DOI: 10.11817/j.issn.1672-7207.2017.06.007

多级固溶对7A04铝合金的力学性能和剥落腐蚀性能的影响

王超群1,赵君文1, 2,李虎1,戴光泽1,韩靖1

(1. 西南交通大学 材料科学与工程学院,四川 成都,610031;

2. 华中科技大学 材料成形与模具技术国家重点实验室,湖北 武汉,430074)

摘要:通过金相显微镜(OM)、扫描电子显微镜(SEM)、室温拉伸及腐蚀剥落性能测试,研究多级固溶处理对7A04铝合金的微观组织、力学性能及剥落腐蚀行为的影响。研究结果表明:7A04铝合金经三级固溶(470 ℃/2 h+480 ℃/1 h+490 ℃/0.5 h)后第二相含量较单级与双级固溶分别减少了36.9%和28.2%;120 ℃/24 h时效后,抗拉强度Rm,屈服强度Rp0.2和伸长率A分别达到718.8 MPa,660.3 MPa和10.6%;当固溶处理工艺从单固溶处理升级到三级固溶处理时,剥蚀敏感性降低,铝合金的耐剥蚀性能等级由EC提高到EA-。

关键词:7A04铝合金;多级固溶;微观组织;力学性能;剥落腐蚀

中图分类号:TG166.3 文献标志码:A 文章编号:1672-7207(2017)06-1458-07

Effects of multi-stage solid-solution treatment on mechanical properties and exfoliation corrosion behavior of 7A04 aluminum alloy

WANG Chaoqun1, ZHAO Junwen1, 2, LI Hu1, DAI Guangze1, HAN Jing1

(1. School of Materials Science and Engineering, Southwest Jiaotong University, Chengdu 610031, China;

2. State Key Laboratory of Materials Processing and Die&Mould Technology,

Huazhong University of Science and Technology, Wuhan 430074, China)

Abstract: The effects of multi-stage solid-solution treatment on the mechanical properties, microstructure and exfoliation corrosion behavior of 7A04 aluminum alloy were investigated by optical microscopy(OM), scanning electron microscopy (SEM), tensile test and exfoliation corrosion test. The results show that compared with single-stage and two-stage solid-solution treatment, the second phase particles fraction of the 7A04 aluminum alloy after triple-stage solid-solution (470 ℃/2 h+480 ℃/1 h+490 ℃/0.5 h) has decreased by 36.9% and 28.2%. And the ultimate tensile strength Rm, yield strength Rp0.2 of the samples by triple-stage solid-solution and peak aging (120 ℃/24 h) are 718.8 MPa, 660.3 MPa, respectively, with approximately 10.6% elongation. When the solid solution stages increase to the triple, the exfoliation susceptibility of the alloy has reduced and the scale of the exfoliation corrosion resistance has improved from EC to EA-.

Key words: 7A04 Aluminum alloy; multi-stage solid-solution; microstructure; mechanical property; exfoliation corrosion

随着我国航空航天、交通运输行业的迅速发展,高强 Al-Zn-Mg-Cu 系铝合金的应用愈加广泛,同时对其性能也提出了越来越高的要求。高强 Al-Zn-Mg-Cu 系铝合金是一种可热处理强化的铝合金,通过热处理可提高其性能[1],以满足更多零部件的使用要求,而较为常规的热处理方法为固溶+时效处理。因单级固溶的温度均在共晶熔点之下,较高熔点的杂质相不能固溶完全,存在许多不足,近几十年越来越多的研究人员通过多级强化固溶来改善铝合金的性能,发现多级固溶温度能够突破单级固溶温度上限,使更多合金相溶入基体,增加时效后合金的强度[2-4]。宁爱林等[5]研究了短时双级固溶对7A04 铝合金组织与性能的影响,并得到高温短时的双级固溶可以获得更细小的晶粒组织及更优良的力学性能。陈康华等[6]通过长时两步固溶处理7系铝合金,得到逐步固溶能够控制合金再结晶体积分数,提高合金的晶间腐蚀、剥落腐蚀和应力腐蚀抗力。黄振宝等[7]研究得到7A55铝合金经双级固溶处理后组织与单级固溶再结晶程度相似,双级固溶能较大幅度提高合金的固溶度。孙文会等[8]研究了7136铝合金经三级固溶处理后的组织变化,得到第三级固溶温度是影响固溶组织的重要因素。本文作者针对7A04这种高强铝合金的长时多级固溶处理制度进行了研究,提出固溶温度逐级升高,固溶时间逐级减半的三级固溶(470 ℃/2 h+480 ℃/1 h+490 ℃/0.5 h)处理方案,并对比分析了单级固溶、双级固溶以及三级固溶热处理对7A04铝合金棒材组织性能及其剥落腐蚀性能的影响。

