DOI: 10.11817/j.issn.1672-7207.2018.08.011

7056铝合金厚板轧制变形不均匀性的实验研究与数值模拟

昌江郁1,陈送义1, 2,陈康华1, 2, 3,周亮1,袁丁玲1

(1. 中南大学 轻合金研究院,湖南 长沙,410083;

2. 中南大学 有色金属先进结构材料与制造协同创新中心,湖南 长沙,410083;

3. 中南大学 粉末冶金国家重点实验室,湖南 长沙,410083)

摘要:采用金相显微镜、织构分析、力学拉伸以及DEFORM有限元技术等分析测试方法研究7056铝合金厚度为20 mm板在厚度方向的组织、织构、性能以及轧制变形规律,重点揭示厚度方向1/4处轧制变形与织构和性能的关系。研究结果表明:从厚板表层到芯部再结晶程度逐渐增加;厚板芯部的轧制织构(Brass{011}<211>,S{123}<634>,Copper{112}<111>)体积分数最大,厚板表层的再结晶织构Cube{001}<100>体积分数最小,剪切织构(r-Cube{001}<110>,{112}<110>)主要分布在厚板的表层和1/4层,且在1/4层的体积分数最大;板材强度沿厚度方向呈“W”型分布,在厚度方向1/4处强度最低。其主要原因是轧制过程中厚板1/4层的剪切应力显著比表层与芯部的大,且该层的应变、应变速度和金属流动速度比表层的高,引起轧制变形不均匀。

关键词:7056铝合金厚板;不均匀性;数值模拟;剪切应力;织构

中图分类号:TG146 文献标志码:A 文章编号:1672-7207(2018)08-1914-08

Numerical simulation and experimental investigation of rolling deformation inhomogeneity of 7056 aluminum alloy thick plate

CHANG Jiangyu1, CHEN Songyi1, 2, CHEN Kanghua1, 2, 3, ZHOU Liang1, YUAN Dingling1

(1. Light Alloy Research Institute, Central South University, Changsha 410083, China;

2. Nonferrous Metal Oriented Advanced Structural Materials and Manufacturing Cooperative Innovation Center,

Central South University, Changsha 410083, China;

3. State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China)

Abstract: The microstructure, texture, property and deformation law of 7056 aluminum alloy thick plate with a thickness of 20 mm were investigated by optical microscopy, electron back-scattered diffraction(EBSD) technique, tensile tests and DEFORM finite element technology. The relationship among rolling deformation, texture and property was revealed. The results show that the fraction of recrystallization increases from the surface to the center layer, the volume fraction of rolling textures of the center is the highest, such as Brass{011}<211>, S{123}<634> and Copper{112}<111>, the volume fraction of recrystallization textures of the surface is the lowest, such as Cube{001}<100>, and the volume fraction of shear textures of the 1/4 layer is the highest, such as r-Cube{001}<110> and {112}<110>. The distribution shape of strength is “W” along the thickness direction, and the strength of 1/4 layer is the lowest. The main reason is that the shear stress of 1/4 layer is higher than that of the surface and center layer during the rolling process, and the strain, strain rate and metal flow velocity of 1/4 layer have similar changes, which can cause the uneven distribution of rolling of 7056 aluminum alloy thick plate along the thickness direction.

Key words: 7056 aluminum alloy thick plate; inhomogeneity; numerical simulation; shear stress; texture

