DOI:10.19476/j.ysxb.1004.0609.2018.12.17

氧气底吹熔炼氧枪枪位优化

郭学益1, 2,闫书阳1, 2,王亲猛1, 2, 3,田庆华1, 2

(1. 中南大学 冶金与环境学院,长沙 410083;

2. 中南大学 中国有色金属工业清洁冶金工程研究中心,长沙 410083;

3. 中南大学 资源加工与生物工程学院,长沙 410083)

摘 要:在氧气底吹熔炼过程中,合理的氧枪枪位是获得良好熔炼效果的重要因素。分别对氧气底吹炉对心异侧(Ⅰ)、对心同侧(Ⅱ)、非对心同侧(Ⅲ) 3种不同氧枪枪位布置方式进行数值模拟,研究(Ⅰ)、(Ⅱ)、(Ⅲ) 3种方式对熔池气液两相分布、熔体喷溅高度、熔池气含率、熔池速度场和熔池流线分布等影响。结果表明:相比于(Ⅰ)、(Ⅱ) 2种方式,(Ⅲ)方式下熔体喷溅高度低,熔池波动平稳,熔池平均气含率高且烟气烟尘率低,是一种适宜的氧枪枪位布置方式,对解决生产过程熔体喷溅、炉体腐蚀严重和烟尘率高等问题有积极作用。

关键词:底吹熔炼;氧枪枪位;数值模拟;气含率;流线分布

文章编号:1004-0609(2018)-12-2539-12 中图分类号:TF811 文献标志码:A

氧气底吹熔池熔炼是我国自主开发的新型强化熔池熔炼工艺[1-2],为国家工信部重点推广对象[3],广泛应用于铜[4]、铅[5]、锑[6]等有色金属冶炼行业。有学者对氧气底吹熔池熔炼工艺进行了大量理论研究[7-10],对推动氧气底吹熔炼工艺发展及明晰熔炼机理起到了一定指导作用,但在实际生产过程中依然存在一些问题需要解决。

氧枪枪位布置方式是氧气底吹熔炼工艺的关键,合理的氧枪枪位对提高熔炼生产效率、降低渣含铜、烟尘率以及减缓熔炼炉衬腐蚀程度等方面具有重要意义[11-13]。闫红杰等[14]和张振扬等[15]运用数值模拟方法研究了底吹炉氧枪倾角、氧枪间距、氧枪直径等对熔池熔炼过程影响。蓝海鹏等[16]采用VOF两相流模型对氧枪吹氧过程和气液两相流在熔池中的相互作用进行了模拟计算,研究了不同氧枪角度和气体流量对熔池气液两相流场影响。余跃等[17]利用水模型实验对底吹炉内流动过程进行了研究,结合数值模拟方法对比分析了4种不同喷口结构对氧枪搅拌区域及喷口压力波动影响。SHUI等[18]通过底吹炉水模型实验研究了不同氧枪角度和气体喷吹流量对熔池表面波的形成、波幅及频率变化影响。

目前关于不同氧枪枪位布置方式对底吹熔炼过程影响研究的相关文献报道较少,为了优化底吹熔炼炉氧枪枪位布置方式,明确底吹熔炼过程气液两相流作用机制,本文作者研究了3种不同枪位方式下底吹熔炼炉内气液两相流流场变化,以期找出合适的底吹熔炼氧枪布置方式,为提高实际生产效率、减轻加料口物料粘结和耐火材料的腐蚀程度等问题提供指导。

1 模型建立

1.1 物理模型

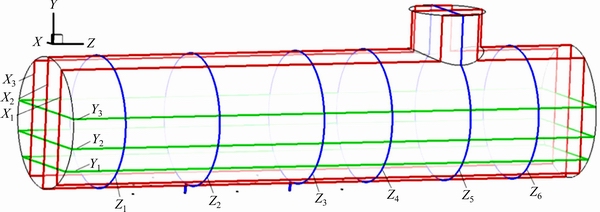

以国内某公司底吹熔炼炉为研究对象,其简化物理模型如下图1所示。

熔炼炉体内径尺寸为d 3.5 m×15 m,底部双排布置9支氧枪,上排5支,下排4支,氧枪直径为0.06 m,熔池深度为1.3 m,氧枪间距为0.65 m。为对比研究3种氧枪枪位方式对底吹熔炼炉内各空间位点流场变化影响,以炉体左端面中心为坐标原点,沿炉体X、Y、Z轴方向依次截取截面X1=-0.85 m、X2=0 m、X3=0.85 m、Y1=-1.1 m、Y2=-0.45 m、Y3=0.35 m、Z1=1.5 m、Z2=4.2 m、Z3=7.2 m、Z4=9.15 m、Z5=11.4 m、Z6=13.35 m。

图1 氧气底吹熔炼炉简化模型

Fig. 1 Simplified model of oxygen bottom blown furnace

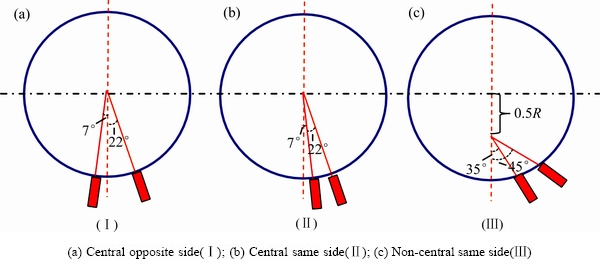

图2 氧气底吹熔炼炉3种氧枪枪位布置方式

Fig. 2 Three layouts of oxygen lances positions of oxygen bottom blown furnace

3种不同氧枪枪位布置方式如图2所示:(Ⅰ)方式为双排对心两侧布置,简称对心异侧方式,角度分别为22°和7°;(Ⅱ)方式为双排对心同侧布置,简称对心同侧方式,角度与(Ⅰ)方式相同;(Ⅲ)方式为双排非对心同侧布置,简称非对心同侧方式,氧枪与截面中心线夹角分别为35°和45°。结合图1各截面,分析气液两相分布、熔体喷溅高度、熔池气含率、流体速度场分布等,探讨熔炼过程气液两相作用机制以及(Ⅰ)、(Ⅱ)、(Ⅲ) 3种枪位布置方式的特点。

