文章编号:1004-0609(2010)S1-s0709-04

Ti-1023合金d 350 mm棒材的锻造工艺

董 洁,王韦琪,李渭清,张 辉,王小龙,白文辉,田 莉

(宝鸡钛业股份有限公司,宝鸡 721014)

摘 要:通过2种方案试制d350 mm Ti-1023合金棒材,分析2种方案生产的棒材横、纵向组织,力学性能和探伤结果的差异。研究结果表明:铸锭开坯及中间锻造采用1次“高低高”锻造,成品锻造在相变温度以下35~50 ℃进行,变形量大于60%;在该锻造工艺下,可生产出满足X/BS5116标准要求的棒材,且棒材的组织均匀性好。

关键词:Ti-1023合金;大规格棒材;锻造工艺;力学性能;显微组织;β斑

中图分类号:TG146.2+3 文献标志码:A

Forging process of d 350 mm bars of Ti-1023 alloy

DONG Jie, WANG Wei-qi, LI Wei-qing, ZHANG Hui, WANG Xiao-long, BAI Wen-hui, TIAN Li

(Baoji Titanium Industry Co. Ltd., Baoji 721014, China)

Abstract: The d350 mm bars of Ti-1023 were manufactured by two solutions, the discrepancies of the microstructures in transverse and longitudinal, the mechanical properties and ultrasonic test results of two bars were analyzed. The results show that in the forging processes, i.e., the breakdown of ingot and intermediate forging adopt “high-low-high” at a time, and the forging of finished products is performed at 35-50 ℃ below the transition temperature and the distortion is greater than 60%. The bars produced can meet the mechanical properties in X/BS 5116 with good homogeneity of structure.

Key words: Ti-1023 alloy; large-sized bars; forging process; mechanical property; microstructure; β spot

Ti-1023作为一种高强高韧近β型钛合金,可以在315 ℃以下使用,是常用的飞机结构材料之一,具有比强度高、断裂韧性高、淬透截面大、各向异性小、锻造温度低等优点,有利于进行等温锻造,且性能可通过锻造之后的热处理工艺调节[1],是一种有应用前景的钛合金。大型飞机的发展对原材料棒材的尺寸、性能和组织要求也越来越高。在此,本文作者对d350 mm大规格棒材的组织均匀性、β斑和各项力学性能进行研究。

1 实验

实验采用工厂生产的Ti-1023铸锭,锭型为d720 mm,锭质量为3 000 kg,是目前世界最大锭型的Ti-1023铸锭。铸锭经3次真空自耗电弧炉熔炼,化学成分(质量分数)为:Al 2.9%~3.3%,V 9.5%~10.5%,Fe 1.6%~2.0%,C 0.02%~0.031%,N低于0.03%,O 0.08%~0.11%,余量为钛。(α+β)/β相的转变温度为790~810 ℃。试验按A和B 2种方案进行。

方案A:铸锭开坯采用镦—拔工艺,开坯锻造后经过二次“高低高”锻造,而后在相变点以下20~40 ℃采用拔长变形,变形量为40%~60%,锻至d 350 mm成品棒材。

方案B:铸锭开坯采用镦—拔工艺,开坯锻造后经过1次“高低高”锻造,而后在相变点以下35~50 ℃采用拔长变形,变形量为60%~80%,锻至d350 mm成品棒材。

2 结果与分析

2.1 变形工艺对力学性能的影响

对经过2种工艺锻造的棒材,各取一套纵向和横向拉伸试样和断裂韧性试样,其力学性能如表1所示。热处理制度为:(760 ℃, 2 h, WC)+(530 ℃, 8 h, AC)。

从表1可以看出:方案A的横向塑性没有完全达到指标要求;且横、纵向数值差异较大,边部KIC没有达到指标要求。方案B的棒材各项性能指标均符合相关指标的要求,且横、纵向的强度差异小,各点性能均匀性好。从2种工艺试制棒材力学性能看,总体上,方案B的综合性能优于工艺A的综合性能。这是因为方案A进行了2次“高低高”锻造,损失了部分两相区变形量,致使塑性指标偏低。方案B减少1次“高低高”锻造,保证了相变点以下变形量为60%~80%,变形充分,各处的变形较均匀。

2.2 变形工艺对组织的影响

2.2.1 对低倍组织的影响

2种工艺方案均采用铸锭开坯镦拔和“高低高”锻造工艺,利用近β合金的β基体在快速完成再结晶时晶粒长大很缓慢这一加工特性,使金属的晶粒处于反复破碎、亚晶粒合并长大和晶界迁移过程中,最终棒材组织趋于均匀一致[2]。工艺区别在于成品锻造时,两相区锻造变形量和温度不同。2种工艺的低倍组织如图1所示。从图1可以看出:方案A的低倍组织为

图1 方案A和方案B的低倍组织

Fig.1 Macrostructures of bars by process A(a) and B(b)