Al-Zn-Mg-Cu 超强铝合金厚板具有超强、高韧、耐腐蚀等特点,广泛应用于飞机上翼壁板等结构[1-2]。为满足飞机大型化及结构构件的整体化研究要求,需要进一步提高超强铝合金板材组织和性能的均匀性[3]。超强铝合金厚板厚度方向组织性能不均匀性与第2相粒子分布、合金成分以及织构状态相关。HENK等[4]研究了7075-T651态铝合金板材力学性能、硬度和断裂韧性在厚度方向的均匀性,发现板材厚度性能不均匀与织构组成、合金成分以及粗大第2相粒子的不均匀分布有关,同时发现板材厚度1/4层强度最低,但未解释引起1/4层性能最低的根本原因。CHEN等[5]研究了7055-T7751铝合金厚板,发现从板材表层到芯部再结晶百分数降低,强度提高,再结晶织构转变为变形织构,其中1/4层的织构为混合织构,并提出该层织构的变化取决于轧辊几何尺寸。MISHIN等[6]研究了不同压下量时铝合金厚板的织构演变,发现厚度方向上织构的变化与轧制过程中不同层的剪切应力有关,提出当压下量较小时,1/4层的剪切应力会更大,将导致该层组织织构异常,这与SCHOENFELD等[7]的研究结果相符。在其他关于7150,7050,7B04和7A55铝合金板材厚度方向不同层组织与织构的演变、成分以及粗大第2相的分布规律中[8-11],也发现板材厚度方向的1/4层性能最低。但国内外对超强铝合金轧板厚度方向上组织性能的不均匀性与轧制过程中金属流动规律的关系没有进行深入研究。为此,本文作者以7056超强铝合金为研究对象,在研究板材厚度方向微观组织、织构和性能的基础上,利用DEFORM有限元模拟轧制成形过程,建立7056超强铝合金厚板在轧制中厚度方向上金属变形规律与组织、织构和性能不均匀性的关系,以便为提高超强铝合金厚板组织性能均匀性提供理论依据。

1 实验方法与有限元模型的建立

采用半连续铸造方法制备厚度为65 mm的7056铝合金扁锭,合金成分(质量分数,%)如下:Zn 9.190 0,Mg 1.900 0,Cu 1.520 0,Zr 0.140 0,Si 0.019 0,Fe 0.011 0,Ti 0.005 6,余量为Al。利用昆明重工产18 kN LG500不可逆两辊轧机进行厚板轧制实验。轧制坯料在430 ℃保温3 h,轧制共分7道次进行,道次间回炉保温30 min。对20 mm厚轧板进行465 ℃/1 h+470 ℃/1 h固溶处理以及120 ℃/24 h+155 ℃/8 h+120 ℃/24 h三级时效热处理。

沿厚度方向将板材分为表层、1/4层和中心层,粗磨、抛光后用Graff Sergent溶液 (3g CrO3+16 mL HNO3+1 mL HF+83 mL H2O) 腐蚀并用光学显微镜观察不同层晶粒形貌和晶粒度。利用配备了EBSD探头的ZEISS EVO MA10扫描电子显微镜表征不同厚度层的织构,试样测试前经机械抛光和电解抛光,试样制备的电解液为10%(体积分数,下同)高氯酸和90%无水乙醇,抛光电压为20 V,抛光时间为15 s。根据GBT 16865—2013,沿厚度方向将板材平均分为8层,制成沿轧向的拉伸试样,在电子万能实验机上进行拉伸力学性能测试。

有限元模型中铝合金厚板长×宽×高为162 mm×145 mm×65 mm,轧辊几何半径为210 mm。根据轧件的中心对称性,取其1/4建模计算,采用长×宽×高为4.5 mm×4.0 mm×4.0 mm的长方体单元将轧件划分为多个细密网格。轧制模型中将考虑在空气中的自然温降、轧辊与轧件间的接触热传导、表面摩擦生热以及轧件在变形时的功热转换和自身的热传递。空气的对流换热系数约为0.02 kW/(m2·℃)。铝合金厚板模型采用刘诗安等[12]研究中7056铝合金300~450 ℃下热变形的流变应力本构方程,摩擦因数取0.4,接触热传导系数取38 kW/(m2·℃)[13-15]。

