile strength of Mo-Ti alloy

2.2 Ti对合金显微组织的影响

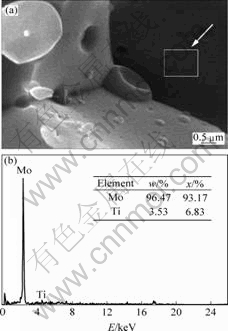

图3所示为Mo-0.8TiH2拉伸样品中的一个Mo晶粒的晶界面的选区能谱分析,可见图谱中出现了明显的Ti的谱线,定量分析得出Ti的含量(质量分数)有3.53%,显然,此Mo晶粒中已固溶进了部分Ti原子。

图3 Mo-0.8TiH2晶界面选区能谱分析

Fig.3 EDX analysis of grain boundary surface of Mo-0.8TiH2 alloy

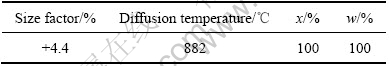

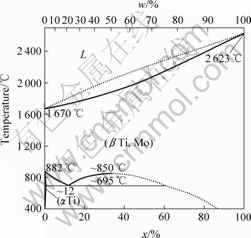

元素之间尺寸因子,即溶质原子直径与溶剂原子直径的差与溶剂原子直径的比,是决定合金元素之间互溶度的最重要因素之一,当元素间尺寸因子的绝对值较小(一般小于5.0)、同时元素晶体结构相似时,就有可能形成连续固溶[14]。而Ti相对于Mo的尺寸因子为+4.4(见表1),在882 ℃以上,即在Ti的体心立方结构存在的范围内(Mo为体心立方结构),Ti与Mo形成连续固溶体(见图4)。因此,Ti原子易于固溶入Mo基体中,加之TiH2脱氢所得Ti原子具有高活性,更有利于其向Mo基体的扩散。Ti原子进入Mo基体中产生固溶强化的效果,溶质原子在基体金属中的摩尔分数越高,强化作用越大,特别是溶质原子摩尔分数很低时,随着固溶量的增加,强化效应的提高更为显著。

表1 Ti相对于Mo的尺寸因子及其在Mo中的溶解度[14]

Table 1 Size factor of Ti to Mo and solubility of Ti in Mo

图4 Mo-Ti相图

Fig.4 Phase diagram of Mo-Ti

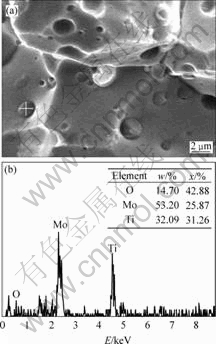

对添加TiH2的合金样品断口进行SEM观察,发现在Mo晶粒间存在大量的第二相粒子和孔隙,而纯Mo样品的晶粒之间无第二相粒子,孔隙较少(见图5)。能谱分析表明,这些粒子的组成元素为Mo、Ti和O,如图6所示。Ti在Mo中的固溶度较高,部分Mo-Ti固溶体吸收了合金中的微量O,形成MoxTiyOz氧化物第二相粒子,对O起到钉扎作用,减少造成钼室温脆性的间隙杂质O在晶界的富集。

图5 Mo-0.8TiH2合金和纯Mo的断口SEM像

Fig.5 SEM fracture images: (a) Mo-0.8TiH2 alloy; (b) Pure Mo

图6 Mo-0.8TiH2合金晶界面处镶嵌的小颗粒定点能谱分析

Fig.6 EDX analysis of particles in grain boundary of Mo-0.8TiH2 alloy

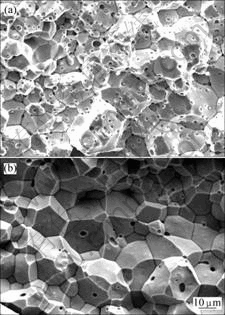

图7 Mo-0.8TiH2合金及纯Mo金相照片

Fig.7 Metallographs of Mo-0.8TiH2 alloy(a) and pure Mo(b)

第二相粒子及孔隙均对晶粒长大具有抑制作用。分别对纯Mo和Mo-0.8TiH2样品的金相组织(图7)进行晶粒度分析,结果表明纯Mo样品的平均晶粒度为22.5 μm,而Mo-0.8TiH2样品的平均晶粒度为18.9 μm。晶界为材料的变形提供抗力,随着晶粒细化,多晶体强度得到提高。尽管添加TiH2的样品孔隙较纯Mo要多,相对密度较低,而且存在大量间隙粒子,但由于晶粒较细小,强度较高。

然而,孔隙和第二相粒子与Mo晶粒的界面容易成为微裂纹源,形成显微空洞,降低材料的断裂韧性,材料容易发生脆性沿晶断裂。孔隙和第二相粒子的尺寸越小,分布越弥散,强化的效果越明显,反之,当第二相粒子尺寸较大时,主要起恶化合金性能的作 用[15-16]。Mo-Ti合金中的孔隙及第二相粒子均已达到了微米级,其脆化晶界的效应不容忽视。

3 结论

1) 添加TiH2的合金其相对密度和拉伸强度均较添加Ti的合金要高。添加TiH2的合金其最佳添加量为0.8%。

2) TiH2脱氢后将生成活性较高的Ti,部分固溶入Mo基体中,其余是以复合氧化物MoxTiyOz第二相粒子的形式存在于Mo晶粒内及晶界处。添加TiH2的合金晶粒间出现的大量的第二相粒子和孔隙,起到了细晶强化的作用,使合金拉伸强度较纯Mo的高。

REFERENCES

[1] 曹维成, 刘 静, 任宜霞. 掺杂不同微量元素对钼材性能的影响[J]. 稀有金属快报, 2006, 25(8): 29-31.