1.2 数学模型

氧气底吹熔池熔炼过程涉及传热传质、相变及化学反应,过程复杂,而本文主要研究不同氧枪布置方式下熔池内部流场变化情况,因此作出以下假设:

1) 气液两相均为不可压缩流体,物性参数不随时间、空间变化。

2) 炉内熔体为铜锍相,忽略渣层影响,初始状态为静止状态。

3) 不考虑熔炼过程化学反应。

结合已有研究成果[19-23],VOF两相流模型能够精确模拟气泡的自由液面,对流体中大气泡运动和气液界面的稳态和瞬态处理具有优良表现。本文采用VOF两相流模型,该模型遵循质量守恒和动量守恒定律,基本控制方程如下。

1) 连续性方程

(1)

(1)

式中: 是p相到q相的质量输送,

是p相到q相的质量输送, 是q相到p相的质量输送,单位为kg;

是q相到p相的质量输送,单位为kg; 为第q相的体积分数;

为第q相的体积分数; 为源相,默认情况下为0;

为源相,默认情况下为0; 为第q相的速度,单位为 m/s;

为第q相的速度,单位为 m/s; 为第q相的密度,单位为kg/m3。

为第q相的密度,单位为kg/m3。

2) 动量方程

(2)

(2)

式中:P为压力,Pa;g为重力加速度,m/s2;F为作用于控制容积上的体积力,N;v为流体速度,m/s; 为有效黏度,Pa·s。

为有效黏度,Pa·s。

2 边界条件与求解策略

2.1 边界条件

氧枪入口设置为质量流量入口边界条件,入口气体为不可压缩空气,入口质量流量为0.5 kg/s,入口压力为0.6 MPa;烟道口处设置为压强出口边界条件,出口压力为-20 Pa;壁面采用无滑移边界条件,近壁面区域采用标准壁面函数处理;本文模拟熔池内部流场分布变化情况,采用空气和铜锍两种流体,具体物性参数见表1所列。

2.2 求解策略

求解器采用瞬态的基于压力的分离隐式算法,根据计算收敛情况调整时间步长,最大时间步长为0.0001 s,多相流模型采用VOF模型,Realizable k-ε湍流模型,压力-速度耦合方式选择PISO格式,离散化格式:压力选择PRESTO,体积分率选择Geo- reconstruct,动量方程选择二阶迎风式。

3 结果与分析

3.1 熔池气液两相分布

3.1.1 X轴截面两相分布

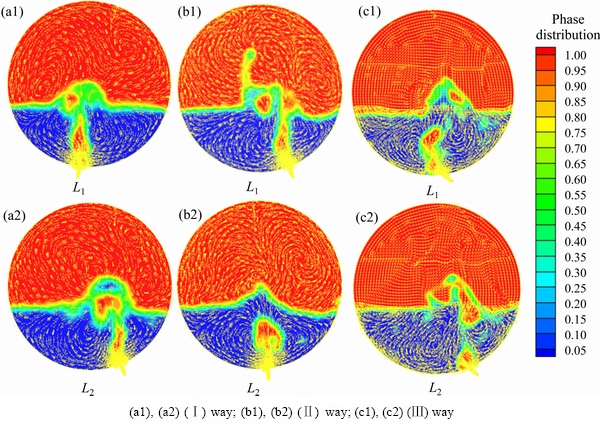

图3所示为t=5.0 s时,对心异侧(Ⅰ)、对心同侧(Ⅱ)、非对心同侧(Ⅲ) 3种方式下气液两相在X轴不同截面分布情况。结果表明,不同枪位布置方式对炉身在X轴方向气液两相分布影响不同,(Ⅰ)方式下,气相主要存在于炉体中心轴区间,两侧气相分布较少;同侧分布方式下,气相主要存在于炉体中心偏向氧枪位区间,相对侧分布较少。熔池内气体主要存在于氧枪区域,表明气液两相作用主要发生于氧枪区域,而(Ⅲ)方式下气体在炉身X轴方向分布范围较(Ⅰ)、(Ⅱ)方式广,主要在于(Ⅲ)方式下气相在X轴方向速度更大,穿透能力更强,使气体在X方向分布更加均匀,有利于气液两相充分反应。

3.1.2 Z轴截面两相分布

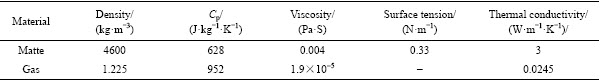

表1 熔炼炉内铜锍和气体物性参数

Table 1 Property parameters of melt and gas in smelting furnace

图3 3种方式下X轴截面气液两相分布

Fig. 3 Gas-liquid phase distribution of X axis section in three layouts of oxygen lances positions

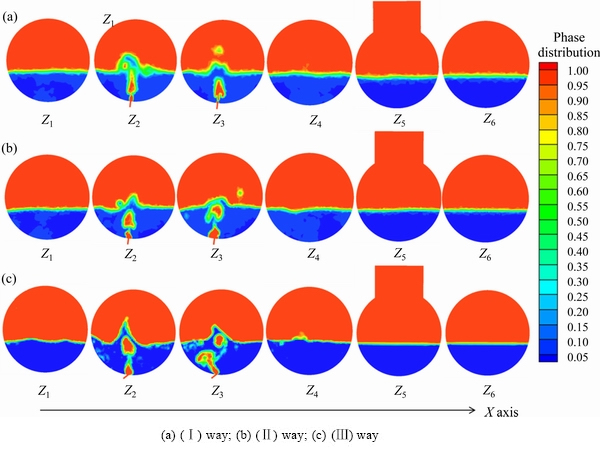

图4 3种方式下Z轴截面气液两相分布

Fig. 4 Gas-liquid phase distribution in Z axis sections in three layouts of oxygen lances positions