2 研究结果

2.1 轧制厚板厚度方向的显微组织

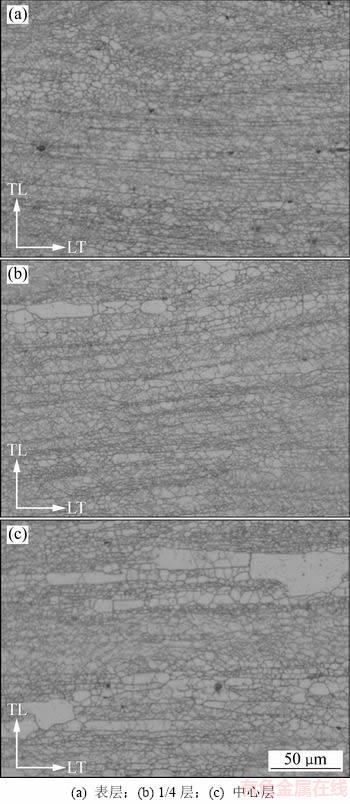

时效热处理后,7056铝合金轧板厚度方向的金相组织如图1所示。经过固溶与热处理后,板材各层发生部分再结晶,其中经过Graff Sergent试剂腐蚀后亚晶区域呈深灰色,再结晶区域呈浅灰色,再结晶晶粒沿轧制方向拉长呈扁平状,部分区域有异常长大的再结晶晶粒。厚度方向上板材各层的组织呈现不均匀分布。表层主要为大量的亚晶组织和晶粒度较小的再结晶晶粒;1/4层再结晶晶粒度增加,出现少量异常长大的再结晶晶粒;中心层的再结晶晶粒明显增多,且异常长大的再结晶晶粒比例明显增加。采用ImageJ软件统计板材各层的再结晶百分数,板材表层再结晶百分数为2.1%,1/4层再结晶百分数为4.9%,中心层再结晶百分数为7.2%。

图1 7056铝合金轧板厚度方向的金相组织

Fig. 1 Optical micrographs of 7056 aluminum alloy plate

2.2 轧制厚板厚度方向的力学性能

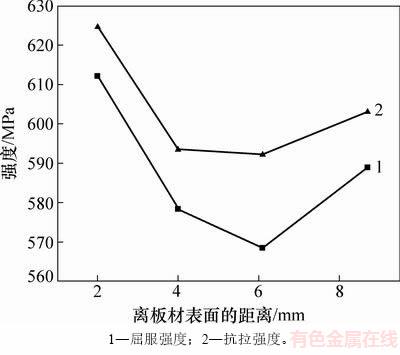

7056铝合金轧板沿厚度方向的强度分布如图2所示。图2中,横坐标表示离板材表面的距离。从图2可见:从板材表层到中心层,抗拉强度与屈服强度均呈先降低后升高的趋势,在1/4层附近抗拉强度与屈服强度达到最低值。其中表层抗拉强度为625 MPa,屈服强度为612 MPa;芯部的抗拉强度为603M Pa,屈服强度为589 MPa;最低点的抗拉强度为592 MPa,屈服强度为568 MPa。

图2 7056铝合金轧板厚度方向上不同层的力学性能

Fig. 2 Mechanical properties of different layers of 7056 aluminum alloy plate

2.3 轧制厚板厚度方向的织构

图3所示为7056铝合金轧板不同厚度层中各织构的体积分数变化。从图3可以看出7056铝合金轧板中主要有3种类型的织构:轧制织构(Brass{011}<211>,S{123}<634>,Copper{112}<111>)、剪切织构(r-Cube{001}<110>,{112}<110>)和再结晶织构Cube{001}<100>。从轧板表层到芯部,轧制织构的体积分数逐渐增大;剪切织构主要分布在轧板的表层和1/4层,并在1/4层的体积分数最大;再结晶织构Cube在厚板表层的体积分数极小,仅0.518%,主要分布在1/4层和芯部,且在1/4层最多。

图3 7056铝合金轧板厚度方向上各织构的体积分数

Fig. 3 Volume fraction of texture of 7056 aluminum alloy plate along thickness direction