1 实验

实验所用合金为7A04铝合金,直径×长度为20 mm×120 mm的挤压棒材,其成分如表1所示。试样分为4组,1组为空白试样(挤压态)、单级固溶+时效、双级固溶+时效和三级固溶+时效并依次标为1号样、2号样、3号样。后3组试样经固溶处理后,统一采用室温水淬、120 ℃保温24 h时效处理。合金试样热处理工艺参数见表2,升温速率为6 ℃/min。

拉伸实验在XYB305C微型电子万能拉伸机上进行,每组3根平行试样,取其平均值。样品固溶处理后进行机械抛光,用Keller试剂腐蚀,采用JSM-7001F型扫描电镜、VK9700彩色3D激光显微镜观察合金内第二相的大小、数量和分布状态。剥落腐蚀(EXCO)实验参照HB 5455—1990标准进行[9]。在标准EXCO 溶液中NaCl,KNO3和HNO3 的浓度分别为4.0 mol/L,0.5 mol/L和0.1 mol/L,溶剂为蒸馏水(或去离子水)。实验温度恒定为(25±2) ℃,腐蚀介质体积与腐蚀面面积之比为20 mL:1 cm2。将试验合金在剥蚀溶液中浸渍48 h,在24 h内不间断地观察,并用数码相机进行照相记录。48 h后将样品取出在潮湿状态时直接检验,并按照评级标准评定等级。

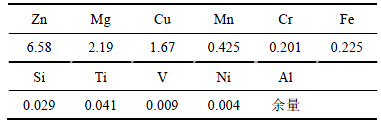

表1 7A04铝合金化学成分(质量分数)

