Trans. Nonferrous Met. Soc. China 22(2012) 1975-1980

Microstructure and mechanical properties of 2A12 aluminum alloy after age forming

CHEN Guo-qing, FU Xue-song, ZHAO Fei, ZHOU Wen-long

School of Materials Science and Engineering, Dalian University of Technology, Dalian 116085, China

Received 30 November 2011; accepted 8 March 2012

Abstract: The comparative experiments of age forming and artificial aging of 2A12 aluminum alloy were carried out. The effect of the age forming on the microstructure and mechanical properties was investigated. The results demonstrate that the grains are further squashed and elongated compared with artificial aging due to the existence of the applied stress during the age forming. Meanwhile, the precipitated phases change from circle shape with random orientation of age forming to long strip shape with uniform orientation of artificial aging. The dislocation configuration in samples changes from ring dislocation or helical dislocation of the artificial aging to long and straight dislocation of the age forming. Otherwise, age forming slightly reduces the tensile properties and fracture toughness of the alloy and enhances its fatigue crack growth rate.

Key words: 2A12 aluminum alloy; age forming; stress orientation effect; mechanical properties

1 Introduction

Age forming is an advanced forming method combined forming technology and artificial aging, namely stress aging and shaping proceeded at the same time. The microstructure and mechanical properties of the material change after age forming, which is a hot topic of research. The stress aging of Al-xCu alloy has been studied and it is found that the flake θ′ phase changes from vertical arrangement to orientation arrangement, meanwhile the stress orientation effect decreases the yield strength [1-3]. BAKAVOS et al [4] also demonstrated that the flake θ′ phase was orientally arranged due to the stress orientation effect in the stress aging of 2XU aluminum alloy. CHEN et al [5,6] carried out the corresponding numerical simulation for the microstructure change. Furthermore, LI et al [7] and YANG et al [8] investigated the effect of external stress on the kinetics of precipitated phase in Al-Cu and Al-Cu-Mg alloys by transmission electron microscopy and presented a mechanism that the external stress accelerated precipitation. Recently, LI et al [9] conducted creep experiments of 7B04 aluminum alloy. Their research indicated that the external stress contributed to the transformation of precipitation and increased the flowability of dislocations. Although previous researches have obtained substantial achievements, there are few reports about the age forming of 2A12 aluminum alloy which is an important material used in structural part of the aircraft. Therefore, the comparative experiments between age forming and artificial aging of 2A12 aluminum alloy were carried out in this work. Research emphasis was put on the effects of age forming on the microstructure and mechanical properties of 2A12 aluminum alloy.

2 Experimental

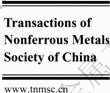

Annealed 2A12 aluminum alloy was produced at the Northeast Light Alloy Co. Ltd. in Harbin, China. Its composition is listed in Table 1. The specimen dimensions were 20 mm×100 mm×400 mm, and its length direction was parallel to the rolling direction. The alloy was subjected to solution treatment at 495 ℃ for 1 h and then subjected to age forming or artificial aging at 160 ℃ for 3 h.

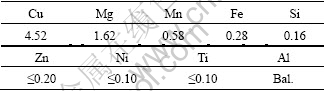

The procedure of the age forming is illustrated in Fig. 1. First, the specimen was applied with elastic load to attach the die. Then, the die and the specimen were heated to the required temperature and kept for a while. During this process, the stress relaxation took place and partial elastic deformation transformed into plastic deformation. Meanwhile, the microstructure and mechanical properties of the specimen were also changed. Finally, the load was removed after heat preservation, then springback occurred.

