文章编号: 1004-0609(2005)05-0716-05

金属铝粉表面纳米膜包覆

杨 毅, 李凤生, 刘宏英

(南京理工大学 化工学院, 南京 210094)

摘 要: 采用扫描电镜、 透射电镜和X射线光电子能谱仪对包覆有纳米膜的复合金属铝粉进行分析, 发现纳米包覆膜的厚度为10nm左右; 金属粉的比表面积(BET)由包覆前的1.46m2/g, 包覆后增加到13.74m2/g, 提高了粉体的分散性; 包覆后的铝粉孔径—孔容图呈很好的光滑曲线, 表现出良好分散颗粒的孔径—孔容分布特征。 热分析研究表明, 包覆后的铝粉热量释放更大、 更快速、 更集中, 适合于固体推进剂所要求的能量释放特点。

关键词: 金属铝粉; 纳米材料; 包覆技术; 复合技术 中图分类号: O614; TB533

文献标识码: A

Al powder coated with nanometer film

YANG Yi, LI Feng-sheng, LIU Hong-ying

(School of Chemical Engineering, Nanjing University of Science and Technology,

Nanjing 210094, China)

Abstract: Nanometer film, which may catalyze the heat decomposing of ammonia perchloride, is coated on activated Al powder to improve the energy and combustion property of Al powder in solid propellant. It may increase the content of active Al of high-energy propellant contained the composite Al powder. Scanning electric microscopy and transmission electric microscopy are employed to analysis the composite Al powder coated with nanometer film. It indicates that the film uniformly coats on micrometer Al powder, and thickness of the film is about 10nm. The specific area of Al powder is increased from 1.46m2/g to 13.74m2/g after coated with nanometer film. The thermal gravimetric analysis results show that the heat release of composite Al powder is faster, more concentrative and the released energy is much higher than that of raw Al powder. These features have a good agreement with the energy release characteristics of high-energy propellant.

Key words: aluminum powder; nanometer materials; coating technique; compounding technique

高能固体推进剂中通常需要加入大量的超细金属铝粉, 以提高推进剂燃烧时的能量及对火箭的推动力[1]。 但是金属的表面十分容易氧化, 特别是活泼金属粉末的表面更容易形成氧化层。 而对于微米级或纳米级的活泼金属铝来说, 由于其比表面很大, 暴露在外(如与空气或其他氧化物接触)的表面原子个数和比例都很大, 这些暴露在外的表面原子十分容易与氧结合而被氧化。 因此, 超细化特别是微米或纳米级的各种金属粉, 尤其是活泼性很强的铝粉, 其氧化物含量占有很大的比例[2-5]。 含有较大比例氧化物的金属粉添加到固体推进剂中后, 非常不利于推进剂能量和燃烧性能的提高。 因为这样的金属氧化物不但在高能推进剂燃烧时不会做功或释放能量, 而且在火箭加速阶段作为惰性成分占有一定的质量份额, 从而直接影响火箭速度的提高和缩短航程; 同时, 由于在火箭推进剂燃烧的过程中整个体系温度会急剧、 快速地上升, 这些惰性物质也会随着体系温度的升高而吸收一定的热量(能量), 因而间接增加了火箭发动机的负荷(以获得催化和稳定固体推进剂燃烧而额外添加的氧化物除外)。 同时, 大量研究发现, 固体推进剂组分中所含有的铝粉在燃烧时其实有较大比例并没有完全燃烧, 即固体推进剂中金属粉的燃烧性能不好。 吕等[6]采用在金属粉表面包覆一层高聚物的方法, 发现其燃烧特性有很大的提高。 但是, 相对推进剂中各种高能物质而言普通高聚物的能量性能较差, 而且对固体推进剂其他组分(除被包覆铝粉外)的燃烧几乎没有促进(催化)作用, 因而在实际应用中具有一定局限性。