Table 1 Chemical composition of 7A04 alloys %

表2 7A04铝合金的固溶和时效处理工艺参数

Table 2 Solid solution-aging process parameters of 7A04 alloy

2 实验结果

2.1 多级固溶处理对7A04铝合金组织性能的影响

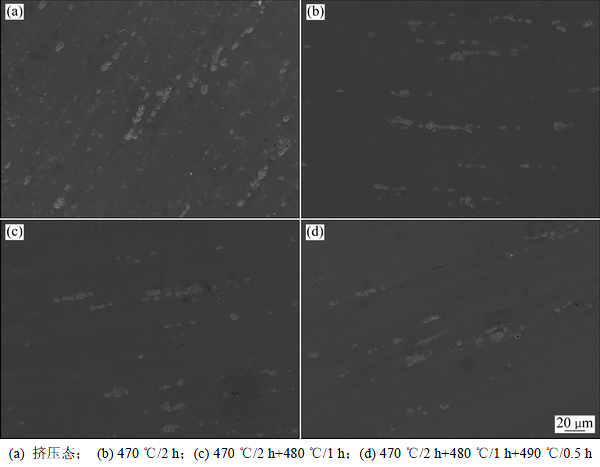

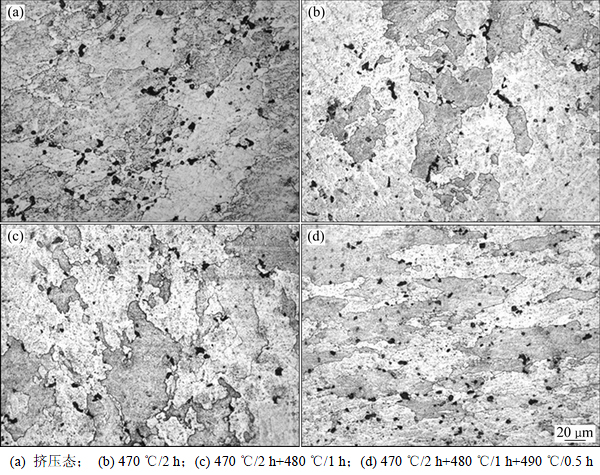

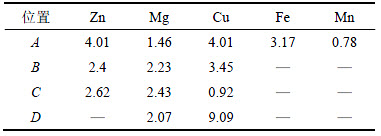

图1所示为7A04铝合金挤压态及经过470 ℃/2 h,470 ℃/2 h+480 ℃/1 h,470 ℃/2 h+480 ℃/1 h+490 ℃/0.5 h固溶处理后的轴向扫描电镜照片。从图1(a)可见:合金在挤压态时,粗大第二相粒子沿挤压方向呈连续分布,从横截面组织(图2(a))观察其形态为粗大的蠕虫状、块状,大多数分布于晶界,选取其中4张金相组织图像通过Image Pro-plus软件统计得出其粗大第二相粒子体积分数约为5.09%。经过470 ℃/2 h一级固溶后,第二相粒子的形貌有明显变化,粗大的粒子含量变少,横截面方向可观察到蠕虫粒子数量减少(见图2(b)),经过统计其含量约占3.71%,与挤压态相比降低了27.11%。随着固溶级数增加至双级固溶(470 ℃/2 h+480 ℃/1 h),粗大的第二相粒子含量减少,体积更加细小,颗粒之间不连续性增加,如图1(c)所示,经过统计得到其体积分数约为3.26%。由图1(d)和图2(d)可见:试样经过三级固溶后,第二相粒子呈细小颗粒状不连续分布,其体积分数为2.34%,与单级固溶和双级固溶相比分别减少了36.9%和28.2%。表4所示为对应图3中未溶相的EDS能谱分析,从表4可知:未溶粗大的相主要是富Cu相或含Fe,Mg杂质相。

图1 7A04铝合金不同固溶状态下第二相分布SEM照片

Fig. 1 SEM images of 7A04 aluminum alloy plates solution-treated under different conditions

图2 7A04铝合金试样不同固溶状态下横截面照片

Fig. 2 Morphologies of 7A04 aluminum alloy plates solution-treated under different conditions

图3 7A04铝合金固溶态未溶相扫描电镜照片

Fig. 3 SEM images of undissoved phases in 7A04 alloy after solution treatment

表4 7A04铝合金试样固溶态未溶相成分(原子数分数)

Table 4 Composition of undissoved phase in 7A04 alloy after solution treatment %

2.2 多级固溶处理对7A04铝合金力学性能的影响

图4所示为7A04铝合金试样固溶时效后的拉伸性能测试结果。挤压态7A04铝合金因经过了长时间自然时效,抗拉强度与屈服强度分别达到573.98 MPa和518.68 MPa。从图4可知:单级固溶470 ℃/2 h后,挤压态相比,合金的拉伸强度及屈服强度增加明显。随着固溶级数增加,7A04铝合金的强度呈现增长的趋势。与单级固溶相比,双级固溶处理(470 ℃/2 h+480 ℃/1 h)抗拉强度从670.6 MPa增长到703.4 MPa,提高了4.80%,屈服强度从612.5 MPa增长到641.4 MPa,提高了4.72%。三级固溶处理(470 ℃/2 h+480 ℃/1 h+490 ℃/0.5 h)后试样的实验强度最好,抗拉强度可达到718.8 MPa,与双级固溶相比提高了2.2%,屈服强度达到660.3 MPa,提高了2.95%。随着固溶级数的增加,试样伸长率下降不明显,三级固溶后的伸长率仍可达到10.6%。

2.3 多级固溶处理对7A04铝合金剥蚀性能的影响

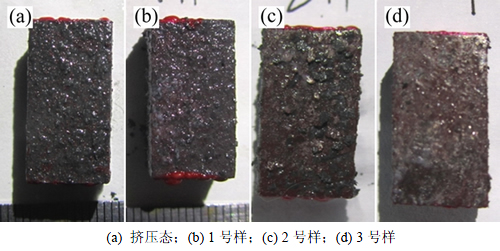

图5所示为4组试样在EXCO溶液中经过48 h浸泡后的宏观形貌照片。从图5可见:4组试样在EXCO溶液中发生剥落腐蚀的程度不同。挤压态和1号试样在腐蚀液中浸泡了48 h后,整个表面腐蚀程度较大,表面鼓泡全部裂开,分层并向金属基体内部延伸,相对基体表面腐蚀深度较深,分别达到425 μm和362 μm(图6(a),(b)),腐蚀液中有大量黑色的剥落腐蚀产物。2号合金试样表面有明显的腐蚀坑痕迹(图5(c)),同时有起皮等明显的剥蚀特征,从横截面腐蚀形貌可见基体表面同时存在点蚀和剥蚀,腐蚀深度约225 μm。3号试样在腐蚀液中浸泡了48 h后主要表现为均匀的点状腐蚀,同时伴随着少量的鼓泡与起皮等较明显的剥落腐蚀的特征,如图5(d)所示,腐蚀深度较浅(图6(d)),腐蚀液中只有少量的黑色剥落产物。

