High-temperature tribological behaviors of Ti2AlNb-based alloys by plasma surface duplex treatment

WU Hong-yan(吴红艳)1, ZHANG Ping-ze(张平则)2, CHEN Wei(陈 伟)3,

WANG Ling2(王 玲)1, ZHAO Hao-feng(赵浩峰)1, XU Zhong(徐 重)2

1. College of Math and Physics, Nanjing University of Information and Technology, Nanjing 210044, China;

2. College of Materials Science and Technology, Nanjing University of Aeronautics and Astronautics,

Nanjing 210016, China;

3. Testing and Analysis Center, Institute for Non-ferrous Metal Research Co., Ltd., Suzhou 215026, China

Received 16 September 2008; accepted 17 January 2009

Abstract: Plasma tungstening followed by carburization (W-C duplex treatment) was performed on the Ti2AlNb-based (O phase) alloy by using the double glow plasma process to enhance its wear resistance. The microstructure and high-temperature tribological behaviors of the un-treated and W-C duplex-treated samples were investigated. The results show that the duplex-treated layer is mainly composed of W2C or W6C2.54 phases and the contents of W and C elements in the alloyed layer change gradually along the depth by surface plasma duplex treatment. The diffusion depth of W is about 12 μm, while the carbon atoms most exist in the depth more than 12 μm. High temperature tribometer tests indicate that the friction coefficient of the W-C duplex-treated layer is approximately 1/6 that of substrate. The wear rate of the duplex-treated layer is about 28% that of the untreated one. So, plasma surface W-C duplex treatment can obviously improve the high-temperature tribological resistance of Ti2AlNb-based alloy. The tribological mechanism of the duplex-treated layer is discussed by dividing the friction process of the duplex-treated layer into three fluctuate stages. The first stage is the formation of oxide film between W-C duplex-treated layer and counterface. The second stage is the detachment of oxide film, acting as “the third body”. The last stage is the period that the friction and wear occur between the compact particle layer and counterface.

Key words: Ti2AlNb-based alloy; W-C duplex treatment; friction; wear

1 Introduction

BANERJEE and NANDY[1] identified a ternary intermetallic based on the stoichiometric Ti2AlNb which was designated as the O phase on the basis of its orthorhombic structure with Cmcm symmetry in 1988. Ti2AlNb-based alloys have been one of the potential materials in aeronautics and astronautics industries due to their high specific strength and stiffness, and high creep as well as oxidation resistance[2-4]. However, poor wear resistance becomes a principal obstacle for preparing tribological components, e.g., shafts and blades in gas turbines, engine valves, and turbochargers [5-6]. To improve their tribological performance, surface modification is an effective and economical method. The double glow plasma surface alloying process, known as Xu-Tec process, is an effective method to improve the surface performance of metals or alloys, such as micro-hardness, wear resistance, and oxidation resistance [7-8].

A previous study indicated that plasma surface- chromized layers on Ti2AlNb alloys can obviously improve the room-temperature and high-temperature oxidation resistances[9]. Tungsten is the main hardmetal composition which is commercially available for coating applications[10]. As Ref.[11] showed, W occupation in Ti sublattice in Ti2AlNb-based alloy led to the change of electron structures. It was predicted that W occupation in Ti sublattice can mainly form Ti-W phase in Ti-Al-Nb system based on empirical electron theory of solid and molecule. It was revealed that addition of W element into Ti2AlNb-based alloy can contribute to the improvement of wear resistance of substrate. Carbon with the smaller atom size can diffuse into the deep location to achieve the WxC1-x/C coating, besides forming W-C phases with tungsten element. The coating was chosen for its low friction characteristics, high relative hardness, low surface energy, and therefore, was expected to reduce adhesive and abrasive wear[12]. So, the plasma surface W-C duplex treatment (carburization following plasma tungstening) was presented in this work. The treatment was performed by the double glow plasma surface alloying process. The tribological mechanisms of WxC1-x/C coating were also discussed.

2 Experimental

2.1 Preparation of materials

The solid solution-treated and aged Ti-22Al-25Nb with composition (mass fraction) of 47% Ti, 10.82%Al and 42.12%Nb was used as the substrate. Before the experiment, specimens (10 mm×10 mm×5 mm) were mechanically polished with Ra below 0.05 μm, then cleaned with acetone and dried.

W (d 100 mm×5 mm) plate with purity of 99.9% was prepared by powder metallurgy method. The high purity graphite plate was manufactured into alveolar shape. They were used as the source electrode for supplying alloying elements.