采用将纳米材料与微米材料进行复合的技术, 既可以提高纳米材料的分散性及催化作用效果等方面的特性, 还可以使微米材料的实用性得到改善, 并有望获得两种材料在包括催化作用在内的多种功能上的协同作用[7-9]。 为了解决微米金属铝粉在燃烧能量和燃烧性能的问题, 本文作者自行合成了一种物质, 采用湿化学法将这种物质的反应物以纳米膜的形式包覆在微米级金属铝粉表面, 防止了铝粉表面的再氧化问题。 这种纳米膜物质对高氯酸铵(Ammonium perchloride, AP)的热分解具有明显的催化作用, 而AP在固体推进剂中含量可高达75%以上。 同时, 通过包覆处理后的复合金属粉的燃烧情况也发生了变化, 更有利于推进剂能量的释放和提高推进剂的做功能力。 获得了一种既对AP热分解具有催化功能, 又自身含有很高能量的金属复合材料。

1 实验

1.1 原料及仪器

实验原料主要有: 微米金属铝粉(中位粒径d50为5~10μm), 异丙醇(分析纯), 自行合成的有机物A3。

实验仪器主要有: 德国1530vp型扫描电子显微镜(SEM), 日本H-800型透射电子显微镜(TEM), 美国SA3100型比表面测试仪(BET), 美国ESCA5300型X射线光电子能谱仪(XPS), 日本DTA-50型差热分析仪(DTA), 日本TGA-50型热重分析仪(TGA)。

1.2 实验过程

将微米金属铝粉分散到稀酸溶液中进行氧化膜去除处理, 然后迅速将活化后的金属铝粉超声分散到装有异丙醇的真空容器里, 控制温度和搅拌速度, 滴加自行合成的有机物A3, 保温一定时间, 通过化学法获得纳米膜包覆的复合金属铝粉。

2 结果与讨论

2.1 样品的SEM及TEM照片分析

使用扫描电子显微镜对包覆前后的金属铝粉进行了分析, 从样品的SEM照片(图略)可以看到, 包覆前的原料铝粉颗粒呈表面光滑的球形, 而经过包覆处理后的复合铝粉颗粒表面变得相对粗糙, 表明颗粒表面已经包覆上了一层新的物质。 由于固体推进剂中的主要组分之一的高氯酸铵(AP)是一种强氧化剂, 如果不对推进剂中的超细金属铝粉进行包覆处理, 在推进剂放置过程中就会加深对铝粉的氧化, 使其能量性能发生大幅度的下降。 通过这层膜物质的包覆, 可以在很大程度上避免氧与金属颗粒的接触, 防止金属粉的氧化。 同时, 粗糙的表面可以使之与推进剂的其他组分接触面更大, 加强组分之间的接触紧密程度, 提高推进剂的力学性能; 膜物质的粗糙表面还可以形成更多的催化活性点, 有利于在燃烧时对推进剂组分(如AP等)发挥更好的催化分解作用。

图1和图2所示分别为铝粉包覆前后的TEM照片。 对比两图可看出包覆后粒子表面有一层明显的透明光晕, 这是包覆铝粉表面所形成的纳米包覆膜, 充分体现出了纳米材料的这种特殊光学现象。 在实验过程中, 随着有机物A3在异丙醇中反应的缓慢进行, 反应产物就以活化铝粉为核, 逐渐在其表面形成了一层包覆膜。 从图中可以看到, 纳米膜的厚度大约在10nm左右, 这与一般金属铝粉表面的氧化膜厚度相当[10]。

图1 原料铝粉的TEM照片

Fig.1 TEM photo of raw Al powder

图2 复合铝粉的TEM照片

Fig.2 TEM photo of coated Al powder

2.2 复合金属铝粉的XPS分析及BET测试

为了了解纳米膜对金属铝粉的包覆情况, 对复合金属粉进行了XPS成分分析。 首先将纳米膜包覆的复合铝粉压制成小薄片, 然后进行XPS粉末溅射检测。 对样品的表面元素分析表明, 铝与包覆膜特征元素的摩尔分数分别为1.35%和98.65%。 随着X射线对压片粉体表面溅射深度的加深, 两种物质量的比例发生了明显的变化, 即包覆膜的特征元素的比例下降, Al的比例增加, 表明表面包覆很成功。

