WC-Ni/SiC摩擦副滑动摩擦性能

易丹青1, 2,黄 亮1, 2,李 荐1, 2,姜媛媛1, 2,彭振文1, 2

(中南大学 有色金属材料科学与工程教育部重点实验室,湖南 长沙,410083

2. 中南大学 材料科学与工程学院,湖南 长沙,410083)

摘 要:以WC-(5, 7, 9)Ni硬质合金与SiC陶瓷材料为摩擦副,在MMU-10型屏显式材料端面摩擦磨损试验机上,研究该摩擦副材料在干摩擦条件下,不同压强、不同滑动速度时的摩擦磨损行为,利用扫描电子显微镜观察磨损后的表面形貌。结果表明:当压强一定时,随着滑动速度的增加,WC-Ni/SiC摩擦副的摩擦因数逐渐下降,并趋于平稳;当滑动速度一定时,随着试验压强p的增加,摩擦因数逐渐减小;摩擦因数还随合金中Ni含量的增加而增大;硬质合金的磨损量随材料的硬度降低而增大;当滑动速度0.95 m/s时,摩擦副材料的磨损机制与合金成分和试验压强p有关,当p=0.15 MPa时,WC-5Ni/SiC为粘着磨损,WC-7Ni/SiC和WC-9Ni/SiC表现为粘着和磨粒磨损综合作用机制;当p=0.60 MPa时,3种摩擦副的磨损机制主要是磨粒磨损。

关键词:硬质合金;摩擦;滑动;磨损机制

中图分类号:TG135.6 文献标识码:A 文章编号:1672-7207(2009)01-0099-07

Sliding friction properties of WC-Ni/SiC friction couple

YI Dan-qing1, 2, HUANG Liang1, 2, LI Jian1, 2, JIANG Yuan-yuan1, 2, PENG Zhen-wen1, 2

( The Key Laboratory of Non-Ferrous Metals, Material Science and Engineering,

Ministry of Education, Central South University, Changsha 410083, China;

2. School of Materials Science and Engineering, Central South University, Changsha 410083, China)

Abstract: The friction and wear behaviors of WC-(5, 7, 9)Ni/SiC friction couples were tested by a MMU-10 frictional tester at different applied pressures and speeds under dry sliding condition, and the morphologies of worn surface were observed by scanning electron microscopy (SEM). The results show that the friction coefficients of these friction couples decrease as the sliding speed increases when pressures are unaltered, and reach stable value eventually. With the increase of test pressure when speed is unaltered, the friction coefficients decrease gradually. The friction coefficients also increase with the increases of nickel content of these hard-materials. The wear loss increases as the hardness decreases. The wear mechanism is connected with the alloying component and test pressure when sliding speed is 0.95 m/s, the WC-5Ni/SiC couple is adhesive wear mechanism when p is 0.15 MPa, WC-7Ni/SiC and WC-9Ni/SiC couples are adhesion and abrasive wear mechanism; but when p is 0.60 MPa, there was abrasive wear mechanism for these WC-Ni/SiC couples.

Key words: cemented carbides; friction; sliding; wear mechanism

机械密封是动密封部件中最重要的组成部分之一,被广泛应用于船舶、油田、泵类、矿山等行业中,密封材料的性能是决定密封可靠性的首要因素[1-4]。硬质合金一直是机械密封中常用的密封面硬材料,其弹性模量和刚性特别大,而且耐磨性好。镍基碳化钨由于其优异的抗氧化和耐腐蚀性能在机械密封中比钴基碳化钨有着更广泛的应用[5]。刘如铁等[6]的研究表明,镍合金在高温下摩擦有一定的自润滑性能,能有效降低摩擦因数,耐磨损能力强;李云平等[7]发现涂覆层中Ni的加入改善了Al-Fe-V-Si耐热铝基复合材料摩擦磨损性能。由于WC-Ni硬质合金在强度和韧性方面的不足,各国学者通过添加Cr,Mo,Al或Cr3C2等来强化镍粘结相以及优化合金制备工艺[8-12],使其机械性能提高,用途也进一步得到推广。Surender等[13]对不同基体上镀Ni-WC复合涂层的摩擦磨损性能进行研究,认为材料的磨损性能取决于涂层中WC颗粒质量分数。目前,有关块状的WC-Ni硬质合金的摩擦磨损性能研究较少,特别是与SiC陶瓷材料组成摩擦副的磨损机理还未见到有研究报道,SiC陶瓷材料具有机械密封所要求的良好性能,被应用于高压、高转速、高温、腐蚀性以及含有固体颗粒介质等工矿条件,是优良的高温结构材料[14]。本文作者选取3种不同成分的WC-Ni硬质合金分别与SiC陶瓷材料异配对进行干摩擦磨损试验,研究在室温条件下这3种WC-Ni硬质合金与SiC陶瓷材料的摩擦磨损性能,探讨WC-Ni/SiC摩擦副在不同摩擦条件下的作用效果与机理,以及粘结相Ni对摩擦副摩擦性能的影响。