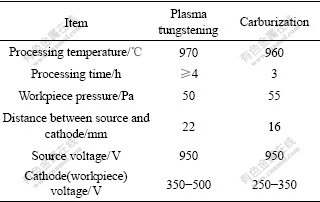

The principle of the double glow plasma surface alloying is as follows. There are anode, negatively charged cathode (workpiece) and source electrode in a vacuum chamber. The source electrode is made of the desired alloying elements which are introduced into the surface of the workpiece to form alloy layer. The work- piece is fixed on a hearth support inside a double walled, water cooled vacuum chamber, connected to vacuum pump system and a gas supply. The tank is evacuated to a pressure of about 5×10-2 Pa and then filled with argon to 20-50 Pa. Two high voltage DC power supplies are used for generation of glow discharges. One is connected between anode and cathode and another between anode and source electrode. When the two power supplies are turned on, both cathode and source electrode are surrounded by glow discharge. One glow discharge heats the work piece and another strikes the source electrode. With the bombardment of the ions or atoms, the desired alloying elements sputtered from the source electrode diffuse into the surface of the workpiece to form alloy layer on the surface of workpiece. The parameters of plasma duplex treatment are listed Table 1.

Table 1 Process parameters of plasma W-C duplex treatment

2.2 Microstructure analysis

The phases of surface-alloyed layers were determined by a Rigaku Y-Q4 X-ray diffractometer (XRD), using Cu Kα radiation over the range from 10? to 90?. The cross-section was ground by SiC paper and polished by diamond paste, then etched in a solution of 7% HNO3 and 0.6% HF (volume fraction). The morphology of the cross-section was observed observed by scanning electron microscope(SEM) with energy dis-persive spectrometer (EDS).

2.3 Friction and wear test

Sliding friction tests were conducted with substrate and W-C duplex-treated samples using HT-500 ball-on- disk tribometer in air at high temperature of (500±4) ℃ and relative humidity of (45±5)% under dry sliding condition. Silicon nitride (Si3N4) balls with the average hardness of HRC77 and a diameter of 3 mm were used as the counterface material. The tests were conducted at a speed of 560 r/min for 10 min with a load of 1.76 N. The rotating radius was 15 mm. The friction coefficients were recorded during sliding test and the wear volumes of the specimens were calculated. The wear resistance was evaluated by wear rate and worn morphologies, of which the wear rate was measured using the surface coarseness profiling instrument (TR-200, Beijing Times, China) and the worn morphologies was analyzed using optical metallography.

Wear rate and wear volume of the samples were calculated as described by MIAO et al[13] and presented below:

K=V/(P?s) (3)

V=πrh(3h2+4w2)/3w (4)

where K is the specific wear rate; V is the wear volume; P is the load; s is the sliding distance; r is the rotating radius; h is the depth of wear track and w is the width of wear track.

3 Results and discussion

3.1 Microstructure and phase distribution

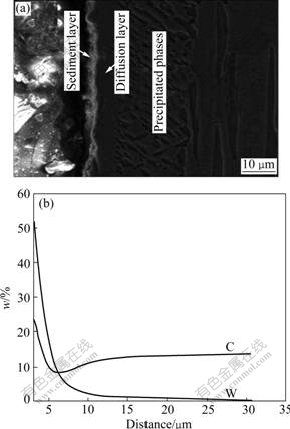

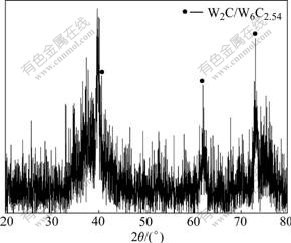

Fig.1(a) shows the SEM image of WxC1-x/C duplex coating, which is composed of sediment layer and diffusion layer. There is no obvious phase interface, which is different from Cr-C duplex-treated layer[14]. Sediment layer is dominated by W element, and diffusion layer mainly exists in the form of WxC1-x. A lot of banding phases precipitate near the diffusion region, dominated by carbon element. Because W is a strong carbide forming element and carbon atoms hinder the inward diffusion of tungsten carbide, the alloyed layer is thinner, about 12 μm. The inward diffusion of redundant carbon atoms with small atomic radius leads to the coexistence of pure carbon, titanium-carbon and niobium-carbon. It can be seen from Fig.1(b) that the diffusion depth of W is about 12 μm, while the diffusion path of carbon atoms is more than 12 μm. Fig.2 shows that the alloyed layer mainly consists of W2C or W6C2.54. The good wear resistance is a result of the alternating tungsten carbide and carbon phases in layers of a few atoms thick, which can also provide good running-in characteristics[12].

Fig.1 SEM morphology of WxC1-x/C duplex coating (a) and content distribution of W and C element (b)

Fig.2 X-ray diffraction pattern of WxC1-x/C duplex coating

3.2 High-temperature friction and wear properties

Effect of temperature on friction coefficient is closely related to the change in surface layer. A great amount of experimental results showed that friction coefficient increased as the temperature increased. When the high surface temperature softened the surface material, friction coefficient decreased[15].