Table 1 Chemical composition of 2A12 aluminum alloy (mass fraction, %)

Fig. 1 Schematic illustration of age forming: (a) Loading; (b) Aging; (c) Unloading

Tensile specimens were machined along the rolling direction of alloy after age forming or artificial aging. Tensile test was carried out at room temperature and the velocity of the crosshead was 1 mm/min. In addition, standard compact tension specimens were prepared along T-L and L-T directions, respectively, to test the fracture toughness. The first letter denotes the normal direction of crack surface, and the second letter signifies the crack propagation direction. L direction is the rolling direction of alloy, and T direction is perpendicular to the rolling direction. Both of tensile properties and fracture toughness were tested by a MTS-810 universal testing machine controlled with electro-hydraulic servo. Samples for TEM observation were initially thinned to 60 μm. Subsequently, the samples were thinned to perforation using a two-jet electropolishing process at -20 ℃ with an electrolyte solution of 25% nitric acid +75% methanol (volume fraction). TEM observation was performed using a Tecnai G220AEM at 200 kV.

3 Results and discussion

3.1 Influence of age forming on microstructure

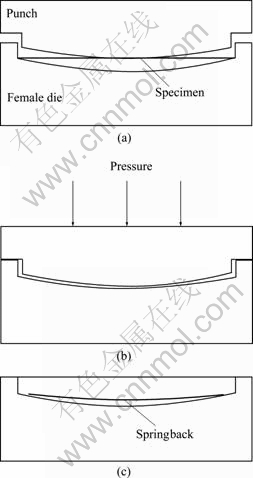

The four-stage precipitation sequence of the ageing of Al-Cu-Mg alloys is as follows: SSS→GPB zone→S′′→S′→S [10], where SSS stands for the supersaturated solid solution. In general, the main precipitated phase of 2A12 aluminum alloy after aging is transient phase S′, and its composition is Al2CuMg [11-13]. The comparison of XRD diffraction patterns between age forming and artificial ageing is shown in Fig. 2. It indicates that the S′ phase precipitates in both age forming and artificial aging. Compared with artificial aging, the number of crystal planes with S′ phase reduces relatively in the alloy after age forming. Furthermore, the total diffraction intensity of S′ phase is also weakened, but it is still detectable.

Fig. 2 XRD patterns of 2A12 aluminum alloy after artificial aging and age forming

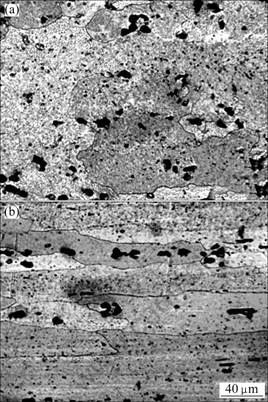

Figure 3 presents the metallographic contrast of 2A12 aluminum alloy between artificial aging and age forming. As the initial 2A12 aluminum alloy plate was as-rolled in this study, the grains shown in Fig. 3 were squashed and elongated along the rolling direction. The microstructures of the artificial aging and age forming present the same characteristic that soluble brown S′ phase particles precipitated in the α(Al) matrix and the large insoluble black impurity phase (FeMn)Al6 distributed along the rolling direction. However, different from the artificial ageing, the grains were further squashed and elongated due to stress relaxation or creep-forming occurred during the age forming.

Fig. 3 OM images of 2A12 aluminum alloy after artificial aging (a) and age forming (b)

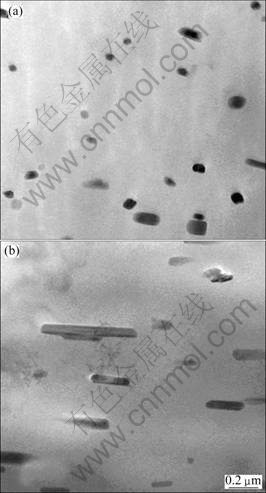

The TEM morphology of the precipitates in 2A12 aluminum alloy after artificial aging or age forming is shown in Fig. 4. The S′ phase in the alloy after artificial aging is in circle shape and evenly distributes with random orientation (Fig. 4(a)), but the S′ phase in the alloy after age forming is in long strip shape with uniform orientation perpendicular to the stress direction (Fig. 4(b)). This is mainly due to the interaction between the external stress and the misfit strain during age forming, which induces preferred orientation of precipitates [14,15]. That is called stress-orienting effect. And ZHU et al [3] also proved that the applied stress makes Al-xCu alloys generate an aligned precipitate structure. YANG et al [16] also demonstrated that the applied stress would affect the morphology evolution of the precipitates in the simulation process of precipitation of the ordered precipitated phase.