CAO Wei-cheng, LIU Jing, REN Yi-xia. Influence of doping elements on the properties of molybdenum material[J]. Rare Metals Letters, 2006, 25(8): 29-31.

[2] 向铁根. 钼冶金[M]. 长沙: 中南大学出版社, 2002.

XIANG Tie-gen. Molybdenum metallurgy[M]. Changsha: Central South University Press, 2002.

[3] 张启修, 赵秦生. 钨钼合金[M]. 北京: 冶金工业出版社, 2005.

ZHANG Qi-xiu, ZHAO Qin-sheng. Tungsten and molybdenum metallurgy[M]. Beijing: Metallurgy Industry Press, 2005.

[4] MROTZEK T, HOFFMANN A, MARTIN U. Hardening mechanisms and recrystallization behaviour of several molybdenum alloys[J]. Refractory Metals & Hard Metals, 2006, 24: 298-305.

[5] NAGAE M, TAKEMOTO Y, YOSHIO T, TAKADA J, HIRAOKA Y. Preparation of structurally controlled dilute molybdenum-titanium alloy through a novel multi-step internal nitriding technique and their mechanical properties[J]. Mater Sci Eng A, 2005, 406: 50-56.

[6] HIRAOKA Y, YOSHIMURA S. Low temperature fracture strength and ductility of carburized Mo-Ti alloys[J]. Refractory Metals and Hard Materials, 1995, 13: 205-210.

[7] INOUE T, HIRAOKA Y, SUKEDAI E I, NAGAE M, TAKADA J. Hardening behavior of dilute Mo-Ti alloys by two-step heat-treatment[J]. Refractory Metals and Hard Materials, 2007, 25: 138-143.

[8] COCKERAM B V. Measuring the fracture toughness of molybdenum-0.5pct titanium-0.1pct zirconium and oxide dispersion-strengthened molybdenum alloys using standard and subsized bend specimens[J]. Metallurgical and Materials Transactions, 2002, 33A: 3685-3707.

[9] SHARMA I G, CHAKRABORTY S P, SURI A K. Preparation of TZM alloy by aluminothermic smelting and its characterization[J]. Journal of Alloys and Compounds, 2005, 393: 122-128.

[10] COCKERAM B V. The mechanical properties and fracture mechanisms of wrought low carbon arc cast (LCAC), molybdenum-0.5pct titanium-0.1pct zirconium (TZM), and oxide dispersion strengthened (ODS) molybdenum flat products[J]. Mater Sci Eng A, 2006, 418: 120-136.

[11] 张军良, 郑 欣, 张 清, 李中奎. Mo-Ti-Zr合金挤压破裂问题的研究[J]. 稀有金属快报, 2004, 23(4): 31-32.

ZHANG Jun-liang, ZHENG Xin, ZHANG Qing, LI Zhong-kui. Study of the extruding fracture problem of Mo-Ti-Zr alloy[J]. Rare Metals Letters, 2004, 23(4): 31-32.

[12] KADOKURA T, HIRAOKA Y, NAKABAYASHI S, YAMAMOTO Y. Effects of sintering conditions on the properties of sintered molybdenum[J]. Powder Metallurgy, 2006: 1153-1154.

[13] 胡赓祥, 蔡 珣. 材料科学基础[M]. 上海: 上海交通大学出版社, 2005.

HU Geng-xiang, CAI Xun. Foundation of materials science[M]. Shanghai: Shanghai JiaoTong University Press, 2005.

[14] 莫尔古诺娃H H. 钼冶金[M]. 北京: 冶金工业出版社, 1984.

MOERKUROVA H H. Molybdenum metallurgy[M], Beijing: Metallurgy Industry Press, 1984.

[15] 李玉清, 刘锦岩. 高温合金晶界间隙相[M]. 北京: 冶金工业出版社, 1990.

LI Yu-qing, LIU Jin-yan. Interstitial phase in the grain boundary of refractory alloy[M]. Beijing: Metallurgy Industry Press, 1990.

[16] 张久兴, 刘燕琴, 刘丹敏, 周美玲, 左铁镛. 微量La2O3对Mo的韧化作用[J]. 中国有色金属学报, 2004, 14(1): 13-17.

ZHANG Jiu-xing, LIU Yan-qing, LIU Dan-ming, ZHOU Mei-ling, ZUO Tie-yong. Toughness of La2O3-doped Mo alloy[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(1): 13-17.

基金项目:国家自然科学基金委员会创新研究群体科学基金资助项目(50721003)

收稿日期:2007-07-23;修订日期:2007-11-12

通讯作者:范景莲,教授,博士;电话:0731-8836652;E-mail: fjl@mail.csu.edu.cn

(编辑 何学锋)