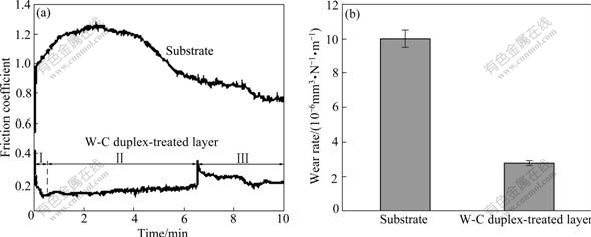

Fig.3(a) shows the friction coefficients for substrate and the duplex-treated layer varied with sliding distance at high temperature. Fig.3(b) shows wear rates of untreated and W-C duplex-treated samples.

Fig.3 Friction coefficient (a) and wear rate (b) of substrate and W-C duplex-treated layer under high temperature

It can be seen from Fig.3(a) that friction coefficient of W-C duplex-treated layer remains at 0.1-0.3 and has three fluctuating stages, while the friction coefficient of the substrate rapidly increases from 0.6 to 1.3, and then decreases. Compared with the former, the friction coefficient of the substrate is much larger.

As shown in Fig.3(b), the wear rate of the duplex-treated layer (2.8×10-6mm3/(N?m)) is about 28% that of substrate (10.0×10-6mm3/(N?m)). The result indicates that the surface duplex treatment can improve the wear resistance of the materials.

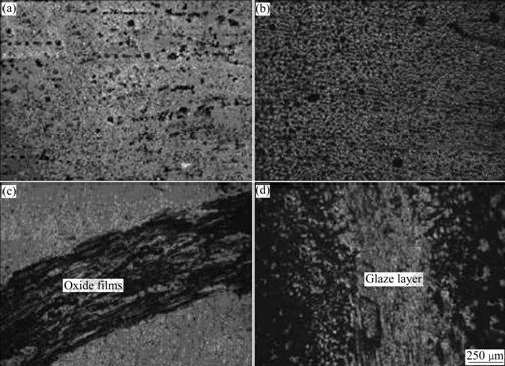

Figs.4(a) and (b) show the surface morphologies of un-treated and duplex-treated samples, respectively. It can be seen that the surface of the duplex-treated layer exhibits amounts of precipitation like fine black particles. Different initial surface morphologies have a significant effect on the wear results.

Fig.4 Surface morphologies and surface worn morphologies of substrate (a, c) and W-C duplex-treated layer (b, d), respectively

From the worn morphologies at high temperature (Figs.4(c) and (d)), the wear track of the W-C duplex-treated layer is more shallow than the substrate. The higher hardness of W-C duplex-treated films supports the lubricous film, so the oxide films are less destroyed[16]. The wear debris is formed during friction and presents along the sides of wear track. Some of the wear particles are extruded from the track[17] (as shown in Fig.4(d)). Friction occurs between Si3N4 and the duplex-treated layer. The tungsten carbides of the duplex-treated layer possess good high-temperature abrasive wear resistance because of their high hardness, unique strong atomic bonds and high-stability under high temperature exposure [18-19].

In addition, the hard coating (WxC1-x/C coating) of the duplex-treated Ti2AlNb increases the yield strength of the contact surface in the substrate/coating system and effectively reduces the tangential stresses and the interfacial stresses [20].

3.3 Friction mechanisms of duplex-treated layer

It is shown in Fig.3(a) that initial friction coefficient is relatively high and decreases gradually in the first stage. Further increase of the sliding time causes the formation of oxide film on the W-C duplex-treated layer, which plays a key role in lubricant. With the softening and detachment of oxide scale, the wear debris is formed, some of which act as “the third body”, others are extruded from the track by the maximum shearing force appearing in the friction process and the friction coefficient increases (the second stage). With the sliding time increases, the wear debris is involved in the formation of load-bearing layer, which is helpful to the friction reduction [21]. The friction coefficient decreases and becomes stable (the third stage). The three fluctuating stages of friction coefficient at high temperature (Fig.3(a)) is due to the formation of oxide films, the detachment of oxide films and the formation of load-bearing layer[22].

4 Conclusions

1) The duplex-treated layer is mainly composed of W2C or W6C2.54 phase. The contents of W and C elements in the alloyed layer decrease gradually along the depth direction. The diffusion depth of W is about 12 μm, while the carbon atoms diffuse much more deeply.

2) The friction coefficient of the W-C duplex-treated layer is approximately 1/6 that of the substrate. The wear rate of the former is about 28% that of untreated one. This indicates that the surface duplex treatment can improve the wear resistance of the materials.

References

[1] BANERJEE D, NANDY T K. A new ordered orthorhombic phase in a Ti3Al-Nb alloy [J]. Acta Metall, 1988, 36(4): 871-882.

[2] GERMANN L, BANERJEE D, GU?DOU J Y, STRUDEL J L. Effect of composition on the mechanical properties of newly developed Ti2AlNb-based titanium aluminide [J]. Intermetallics, 2005, 13(9): 920-924.