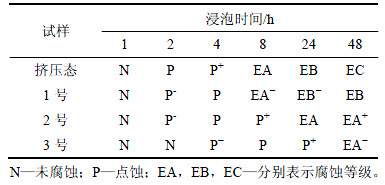

按照剥落腐蚀(EXCO)实验标准[6, 10]对各试样在实验时间内进行剥蚀评级,结果见表5。浸泡2 h后,挤压态试样表面失去金属光泽,颜色变深,同时伴随出现点蚀现象;1号和2号试样分别浸泡4 h和8 h后表面才出现点蚀,但表面仍为金属银白色;而3号试样浸泡24 h时,表面才逐渐失去金属光泽,出现较严重的点蚀现象。

图5 不同固溶态7A04铝合金试样在EXCO溶液中浸泡48 h后的表面腐蚀形貌

Fig. 5 Exfoliation corrosion morphologies of surface of 7A04 alloy samples immersed in EXCO solution for 48 h

图6 7A04铝合金试样在EXCO溶液中浸泡48 h横截面剥蚀形貌

Fig. 6 Cross-sectional microstructure of 7A04 alloy samples immersed in EXCO solution for 48 h

表5 7A04铝合金试样在EXCO溶液中浸泡后的腐蚀等级

Table 5 Ratings of exfoliation corrosion of 7A04 alloy after immersing in EXCO for different time

3 分析与讨论

7A04铝合金是可热处理强化变形铝合金,影响其固溶处理效果的因素有固溶温度、固溶时间及淬火冷却速率,其中固溶温度的影响最为显著[11]。在本实验中,三级固溶试样第二相含量比双级与单级固溶的低,这是因为挤压态连续分布于晶界周围的粗大第二相经过单级固溶处理初始阶段,Mg与Zn元素具有较快的扩散系数故主要强化相MgZn2(η相)和Al2Mg3Zn3(T相)能快速溶入基体,而低熔点的粗大相(AlZnMgCu相和Al2CuMg相等)则逐渐溶于铝基体中,但随着固溶时间的延长,基体中溶质浓度逐渐升高,杂质相溶解速率减慢,故单级固溶态试样的第二相含量较高;通过分析固溶态未溶相的能谱(表4),发现这些相主要含有Fe,Zn,Mg和Cu元素, 且Cu的含量较高,这是因为相对其他元素Cu的扩散速率较小[12],故初生含Cu相在固溶时溶解缓慢。根据Arrhenius公式扩散系数与温度呈指数关系可知:温度越高,原子动能越大,扩散系数呈指数增加。故通过提高固溶温度,能够提高合金元素在基体中的溶解度和增加Cu元素在合金基体中的扩散速率,从而大大促进初生含Cu相的溶解。因此,当固溶温度由470 ℃升至490 ℃时, 由于合金元素溶解度和原子扩散速率的提高而使残留初生AlZnMgCu相溶解速度增加, 溶解量增大(如图1(d)),第二相含量降低,残留第二相主要是少量的Al2CuMg相及高熔点的含Fe相等。

从图2可见:与双级固溶和单级固溶相比,三级固溶晶粒没有明显长大,这是因为7A04 合金固溶处理前的原始组织为挤压态组织, 这种形变组织储存大量的变形储能,在高温下进行固溶处理必定会发生由回复到再结晶的组织转变,而这2种转变又相互竞争制约[13],在分级固溶的470 ℃低温段,形变组织主要发生回复消耗大量的变形储能,来不及完成再结晶并获得较大比例的亚晶, 晶界角度较小的亚晶具有较小的晶界迁移速率,从而在分级固溶高温段未得到尺寸较大的晶粒组织。

与单级固溶和双级固溶处理相比,三级固溶处理试样强度略有提高,一方面是因为三级固溶温度较高,第二相粒子在基体中溶解量较大,提高了基体的过饱和度[14],增加时效析出相的数量;且高温固溶提高了合金元素在基体中的扩散速率,提高了合金的成分均匀性,使其在时效过程中易析出均匀的析出相,增加时效强化效果。另一方面根据晶体空位浓度与温度成指数关系,得到随着固溶温度的提高,晶体内空位浓度越高,三级固溶温度达到490℃有利于提高晶体内空位浓度,有利于随后的时效强化效果,提高合金的强度。