采用美国Coulter公司生产的比表面测试仪, 以氮气吸附法对原料铝粉和包覆后的铝粉进行了比表面积测试, 发现两者的BET比表面积分别为1.46m2/g和13.74m2/g。 包覆后的铝粉的比表面积有明显的提高, 表明经过包覆处理后铝粉的分散性得到了很大改善, 有利于提高纳米催化粒子的沉积复合和纳米复合粒子在固体推进剂中的分散均匀性。

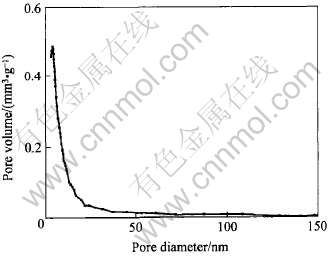

通过测试包覆前后铝粉的孔容、 孔径分布情况(如图3和图4所示), 发现两者的孔容分别为4.8mm3/g和7.3mm3/g。 包覆前后的孔容并没有发生明显的变化, 表明包覆层是以纳米膜的形式存在的, 而未形成多孔的包覆状态。 对比两者的孔径—孔容分布曲线可以发现, 包覆前铝粉的孔径分布曲线呈曲折的趋势线, 这是由于金属铝粉有一定程度团聚的原因。 颗粒团聚形成的孔与松散堆积的孔在孔容的量上进行叠加, 从而表现在某一孔径范围内的孔容发生突跃, 出现局部孔容增加的现象, 使原本松散堆积情况下孔径—孔容曲线平滑的趋势发生变化。 而包覆后铝粉的孔径—孔容分布是平滑的分布曲线, 表明颗粒的分散状态得到了很大的提高, 从包覆后铝粉孔容的微量增加也可以间接说明一点。 另外, 虽然包覆前铝粉由于团聚在某一孔径的局部范围内有增加的现象, 但在总的孔容量上却由于分散不好而偏低。 这与包覆前后铝粉比表面积的变化情况相一致。

2.3 金属铝粉复合前后的热重分析

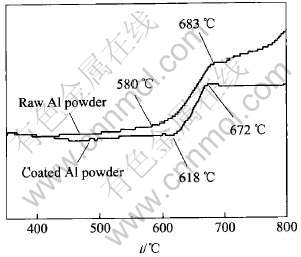

将样品装在刚玉陶瓷坩埚内, 在气流流速为20 mL/min的空气气氛下, 以20℃/min的升温速率, 采用日本Shimadzu TGA-50热分析仪对包覆前后的金属铝粉进行了热重分析(TGA)。 实验结果对比曲线如图5所示。

图3 包覆前铝粉孔径—孔容的分布

Fig.3 Pore diameter—pore volume distribution of raw Al powder

图4 包覆后铝粉孔径—孔容的分布

Fig.4 Pore diameter—pore volume distribution of coated Al powder

图5 铝粉包覆前后热重曲线

Fig.5 TGA curves of raw and coated Al powder

从图5中可以看出, 原料铝粉的主要质量变化发生在580~683℃之间, 而且随后还有继续反应并增加质量的现象, 表明在此区间铝粉并没有完全反应; 而包覆后铝粉的质量变化发生在618~672℃之间, 在该区间前后均无明显的质量变化。 表明经过包覆处理后的铝粉发生热反应的温度区间更集中。 同时, 从图中两个样品主要质量变化区间曲线的斜率也可以看出, 包覆后的铝粉热重曲线更陡, 说明经过纳米膜包覆处理的铝粉在该温度区间发生反应的速度更快。 这种情况与文献[2, 7]中所提到的包覆铝粉发生破裂式燃烧的情况非常相似, 完全符合固体推进剂的燃烧速度快及能量释放迅速和集中的特征。