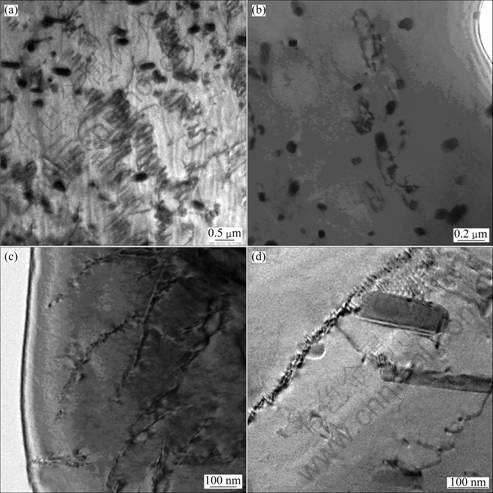

Figure 5 presents the dislocation morphology of 2A12 aluminum alloy after artificial aging and age forming. It is found that a large number of ring dislocations (Fig. 5(a)) and helical dislocations (Fig. 5(b)) exist in the alloy after artificial aging. In comparison, few ring dislocations can be seen and only a lot of long and straight dislocations appear after age forming (Figs. 5(c) and (d)). The alloy after solution treatment contains many clustered vacancies. The collapse of these vacancies produces ring dislocations which are unstable. They grow up quickly and easily change into helical dislocations [17]. So a lot of helical dislocations exist in the alloy after artificial aging. But many long and straight dislocations present in the alloy after age forming and there are few helical dislocations, which may be caused by the applied stress. The dislocation line is a kind of crystal defects, and its energy is proportional to the length. When the dislocation is curve, its length relatively increases, so the energy also increases. Therefore, the curve helical dislocation is unstable and has a tendency to straighten. Under the external load during age forming, the helical dislocation is prone to evolve into the long and straight dislocation gradually. Therefore, it is observed that there is almost no helical dislocation but only a large number of long and straight dislocations in the alloy after age forming.

Fig. 4 TEM images of precipitates in 2A12 aluminum alloy after artificial aging (a) age forming (b)

3.2 Effect of age forming on mechanical properties

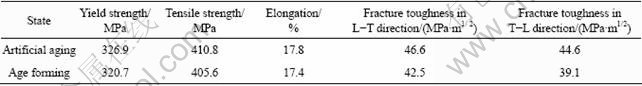

Mechanical tests were carried out on 2A12 aluminum alloy specimens after artificial aging or age forming. As listed in Table 2, age forming slightly decreases the tensile properties and fracture toughness compared with artificial aging. The data in Table 2 indicate that the tensile properties, i.e., the field strength, tensile strength and elongation reduce less than 3%. The alloy, no matter by age forming or by artificial aging, precipitates particles which could cause aging hardening effect. The size, number and distribution of the precipitate particles all have an effect on the tensile properties of the alloy. Microstructure analysis shows that the number of precipitate particles after age forming is basically the same to that of the artificial aging, but the size increases and presents a certain direction. The directional precipitation of precipitate particles after age forming leads to the uneven distribution of precipitated phase, which results in the slightly decrease of the tensile properties. In general, similar tensile properties could be obtained in the age forming process compared with artificial aging, which is similar to the previous results [2]. From Table 2, it could also be found that the fracture toughness either in the L-T direction or T-L direction after age forming is less than that after artificial aging. The directional distribution of precipitated phase after age forming has an adverse effect on slowing the crack growth and the elongation of the alloy is lower. Both the above reasons would cause the decrease of the fracture toughness. Table 2 indicates that the fracture toughness in the L-T direction is larger than that in the T-L direction. This is mainly because the insoluble phase, undissolved phase and inclusion are all arranged in the rolling direction and the grain is also elongated along the rolling direction. In the fracture process, a crack propagation channel is formed along the rolling direction, in which the fracture resistance is small. In the L-T direction, the crack extension track is perpendicular to the rolling direction, and the fracture crack should be deflected many times during the propagation process, and all that contribute to improving the fracture toughness.