1 实 验

1.1 材料制备

3种WC-Ni硬质合金材料样品(粘结相Ni质量分数分别为5%,7%和9%,其余为WC)均采用粉末冶金工艺来制备[15],所用的匹配副材料SiC陶瓷试样由上海硅酸盐研究所提供。样品经过机械加工制成尺寸(外径×内径×厚度)为 30 mm×20 mm×10 mm的环块,对试样摩擦面进行研磨抛光,使其表面粗糙度Ra为1~2 μm;并用丙酮和无水乙醇进行清洗,放入干燥箱烘干以备试验。

1.2 实验方法

采用阿基米德排水法测定试样体积密度,利用HR-150A型洛氏硬度计检测试样的洛氏硬度,用CSS-4100型力学万能试验机(标准样B406-95)测试样品的横向断裂强度。在MMU-10型屏显式材料端面摩擦磨损试验机上模拟摩擦试验。动环为WC-Ni硬质合金,静环用SiC陶瓷材料。试验条件为:试验压强p分别取0.15,0.30,0.45和0.60 MPa,滑动速度为0.35~1.0 m/s。通过高精度负荷传感器测量摩擦力F,摩擦因数由试验机自动测出的摩擦力根据μ=F/(pA)计算(其中p为试验压强,A为摩擦面积),取磨合稳定阶段时的数值。利用Mettler-Toledo AB204N型电子分析天平(精度0.1 mg)称量试验前后样品的质量,其质量差即为磨损量?m,摩擦因数和磨损量均取4次试验结果的平均值。采用KYKY-2800和JSM-5600LV型扫描电子显微镜观察和分析试验环块磨损前后表面形貌。

2 结果与讨论

2.1 微观结构与物理性能分析

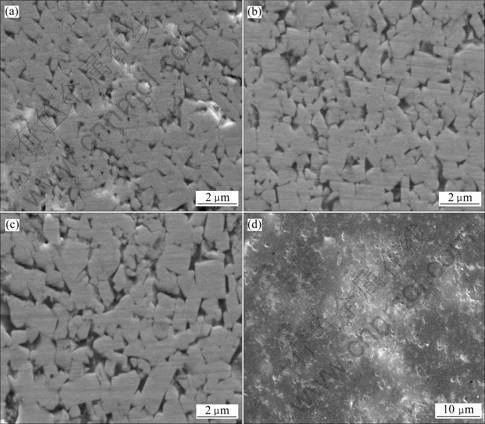

经研磨抛光后的WC-Ni硬质合金和SiC陶瓷的SEM照片如图1所示。根据相关资料可知,硬质合金的微观组织主要由硬质相WC和粘结相Ni组成。图1(a)~(c)中颜色较浅的为WC硬质相,碳化钨晶粒的形状呈不规则的多边形;SiC陶瓷表面的微观形貌呈鳞片状。试样的密度、硬度、晶粒大小和横向断裂强度如表1所示。