2.4 纳米包覆膜对AP热分解的影响

选择有机物A3的反应产物包覆金属铝粉, 是由于这种纳米级的产物(铝粉表面的纳米包覆膜)对推进剂主要组分AP的燃烧具有较好的催化作用。 将1%(质量分数)的这种包覆物超声分散于乙醚中, 加入AP继续超声分散数分钟, 然后研磨, 常温干燥, 再经研磨得AP与纳米包覆物的复合物。 采用差热分析(DTA)仪对复合物与纯AP进行了对比分析测试(升温速率为20℃/min, N2气气氛的流速为20mL/min, 铝质样品池), 图6所示为两者的热分解对比曲线。

图6 包覆膜物质对AP热分解的催化作用

Fig.6 Catalysis of coating material on AP decomposition

从图中可以看到, 混合有包覆物质的AP的高温阶段分解温度比纯AP的有所降低(12.3℃), 表明前者更易分解; 但其低温分解峰却有所滞后(达25.5℃), 表明该包覆材料仅在高温的环境下对AP的热分解具有催化作用, 低温时却抑制其分解。 这样的物质有利于固体推进剂在高温时热量的集中释放, 从而提高其做功效率。

一般认为AP的热分解分两个阶段进行[11-16]: 在低温阶段主要是固-气多相反应, 存在离解与升华的过程, 进入气相的NH3和HClO4发生一系列的反应, 产物主要有N2O, O2, Cl2, H2O和少量的NO; 在高温分解阶段主要是气相反应, 产物有N2O, O2, Cl2和H2O等。 纳米材料由于比表面积巨大、 表面原子数多及表面原子的配位不饱和性, 其表面具有很多的活性中心, 催化活性很高。 AP的高温分解反应主要是气相反应, 纳米材料对AP热分解中的气相物质有很好的吸附作用, 可以将气相反应物分子(如NH3等)吸附于其表面, 从而有利于气相反应的快速进行和反应放热, 使AP的高温热分解加快, 分解温度降低。 研究发现, 这种纳米膜材料对H2O蒸气和NH3都具有很好的吸附作用。 对于AP的低温分解阶段, 如果纳米材料在被分散体系中分散较好, 就会存在纳米材料覆盖在AP晶粒表面的情况, 此时纳米材料阻碍AP固相离解与升华的作用就大于其催化作用, 造成AP的低温分解温度升高。

3 结论

1) 在活化金属铝粉表面包覆了一层与普通铝粉表面氧化层厚度相当的纳米膜, 这种纳米包覆物可有效地防止铝粉的再氧化, 并在其燃烧时实现破裂式燃烧, 使复合金属粉热分解的温度区间更短、 更集中, 提高了金属铝粉的热量释放效率。

2) 纳米包覆物可实现对固体推进剂燃烧的特殊催化作用, 这种作用主要体现在对固体推进剂主要组分AP的高温热分解的促进(分解温度降低)和低温分解的抑制(分解温度升高)两个方面, 从而使固体推进剂热量释放区间更集中, 有利于提高推进剂的作功效率。

REFERENCES

[1]周起槐, 任务正. 火药物理化学性能[M]. 北京: 国防工业出版社, 2000. 67-72.

ZHOU Qi-huai, REN Wu-zheng. Powder Physical and Chemical Properties[M]. Beijing: National Defense Industry Press, 2000. 67-72.

[2]Cui N, Luo J L, Chuang K T. Nickel-metal hydride (Ni-MH) battery using Mg2Ni-type hydrogen storage alloy [J]. J Alloys Comp, 2000, 30(2): 218-226.

[3]Cui N, He P, Luo J L. Synthesis and characterization of nanocrystalline magnesium-based hydrogen storage alloy electrode materials [J]. Electrochemica Acta, 1999, 44(3): 3549-3558.

[4]Lenain C, Aymard L, Dupont L, et al. A new Mg0.9Y0.1Ni hydride forming composition obtained by mechanical grinding [J]. J Alloys Comp, 1999, 29(2): 84-91.