2.4 有限元中轧板厚度方向的变形场

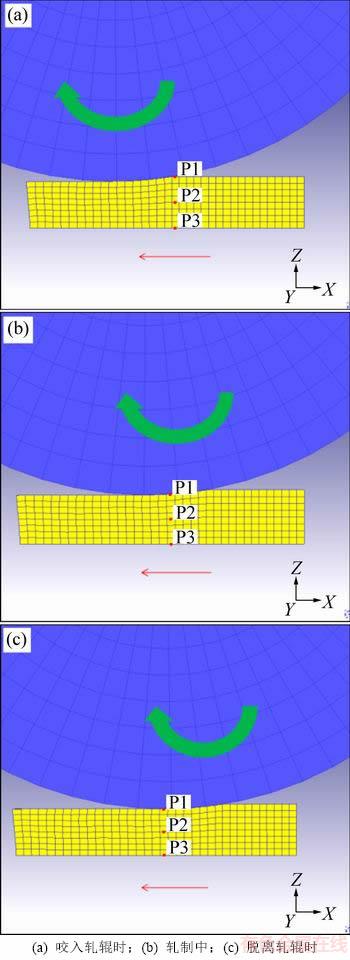

图4所示为7056铝合金轧板有限元模拟轧制过程。轧板某一厚截面上P1,P2和P3即轧板的表层、1/4层、中心层,每道次轧制中该厚截面都将从咬入轧辊开始到脱离轧辊结束。图4中,坐标轴X轴的负方向为轧件前进方向,因此,将根据有限元中任一个厚截面不同层的演变过程,研究轧制变形不均匀性。

轧件的表层与轧辊接触,主要受接触摩擦的作用而向前运动,1/4层以及中心层的金属受周边影响在相互作用力下运动,因此,作用在轧件轧制方向(X方向)的力呈不均匀分布,同时受板材厚度影响作用在沿Z轴方向的轧辊作用力也呈不均匀分布。通过有限元模拟轧制中厚截面不同层XZ向剪切应力的演变,研究各层变形场的变化趋势。

图4 任一厚截面经历的轧制过程

Fig. 4 Rolling processes of any thick section

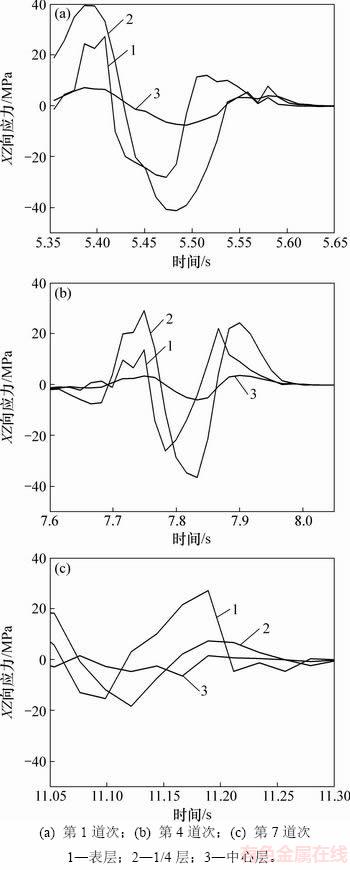

图5(a)~(c)所示为7056铝合金轧板不同轧制道次厚截面上表层、1/4层、中心层XZ向剪切应力随轧制过程的演变规律。当受到与轧板运动方向一致的应力时,应力为负;当受到与轧板运动方向相反的应力时,应力为正。图5(a)所示为第1道次轧制过程。从图5(a)可见:5.40 s时该厚截面咬入轧辊,各层所受的剪切应力均为正,1/4层所受剪切应力比表层的大;随后,各层的应力迅速减小并由正转负,但越靠近芯部,应力变化速度越慢,从而当表层受到的剪切应力变为-10 MPa时,1/4层剪切应力为17 MPa,中心层剪切应力为6 MPa,因此,厚度方向的1/4层剪切应力与其他层的绝对差值最大;5.45 s时,1/4层所受剪切应力再次超过表层剪切应力,且在5.49 s时1/4层与表层剪切应力差值达到最大,此时1/4层剪切应力为-39 MPa,表层为-3 MPa;从5.50 s起,该厚截面脱离轧辊,直到该道次结束各层剪切应力为0 MPa。图5(b)所示为第4道次XZ向剪切应力的变化,变化趋势与第1道次的相同。图5(c)所示的第7道次中,该厚截面的轧制时间为11.1~11.2 s。从图5(c)可以看出:随轧制道次增加,轧件厚度减小;在该道次各层剪切应力的变化起伏程度最小,但轧件各层XZ向剪切应力变化趋势仍与前几个道次的类似。