表1 棒材的力学性能

Table 1 Mechanical properties for bars

均匀、半清晰晶,方案B的低倍组织为均匀、半模糊晶。2种方案的低倍组织都较均匀,无β斑。

2.2.2 对高倍组织的影响

在OLYMPUS GX71金相显微镜下观察Ti-1023合金d350大规格棒材从中心至边部5个点经(760 ℃, 2 h, WC)+(530 ℃, 8 h, AC)固溶时效处理后的显微组织形貌。2种工艺的高倍组织如图2所示。

从图2可以看出:方案A中各点横、纵向显微组织差异较大,横向组织为时效β基体+球状、针状初生α组织,纵向组织为β基体+长条初生α组织,且有一定的趋向性。方案B中的横、纵向显微组织差异不大,均为时效β基体+球状、针状初生α组织。这是由于方案B两相区变形量较充分,变形均匀。

2.2.3 对β斑的影响

Ti-1023合金β斑形成的主要原因为合金Fe成分的偏析富集,由于合金材料的局部偏析富集而造成此部分β转变温度与基体的温度相比下降,从而形成一种初生α相含量少,甚至不含初生α相的区域,这一区域即所谓的β斑。

Ti-1023合金铸锭Fe成分不均匀是形成β斑的“先天”因素,后续的热加工和热处理制度是影响β斑产生的“后天”因素。从以往的研究可知:一般存在β斑的区域,其相变温度比正常区域的温度低20~30 ℃。图3所示是2种工艺方案在774 ℃, 2 h, WC下β斑显微组织照片。

从图3可以看出:方案A的贫α区虽面积没有超过0.58 mm2(β斑定义区),但有发展成为β斑的趋势。这主要是由于两相区变形锻造温度略偏高,没有完全避开产生β斑的锻造温度区间。方案B无明显β斑,这是由于方案B采取在相变温度以下30~40 ℃进行

图2 方案A和方案B的高倍组织

Fig.2 Microstructures of bars by process A and B: (a) Process A, center T; (b) Process A, center L; (c) Process B, center T; (d) Process B, center L; (e) Process A, 1/2R T; (f) Process A, 1/2R L; (g) Process B, 1/2R T; (h) Process B, 1/2R L; (i) Process A, edge T; (j) Process A, edge L; (k) Process B, edge T; (l) Process B, edge L

图3 方案A和方案B的β斑显微组织

Fig.3 β spots of bars by process A(a) and B(b)

变形,在锻造中避免由于β斑的存在导致棒材的显微组织均匀性不好的情况。

2.3 变形工艺对探伤水平的影响

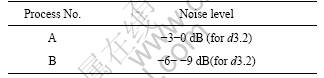

分别对2种工艺得到的成品棒材按GB5193进行超声检验,采用CTS-23B型探伤仪,用5PΦ20探头,并采用接触法检验。具体的杂波水平评判结果见表2所列。

表2 杂波水平评判结果

Table 2 Testing result of noise level

杂波是组织不均匀性的反映[3]。从表2可以看出:方案B的杂波水平高于方案A的杂波水平,这是方案B变形温度低、变形充分、组织均匀所致,与显微组织结果一致。

3 结论

1) 采用方案A锻造的Ti-1023 d350棒材,横向塑性值和边部KIC没有达到指标要求。方案B生产的锻棒各项力学性能都符合标准要求,且横、纵向的强度差异小,各点性能均匀性好。

2) 采用方案A生产的锻棒,低倍组织为均匀、半清晰晶,高倍组织为时效β基体+条状、针状初生α组织,纵向组织有一定的趋向性,无β斑。由方案B生产的锻棒低倍组织为均匀、半模糊晶,高倍组织均为时效β基体+球状、针状初生α组织,横、纵向显微组织差异不大,无β斑。采用这2种方案生产的棒材金相组织都满足标准要求。

3) 由方案A生产的锻棒探伤杂波水平为-3~ 0 dB(对d3.2)。方案B生产的锻棒探伤杂波水平可达到-6~ -9 dB(对d3.2)。

4) 铸锭开坯及中间采用1次“高低高”锻造,成品锻造在相变温度以下35~50 ℃进行,变形量大于60%的锻造工艺,可生产出满足X/BS5116标准性能要求的棒材,且棒材的组织均匀性好。

REFERENCES

[1] ALEXANDER J D. 宇航材料的锻造和性能[M]. 贺开运, 孙荣科, 袁瑞琛, 等译. 北京: 国防工业出版社, 1977: 300.

ALEXANDER J D. Forging and properties of aerospace materials[M]. HE Kai-yun, SUN Rong-ke, YUAN Rui-chen, et al, transl. Beijing: National Defense Industry Press, 1977: 300.

[2] 亚历山大B K, 等. 钛合金半成品加工[M]. 宁兴龙, 等译. 西安: 冶金工业出版社, 1984: 153.

[3] 胡宗式. 合金超声探伤中杂波与组织的关系[C]//第11届全国钛及钛合金学术交流会文集. 沈阳, 2002: 670.

HU Zong-shi. Relationship between hybrid wave and structure in ultrasonic detecting damage for alloy[C]//Proceeding of the 11th National Conference on Titanium and Titanium Alloys. Shenyang: Liaoning Science and Technology Press, 2002: 670.

(编辑 陈灿华)

通信作者:董 洁;电话:0917-3386921;E-mail: dongjiecool@163.com