文章编号: 1004-0609(2006)05-0811-06

倾斜式冷却剪切技术制备Al-3%Mg半固态合金坯料

管仁国, 康立文, 杜海军, 温景林, 崔建忠

(东北大学 材料与冶金学院, 沈阳 110004)

摘 要: 应用自行设计倾斜式冷却剪切实验装置, 对制备Al-3%Mg半固态合金坯料进行研究, 分析工艺条件对半固态合金组织的影响, 以及半固态合金坯料的二次加热组织及最优二次加热工艺。 结果表明, 采用倾斜式冷却剪切技术可以制备具有良好组织的Al-3%Mg合金半固态坯料。 获得了制备半固态Al-3%Mg合金坯料的最优工艺条件: 浇注温度660~680℃; 倾角40°~60°。 在合理的二次加热工艺条件下, 可获得优良的适于进行触变成形的半固态合金组织。 二次加热的最优工艺条件为: 加热温度620~630℃; 保温时间90~120min。

关键词: Al-3%Mg合金; 半固态; 倾斜式冷却剪切; 显微组织 中图分类号: TG111.4; TG244.1

文献标识码: A

Preparing semisolid billet of Al-3%Mg alloy by sloping cooling/shearing process

GUAN Ren-guo, KANG Li-wen, DU Hai-jun, WEN Jing-lin, CUI Jian-zhong

(School of Materials and Metallurgy, Northeastern University, Shenyang 110004, China)

Abstract: By using the self-designed experimental setup of sloping cooling/shearing, preparing semisolid billet of Al-3%Mg alloy was studied. The effects of technological conditions on the microstructures of the semisolid alloy were analyzed. The microstructures of the remelted semisolid billet were observed and the optimal remelting process was investigated. The results show that the semisolid billet of Al-3%Mg alloy with good microstructures can be obtained by the sloping cooling/shearing process. The optimal process conditions for preparing semisolid billet of Al-3%Mg alloy were obtained: pouring temperature is in the range of 660-680℃, sloping angle is in the range of 40°-60°.Under the proper remelting conditions, the excellent semisolid microstructures that are suitable for semi-solid forming can be obtained. The optimal conditions of remelting process are: remelting temperature range of 620-630℃, holding time range of 90-120min.

Key words: Al-3%Mg alloy; semisolid; sloping cooling/shearing; microstructure

半固态成形技术已有30多年的历史了, 其应用领域也不断扩大。 在国外, 流变与触变成形工艺已经成功应用于汽车和航空航天零件的生产, 并逐步应用于电子与电器结构部件的生产[1-4]。 虽然从20世纪80年代开始我国开始投入力量对半固态金属流变学理论及铸造工艺进行理论与应用进行研究, 取得了许多重要成果。 然而, 在我国半固态成形技术仍不成熟, 尚无成熟的工业化应用[3-10]。 倾斜式冷却剪切技术在冶金学上曾作为制备细晶材料的有效手段而被讨论过, 而作为一种新的半固态成形技术近年来才被人们重视, 又称为“斜坡冷却法”, 用来制备铝合金与镁合金半固态浆料。 目前该技术在日本已经初步实现了铝合金薄带的流变轧制, 并且在欧洲已经申报了发明专利[11-14]。 它具有工艺简捷, 设备成本低廉, 易于实现, 可制备高熔点半固态材料的特点, 有望解决半固态成形的工业化应用以及高熔点半固态浆料的制备等问题, 具有重要的研究意义。 本文作者自行设计实验装置, 对斜板进行了改进, 采用带有波浪形表面的倾斜板进行实验, 对倾斜式冷却剪切技术制备Al-3%Mg半固态合金坯料进行了探索, 并对二次加热工艺及二次加热组织及触变成形性能进行了研究。