Fig. 5 TEM images showing dislocations: (a) Ring dislocation, artificial aging; (b) Helical dislocation, artificial aging; (c) Long and straight dislocation, age forming; (d) Long and straight dislocation, age forming

Table 2 Comparison of mechanical properties of 2A12 aluminum alloy between artificial aging and age forming

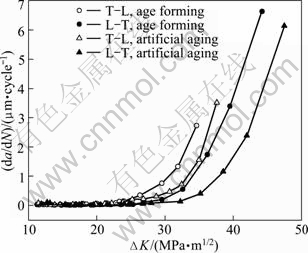

The comparison of the fatigue crack growth rate in 2A12 aluminum alloy between age forming and artificial aging is shown in Fig. 6. The results could be summarized into three aspects. First, the fatigue crack growth rate of the alloy after age forming is consistent with that after artificial aging when DK is less than 25 MPa·m1/2, where ΔK is the stress intensity factor range. Second, the fatigue crack growth rate of the alloy of age forming either in the L-T or T-L direction is higher than that of artificial aging when DK is greater than 25 MPa·m1/2. Third, the fatigue crack growth rate in the T-L direction is higher than that in the L-T direction for alloys in the same state. Those results indicate that the directional precipitation of precipitate particles after age forming reduces the fatigue crack propagation resistance of the alloy and decreases the fatigue properties. The crack source and crack propagation channel are easily formed along the rolling direction, which diminishes the ability of hindering the crack propagation. Because the propagation direction in the T-L direction is parallel to the rolling direction, the fatigue crack growth rate is relatively large in the T-L direction.

Fig. 6 Comparison of fatigue crack growth rate in 2A12 aluminum alloy between age forming and artificial aging

4 Conclusions

1) Compared with the artificial aging, the grains after age forming are further squashed and elongated, and the precipitated phase changes from circle shape to long strip shape with uniform orientation.

2) The dislocation configuration in the alloy of the age forming is quite different from that of the artificial aging. The dislocation mode of the artificial aging is ring or helical, while that of the age forming is long and straight.

3) Age forming slightly reduces the tensile properties of 2A12 aluminum alloy, which is less than 3%.

4) The fracture toughness of the alloy of the age forming is slightly lower than that after artificial aging. And the fracture toughness in the L-T direction is larger than that in the T-L direction for the same state alloys.

References

[1] ZHU A W, STARKE E A Jr. Materials aspect s of age-forming of Al-xCu alloys [J]. Journal of Materials Processing Technology, 2000, 117(3): 354-358.

[2] ZHU A W, CHEN J, STARKE E A Jr. Precipitation strengthening of stress-aged Al-xCu alloys [J]. Acta Mater, 2000, 48: 2239-2246.

[3] ZHU A W, STARKE E A Jr. Stress aging of Al-xCu alloys: experiment [J]. Acta Mater, 2001, 49: 2285-2295.

[4] BAKAVOS D, PRANGNELL P B, DIF R. A comparison of the effects of age forming on the precipitation behavior in 2×××, 6××× and 7××× aero space alloys [J]. Materials Forum, 2004, 28: 124-131.

[5] CHEN Da-qin, LI Shi-chen, ZHENG Zi-qiao, LIU Zu-yao, LI Jian, ZHOU Ming, CHEN Zhi-guo. Simulation of precipitation process of coherent particles I—microstructure evolution [J]. The Chinese Journal of Nonferrous Metals, 2005, 15(12): 1945-1952. (in Chinese )

[6] CHEN Da-qin, LI Shi-chen, ZHENG Zi-qiao, LIU Zu-yao, LI Jian, ZHOU Ming, CHEN Zhi-guo. Simulations of precipitation process of coherent particles II—effect of external stress [J]. The Chinese Journal of Nonferrous Metals, 2006, 16(1): 116-122. (in Chinese)