(a) WC-5Ni;(b) WC-7Ni;(c) WC-9Ni;(d) SiC

图1 WC-Ni硬质合金和SiC陶瓷抛光后的SEM像

Fig.1 SEM images of WC-Ni cemented carbides and SiC ceramics after polishing

表1 试验样品WC-Ni硬质合金和SiC陶瓷的成分及性能

Table 1 Composition and properties of the investigated WC-Ni cemented carbides and SiC ceramics

2.2 摩擦磨损性能分析

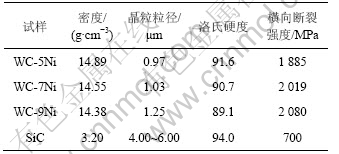

图2所示为3种WC-Ni硬质合金与SiC陶瓷材料配副在不同压强下摩擦因数与滑动速度变化的关系曲线。可以看出,对于同一摩擦副,在试验压强为0.15~0.6 MPa范围内,摩擦因数随着压强的增加而减小,这主要是与摩擦表面的啮合程度和表面变形有关;随着滑动速度的增加,这3种硬质合金摩擦副的摩擦因数是逐渐降低的,然后趋于平稳,变化幅度不大;对于同一摩擦条件下的摩擦副,Ni含量越多,摩擦因数越高。在该摩擦试验条件下,WC-5Ni硬质合金的摩擦因数最小(为0.17~0.26),而WC-9Ni合金摩擦因数达到0.24~0.33。

(a) WC-5Ni;(b) WC-7Ni;(c) WC-9Ni

1—0.15 MPa; 2—0.30 MPa; 3—0.45 MPa; 4—0.60 MPa

图2 WC-xNi/SiC摩擦因数在不同压强下随滑动速度的变化

Fig.2 Variations of WC-xNi/SiC couples’ friction coefficients vs. sliding speed at different pressures

从微观尺寸来看,试样表面是粗糙的,当动环和静环相互作用时,实际接触面积远远小于表观接触面积,根据固体摩擦学原理[16],可以认为摩擦因数是粘着和摩擦表面凸起啮合及性质的函数,在压强不大时,摩擦表面的啮合程度小,由于弹性变形(不经破坏)的结果可能使凸起分离,此时,摩擦和摩擦阻力产生的原因主要是表面微凸体啮合的机械力作用,随着试验压强的增加,啮合和变形的程度增加,对于硬材料组成的摩擦副,摩擦力与法向载荷不满足正比关系,材料的摩擦因数会随着滑动速度和载荷的变化而变化,由摩擦二项式定律

可知,摩擦因数 并不是一个常量,它随A/W的变化而变化,对于表面处于塑性接触状态的摩擦副,实际接触面积A与法向载荷W呈线性关系,摩擦因数μ与载荷无关,而符合Amonton定律[16]。式(1)中:

并不是一个常量,它随A/W的变化而变化,对于表面处于塑性接触状态的摩擦副,实际接触面积A与法向载荷W呈线性关系,摩擦因数μ与载荷无关,而符合Amonton定律[16]。式(1)中: 为摩擦因数;A为实际接触面积;W为法向载荷;

为摩擦因数;A为实际接触面积;W为法向载荷; 和

和 分别由摩擦表面的物理和力学性能决定的系数。对于表面是弹性变形状态时,实际接触面积与法向载荷的2/3成正比,故而摩擦因数随载荷的增加而减小。WC-Ni硬质合金和SiC陶瓷都属于脆性材料,有很高的硬度和弹性模量,在所选定的试验压强内,发生塑性变形很不容易,所以,组成摩擦副的摩擦因数是变化的。

分别由摩擦表面的物理和力学性能决定的系数。对于表面是弹性变形状态时,实际接触面积与法向载荷的2/3成正比,故而摩擦因数随载荷的增加而减小。WC-Ni硬质合金和SiC陶瓷都属于脆性材料,有很高的硬度和弹性模量,在所选定的试验压强内,发生塑性变形很不容易,所以,组成摩擦副的摩擦因数是变化的。

