文章编号:1004-0609(2011)04-0908-05

石煤微波空白焙烧-酸浸提钒工艺

张小云1, 2,覃文庆1,田学达2,陈燕波2,谷 雨2,习晓光2

(1. 中南大学 资源加工与生物工程学院,长沙 410083;

2. 湘潭大学 化工学院,湘潭 411105)

摘 要:通过微波空白焙烧-酸浸提钒与传统加热焙烧-酸浸提钒和直接酸浸提钒的对比实验,考察H2SO4用量和浸出时间对石煤中钒浸出的影响。结果表明:石煤在700 ℃下微波焙烧60 min,H2SO4用量为矿样质量的22%,浸出温度为90 ℃时,V2O5浸出率达到83.50%,比传统加热焙烧-酸浸提钒和直接酸浸的浸出率提高约30%。通过对焙烧熟料酸浸和直接酸浸时Al2O3 浸出率的分析发现,V2O5浸出率与Al2O3 浸出率呈正相关性。结合矿物晶体构造与微波加热原理,探讨了微波焙烧改善酸浸提钒的机理,认为微波焙烧可破坏含钒云母的晶体结构,是提高V2O5浸出率的主要原因。

关键词:石煤;五氧化二钒;微波焙烧;酸浸工艺

中图分类号:TQ522.59 文献标志码:A

Microwave roasting-acidic leaching technique for extraction of vanadium from stone coal

ZHANG Xiao-yun1, 2, QIN Wen-qing1, TIAN Xue-da2, CHEN Yan-bo2, GU Yu2, XI Xiao-guang2

(1. School of Mineral Processing and Bioengineering, Central South University, Changsha 410083, China;

2. College of Chemical Engineering, Xiangtan University, Xiangtan 411105, China)

Abstract: Compared with the conventional roasting-acidic leaching procedure and acidic leaching process of raw stone coal, the microwave roasting-acidic leaching technique for extraction of vanadium from stone coal was developed, and the effects of H2SO4 dosage and leaching time on vanadium extraction were investigated. The results show that the leaching rate of V2O5 reaches up to 83.5% when the tested sample is microwave roasted (without any additive) at 700 ℃ for 60 min, the dosage of sulfuric acid is 22% of V2O5 leaching at 90 ℃. The leaching rate is improved by about 30%, more than that obtained from the conventional roasting or acidic leaching of raw stone coal under the same leaching conditions. The positive correlation between the leaching rate of V2O5 and Al2O3 is found out by leaching V2O5 and Al2O3 from both the roasted samples and raw stone coal. Based on the minerals crystal constitution and the characteristics of microwave roast, the mechanism on improving the leaching rate of V2O5 by microwave roasting was discussed. It is indicated that the breakage of the minerals crystal constitution resulted from microwave roasting is the key factor of affecting the improvement of V2O5 leaching rate.

Key words: stone coal; vanadium pentoxide; microwave roasting; acidic leaching technique

石煤是我国作为钒的单独矿床开采的主要含钒资源,V2O5品位较低,一般为1.0%左右。我国从20世纪60年代开始对石煤提钒进行研究,70年代开始工业生产,所使用的工艺均为钠化焙烧(NaCl)—水浸或酸浸工艺[1]。这种工艺存在两个严重缺陷:一是因为焙烧过程生成Cl2、HCl、SO2 混合气体而造成环境污染;二是钒回收率普遍为45%~55%,使50%左右的钒矿资源得不到有效利用而浪费。

为改变和取代钠化焙烧工艺,科技工作者进行钙法焙烧、空白焙烧和湿法酸浸等新工艺的研究[2-12]。钙法焙烧过程受矿石种类和性质影响较大,生产实践中还需要解决焙烧气氛、时间、温度和钙盐用量等操作控制因素。空白焙烧主要是解决石煤脱碳和低价钒的氧化问题,但不能明显提高钒的回收率。湿法酸浸工艺不需要焙烧过程,适合大规模生产,因此成为石煤提钒研究的重点[12]。湿法酸浸提钒工艺的基础理论研究也有一些进展[13]。然而,酸浸提钒工艺还存在一些需要解决的问题,一是为得到较高V2O5浸出率,不得不消耗大量H2SO4;二是酸性浸出液的净化除杂、Fe(Ⅲ)还原和pH值调整等工序需要消耗大量药剂,特别是氨水,从而导致氨氮废水的产生及处理问题。有人研究采用HF、H2SO4和NaClO3共同作用浸出石煤中的钒[7],不过,HF酸消耗和NaClO3消耗太多,且该研究没有涉及含氟废气处理、浸出液中钒的分离和废水处理等问题[4, 9]。其实,石煤酸浸提钒要解决的关键问题是在提高V2O5浸出率和回收率的前提下,如何降低消耗和避免环境污染,研究方向应该是开发低消耗低成本的清洁生产工艺。