图4所示为t=5.0 s时,对心异侧(Ⅰ)、对心同侧(Ⅱ)、非对心同侧(Ⅲ) 3种方式下气液两相在Z轴不同截面分布情况。分析表明,位于氧枪区域的Z2、Z3截面含有较高气含率,Z1、Z4、Z5、Z6等截面气含率很低,即气相与液相相互作用发生能量传递并逐渐衰减,导致气相在熔炼炉身两侧分布减少,在Z轴方向炉身右侧形成渣锍两相分离沉淀区,为渣锍沉降分离提供了有利条件。

为了进一步分析(Ⅰ)、(Ⅱ)、(Ⅲ) 3种枪位布置方式下气液相间作用情况,绘制出一对氧枪纵截面L1、L2矢量图,如图5所示。

图5所示为对心异侧(Ⅰ)、对心同侧(Ⅱ)、非对心同侧(Ⅲ) 3种枪位布置方式下氧枪截面矢量分布图。分析可知,气相经氧枪高速喷入液相,对液相产生作用并在氧枪两侧形成一对运动方向相反的涡漩,在涡旋卷吸作用下,熔池上部流体向下运动,与下部流体发生交互运动。涡旋的形成在富氧底吹熔炼过程中具有重要意义,熔池流体呈涡旋运动,使上方物料快速进入熔池内部,并与底部流体发生交互反应,加速物料反应以及铜锍的生成。

对比3种方式下矢量图发现,(Ⅲ)方式下液相内部涡旋强度最大,(Ⅱ)次之,(Ⅰ)方式涡旋强度最小;而在液面上方气体涡旋强度最大为(Ⅱ)方式,(Ⅲ)方式涡旋强度最小。上述结果表明,不同枪位布置方式下气液两相形成的涡旋强度不同,其主要原因在于:(Ⅲ)方式下气相在炉身X轴方向分速度大于(Ⅰ)、(Ⅱ)方式,气体在X轴方向对熔体具有更强烈的搅动作用,形成涡旋强度更大;在(Ⅰ)、(Ⅱ) 2种方式下,气相所形成的涡旋强度要大于(Ⅲ)方式下形成的涡旋,原因在于气相在Y轴方向有更大分速度,液面上方气相运动更加剧烈,涡旋强度更大,有利于炉内气相成分均匀分布。相比于(Ⅰ)、(Ⅱ)方式,(Ⅲ)方式下气体穿透熔池液面路径更长,在液相内具有更长停留时间,有利于气液两相充分反应,在实际生产上表现为熔体在X轴方向运动更剧烈,在涡旋作用下物料与熔池底部熔体间反应更加迅速、充分,且炉壁两侧不易存在“死区”。

3.2 熔体喷溅高度对比

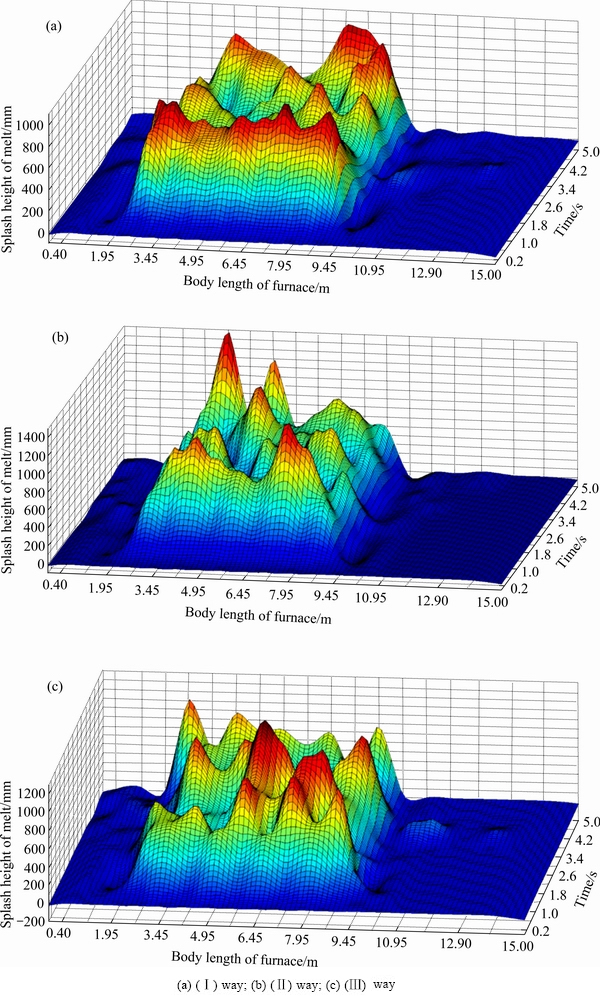

熔体喷溅高度是衡量氧枪枪位布置方式好坏的重要因素,实际生产中经常存在熔体喷溅高度过高导致加料口堵塞,从而影响炉料顺利入炉、降低生产效率等问题。本文设定熔体喷溅高度以熔池静止液面为基准面,熔体在炉身Y轴方向最大高度减去基准面高度即为熔体最大喷溅高度。为了对比3种枪位方式对熔体喷溅高度影响,沿炉身Z轴方向每隔0.75 m截取纵截面,共18个截面,绘制不同时间下各截面熔体最大喷溅高度曲面图。

图5 3种方式下氧枪截面矢量图

Fig. 5 Vector diagrams of oxygen lance sections in three layouts of oxygen lances positions

图6所示为对心异侧(Ⅰ)、对心同侧(Ⅱ)、非对心同侧(Ⅲ) 3种氧枪枪位布置方式下底吹熔炼炉内不同时间、不同位点熔体的喷溅高度三维曲面图。由图6可知,(Ⅰ)方式下熔体最大喷溅高度约为1100 mm,(Ⅱ)方式下最大喷溅高度约为1500 mm,(Ⅲ)方式下熔体最大喷溅高度约为1300 mm,其中(Ⅰ)、(Ⅲ)方式下熔体波动随时间变化比较均匀、平缓,而(Ⅱ)方式下熔体波动较为紊乱、剧烈。分析表明,在总能量一定的情况下,纵向能量消耗越大大,则横向传递能量较少,(Ⅱ)方式下,Y轴方向气相存在叠加作用,则气相在Y轴方向对熔体作用更加强烈,气液两相间能量转化程度更高,熔体喷溅高度更大;(Ⅰ)方式下,气相存在一定抵消作用;(Ⅲ)方式下,气相在炉身X轴方向能量消耗大,在Y轴方向能量转化较低,(Ⅱ)方式波形横向传播距离最短,则沉淀区域最长,(Ⅰ)、(Ⅲ)方式下沉淀区长度基本相同。