摩擦因数随滑动速度的增加而减小,可能是由于高滑动速度下摩擦面凸起啮合程度的减小,也就是说啮合不到完全深度;但随着转速的继续增加,一方面,在摩擦面间形成空气膜,起到一定的润滑减摩作用,另一方面,可能是单位时间内生成的摩擦热越来越多,而累积在微凸体上的瞬间摩擦热很高,出现软化效应,使得凸体具备一定的流变能力,摩擦阻力相应减弱。随着粘结相Ni含量的增加,摩擦因数也逐渐增加,这可能主要与摩擦副表面的硬度有关。当处在相同的摩擦条件时,与SiC配副的材料的表面硬度越低,凸起的啮合程度越大,所受的摩擦阻力也会增大,摩擦因数也随之增大。当两环相对滑动时,导致表层的组织脱落而不断被损耗,产生磨损现象。

图3所示为3种WC-Ni硬质合金在线速度为0.95 m/s时不同压强下滑动2 h后的磨损量关系。从图3可以看出,磨损量随压强的增大而呈增加趋势,但没有很明显的线性比例关系,主要是因为摩擦系统是一个非常复杂的体系,摩擦过程会发生表面物理、化学的变化,这些与边界条件和实验条件如速度、压力、环境温度、接触方式等因素有关。从图3还可以看出,WC-5Ni硬质合金在压强为0.15 MPa和0.30 MPa时磨损量非常小,为0~0.1 mg,各种压强作用下SiC陶瓷的磨损量也非常小,无法检测。在同等条件下,WC- Ni硬质合金的磨损量从大到小的顺序是:WC-9Ni,WC-7Ni,WC-5Ni。可见,WC-5Ni/SiC摩擦副的耐磨性能最好。

图3 WC-Ni硬质合金不同压强下滑行2 h后的磨损量

Fig.3 Wear mass losses of WC-Ni cemented carbides at sliding time of 2 h and different applied pressures

从表1可以看出,随着合金中镍含量的增高,硬质合金材质的硬度下降。与之配对的SiC陶瓷材料硬度更高。根据摩擦副的工况条件,选择合适的对摩材料能有效地提高材料的使用寿命。既要有足够的强度和韧性,也要保证材质的硬度,所以,研制超细/纳米晶硬质合金成为当今人们研究的热点。

用于耐磨密封材料的性能应具有较低的摩擦因数和较高的耐磨性,这将决定着摩擦部件的能耗和最大的使用寿命。从以上结果可知,在所研究的3种硬质合金中,WC-5Ni合金在各种试验条件下具有最低的摩擦因数,表现出较强的耐摩擦性能。

2.3 磨损表面形貌分析

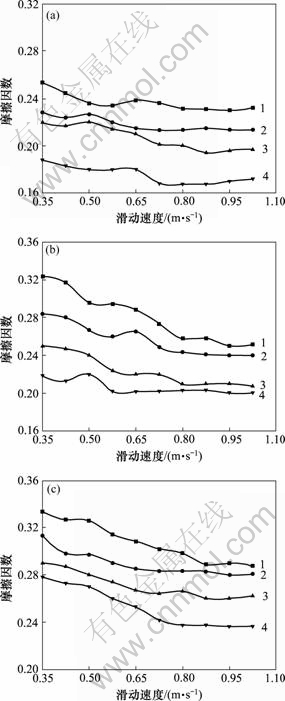

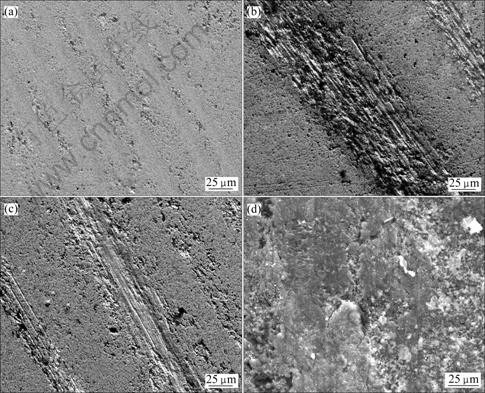

摩擦副在滑动速度为0.95 m/s,压强为0.15 MPa作用下滑动2 h后磨损表面的形貌如图4所示。可以看出,对于不同的摩擦材料,摩擦表面的磨损程度不一,随着硬质合金镍含量的增加,也就是合金硬度的降低,磨损面的摩擦划痕越来越深。WC-5Ni合金表面沿滑动方向有少量磨削脱落留下的微孔,而WC-7Ni和WC-9Ni合金不仅有大量的微孔,还有明显经脱落的硬质颗粒嵌入随滑移方向而形成的犁沟,对偶材料SiC陶瓷表面光滑平整。