微波作为一种新的冶金方法,在磨矿、还原、干燥、焙烧、金属提取等方面都有了较深入的研究和实际应用[14-15]。由于微波对矿物的选择性加热,可使矿石中的某些矿物发生化学反应或物相转变。本文作者在前期工作中研究了石煤微波焙烧-酸浸工艺[2],由于焙烧时使用了碱性添加剂Na2CO3,焙烧熟料须经水 浸-酸浸两段浸出,操作过程偏复杂,不易在生产中推广使用。因此,本文作者在已有研究基础上,采用微波对石煤进行空白焙烧,然后进行酸浸提钒,在研究微波焙烧对石煤提钒过程的影响的同时,进一步探讨微波焙烧改善石煤提钒的机理。

1 实验

1.1 实验材料

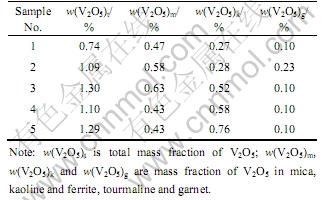

矿样取自湖南某石煤矿,根据矿石分布,在5个矿点分别取样。石煤中主要含钒矿物为云母类、高岭土、铁氧体、电气石及石榴子石。矿样经物相分析,钒主要存在于云母类矿石中,占总钒的43%~63%,且高价V(Ⅴ)只占10%左右,低价V(Ⅲ)和V(Ⅳ)占90%左右。钒在各类矿石中的分布见表1。

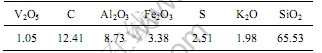

试验用矿样为5个矿点的混合矿样,其化学成分见表2。

表1 钒在5个矿点样品中的分布

Table 1 Distribution of V2O5 in 5 samples

表2 试验矿样的化学成分

Table 2 Chemical composition of sample for tests (mass fraction, %)

1.2 微波设备

微波设备为湖南株洲华威工业微波设备有限公司的HW-18型工业微波炉,额定功率为18 kW。温度测定采用MX4+便携式红外测温仪。

1.3 实验方法

1.3.1 焙烧-酸浸实验

石煤矿石破碎至粒径小于1 mm后,在125 ℃下干燥至质量恒定。微波焙烧每次取样2 kg,焙烧温度700 ℃,焙烧时间60 min;马弗炉焙烧(代表传统的加热焙烧)每次取样100 g,焙烧温度800 ℃,焙烧时间240 min。焙烧后将熟料细磨至65%熟料的粒径小于74 μm。酸浸实验时,根据焙烧前后矿样质量变化比例,取相当于100 g焙烧前矿样的熟料,液固比1.5?1,浸出温度95 ℃。在浸出过程的最后10 min左右,将液固比调至约3?1。浸出后液固分离时,用2.5%稀硫酸洗涤滤饼2次。浸出液(含洗涤液)总量控制在450 mL左右。

尽管石煤矿石和浸出液中的V基本不是以V(Ⅴ)形式存在,但本研究按习惯仍用V2O5表示。本研究中的液固比,是指浸出时加入的水量(mL)与待浸物料的质量(g)之比;H2SO4用量是指酸料质量比,即100 g待浸出物料所消耗的H2SO4质量(g)。

1.3.2 直接酸浸实验

矿石破碎至粒径小于1 mm并干燥至质量恒定后,细磨至65%熟料的粒径小于74 μm。浸出过程的控制同焙烧-酸浸实验一致。

2 结果与讨论

2.1 微波空白焙烧对钒浸出率的影响

2.1.1 H2SO4用量对浸出率的影响

H2SO4用量较大是石煤酸浸工艺的主要缺点,降低酸耗对石煤酸浸提钒具有重要的经济和环境意义。分别用微波空白焙烧熟料、马弗炉空白焙烧熟料和石煤矿样进行酸浸实验,浸出时间24 h,H2SO4用量与V2O5浸出率的关系如图1所示。