3.3 熔池气含率对比

气含率指气相占气液混合物体积的百分率,在底吹熔炼过程中熔池气含率越大,熔池内部气体浓度越大,气液两相间化学反应越迅速、充分,是表征熔炼反应效率的重要参数。为了对比3种氧枪枪位布置方式下熔池气含率的变化,以熔池静止液面为基准,计算不同喷吹时间内熔池平均气含率,并绘制相关变化曲线。

图7所示为对心异侧(Ⅰ)、对心同侧(Ⅱ)、非对心同侧(Ⅲ) 3种方式下熔池气含率随着气体喷吹时间延长而变化的曲线图。由图7可知,在气相进入熔池初期阶段,3种方式下熔池气含率均呈连续增大趋势。在氧枪喷吹作用下,气相进入液相形成气泡,随着气流量持续增大,气泡直径逐渐增大且运动速度得到发展,此时气含率逐渐增大。由于(Ⅲ)方式下气体喷吹方向与Y轴夹角大于(Ⅰ)、(Ⅱ) 2种方式下夹角,气体在X轴方向所受液相压力较大,气体速度增大趋势较(Ⅰ)、(Ⅱ) 2种方式缓慢,则(Ⅲ)方式下熔池气含率增大速率低于(Ⅰ)、(Ⅱ) 2种方式。当气泡直径增大到一定程度时气泡发生破裂,并从液面逸出导致熔池气含率降低,随着气相持续喷入熔体,熔池气含率呈现规律性变化,并在一定范围内保持稳定。

分析表明,当气体喷吹时间达到2 s及以后,熔池气含率呈规律性起伏变化,据此判定熔池内部气液两相运动基本处于动态平衡状态。在2 s以后,3种方式下熔池气含率基本维持在6%~8%范围内,其中(Ⅲ)方式下熔池气含率高于(Ⅰ)、(Ⅱ) 2种方式下熔池气含率,即(Ⅲ)方式熔池反应效率要高于(Ⅰ)、(Ⅱ) 2种方式,其主要原因在于(Ⅲ)方式下气相在炉身X轴方向运动路径更长,涡旋强度更大,致使气体在熔体内停留时间更长,对应熔池气含率更大。

图6 3种方式下不同时间不同位点熔体喷溅高度

Fig. 6 Splash height of melt in three layouts of oxygen lances at different times and positions

图7 3种氧气布置方式下熔池气含率

Fig. 7 Gas volume fraction of smelting bath in three layouts of oxygen lances positions

3.4 熔池速度场分布对比

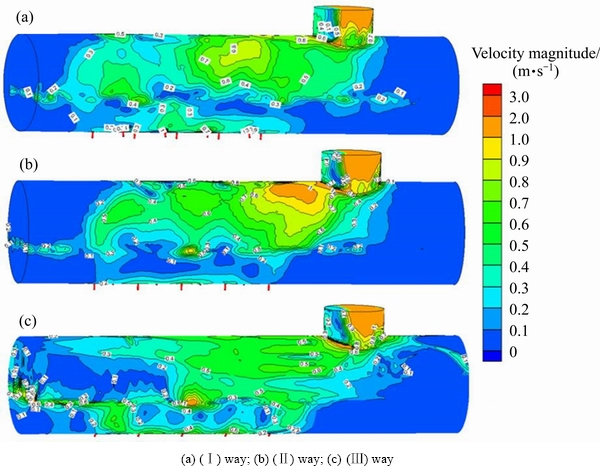

熔池流体速度场分布表明了气相对液相的搅拌作用、炉内气液两相混合程度,对判断炉内“死区”位置、流体对炉壁冲刷腐蚀程度、烟尘率大小等方面有重要指导作用。为详细了解炉内各空间位点速度分布,分别绘制了(Ⅰ)、(Ⅱ)、(Ⅲ) 3种方式下底吹熔炼炉炉壁和炉体X轴、Y轴、Z轴方向不同截面速度场分布图,如图8所示。

3.4.1 底吹炉壁面速度场分布

图8为t=5.0 s时对心异侧(Ⅰ)、对心同侧(Ⅱ)、非对心同侧(Ⅲ) 3种方式下底吹熔炼炉壁面速度场分布图。由图可知,在气相作用下炉体壁面速度分布主要集中在氧枪区域与烟道口处;由于熔炼烟道口一般为负压操作,存在压力差,因此该处气体速度较大,气体对该处炉壁和烟道冲刷腐蚀情况较为严重,在实际生产中应注重检测该位置腐蚀程度并使用抗冲刷材料。铜锍熔体为高密度、高黏度流体,气液两相间发生动量传递时,转化为液相速度较小,且在能量传播过程中动能转化为内能损失较大,因此底吹熔炼炉内速度主要分布在氧枪作用区域,而在炉体两端液相速度较小,尤其在炉体右侧存在一定液相静止区域即“沉淀区”,为渣锍的沉降分离提供了有利条件。

此外,(Ⅰ)、(Ⅱ)、(Ⅲ) 3种方式下炉体两侧均存在部分“死区”,其中(Ⅱ)方式下“死区”范围最大,(Ⅰ)方式次之,(Ⅲ)方式下死区范围最小。(Ⅲ)方式液面上方自由空间气相所形成的“死区”也较(Ⅰ)、(Ⅱ) 2种方式小,主要原因在于枪位布置方式的不同导致流体运动条件不同,以下通过对炉身X轴、Y轴及Z轴不同截面速度场分布具体分析解释说明。