(a) WC-5Ni; (b) WC-7Ni; (c) WC-9Ni; (d) SiC

图4 WC-xNi/SiC摩擦副在p=0.15 MPa时磨损后表面SEM像(v=0.95 m/s)

Fig.4 SEM images of WC-xNi/SiC friction couples’ wore surface under p=0.15 MPa

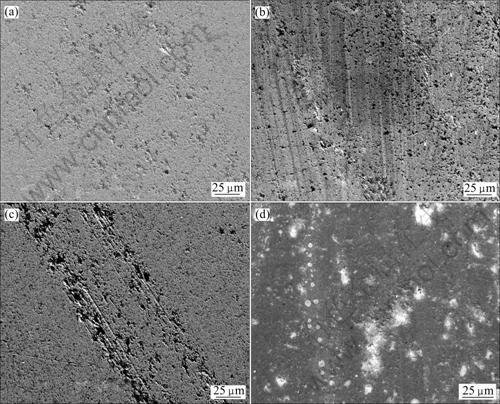

图5所示为摩擦副在滑动速度为0.95 m/s,压强为0.60 MPa作用下滑动2 h后磨损表面的SEM形貌。可以看出,增大试验载荷,磨损面出现较为严重的摩擦划痕,各合金的磨损程度也有差异,对于硬度较高的WC-5Ni硬质合金,所含低熔点组元较少,摩擦面能承受较多的热量,磨损表面被破坏的程度最小;而硬度相对较低的WC-7Ni和WC-9Ni合金由于被脱落下来的硬质颗粒嵌入,随着滑行方向出现较深的犁沟,并出现大面积的摩擦面被擦伤的区域,SiC陶瓷表面也因为摩擦热作用出现了裂纹。载荷的增加引起弹塑性变形,必然导致高温出现,在摩擦的起始阶段,摩擦表面的微凸体相互嵌入,需要发生较大的变形才能克服静摩擦力;由于跑合时表面微凸体断裂形成磨削,随着摩擦时间的增加,将形成一层磨削膜导致摩擦力降低;WC-Ni硬质合金材料内各组分硬度不同,成膜能力有差异,随着载荷的不同,磨削膜的形成也不一样,这些因素的综合作用,使得摩擦磨损性能有所差异。

(a) WC-5Ni; (b) WC-7Ni; (c) WC-9Ni ; (d) SiC

图5 WC-xNi/SiC摩擦副在v=0.95 m/s 和p=0.60 MPa作用下磨损后表面SEM像

Fig.5 SEM images of WC-xNi/SiC friction couples’ wore surface under p=0.60 MPa and v=0.95 m/s