[5]Liu W H, Wu H Q, Lei Y Q, et al. Effect of substitution of other elements for nickel mechanically alloyed Mg50Ni50 amorphous alloys for nickel-metal hydrogen batteries [J]. J Alloys Comp, 1997, 26(1): 289-297.

[6]杜磊, 张小平, 吕公连. 铝粉表面自组装对铝粉/聚醚胶片力学性能的影响[J]. 固体火箭技术, 2001, 24(2): 27-30.

DU Lei, ZHANG Xiao-ping, L Gong-lian. Effect of self-assembly of Al powder surface on mechanical properties of Al/polyether films[J]. Solid Propellants Technology, 2001, 24(2): 27-30.

[7]汪亮, 刘华强, 刘敏华, 等. 包覆铝粉破裂燃烧的实验观测[J]. 固体火箭技术, 1999, 22(2): 40-44.

WANG Liang, LIU Hua-qiang, LIU Min-hua, et al. Experimental observations on disruptive burning of coated aluminum particles[J]. Solid Propellants Technology, 1999, 22(2): 40-44.

[8]张耀, 李寿权, 应窕, 等. 球磨表面包覆对镁基储氢合金电化学性能的影响[J]. 中国有色金属学报, 2001, 11(4): 582-586.

ZHANG Yao, LI Shou-quan, YING Tiao, et al. Effect of surface coating by ball milling on cycle stability of Mg-based hydrogen storage electrodes[J]. The Chinese Journal of Nonferrous Metals, 2001, 11(4): 582-586.

[9]李凤生, 杨毅. 纳米/微米粒子复合技术及应用[M]. 北京: 国防工业出版社, 2002. 6-9.

LI Feng-sheng, YANG Yi. Nano-Micrometer Particles Composite Technology and Application[M]. Beijing: National Defense Industry Press, 2002. 6-9.

[10]张青莲. 无机化学丛书(第2卷)[M]. 北京: 科学出版社, 1998. 114-115.

ZHANG Qing-lian. Organic Chemical Series (Vol.2)[M]. Beijing: Science Press, 1998. 114-115.

[11]Rosser W A, Inami S H. Thermal decomposition of ammonium perchlorate [J]. Combust and Flame, 1968, 12(5): 427-433.

[12]Jacobsatc P W M. The thermal decomposition of ammonium perchlorate (Ⅰ): introduction experimental analysis of gaseous products and thermal decomposition experiments [J]. Combust and Flame, 1969, 13(4): 419-425.

[13]Ssid A A. Thermal decomposition of ammonium perchlorate doped with iron, cobalt or nickel hydroxides [J]. J Therm Anal, 1991, 37(1): 959-968.

[14]Liu L L, Li F S, Tan L H, et al. Effects of nanometer Ni, Cu, Al and NiCu powders on the thermal decomposition of ammonium perchlorate [J]. Propellants, Explosives, Pyrotechnics, 2004, 29(1): 34-38.

[15]Liu L L, Li F S, Tan L H, et al. Effects of metal and composite metal nano-powders on the thermal decomposition of ammonium perchlorate (AP) and the ammonium perchlorate/ hydroxyterminated polybutadiene (AP/HTPB) composite solid propellant [J]. Chinese Journal of Chemical Engineering, 2004, 12(4): 595-598.

[16]杨毅, 李凤生, 谈玲华. 纳米α-Fe2O3的制备及其催化高氯酸铵热分解[J]. 兵工学报, 2004, 25(1): 82-85.

YANG Yi, LI Feng-sheng, TAN Ling-hua. The preparation of nanometer α-Fe2O3 and its catalysis on AP[J]. Acta Armamentarll, 2004, 25(1): 82-85.

基金项目: 国家自然科学基金资助项目(50306008); 江苏省自然科学基金资助项目(BK2003421); 总装备部预先研究资助项目(41328030507)

收稿日期: 2004-09-29; 修订日期: 2005-03-09

作者简介: 杨 毅(1973-), 男, 讲师, 博士.

通讯作者: 杨 毅; 电话/传真: 025-84315042; E-mail: hcyyi@sina.com

(编辑陈爱华)