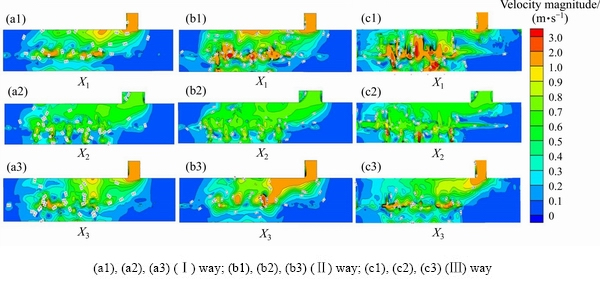

3.4.2 X轴方向速度场分布

图9所示为t=5.0 s时,底吹熔炼炉在对心异侧(Ⅰ)、对心同侧(Ⅱ)、非对心同侧(Ⅲ) 3种方式下炉体X轴不同截面速度分布图。由图可知,气液两相相互作用主要发生在炉体氧枪区域,且在X2=0 m截面即炉体中心轴截面处流体速度较大,气液两相作用较为激烈,气相对液相形成强烈搅拌。由于(Ⅱ)、(Ⅲ)方式为同侧排布,位于X轴负方向侧,因此在X1=-0.85 m截面上速度分布受两排氧枪所喷吹气体影响,速度值比较大,范围较广;而(Ⅰ)方式下,X1=-0.85 m截面受一排氧枪喷吹气体影响,速度值及分布范围均小于(Ⅱ)、(Ⅲ)两方式。

图8 3种方式下炉体壁面速度场分布(t=5.0 s)

Fig. 8 Distribution of furnace wall velocity field in three layouts of oxygen lances positions (t=5.0 s)

图9 3种方式下炉体X轴不同截面速度场分布(t=5.0 s;X1=-0.85 m,X2=0 m,X3=0.85 m)

Fig. 9 Distribution of velocity field in X axis sections in three layouts of oxygen lances positions (t=5.0 s; X1=-0.85 m, X2=0 m, X3=0.85 m)

(Ⅲ)方式下底吹炉内气相运动范围比(Ⅰ)、(Ⅱ) 2种方式广,尤其在液面上方自由空间内(Ⅲ)方式气相运动范围几乎为整个自由空间范围,表明该方式下气体横向运动条件较好,而(Ⅰ)、(Ⅱ) 2种方式下自由空间两侧存在一定的“死区”,在底吹熔炼生产过程中表现为烟气组分浓度分布不均匀,影响熔炼反应传热传质。

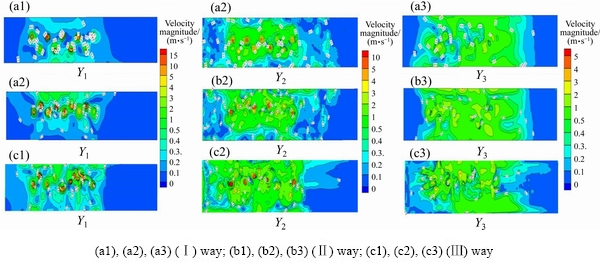

3.4.3 Y轴方向速度场分布

图10所示为t=5.0 s时,底吹熔炼炉在对心异侧(Ⅰ)、对心同侧(Ⅱ)、非对心同侧(Ⅲ) 3种方式下炉体Y轴不同截面速度分布图。由于底吹熔炼喷吹系统采用高压操作,气相经氧枪以高速度射入液相,此时气液两相接触时间很短,气体动能来不及传递给液相,导致熔池底部流体速度较小,速度场分布范围较窄,底部铜锍波动较为平缓,结果如图中Y1截面所示。随着气相继续运动,气泡逐渐增大并破裂,对液相形成强烈搅动,两相间能量迅速转化,流体速度得到充分发展,如图中Y2截面所示。气液两相发生反应生成气体,气体从液面逸出进入自由空间,带动上方气相运动,在炉内外压力差作用下向炉口运动。

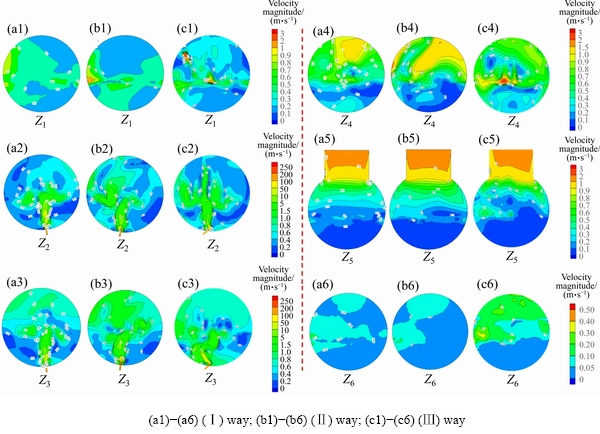

3.4.4 Z轴方向速度分布

图11所示为t=5.0 s时,底吹熔炼炉在对心异侧(Ⅰ)、对心同侧(Ⅱ)、非对心同侧(Ⅲ) 3种方式下炉体Z轴不同截面速度分布图。由图11可知,在底吹熔炼过程中随着炉身沿Z轴方向延长,截面速度分布呈现先增强后减弱的趋势,其中在氧枪截面Z2、Z3上气相以大于200 m/s的速度喷射进入液相,对液相强烈搅拌,造成该截面上速度分布波动较大且范围较广;而在截面Z1、Z6上流体速度较小,其中Z6截面处于熔池的“死区”,液相速度约为0.05~0.1 m/s范围,熔池波动弱且平缓,有利于渣锍分离。