磨损机制的分类主要有磨粒磨损、粘着磨损、疲劳磨损和腐蚀磨损[16]。磨粒磨损主要有微观切削、挤压剥落和疲劳破坏3种作用形式;粘着磨损是由于粘着效应所形成粘着结点发生剪切断裂,被剪切的材料或脱落成磨屑,或由一个表面迁移到另一个表面,这类磨损的破坏主要发生在软金属的表层上。疲劳磨损是在循环变化的接触应力作用下由于材料的疲劳剥落而形成的磨损方式;腐蚀磨损则是由于金属与周围介质发生化学或电化学反应而产生的表面损伤磨损,如氧化磨损和特殊介质腐蚀磨损。WC-Ni硬质合金和SiC陶瓷都含有高熔点的组元,对摩擦热产生的影响不是很敏感,只有低熔点组元Ni,在摩擦过程中能形成磨削膜,但这种膜在硬质颗粒的作用下并不能起到很好的减摩效果,反而使得摩擦表面的微凸体更容易嵌入到基体组织中,增大摩擦阻力。根据磨损形貌及其形成机理,在压强为0.15MPa作用下,WC-5Ni合金磨损面上的孔洞可能是粘着脱落而形成的,磨损量非常小,因此,可以推测这种作用机制主要为轻微的粘着磨损;而WC-7Ni和WC-9Ni合金不仅有磨屑脱落形成的孔洞,还有经硬质颗粒挤压形成细小的犁沟,表现为粘着和磨粒磨损综合作用,而且从所受摩擦力的结果来看,随着Ni含量的增加,摩擦阻力增大,表现为摩擦因数升高。随着试验载荷力的增大,由于硬质合金表面硬度比SiC陶瓷的低,在摩擦过程中,其表面易发生变形、嵌入和撕裂,可以看出硬质合金磨损表面的犁沟效应比较显著,WC-5Ni合金由于表面硬度较高,硬颗粒嵌入的难度大,其机制表现出微观切削作用的磨粒磨损机制。而WC-7Ni和WC-9Ni合金主要表现为犁沟效应和挤压剥落作用的磨粒磨损机制。

3 结 论

a. WC-Ni/SiC摩擦副摩擦因数的变化规律是:在滑动速度为0.35~1.0 m/s时,随滑动速度的增加而减小,后趋于稳定;在压强为0.15~0.60 MPa时,随压强的增大而减小;随Ni含量的增大而增加,在相同的摩擦条件下,与WC-7Ni和WC-9Ni 2种合金相比,WC-5Ni合金摩擦因数较低(0.17~0.24)。

b. WC-Ni硬质合金的磨损量与材质的硬度有关,在滑动速度为0.95 m/s、压强为0.15~0.60 MPa时,WC-5Ni,WC-7Ni和WC-9Ni这3种硬质合金中WC-5Ni合金几乎无磨损,WC-9Ni的磨损量最大,WC-7Ni合金的磨损量介于WC-5Ni和WC-9Ni中间,WC-5Ni合金表现出优良的耐磨性能。

c. 当滑动速度0.95 m/s时,WC-Ni/SiC摩擦副的磨损机制与材料的成分和试验压强p有关,WC-5Ni合金在p为0.15 MPa时为粘着磨损,WC-7Ni和WC-9Ni合金的磨损机制主要是轻微粘着磨损和磨粒磨损综合作用;在p为0.60 MPa时,3种WC-Ni合金的磨损机制主要为磨粒磨损。

参考文献:

[1] 姚世卫, 王 娟, 王 隽. 深水艉轴密封装置摩擦副试验研究[J]. 润滑与密封, 2006(10): 154-156.

YAO Shi-wei, WANG Juan, WANG Jun. Research of friction materials matching examination of great-diving stern shaft sealing[J]. Lubrication Engineering, 2006(10): 154-156.

[2] 曾 涛. 机械密封的摩擦副材料[J]. 润滑与密封, 1999(6): 66-67.

ZENG Tao. The frictional couple material of mechanical seal[J]. Lubrication Engineering, 1999(6): 66-67.

[3] 彭宽平. 充气集装式机械密封在化工泵中的应用[J]. 液压与气动, 2007(8): 61-62.

PENG Kuan-ping. Application of gas cartridge mechanical seal in chemical pump[J]. Chinese Hydraulics & Pneumatics, 2007(8): 61-62.

[4] 罗 斌. 潜艇水润滑机械密封摩擦副材料性能的试验研究[J]. 船舶工程, 2002(4): 56-58.

LUO Bin. Experimental study on properties of frictional materials for water-lubricating mechanical seal in submarine[J]. Ship Engineering, 2002(4): 56-58.

[5] Voitovich V B, Sverdel V V, Voitovich R F, Golovko E I. Oxidation of WC-Co, WC-Ni and WC-Co-Ni hard metals in the temperature range 500-800 ℃[J]. International Journal of Refractory Metals and Hard Materials, 1996, 14(4): 289-295.

[6] 刘如铁, 李溪滨, 熊党生, 等. 一种镍基高温自润滑材料摩擦学特性的研究[J]. 中南工业大学学报: 自然科学版, 2000, 31(3): 260-263.