剥落腐蚀是Al-Zn-Mg-Cu 系合金局部腐蚀形式之一,是内应力与晶间腐蚀协同作用下所发生的一种腐蚀形态,其本质是晶界上优先发生腐蚀[15]。对于7系铝合金,在剥落腐蚀环境中,晶界上的粗大杂质相以及铝基体可优先溶解,其中杂质相作为阳极溶解的趋势更甚。这些沿晶界杂质相与析出相发生腐蚀后,产生体积大于所消耗金属体积的腐蚀产物,它们聚集在晶界周围,形成“楔入效应”[16],顶压上面没有发生腐蚀的金属层并产生应力,使长轴晶粒相互作用萌生微裂纹,随着腐蚀产物堆积加速了裂纹的萌生与扩展,从而造成腐蚀沿晶界扩展,引起分层剥落。由于挤压态7A04铝合金的晶粒平行于材料表面、宽而长呈扁平状,第二相粒子沿晶界连续分布,在剥蚀浸泡环境中,腐蚀液可沿着先前腐蚀微裂纹不断进入,造成沿着晶界的杂质相连续溶解,从而导致合金的抗腐蚀性能急速下降。如对于未经过多级固溶处理挤压态和1号合金样品(图6(a)和图6(b)),腐蚀正是沿着其连续分布于晶界的粗大第二相发展,连续贯通,使基体呈现层状剥落。随着固溶级数升到三级,固溶温度升高与时间延长使合金中连续分布的非平衡结晶的粗大杂质相溶解更充分,减少了剥蚀腐蚀源;第二相粒子的不连续性增加,有效地阻断了腐蚀的传播路径;合金的成分均匀性增加,缩小晶粒与晶界的电位差,降低了腐蚀敏感性,故三级固溶试样才表现为均匀的点蚀,提高了合金的耐剥蚀性能。

4 结论

1) 与单级固溶和双级固溶相比,经三级固溶(470 ℃/2 h+480 ℃/1 h+490 ℃/0.5 h)后7A04铝合金棒材组织中粗大、难溶的第二相含量分别减少了36.9%和28.2%,固溶后未溶相主要是富Cu相及含Mg和Zn的杂质相。

2) 7A04铝合金棒材经三级固溶和120℃/24h时效后,抗拉强度Rm、屈服强度Rp0.2和伸长率A分别达到718.8 MPa,660.3 MPa和10.6%。抗拉强度相较于单级固溶与二级固溶分别提高了7.2%和2.2%。

3) 三级固溶温度较高,减少基体中第二相数量与尺寸,缩小晶粒与晶界的电位差,使合金剥落腐蚀的敏感性降低,7A04铝合金剥蚀等级由EC提升到EA-。

参考文献:

[1] HEINZ A, HASZLER A. Recent development in aluminum alloys for aerospace applications[J]. Mater Sci Eng A, 2000, 280: 102.

[2] CHEN Kanghua, LIU Hongwei, ZHANG Zhuo, et al. The improvement of constituent dissolution and mechanical properties of 7055 aluminum alloy by stepped heat treatments[J]. Journal of Materials Processing Technology, 2003, 142: 190-196.

[3] 罗勇, 许晓静, 张允康, 等. 强化固溶处理对7075铝合金晶间腐蚀和剥落腐蚀性能的影响[J]. 热加工工艺, 2012, 41(14): 203-205.

LUO Yong, XU Xiaojing, ZHANG Yunkang, et al. Effect of enhanced-solid-solution on intergranular corrosion and exfoliation corrosion of 7075 Al alloy[J]. Material & Heat Treatment, 2012, 41(14): 203-205.

[4] 陈小明, 宋仁国, 李杰. 7xxx系铝合金的研究现状及发展趋势[J]. 材料导报, 2009, 23(2): 67-90.

CHEN Xiaoming, SONG Renguo, LI Jie. Current research status and development trends of 7xxx series aluminum alloys[J]. Material Review, 2009, 23(2): 67-90.

[5] 宁爱林, 刘志义, 郑青春, 等. 分级固溶对7A04铝合金组织与性能的影响[J]. 中国有色金属学报, 2004, 14(7): 1212-1216.

NIN Ailin, LIU Zhiyi, ZHENG Qingchun, et al. Effects of progressive solution treatment on microstructure and mechanical properties of 7A04 aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(7): 1212-1216.

[6] 陈康华, 巢宏, 方华婵, 等. 逐步固溶处理对Al-Zn-Mg-Cu 系铝合金组织和局部腐蚀性能的影响[J]. 中南大学学报(自然科学版), 2010, 41(5): 1731-1732.