图1 H2SO4用量对V2O5浸出率的影响

Fig.1 Effect of H2SO4 dosage on V2O5 leaching rate

由图1可知:石煤经微波空白焙烧后,H2SO4用量有较大降低,V2O5浸出率明显提高;当H2SO4用量为22%时,经微波焙烧后的V2O5浸出率已达到83.5%,而直接酸浸的浸出率为50.0%左右;当H2SO4用量达到35%时,直接酸浸的浸出率也仅为70%左右。马弗炉焙烧熟料浸出时,当H2SO4用量低于25%,V2O5浸出率较低,甚至低于直接酸浸的指标,只有在较高H2SO4用量时,浸出率才略高于直接酸浸的结果。因此可以认为,对本研究的石煤,采用微波焙烧可以改善V2O5的浸出效果,而传统焙烧方法对这种矿石的V2O5浸出没有意义。

2.1.2 浸出时间对浸出率的影响

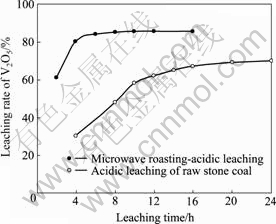

分别取微波空白焙烧熟料和石煤样进行酸浸,焙烧熟料浸出时H2SO4用量为22%,直接酸浸时,H2SO4用量为30%,考查浸出时间对V2O5浸出率的影响,其结果如图2所示。

由图2看出:经微波焙烧后,在较低H2SO4用量

图2 浸出时间对V2O5浸出率的影响

Fig.2 Effect of leaching time on V2O5 leaching rate

下,石煤中钒能在较短时间浸出;H2SO4用量为22%,浸出6 h后,V2O5浸出率即可超过80.0%;而直接酸浸需20 h左右才能使V2O5浸出率达到70.0%左右。

2.2 微波焙烧改善石煤提钒的机理

大量研究表明,在微波场中,半导体型的矿物和化合物比绝缘体型的更能有效地吸收微波;过渡键型矿物和化合物吸收微波的能力大于纯共价键和纯离子键的矿物和化合物[15]。在微波辐照下,单位体积介质能转化的能量,即比例因子,V2O5的为0.71,Fe2O3的为1.23,Al2O3的为0.21,因此,微波辐射下V2O5、Fe2O3升温比Al2O3升温快。由于石煤矿样中的Al2O3与SiO2等成分在微波场中升温很慢或基本上不升温,而C、V2O5和Fe2O3等的升温速率较大,所以矿物各组分在微波场中因热膨胀系数不同而在晶格间产生应力,从而导致矿物颗粒的龟裂。

本文作者在以前的研究中,对焙烧熟料进行粒度变化与V2O5分布变化的分析。结果表明,传统的加热焙烧方法对矿样粒度基本无影响,而微波焙烧后,矿样中有10%左右爆裂,其中包括含钒的矿粒。因温度升高后的钒矿物体积膨胀,致使矿样产生龟裂,由此提出微波焙烧过程石煤矿样裂解模型[2]。

石煤矿样裂解模型虽然可以较好地解释微波焙烧比常规焙烧更有利于V2O5的浸出,但也只是解释V2O5浸出率提高的现象,要从冶金工艺的本质上说明机理,还需要进一步分析石煤的矿物组成及其经微波焙烧后的浸出行为。

石煤中的钒主要以类质同象存在于云母等铁铝矿物的硅氧四面体结构中。云母是碱金属和碱土金属的铝硅酸盐,其化学组成可用下列通式表示:X{Y2-3[Z4O10(OH)2]},式中Z组阳离子主要为Si和Al,位于硅氧四面体层中;Y组阳离子主要为AL3+和Fe3+和Mg2+,位于八面体层中;X组阳离子主要是K+、Na+等,位于云母结构层之间;OH-是附加阴离子。白云母的化学式为KAl2[AlSi3O10](OH)2,镁硅白云母则为KAl3(Mg,Fe2+)[AlSi7O20](OH)4。白云母在550 ℃高温下性质未改变,在700 ℃时脱水,而1 050 ℃时结构被破坏。白云母具有良好的化学稳定性,它与碱几乎不起作用,不溶于热酸中,但能在沸腾的硫酸长时间作用下发生分解[1]。

现假定1个V原子取代了白云母硅氧四面体结构中1个Al原子,则含钒白云母的化学式应可表示为KAl2[VSi3O10](OH)2。微波焙烧时,钒氧化物温度因微波辐照而迅速上升,而SiO2是依靠传热而缓慢升温,从而导致含钒白云母的硅氧四面体结构被破坏。此外,在微波焙烧时,当矿样总体温度达到700 ℃时,V和Fe含量较高的局部温度可能已经超过白云母结构被破坏的临界温度1 050 ℃,而传统加热焙烧不会出现这种现象。