沿着炉体Z轴方向延长,熔炼炉内可分为三大区域:气液两相反应区、分离过渡区和沉降区[7]。反应区位于炉内氧枪区域,约为截面Z1至Z4之间范围,该区域内气液两相强烈作用,快速传热传质,是底吹熔炼过程的主要反应区域。分离过渡区主要位于截面Z4至Z5之间范围,该区域内熔体速度约为0.1~0.3 m/s,熔体波动较为平缓,气液两相间发生一定反应,但炉渣和铜锍开始分层,为后续渣锍沉降分离提供前提条件。沉降区位于截面Z5至炉身最右端,该区域内渣锍界面明显,熔体速度约为0.05~0.1 m/s,熔体微弱的波动可为铜锍中渣滴、渣中铜锍滴的迁移聚集以及上浮下沉提供部分动力,加快渣锍沉降分离。对比3种方式可知,(Ⅲ)方式下反应区气液两相速度分布更广泛,气液两相作用更剧烈,熔池反应效率更高,且沉降区液面上方自由空间气相运动速度大于(Ⅰ)、(Ⅱ) 2种方式,熔炼烟气组分分布更均匀;(Ⅱ)方式下沉淀区最长,更有利于渣锍沉降分离。

图10 3种方式下炉体Y轴不同截面速度场分布(t=5.0 s;Y1=-1.1 m,Y2=-0.45 m,Y3=0.35 m)

Fig. 10 Distribution of velocity field in Y axis sections in three layouts of oxygen lances positions (t=5.0 s; Y1=-1.1 m, Y2=-0.45 m, Y3=0.35 m)

图11 3种方式下炉体Z轴不同截面速度场分布(t=5.0 s;Z1=1.5 m,Z2=4.2 m,Z3=7.2 m,Z4=9.15 m,Z5=11.4 m,Z6=13.35 m)

Fig. 11 Distribution of velocity field in Z axis sections in three layouts of oxygen lances positions (t=5.0 s; Z1=1.5 m, Z2=4.2 m, Z3=7.2 m, Z4=9.15 m, Z5=11.4 m, Z6=13.35 m)

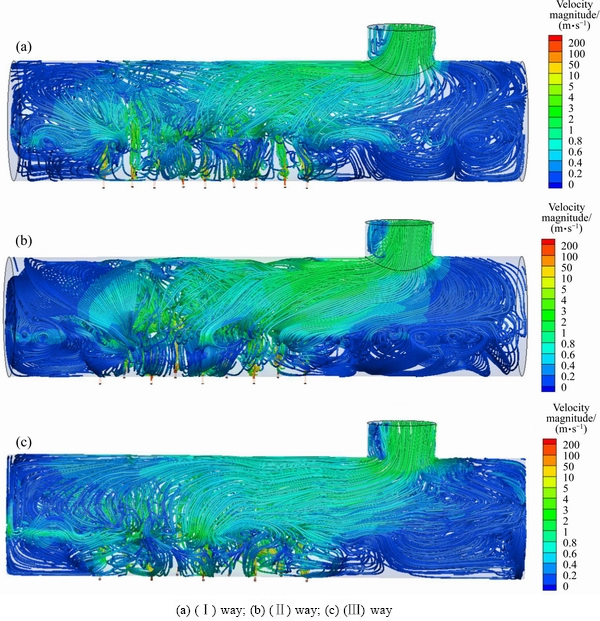

3.5 熔池流线图分布

图12 (Ⅰ)、(Ⅱ)、(Ⅲ) 3种方式下熔炼炉内速度流线分布(t=5.0 s)

Fig.12 Streamline distribution of furnace in three layouts of oxygen lances positions (t=5.0 s)

流体流线图采用不同颜色描述质点运动轨迹,是反映计算域内质点运动情况的重要手段。为了明晰底吹熔炼过程中气体经氧枪喷入后具体运动轨迹,分别绘制(Ⅰ)、(Ⅱ)、(Ⅲ) 3种方式下气相速度流线分布图。

图12所示为t=5.0 s时,底吹熔炼炉在对心异侧(Ⅰ)、对心同侧(Ⅱ)、非对心同侧(Ⅲ) 3种方式下速度流线分布图。由图12可知,气体经氧枪喷入熔池后经气液两相间作用后充斥整个炉体,但炉内各空间位点气相浓度分布不同,其中反应区为主要作用区域,气相浓度最大,而分离过渡区和沉降区浓度分布较少。由于熔炼炉内部为负压,气体最终经底吹炉出口进入烟气烟道。

对比分析可知,(Ⅲ)方式下气相在炉内运动范围较(Ⅰ)、(Ⅱ) 2种方式更广,与上述小节研究结果相一致。从图12中标记区域可以看出,在(Ⅰ)、(Ⅱ) 2种方式下底吹炉两端气液两相界面处存在明显涡旋,炉体自由空间的气相与液相发生交互作用,该现象在底吹熔炼过程中可表现为:1) 当烟道密封性良好时,底吹炉烟气漏风氧量很低,由于熔炼烟气为高浓度SO2烟气,则上方烟气对熔体尤其是位于烟道出口下方沉降分离区的熔体具有一定的还原作用;2) 当烟道漏风较为严重时,炉口下方烟气中氧含量大大增加,则可能对沉降分离区的熔体具有一定的氧化作用。此外,熔池表面的气流速度决定了熔炼烟尘率的大小,表面气流速度越小,熔池液面上方空间飞溅物越少;反之,表面气流速度越大,熔池液面上方空间飞溅物越多,对应烟尘率越大。图12中所示,(Ⅱ)方式下熔池表面气流平均速度大于(Ⅰ)、(Ⅲ) 2种方式,则(Ⅱ)方式熔炼过程中烟尘率要高于(Ⅰ)、(Ⅲ) 2种方式。

4 结论

1) (Ⅰ)方式下气体主要作用于炉体中心轴区间,两侧气体分布少,熔体喷溅高度大,熔池平均气含率低于(Ⅲ)方式下的,熔池速度分布不均匀,烟尘率高于(Ⅲ)方式下的。

2) (Ⅱ)方式下气体在炉体氧枪作用区域Y轴方向能量叠加,熔体具有最大喷溅高度,熔池平均气含率低,熔池速度分布不均匀,烟尘率最大,但具有较长沉淀区域。

3) (Ⅲ)方式下气体在炉体X轴方向运动路径较长,停留时间增大,熔池平均气含率最大,熔池波动平缓,熔体喷溅高度低,速度分布均匀,烟尘率低,是一种合适的氧枪枪位布置方式。

REFERENCES

[1] 崔志祥, 申殿邦, 王 智, 李维群, 边瑞民. 高富氧底吹熔池炼铜新工艺[J]. 有色金属(冶炼部分), 2010(3): 17-20.