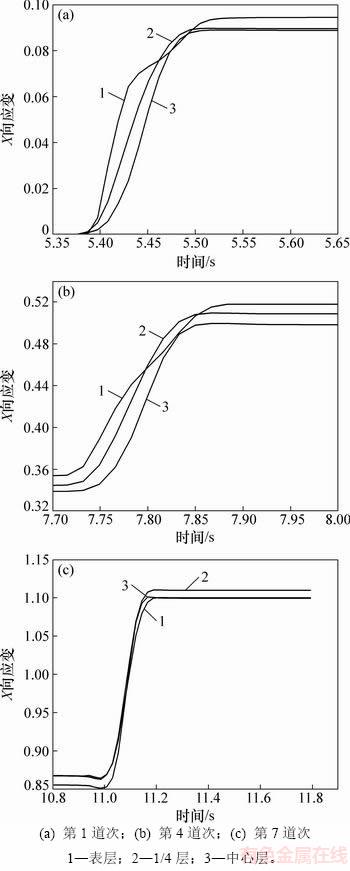

图6(a)~(c)所示分别为不同轧制道次中轧件某厚截面上表层、1/4层、中心层X向应变的变化趋势。从图6可以看出:该厚截面咬入轧辊后,表层应变的增加趋势骤降,5.45 s时1/4层的应变超过表层的应变,该时刻正是图5(a)~(c)中1/4层的XZ向剪切应力为负值时超过表层的时刻。在轧制的最终道次,图6(c)所示厚度方向上1/4层的X向应变最大。

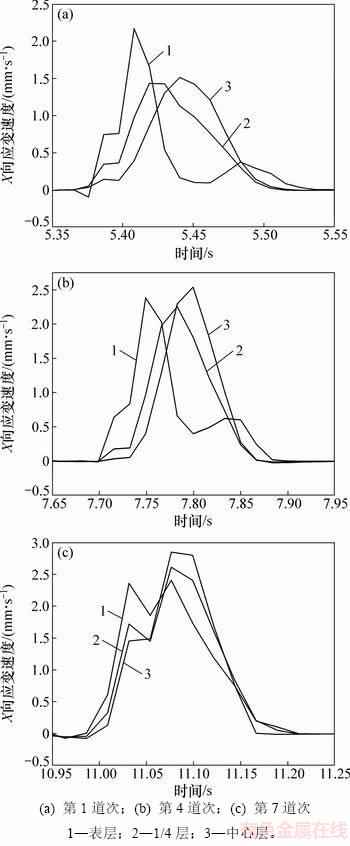

图7(a)~(c)所示为厚截面不同层X向应变速度在多道次轧制中的变化,通过应变速度的演变趋势能直观地了解剪切应力对轧件厚度方向上不同层变形的影响。从图7(a)可见:5.40 s时,该厚截面咬入轧辊,厚度方向上表层的X向应变速度最大,随后表层X向应变速度陡降,1/4层和中心层X向应变速度增加,达到表层的数倍;5.45 s时,1/4层剪切应力、X向应变比表层的大,1/4层与表层的X向应变速度差值达到最大。虽然图7中所示轧件中心层的X向应变速度最大,但由于中心层应力与应变很小,所以,对变形不均匀性的影响比1/4层的小。

图5 厚截面上不同层XZ向应力场的变化

Fig. 5 Variation of stress in XZ direction in different layers on simulation

图8(a)~(c)所示分别为厚截面不同层的X向金属流动速度在多道次中的变化。由图8可知:轧件剪切应力的变化影响不同层的金属流动速度场。图8(a)中,5.4 s时厚截面咬入轧辊,厚度方向上越靠近表层金属流动速度越快,但随着图8(a)中表层剪切应力增加幅度变小,表层金属流动速度的增加趋势也骤降,进入一段较平滑的变化期,此时,与厚截面的其他层相比,表层的变形较难发生,而1/4层的金属流动速度仍然增加并比表层的高;随后,中心层的金属流动速度也比表层的高,这与王祝堂等[16]在研究轧制不均匀变形中所得结果一致。