如果因硅氧四面体结构被破坏而使V2O5浸出率提高,则可推断,在钒的浸出过程,Al2O3 的浸出率也应当能够提高。为此,分别在常温(25 ℃)和加温(95 ℃)条件下对石煤微波焙烧(700 ℃)熟料、传统加热焙烧(800 ℃)熟料和石煤原矿进行浸出,浸出时间24 h,测定不同H2SO4用量时浸出液中Al2O3的浸出率,其结果如图3和4所示。

由图3和4可以看出,加温(95 ℃)时Al2O3的浸出率明显高于常温时的浸出率,微波焙烧-酸浸 时,Al2O3 的浸出率明显高于传统焙烧酸浸和石煤直接酸浸的,这些规律与V2O5浸出率变化规律是一致的。常温浸出时,传统焙烧酸浸和石煤直接酸浸得到的Al2O3浸出率均不高,因为在此条件下含钒石煤中

图3 常温(25 ℃)下H2SO4用量对Al2O3浸出率的影响

Fig.3 Effect of H2SO4 dosage on Al2O3 leaching rate at 25 ℃

白云母的结构未得到化学破坏,理论上Al2O3不能浸出,实验中Al2O3的少量浸出应该是由于破碎磨矿的机械作用使部分白云母结构遭到物理破坏。

通过考查加温浸出液中Al2O3的浸出率与V2O5浸出率的关系,发现二者呈正相关性,以Al2O3的浸出率为横坐标,以V2O5浸出率为纵坐标,二者的相关关系如图5所示。

图4 加温(95 ℃)下H2SO4用量对Al2O3浸出率的影响

Fig.4 Effect of H2SO4 dosage on Al2O3 leaching rate at 95 ℃

图5 加温(95 ℃)酸浸V2O5浸出率与Al2O3浸出率的关系

图5 Relationship between acidic leaching rates of V2O5 and Al2O3 at 95 ℃

根据图5结果进行数据处理,以x表示Al2O3的浸出率,y表示V2O5浸出率,可以得到V2O5浸出率与Al2O3浸出率的直线回归方程。

石煤微波焙烧-酸浸时:

y=1.593 5x+10.569 (R2=0.983 6) (1)

石煤传统焙烧-酸浸时:

y=1.593 8x+15.311 (R2=0.989 0) (2)

石煤直接酸浸时:

y=1.343 7x+25.756 (R2=0.765 4) (3)

由图5可看出,石煤酸浸提钒工艺中,V2O5的浸出与Al2O3的浸出是同步进行的。这一结果在以往石煤提钒研究中未见报道。认识到这一规律至少有两方面的意义:一是可从理论上估算酸浸时的H2SO4用量,换言之,如果石煤中含钒矿物的结构得到了破坏,为V2O5浸出创造了基本条件,则只要满足Al、Fe、Mg等氧化物溶解和V(Ⅲ)溶出的酸用量即可,并不需要无根据地增大H2SO4用量;二是V2O5的酸法浸出问题,其实质是含钒矿物的结构破坏问题。含钒矿物的结构破坏方法可以是物理方法(如超细磨)、微波焙烧、添加剂焙烧和化学法(如通过HF酸破坏Si—O四面体、高浓度沸腾H2SO4长时间作用)等。这为今后含钒石煤酸浸提钒的理论研究和生产实践指明方向。

3 结论

1) 微波空白焙烧-酸浸提钒工艺可以在较低H2SO4用量、较短浸出时间得到较高V2O5浸出率。石煤在700 ℃经60 min的微波空白焙烧后,用H2SO4浸出,H2SO4用量为矿石质量的22%时,V2O5浸出率可达83.5%;传统焙烧方法不能改善本研究中石煤的V2O5浸出效果。

2) 石煤焙烧熟料酸浸和直接酸浸时,V2O5的浸出与Al2O3的浸出是同步进行的,V2O5浸出率与Al2O3浸出率呈正相关性。

3) V2O5的酸法浸出问题,其实质是含钒矿物的结构破坏问题。微波焙烧可破坏含钒云母的晶体结构,是提高V2O5浸出率的主要原因。石煤微波空白焙烧-酸浸提钒工艺在提高V2O5浸出率的前提下,降低H2SO4消耗,没有引入新的环境污染因子。

REFERENCES

[1] 任觉世. 工业矿产资源开发利用手册[M]. 武汉: 武汉工业大学出版社, 1993: 63-76, 1055-1070.

REN Jue-shi. A handbook for processing and utilization of industrial minerals resource[M]. Wuhan: Publishing House of Wuhan University of Technology, 1993: 63-76, 1055-1070.

[2] 欧阳国强, 张小云, 田学达, 李 熠, 谢 森. 微波焙烧对石煤提钒的影响[J]. 中国有色金属学报, 2008, 18(9): 750-754.