CUI Zhi-xiang, SHEN Dian-bang, WANG Zhi, LI Wei-qun, BIAN Rui-min. New process of copper smelting with oxygen enriched bottom blowing technology[J]. Nonferrous Metals (Extractive Metallurgy), 2010, (3): 17-20.

[2] 朱祖泽, 贺家齐. 现代铜冶金学[M]. 北京: 科学出版社, 2003: 319-320.

ZHU Zu-ze, HE Jia-qi. Current copper metallurgy[M]. Beijing: Science Press, 2003: 319-320.

[3] 中华人民共和国工业和信息化部. 铜冶炼行业规范条 件[EB/OL]. [2014-04-28]. http://www.miit.gov.cn/n11293472/ n11293832/n12845605/n13916898/15976630.html.

Ministry of industry and information technology of the people’s republic of China. Copper smelting industry norms conditions[EB/OL]. [2014-04-28]. http://www.miit.gov.cn/ n11293472/n11293832/n12845605/n13916898/15976630.html.

[4] 梁帅表, 陈知若. 氧气底吹炼铜技术的应用与发展[J]. 有色冶金节能, 2013(2): 16-19.

LIANG Shuai-biao, CHEN Zhi-ruo. Application and development of oxygen bottom blowing copper smelting technology[J]. Energy Saving of Nonferrous Metallurgy, 2013(2): 16-19.

[5] 胡立琼. 氧气底吹炼铅与炼铜新工艺产业化应用[J]. 有色冶金节能, 2011(3): 6-8.

HU Li-qiong. Industrialization application of new lead smelting and copper smelting process with oxygen bottom blowing[J]. Energy Saving of Nonferrous Metallurgy, 2011(3): 6-8.

[6] LIU Wei-feng, YANG Tian-zu, ZHANG Du-chao, CHEN Lin, LIU Yu-feng. A new pyrometallurgical process for producing antimony white from by-product of lead smelting[J]. JOM, 2014, 9(66): 1694-1700.

[7] 郭学益, 王亲猛, 田庆华, ZHAO Bao-jun. 氧气底吹铜熔炼工艺分析及过程优化[J]. 中国有色金属学报,2016, 26(3): 689-699.

GUO Xue-yi, WANG Qin-meng, TIAN Qing-hua, ZHAO Bao-jun. Analysis and optimization of oxygen bottom blowing copper smelting process[J]. The Chinese Journal of Nonferrous Metals, 2016, 26(3): 689-699.

[8] 郭学益, 王亲猛, 田庆华, 张永柱. 基于区位氧势硫势梯度变化下铜富氧底吹熔池熔炼非稳态多相平衡过程[J]. 中国有色金属学报, 2015, 25(4): 1072-1079.

GUO Xue-yi, WANG Qin-meng, TIAN Qing-hua, ZHANG Yong-zhu. Non-steady multiphase equilibrium process of copper oxygen-enriched bottom blowing bath smelting with gradual change of oxygen and sulfur potential of different positions in furnace[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(4): 1072-1079.

[9] 王亲猛, 郭学益, 廖立乐, 田庆华, 张永柱. 氧气底吹炼铜多组元造锍行为及组元含量的映射关系[J]. 中国有色金属学报, 2016, 26(1): 188-196.

WANG Qin-meng, GUO Xue-yi, LIAO Li-le, TIAN Qing-hua, ZHANG Yong-zhu. Mapping relationship between multicomponent matte formating behavior and content in copper oxygen bottom blowing bath smelting process[J]. The Chinese Journal of Nonferrous Metals, 2016, 26(1): 188-196.

[10] 郭学益, 王亲猛, 廖立乐, 田庆华, 张永柱. 铜富氧底吹熔池熔炼过程机理及多相界面行为[J]. 有色金属科学与工程, 2014(5): 28-34.

GUO Xue-yi, WANG Qin-meng, LIAO Li-le, TIAN Qing-hua, ZHANG Yong-zhu. Mechanism and multiphase interface behavior of copper sulfide concentrate smelting in oxygen-enriched bottom blowing furnace[J]. Nonferrous Metals Science and Engineering, 2014(5): 28-34.

[11] LI Ming-ming, LI Qiang, ZOU Zong-shu, AN Xi-zhong. Computational investigation of swirling supersonic[J]. Metallurgical and Materials Transaction B, 2017, 48B: 713-725.

[12] DONG Kai, ZHU Rong, GAO Wei, LIU Fu-hai. Simulation of three-phase flow and lance height effect on the cavity shape[J]. Int J Miner Metall Mater, 2014, 6(21): 523-530.

[13] KAPUSTA J P T. Submerged gas jet penetration: A study of bubbling versus jetting and side versus bottom blowing in copper bath smelting[J]. JOM, 2017, 69(6): 970-979.

[14] 闫红杰, 刘方侃, 张振扬, 高 强, 刘 柳, 崔志祥, 申殿邦. 氧枪布置方式对底吹熔池熔炼过程的影响[J]. 中国有色金属学报, 2012, 22(8): 2393-2400.

YAN Hong-jie, LIU Fang-kan, ZHANG Zhen-yang, GAO Qiang, LIU Liu, CUI Zhi-xiang, SHEN Dian-bang. Influence of lance arrangement on bottom-blowing bath smelting process[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(8): 2393-2400.

[15] 张振扬, 闫红杰, 刘方侃, 王计敏. 富氧底吹熔炼炉内氧枪结构参数的优化分析[J]. 中国有色金属学报, 2013, 23(5): 1471-1478.

ZHANG Zhen-yang, YAN Hong-jie, LIU Fang-kan, WANG Ji-min. Optimization analysis of lance structure parameters in oxygen enriched bottom blown furnace[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(5): 1471-1478.