图6 厚截面上不同层X向应变场的变化

Fig. 6 Variation of strain in X direction in different layers on simulation

图7 厚截面上不同层X向应变速度场的变化

Fig. 7 Variation of strain rate in X direction in different layers on simulation

图8 厚截面上不同层X向金属流动速度场的变化

Fig. 8 Variation of metal flow velocity in X direction in different layers on simulation

3 分析与讨论

Al-Zn-Mg-Cu合金板材厚度方向上各层的织构变化与轧制变形有关[17-18]。如图3所示,从厚板表层到芯部,轧制织构的体积分数逐渐增大,剪切织构主要分布在轧件表层与1/4层。由DEFORM有限元分析可知:在轧制过程中,由于板材芯部剪切应变小,处于理想的平面应变状态,因此,厚板芯部的轧制织构体积分数最大[19];同时,轧制中轧板厚度方向上从表层到中心层,剪切应力的变化趋势并非呈递减分布规律(如图5(a)~(c)所示),1/4层的剪切应力变化幅度最大,所受剪切应力为表层和中心层的数倍。由于剪切应力的作用使表层的轧向应变、应变速度和金属流动速度增长趋势减慢甚至比1/4层的低,使轧件表层与1/4层形成剪切织构,并在1/4层其体积分数最大。

轧板的屈服强度与织构和微观组织有关[20]。一般用泰勒因子M表征织构对屈服强度的影响。不同种类的织构其泰勒因子M不同,M越大,表明该织构有利于提高屈服强度。而Al-Zn-Mg-Cu合金作为多晶材料,在塑性变形时采用HUTCHINSON的自洽模型分析[21],此时剪切织构(r-Cube,{112}<110>)的M为2.6,再结晶织构(Cube)的M为2.45,轧制织构Brass,S和Copper的M分别为2.94,2.97和3.44[22],可见剪切织构(r-Cube,{112}<110>)和再结晶织构(Cube)的M均比轧制织构(Brass,S和Copper)的低,因此,与轧制织构相比,剪切织构和再结晶织构不利于屈服强度的提高。此外,Al-Zn-Mg-Cu合金的晶粒形貌也影响合金强度。轧制中越靠近轧板芯部第二相粒子的破碎程度越低,从而在板材芯部分布粗大的第2相粒子,固溶处理时易诱发再结晶[8, 11, 23]。随着再结晶晶粒度与再结晶百分数增加,亚晶界强化作用与细晶强化作用大大降低,从而降低厚板强度[24-25]。因为厚度方向上板材各层剪切应力的变化影响织构的分布,在织构分析结果中,板材1/4层形成的剪切织构体积分数最大;再结晶织构也主要分布在1/4层和芯部,导致板材1/4层的强度损失最严重。板材芯部的再结晶晶粒度与再结晶百分数最大,表层的再结晶程度最低(如图1所示),这导致板材表层的强度比芯部高,因此,厚度方向上板材的强度呈“W”型不均匀分布。

针对影响板材轧制中变形均匀性的各因素,改变轧制各道次压下量、轧件几何因素、轧辊与轧件的摩擦条件等都将使轧板厚度方向上的剪切应力发生变化,为降低轧制变形不均匀性以及超强铝合金板材厚度方向性能不均匀性创造了有利条件。

4 结论

1) 7056铝合金轧板在厚度方向上组织、织构与性能呈不均匀分布,从表层到中心层再结晶程度增大,1/4层的剪切织构体积分数最大,厚度方向强度呈“W”型分布,在1/4层强度损失最严重。

2) 轧制期间铝合金轧板沿厚度方向上1/4层的剪切应力、轧向应变、轧向应变速度与轧向金属流动速度比表层大,引起轧制加工的变形不均匀。

3) 轧件厚度方向1/4层的剪切应力变化使该层剪切织构分布最多,这是导致轧板1/4处性能最低的主要原因。

参考文献:

[1] WILLIAMS J C, STRAKE E A. Progress in structural materials for aerospace systems[J]. Acta Materialia, 2003, 51(19): 5775-5799.