CHEN Kanghua, CHAO Hong, FANG Huachan, et al. Effect of step-solution microstructure and local corrosion properties of Al-Zn-Mg-Cu aluminum alloy[J]. Journal of Central South University (Science and Technology), 2010, 41(5): 1731-1732.

[7] 黄振宝, 张新明, 刘胜胆, 等. 固溶处理对7A55铝合金的组织和力学性能的影响[J]. 材料热处理学报, 2007, 28(1): 88-91.

HUANG Zhenbao, ZHANG Xinming, LIU Shengdan, et al. Effect of solution treatment on microstructure and mechanical properties of 7A55 aluminum alloy[J]. Transactions of Materials and Heat Treatment, 2007, 28(1): 88-91.

[8] 孙文会, 张永安, 李锡武, 等. 固溶热处理对7136 铝合金组织性能的影响[J]. 航空材料学报, 2014, 34(3): 36-40.

SUN Wenhui, ZHANG Yongan, LI Xiwu, et al. Effect of solution treatment on microstructure properties of 7136 aluminum alloy[J]. Journal of aeronautical materials, 2014, 34(3): 36-40.

[9] HB 5455—1990. 铝合金剥层腐蚀试验方法[S].

HB 5455—1990. The method for determining exfoliation corrosion of aluminum alloys[S].

[10] 巢宏, 陈康华, 方华婵, 等. 三级固溶处理对 Al-Zn-Mg-Cu 系铝合金组织和剥落腐蚀性能的影响[J]. 粉末冶金材料科学与工程, 2009, 14(3): 179-183.

CHAO Hong, CHEN Kanghua, FANG Huachan, et al. Effect of triple-solution on microstructure and exfoliation corrosion properties of Al-Zn-Mg-Cu aluminum alloy[J]. Materials Science and Engineering of Powder Metallurgy, 2009, 14(3): 179-183.

[11] HAN N M, ZHANG X M, LIU S D, et al. Effect of solution treatment on the strength and fracture toughness of aluminum alloy 7050[J]. Journal of Alloys and Compounds, 2011, 509: 4138-4145.

[12] 刘胜胆, 张新明, 黄振宝. 固溶处理对高纯7055铝合金组织的影响[J]. 材料热处理学报2006, 27(3): 54-58.

LIU Shengdan, ZHANG Xinming, HUANG Zhenbao. Effect of solution treatment on microstructure properties of 7055 aluminum alloy[J]. Transactions of Materials and Heat Treatment, 2006, 27(3): 54-58.

[13] 李松瑞, 周善初. 金属热处理[M]. 长沙: 中南大学出版社, 2003: 30-47.

LI Songrui, ZHOU Shanchu. Heat treatment of metals[M]. Changsha: Central South University Press, 2003: 30-47.

[14] 张新明, 何道广, 刘胜胆, 等. 多级强化固溶处理对 7050 铝合金厚板强度和断裂韧性的影响[J]. 中国有色金属学报, 2012, 22(6): 1548-1550.

ZHANG Xinming, HE Daoguang, LIU Shengdan, et al. Effects of multi-stage promotively-solutionizing treatment on strength and fracture toughness of 7050 aluminum alloy thick plate[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(6): 1548-1550.

[15] NAJJAR D, MAGNIN T, WARNER T J. Influence of critical surface defects and localized competition between anodic dissolution and hydrogen effects during stress corrosion cracking of a 7050 aluminum alloy[J]. Mater Sci Eng A, 1997, 238(2): 293-302.

[16] FANG H C, CHAO H, CHEN K H. Effect of recrystallization on intergranular fracture and corrosion of Al-Zn-Mg-Cu-Zr alloy[J]. Journal of Alloys and Compounds, 2015, 622(11): 166-173.

(编辑 赵俊)

收稿日期:2016-10-23;修回日期:2016-12-25

基金项目(Foundation item):国家科技支撑计划项目(2015BAG12B01);材料成形与模具技术国家重点实验室开放课题基金资助项目(P2015-10) (Project(2015BAG12B01) supported by the National Key Technology R&D Program of China; Project(P2015-10) supported by the State Key Laboratory of Materials Processing and Die & Mould Technology, Huazhong University of Science and Technology)

通信作者:赵君文,博士,副教授,从事高性能有色合金及复合材料研究;E-mail:swjtuzjw@swjtu.cn