[16] 蓝海鹏, 温 治, 刘训良, 苏福永, 楼国锋, 郝晓红. 基于CFD的喷吹气流对底吹炉熔池的搅拌作用[J]. 冶金能源, 2014(6): 24-27.

LAN Hai-peng, WEN Zhi, LIU Xun-liang, SU Fu-yong, LOU Guo-feng, HAO Xiao-hong. Mixing effect of jet flow in the bottom blown furnace based on CFD[J]. Energy for Metallurgical Industry, 2014(6): 24-27.

[17] 余 跃, 温 治, 刘训良, 苏福永, 蓝海鹏, 郝晓红. 喷枪结构对底吹炼铜炉流场影响的模拟及实验研究[J]. 中南大学学报(自然科学版), 2014, 45(12): 4129-4137.

YU Yue, WEN Zhi, LIU Xun-liang, SU Fu-yong, LAN Hai-peng, HAO Xiao-hong. Simulation and experiment of influence of nozzle structure on bottom blowing furnace flowing process[J]. Journal of Central South University (Science and Technology), 2014, 45(12): 4129-4137.

[18] SHUI Lang, CUI Zhi-xiang, MA Xiao-dong, AKBARRHAMDHANI M, NGUYEN A V, ZHAO Bao-jun. Understanding of bath surface wave in bottom blown copper smelting furnace[J]. Metallurgical and Materials Transaction B, 2016, 47B: 135-144.

[19] WANG Xiao-ling, DONG Hai-feng, ZHANG Xiang-ping, YU Liang, ZHANG Suo-jiang, XU Yan. Numerical simulation of single bubble motion in ionic liquids[J]. Chemical Engineering Science, 2010, 65(22): 6036-6047.

[20] CHEN Wen-yi, WANG Jing-bo, JIANG Nan, ZHAO Bin, WANG Zhen-dong. Numerical simulation of gas-liquid two-phase jet flow in air-bubble generator[J]. Central South University of Technology, 2009, 16(S1): s140-s144.

[21] WANG Han, ZHANG Zhen-yu, YANG Yong-ming, ZHANG Hui-sheng. Numerical investigation of the interaction mechanism of two bubbles[J]. International Journal of Modern Physics C, 2010, 21(1): 33-49.

[22] LIANOS C A, GARCIA HERNANDEZ H S, RAMOSBANDERAS J A, DEBARRETO J, SOLORIODIAZ G. Multiphase modeling of the fluid dynamics of bottom argon bubbling during ladle operations[J]. ISIJ International, 2010, 50(3): 396-402.

[23] LIU He-ping, QI Zhen-ya, XU Mian-guang. Numerical simulation of flow and interfacial behavior in three-phase argon-stirred ladles with one plug and dual plugs[J]. Steel Research International, 2011, 82(4): 440-458.

[24] 郭学益, 闫书阳, 王 双, 王亲猛, 田庆华. 数值模拟氧气底吹熔炼工艺参数优化[J]. 有色金属科学与工程, 2017, 8(5): 21-25.

GUO Xue-yi, YAN Shu-yang, WANG Shuang, WANG Qin-meng, TIAN Qing-hua. Numerical simulation and parameter optimization of oxygen bottom blowing smelting process[J]. Nonferrous Metals Science and Engineering, 2017, 8(5): 21-25.

[25] 郭学益, 王松松, 王亲猛, 田庆华. 氧气底吹炼铜模拟软件SKSSIM开发与应用[J]. 有色金属科学与工程, 2017, 8(4): 1-6.

GUO Xue-yi, WANG Song-Song, WANG Qin-meng, TIAN Qing-hua. Development and application of oxygen bottom blowing copper smelting simulation software SKSSIM[J]. Nonferrous Metals Science and Engineering, 2017, 8(4): 1-6.

Layout optimization of oxygen lances of oxygen bottom blown furnace

GUO Xue-yi1, 2, YAN Shu-yang1, 2, WANG Qin-meng1, 2, 3, TIAN Qing-hua1, 2

(1. School of Metallurgy and Environment, Central South University, Changsha 410083, China;

2. Cleaner Metallurgical Engineering Research Center, Nonferrous Metal Industry of China, Changsha 410083, China;

3. School of Minerals Processing and Bioengineering, Central South University, Changsha 410083, China)

Abstract: During oxygen bottom blown smelting process, a reasonable oxygen lance layout is an important factor to obtain a better smelting effect. Three oxygen lance layouts of oxygen bottom blown furnace such as the central opposite side (Ⅰ), central same side (Ⅱ) and non-central same side (Ⅲ) were simulated. The influences of (Ⅰ), (Ⅱ) and (Ⅲ) ways on the gas-liquid phase distribution, melt splash height, gas volume fraction, bath velocity field and the streamline distribution of furnace were researched, respectively. The results show that, comparing with (Ⅰ) and (Ⅱ) ways, the melt splash height is lower and the bath fluctuates most smoothly in the (Ⅲ) way. Besides, the gas volume fraction of the bath in the (Ⅲ) way is the highest and the dust rate is low. The (Ⅲ) way is a suitable oxygen lance layout for oxygen bottom blown smelting process and has a positive effect for solving the melt splashing, furnace body erosion and high dust rate problems.

Key words: oxygen bottom blown smelting; oxygen lance layout; numerical simulation; gas volume fraction; streamline distribution

Foundation item: Project(51620105013) supported by the Funds for International Cooperation and Exchange of the National Natural Science Foundation of China

Received date: 2017-09-26; Accepted date: 2018-02-28

Corresponding author: WANG Qin-meng; Tel: +86-731-88876255; E-mail: qmwang@csu.edu.cn

(编辑 王 超)

基金项目:国家自然科学基金重点国际(地区)合作项目(51620105013)

收稿日期:2017-09-26;修订日期:2018-02-28

通信作者:王亲猛,博士;电话:0731-88876255;E-mail:qmwang@csu.edu.cn