[2] 王祝堂. A380铝材研发路线图[J]. 有色金属加工, 2014, 43(5): 5-9.

WANG Zhutang. Development roadmap of aluminum alloys for A380 airplane[J]. Nonferrous Metals Processing, 2014, 43(5): 5-9.

[3] DIXIT M, MISHRA R, SANKARAN K K. Structure-property correlations in Al 7050 and 7055 high-strength aluminum alloys[J]. Materials Science and Engineering A, 2008, 478(1/2): 163-172.

[4] HENK F, DE J. Thickness direction inhomogeneity of mechanical properties and fracture toughness as observed in aluminum 7075-T651 plate material[J]. Engineering Fracture Mechanics, 1980, 13(1): 175-192.

[5] CHEN J Z, ZHEN L, ZHANG B Y, et al. Through-thickness microstructure, texture and strength gradients in AA 7055 rolled plate[J]. Materials Science Forum, 2007, 546/547/548/549: 957-960.

[6] MISHIN O V, BAY B, WINTHER G, et al. The effect of roll gap geometry on microstructure in cold-rolled aluminum[J]. Acta Materialia, 2004, 52(20): 5761-5770.

[7] SCHOENFELD S E, ASARO R J. Through thickness texture gradients in rolled polycrystalline alloys[J]. International Journal of Mechanical Sciences, 1996, 38(6): 661-683.

[8] 丛福官, 赵刚, 田妮, 等. 7150-T7751铝合金厚板性能的不均匀性[J]. 材料研究学报, 2013, 27(2): 145-148.

CONG Fuguan, ZHAO Gang, TIAN Ni, et al. Inhomogeneity of properties of 7150-T7751 aluminum alloy thick plate[J]. Chinese Journal of Materials Research, 2013, 27(2): 145-148.

[9] 张新明, 韩念梅, 刘胜胆, 等. 7050铝合金厚板织构、拉伸性能及断裂韧性的不均匀性[J]. 中国有色金属学报, 2010, 20(2): 203-208.

ZHANG Xinming, HAN Nianmei, LIU Shengdan, et al. Inhomogeneity of texture,tensile property and fracture toughness of 7050 aluminum alloy thick plate[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(2): 203-208.

[10] 张智慧, 左玉婷, 刘淑凤. 7B04铝合金板沿厚度方向显微组织、织构及力学性能的研究[J]. 电子显微镜学报, 2011, 10(4): 323-326.

ZHANG Zhihui, ZUO Yuting, LIU Shufeng. Study on microstructure, texture and tensile property of 7B04 aluminum alloy plate along thickness direction[J]. Journal of Chinese Electron Microscopy Society, 2011, 10(4): 323-326.

[11] 冯迪, 张新明, 刘胜胆, 等. 7A55铝合金厚板的微观组织和性能不均匀性[J]. 中南大学学报(自然科学版), 2015, 46(8): 2825-2830.

FENG Di, ZHANG Xinming, LIU Shengdan, et al. Inhomogeneity of microstructure and properties of 7A55 aluminum alloy thick plate[J]. Journal of Central South University (Science and Technology), 2015, 46(8): 2825-2830.

[12] 刘诗安, 孟显娜, 金能萍, 等. 7056铝合金高温热压缩流变应力行为[J]. 材料热处理技术, 2009, 38(24): 27-29.

LIU Shian, MENG Xianna, JIN Nengping, et al. Flow stress behavior of 7056 aluminum alloy during hot compression deformation at elevated temperature[J]. Material & Heat Treatment, 2009, 38(24): 27-29.

[13] MIRZA M S, SELLARS C M, KARHAUSEN K. Multipass rolling of aluminium alloys: finite element simulations and microstructural evolution win-roll strip casting of iron-base amorphous alloys[J]. Materials Science and Technology, 2001, 17(7): 874-879.

[14] BAGHERIPOOR M, BISADI H. Effects of rolling parameters on temperature distribution in the hot rolling of aluminum strips[J]. Applied Thermal Engineering, 2011, 31(10): 1556-1565.