OUYANG Guo-qiang, ZHANG Xiao-yun, TIAN Xue-da, LI Yi, XIE Sen. Effect of microwave roasting on vanadium extraction from stone coal[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(9): 750-754.

[3] 谭爱华. 某石煤钒矿空白焙烧-碱浸提钒工艺研究[J]. 湖南有色金属, 2008, 24(1): 24-26, 57.

TAN Ai-hua. Study on extracting V2O5 by the roasting- alkaline leaching[J]. Hunan Nonferrous Metals, 2008, 24(1): 24-26, 57.

[4] 冯其明, 何东升, 张国范. 石煤提钒过程中钒氧化和转化对钒浸出的影响[J]. 中国有色金属学报, 2007, 17(8): 1348.

FENG Qi-ming, HE Dong-sheng, ZHANG Guo-fan. Effect of vanadium oxidation and conversion on vanadium leaching in extraction process of vanadium from stone coal[J]. The Chinese Journal of Nonferrous Metals, 2007, 17(8): 1348.

[5] NAVARRO R, GUZMAN J. Vanadium recovery from oil fly ash by leaching, precipitation and solvent extraction processes[J]. Waste Management, 2007, 27: 425-438.

[6] WANG Ming-yu, XIAO Lian-sheng, LI Qing-gang, WANG Xue-wen, XIANG Xiao-yan. Leaching of vanadium from stone coal with sulfuric acid[J]. Rare Metals, 2009, 28(1): 1-4.

[7] LIU Yan-hua, YANG Chao, LI Pei-you, LI Shi-qi. A new process of extracting vanadium from stone coal[J]. Chemistry and Materials Science: International Journal of Minerals, Metallurgy, and Materials, 2010, 17(4): 381-388.

[8] WANG Ming-yu, XIANG Xiao-yan, ZHANG Li-ping, XIAO Lian-sheng. Effect of vanadium occurrence state on the choice of extracting vanadium technology from stone coal[J]. Rare Metals, 2008, 27(2): 112-115.

[9] HE Dong-sheng, FENG Qi-ming, ZHANG Guo-fan, OU Le-ming, LU Yi-ping. An environmentally-friendly technology of vanadium extraction from stone coal[J]. Minerals Engineering, 2007, 20(12): 1184-1186.

[10] ZHU Yang-ge, ZHANG Guo-fan, FENG Qi-ming, LU Yi-ping, OU Le-ming, HUANG Si-jie. Acid leaching of vanadium from roasted residue of stone coal[J]. Transactions of Nonferrous Metals Society of China, 2010, 20(S1): s107-s111.

[11] CHEN Xiang-yang, LAN Xin-zhe, ZHANG Qiu-li, MA Hong-zhou, ZHOU Jun. Leaching vanadium by high concentration sulfuric acid from stone coal[J]. Transactions of Nonferrous Metals Society of China, 2010, 20(S1): s123-s126.

[12] YANG Kang, ZHANG Xiao-yun, TIAN Xue-da, YANG Yong-long, CHEN Yan-bo. Leaching of vanadium from chromium residue[J]. Hydrometallurgy, 2010, 103(1/4): 7-11.

[13] 张小云, 田学达. 石煤提钒湿法工艺的动力学研究[J]. 湘潭大学自然科学学报, 2005, 27(2): 104-107.

ZHANG Xiao-yun, TIAN Xue-da. Leaching kinetics of extraction of vanadium pentoxide from stone coal[J]. Natural Science Journal of Xiangtan University, 2005, 27(2): 104-107.

[14] 佟志芳, 毕诗文, 杨毅宏. 微波加热在冶金领域中应用研究现状[J]. 材料与冶金学报, 2004, 3(2): 117-120.

TONG Zhi-fang, BI Shi-wen, YANG Yi-hong. Present situation of study on microwave heating application in metallurgy[J]. Journal of Materials and Metallurgy, 2004, 3(2): 117-120.

[15] 彭金辉, 刘纯鹏. 微波场中矿物及其化合物的升温特性[J]. 中国有色金属学报, 1997, 7(3): 50-51.

PENG Jin-hui, LIU Chun-peng. Characteristics of temperature increase of minerals and compounds in microwave field[J]. The Chinese Journal of Nonferrous Metal, 1997, 7(3): 50-51.

(编辑 李艳红)

基金项目:科技部科技型中小企业技术创新基金项目(10C26214302544)

收稿日期:2009-05-19;修订日期:2010-11-24

通信作者:田学达,教授,博士;电话:0731-58292246;E-mail: snowy@xtu.edu.cn