LIU Ru-tie, LI Xi-bin, XIONG Dan-sheng, et al. Study on the tribological characteristics of a high-temperature self-lubricating nickel-base material[J]. Journal of Central South University of Technology: Natural Science, 2000, 31(3): 260-263.

[7] 李云平, 李溪滨. 涂覆颗粒增强耐热铝基复合材料的性能[J]. 中南工业大学学报: 自然科学版, 2001(12): 612-616.

LI Yun-ping, LI Xi-bin. Mechanical properties of coating particulates reinforced aluminium alloy matrix composites[J]. Journal of central south university of technology: Natural Science, 2001(12): 612-616.

[8] 孔德会, 何宝山, 刘林海. Cr含量对WC基硬质合金组织和性能的影响[J]. 上海有色金属, 2005(6): 53-56.

KONG De-hui, HE Bao-shan, LIU Lin-hai. Effect of chromium content on structure and properties of WC-based cemented carbide[J]. Shanghai Nonferrous Metals, 2005(6): 53-56.

[9] 索进平, 冯 涤, 骆合力, 等. 耐磨耐蚀Ni-Al金属间化合物基复合保护层的研制[J]. 材料保护, 2002(2): 34-36.

SUO Jin-ping, FENG Di, LUO He-li, et al. Developing of anticorrosion and anti-wear composite coating by nickel-aluminum intermetallic compound[J]. Materiais Protection, 2002(2): 34-36.

[10] 王清波, 窦新旺, 晁明举, 等. Mo对高硬度镍基合金激光熔覆层组织和耐磨性的影响[J]. 应用激光, 2005(2): 97-100.

WANG Qing-bo, DOU Xin-wang, CHAO Ming-ju, et al. Effect of Mo-doping on the microstructure and wear properties of laser-clad nickel-based coatings[J]. Applied Laser, 2005(2): 97-100.

[11] 史晓亮, 邵刚勤, 段兴龙, 等. VC, Cr3C2对WC-Co纳米粉烧结性能的影响[J]. 北京科技大学学报, 2004(6): 612-614.

SHI Xiao-liang, SHAO Gang-qin, DUAN Xing-long, et al. Influence of VC, Cr3C2 on sintering properties of nanocrystalline WC-Co composite powders[J]. Journal of University of Science and Technology Beijing, 2004(6): 612-614.

[12] 贾佐诚. 烧结态硬质合金的HIP处理[J]. 粉末冶金工业, 2000(5): 22-25.

JIA Zuo-cheng. HIP processing of as-sintered cemented carbides[J]. Power Metallurgy Industry, 2000(5): 22-25.

[13] Surender M, Basu B, Balasubramaniam R. Wear characterization of electrodeposited Ni-WC composite coatings[J]. Tribology International, 2004, 37: 743-749.

[14] 于新奇, 任欧旭, 鲁占全. 碳化硅材料在机械密封中的应用[J]. 河北工业科技, 2005(3): 134-137.

YU Xin-qi, REN Ou-xu, LU Zhan-quan. Application of silicon carbide in mechanical seals[J]. Hebei Journal of Industrial Science & Technaology, 2005(3): 134-137.

[15] 株洲硬质合金厂. 硬质合金的生产[M]. 北京: 冶金工业出版社, 1974.

Zhuzhou Cemented Carbide Company. The manufacture of cemented carbide[M]. Beijing: Metallurgical Industry Press, 1974.

[16] 温诗铸. 摩擦学原理[M]. 北京: 清华大学出版社, 1991.

WEN Shi-zhu. Principles of tribology[M]. Beijing: Tsinghua University Press, 1991.

收稿日期:2008-01-18;修回日期:2008-04-21

基金项目:国家科技支撑计划资助项目(2006BAE03B03);中南大学博士后基金资助项目(2004年)

通信作者:易丹青(1953-),男,湖南湘乡人,教授,从事粉末冶金材料制备及性能研究;电话:0731-8836320;E-mail: danqing@mail.csu.edu.cn