[15] DUAN X, SHEPPARD T. Prediction of temperature evolution by FEM during multi-pass hot flat rolling of aluminium alloys[J]. Modelling and Simulation in Materials Science and Engineering, 2001, 9(6): 525-538.

[16] 王祝堂, 戴圣龙. 铝合金厚板生产技术与应用手册[M]. 长沙: 中南大学出版社, 2015: 73-76.

WANG Zhutang, DAI Shenglong. Handbook of aluminum plate production and application[M]. Changsha: Central South University Press, 2015: 73-76.

[17] 毛卫民. 金属材料的晶体学织构与各向异性[M]. 北京: 科学出版社, 2002: 47-53.

MAO Weimin. Metal materials of crystallographic texture and anisotropy[M]. Beijing: Science Press, 2002: 47-53.

[18] CHEN M B, LI J, ZHAO Y M, et al. Comparison of texture evolution between different thickness layers in cold rolled Al-Mg alloy[J]. Materials Characterization, 2011, 62(12): 1188-1195.

[19] CHOI C, KON J, OH K H, et al. Analysis of deformation texture inhomogeneity and stability condition of shear components in FCC metals[J]. Acta Materialia, 1997, 45(12): 5119-5128.

[20] 陈军洲, 甄良, 戴圣龙, 等. 晶粒形貌及织构对AA7055铝合金板材不同厚度层屈服强度的影响[J]. 稀有金属材料与工程, 2008, 37(11): 1967-1969.

CHEN Junzhou, ZHEN Liang, DAI Shenglong, et al. Effects of grain shape and texture on the through-thickness yield strength of AA7055 aluminum alloy plate[J]. Rare Matel Materials and Engineering, 2008, 37(11): 1967-1969.

[21] HUTCHINSON J W. Elastic-plastic behaviour of polycrystalline metals and composites[J]. Proceedings of the Royal Society of London, 1970, 1537(319): 247-272.

[22] STARINK M J, WANG S C. A model for the yield strength of overaged Al-Zn-Mg-Cu alloys[J]. Acta Materialia, 2003, 51(17): 5131-5150.

[23] 彭国胜. 变形和热处理对Al-Zn-Mg-Cu系超强铝合金组织和性能的影响[D]. 长沙: 中南大学粉末冶金研究所, 2011: 4-6.

PENG Guosheng. The effect of deformation and heat treatment on microstructure and properties of the super-strength Al-Zn-Mg-Cu aluminium alloy[D]. Changsha: Central South University.Powder Metallurgy Research Institute, 2011: 4-6.

[24] 王东, 马宗义. 轧制工艺对7050铝合金显微组织和力学性能的影响[J]. 金属学报, 2008, 44(1): 49-54.

WANG Dong, MA Zongyi. Effects of rolling process on microstructure and mechanical property of 7050 aluminum alloy[J]. Acta Metallurgica Sinica, 2008, 44(1): 49-54.

[25] 陈送义, 陈康华, 彭国胜, 等. 热变形温度和淬火速率对7085铝合金组织和性能的影响[J]. 中国有色金属学报, 2012, 22(4): 1034-1038.

CHEN Songyi, CHEN Kanghua, PENG Guosheng, et al. Effect of hot deformation temperature and quench rate on microstructure and property of 7085 aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(4): 1034-1038.

(编辑 陈灿华)

收稿日期:2017-08-10;修回日期:2017-10-22

基金项目(Foundation item):国家重点研发计划项目(2016YFB0300801);国家重点基础研究发展规划(973计划)项目(2012CB619502);国家自然科学基金重大科研仪器设备研制专项(51327902);国家自然科学基金资助项目(51201186)(Project(2016YFB0300801) supported by the National Key Research and Development Program of China; Project(2012CB619502) supported by the National Basic Research Program(973 Program) of China; Project(51327902) supported by the Major Research Equipment Development Program of National Natural Science Foundation of China; Project(51201186) supported by the National Natural Science Foundation of China)

通信作者:陈康华,博士,教授,从事铝及铝基复合材料研究;E-mail:khchen@csu.edu.cn