[3] NANDY T K, BANERJEE D. Creep of the orthorhombic phase based on the intermetallic Ti2AlNb [J]. Intermetallics, 2000, 8(8): 915-928.

[4] MAO Yong, LI Shi-qiong, ZHANG Jian-wei, PENG Ji-hua, ZOU Dun-xu, ZHONG Zeng-yong. Study on microstructure and mechanical properties of Ti-22Al-20Nb-7Ta intermetallic alloy [J]. Acta Metall Sinica, 2000, 36: 135-140.

[5] YANGA S J, NAMA S W, HAGIWARAB M. Investigation of creep deformation mechanisms and environmental effects on creep resistance in a Ti2AlNb based intermetallic alloy [J]. Intermetallics, 2004, 12(3): 261-274.

[6] MIYOSHI K, LERCH B A, DRAPER S L. Fretting wear of Ti-48Al-2Cr-2Nb [J]. Tribol Inter, 2003, 36(2): 145-153.

[7] LIU Xiao-ping, XU Zhong, XU Wei. Plasma surface alloying with molybdenum and carburization of TiAl based alloys [J]. Trans Nonferrous Met Soc China, 2005, 15(3): 420-424.

[8] XU Zhong, GAO Yuan. Plasma surface metallurgy technology [J]. J Adv Mater, 2002, 34(3): 32-38.

[9] WU Hong-yan, ZHANG Ping-ze, LI Jiang-liang, MA Shi-jian, XU Zhong. Microstructures and tribological properties of surface plasma chromising on Ti2AlNb-based alloy [J]. The Chinese Journal of Nonferrous Metals, 2007, 17(10): 1650-1660. (in Chinese)

[10] ASHOK K S, KARABI D. Microstructure and abrasive wear study of (Ti,W)C-reinforced high-manganese austenitic steel matrix composite [J]. Mater Lett, 2008, 62: 3947-3950.

[11] WU Hong-yan, ZHANG Ping-ze. Effect of W occupation on electronic structures and properties of Ti2AlNb-based alloy [J]. Rare Metal Mater Eng, 2007, 36: 846-848.

[12] TIMOTHY A, SOLZAK A, POLYCARPOU A. Tribology of WC/C coatings for use in oil-less piston-type compressors [J]. Surface and Coatings Technology, 2006, 201(7): 4260-4265.

[13] MIAO Qiang, CUI Cai-e, PAN Jun-de, DUAN Liang-hui, LIU Xiao-ping. Tribological behavior of magnesium alloy AZ91 coated with TiN/CrN by arc-glow plasma depositing [J]. Chinese Journal of Aeronautics, 2006, 19(3): 266-270.

[14] WU Hong-yan, ZHANG Ping-ze, LI Jiang-liang, HUSSAIN G, XU Zhong. The friction and wear properties of Ti-Al-Nb intermetallics by plasma surface alloying [J]. Tribol Lett, 2008, 30(1): 61-68.

[15] JEON G H, JOO S Y, KIM H J, SONG K. High temperature wear resistance of (TiAl)N films synthesized by cathodic arc plasma deposition [J]. Surf Coat Technol, 1996, 86/87(1/3): 82-87.

[16] STOTT F H. High temperature sliding wear of metals [J]. Tribol Inter, 2002, 35: 489-495.

[17] KIRAKOSYAN K G, MANUKYA K V, KHARATYAN S L. Synthesis of tungsten carbide-carbon nanomaterials by combustion reaction[J]. Mater Chem Phys, 2008, 110: 454-456.

[18] ZHANG D W, LEI T C, LI F J. Laser cladding of stainless steel with Ni-Cr3C2 for improved wear performance [J]. Wear, 2001, 251: 1372-1376.

[19] ZHANG D W, LEI T C. The microstructure and erosive-corrosive wear performance of laser-clad Ni-Cr3C2 composite coating [J]. Wear, 2003, 255: 129-133.

[20] WANG Y, QIAN Z, LI X Y. Sliding wear properties of TiAl alloys with/without TiN coatings [J]. Surf Coat Technol, 1997, 91(1/2): 37-42.

[21] PETERSON M B, LI S Z, MURRAY S F. Wear-resisting oxide films for 900 ℃ [J]. Mater Sci Technol, 1997, 13: 99-106.

[22] STOTT F H. The role of oxidation in the wear of alloys [J]. Tribol Inter, 1998, 31(1/3): 61-71.

Foundation item: Project supported by the Scientific Research Foundation of Nanjing University of Information and Technology, China

Corresponding author: ZHANG Ping-ze; Tel: +86-25-52112904-83132; E-mail: pzzhang@nuaa.edu.cn

DOI: 10.1016/S1003-6326(08)60417-3

(Edited by YANG Bing)