[7] LI Jian, ZHENG Zi-qiao, CHEN Da-qin, LI Shi-chen, YIN Shun-gao, LIU Zu-yao. Kinetics study on stress aging of Al-Cu alloy [J]. Chinese Journal of Rare Metals, 2005, 29(4): 539-544. (in Chinese)

[8] YANG Pei-yong, ZHENG Zi-qiao, XU Fu-shun, LI Shi-chen, LI Jian, ZHOU Ming. Effect of external stress on kinetics of precipitation and morphologies of precipitates in Al-Cu-Mg alloy with high Cu/Mg ratio [J]. Chinese Journal of Rare Metals, 2006, 30(3): 324-328. (in Chinese)

[9] LI Chao, WAN Min, HUANG Lin. Effect on precipitation phases of 7B04 aluminum alloy during creep process [J]. Journal of Aeronautical Materials, 2009, 29(2): 13-17. (in Chinese)

[10] WANG S C, STARINK M J, GAO N. Precipitation hardening in Al-Cu-Mg alloys revisited [J]. Scripta Materialia, 2006, 54: 287-291.

[11] WILSON R N, PARTRIDGE P G. The nucleation and growth of S′ precipitates in an aluminium-2.5%copper-1.2% magnesium alloy [J]. Acta Metall, 1965, 13(12): 1321-1327.

[12] JENA A K, GUPTA A K, CHATURVEDI M C. A differential scanning calorimetric investigation of precipitation kinetics in the Al-1.53wt%Cu-0.79wt%Mg alloy [J]. Acta Metall, 1989, 37(3): 85-90.

[13] CUISIAT F, DUVAL P, GRAF R. Study on the first stage of decomposition of an Al-Cu-Mg alloy [J]. Scr Metall, 1984, 18(10): 1051-1056. (in French)

[14] LI D Y, CHEN L Q. Shape evolution and splitting of coherent particles under applied stress [J]. Acta Mater, 1999, 47(1): 247-257.

[15] CHEN D Q, ZHENG Z Q, LI S C, CHEN Z G, LIU Z Y. Effect of external stress on the growth of precipitates in Al-Cu and Al-Cu-Mg-Ag alloys [J]. Acta Metallrugica Sinica, 2004, 40(8): 799-804.

[16] YANG Pei-yong, LI Shi-chen, ZHENG Zi-qiao, ZHOU Ming, WANG Dong-lin. Precipitation and coarsening of coherent and ordered second phase during stress aging by using phase-filed simulations [J]. Rare Metal Materials and Engineering, 2007, 8(36): 1341-1345. (in Chinese)

[17] WILSON R N, MOORE D M, FORSYTH P J E. Effects of 0.25% silicon on precipitation processes in an aluminium-0.25% copper-1.2% magnesium alloy [J]. Inst Metal, 1967, 95(6): 177-182.

2A12铝合金时效成形的微观组织和力学性能

陈国清,付雪松,赵 飞,周文龙

大连理工大学 材料科学与工程学院,大连 116085

摘 要:对2A12铝合金进行时效成形和人工时效的对比实验,考察时效成形对其微观组织和力学性能的影响。结果表明:与人工时效相比,时效成形过程中由于应力的存在,使得合金在时效成形后晶粒被进一步压扁、拉长,沉淀相由取向随机分布的点状变为具有一定方向性的长条状,同时其位错形态由位错圈或蜷线位错向长直态位错转变。时效成形后,合金的拉伸性能、断裂韧性均比人工时效时的略有降低,疲劳裂纹扩展速率却有所提高。

关键词:2A12铝合金;时效成形;应力位向效应;力学性能

(Edited by FANG Jing-hua)

Foundation item: Project (NCET-10-0278) supported by the Program for New Century Excellent Talents in University, China; Project (20102024) supported by the Natural Science Foundation of Liaoning Province, China

Corresponding author: CHEN Guo-qing; Tel: +86-411-84707970; Fax: +86-411-84709967; E-mail: gqchen@dlut.edu.cn

DOI: 10.1016/S1003-6326(11)61416-7