1 实验

实验材料为自行配制熔炼的Al-3%Mg合金, 其液相线温度为640℃, 固相线温度为600℃。

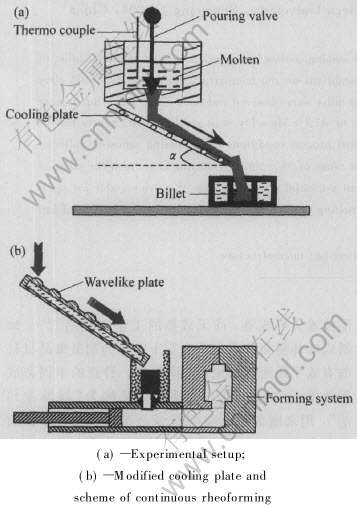

所用实验装置如图1(a)所示。 主要由浇注系统、 倾斜式冷却剪切系统与收料系统三部分组成。 可以将制备装置与成形设备设计为一体, 以便进行半固态流变成形, 如图1(b)所示。 为增强冷却剪切效果, 在原有基础上对冷却板进行了改造, 将冷却板表面加工成具有一定波浪形的冷却表面, 如图1(b)所示。 冷却板采用紫铜材质, 冷却板内通有冷却水, 冷却板长度为640mm。 通过控制倾角α来控制合金的流动速度, 分别在倾角α为30°、 45°、 60°进行浇注。 浇注温度控制在660~700℃。 当合金在预定浇注温度条件下进行浇注时, 合金在经过冷却板表面时, 会受到冷却板与重力引起的剪切冷却作用, 从而形成组织优良的半固态合金浆料。 通过收料系统可以将半固态浆料铸成供触变成形用的坯料, 也可直接进行流变成形。 为进行对比观察, 按照常规铸造工艺进行了水冷铜模铸造。 对制备得到的半固态合金浆料在水冷铜模中进行铸锭, 取样处理后观察其组织。

图1 倾斜式冷却剪切半固态成形技术示意图

Fig.1 Schematic of sloping cooling/shearing process for semisolid forming

对上述制备的半固态Al-3%Mg合金坯料取样, 将试样置于保温炉中进行恒温式二次加热, 淬火后观测其二次加热组织。 二次加热温度为600~630℃, 保温时间为30~120min。 同时取d8mm×15mm标准试样在Gleeble1500热模拟试验机上进行半固态压缩实验, 以考察制备的半固态坯料触变成形性能, 变形温度为610, 615, 620℃, 保温时间为3min, 变形速率ε[DD(-*2]·[DD)]为0.1s-1。

2 结果与分析

2.1 半固态Al-3%Mg合金坯料的显微组织

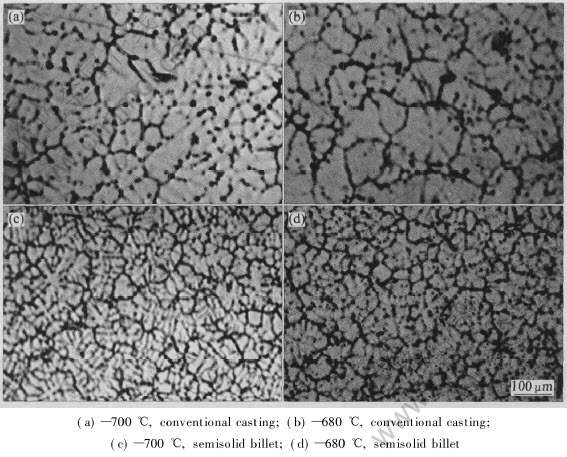

图2所示为700℃与680℃浇注, 分别采用常规水冷铜模铸造与倾斜式冷却剪切技术制备的Al-3%Mg合金组织。 常规铸造合金组织主要由粗大的枝晶网络组成, 而半固态合金坯料的组织主要由细小的等轴晶和少量近球形晶组成。 这种合金组织的形成与合金经过冷却板表面时所受到的冷却剪切作用密切相关。

当合金液被浇注到冷却板表面时, 随着合金不断向下移动, 受到冷却板的冷却作用, 合金主要依附在冷却板表面发生非均匀形核, 这种机制与低温液相线铸造过程合金的形核过程类似, 不同之处在于合金是依附在冷却板表面形核, 属非均匀形核。 Motegi等[12]认为由于在冷却板表面产生的大量晶核被带到铸模中, 从而使合金发生细化和球化。 这种机制与传统的熔体爆发形核理论相吻合。

此外, 另一种作用机制不容忽视, 合金在重力作用下流经波浪形的冷却板表面时会发生激烈的紊流运动, 合金形成的枝晶在与波浪形冷却板表面碰撞的过程中, 枝晶臂会发生断裂, 虽然目前对于枝晶臂的断裂机制观点不一, 枝晶臂可能发生的断裂方式有待于研究, 但是这种断裂过程是必然存在的, 作者在同类研究中也对该过程进行了描述, 认为枝晶臂的断裂与枝晶臂机械折断与熔断都有关系[15, 16]。 枝晶臂的断裂也会引起晶核增殖与晶粒“磨圆”, 从而使合金不断细化与球化。 浇注温度较高时, 熔体中尚有大量液相, 在铸模中凝固后形成了细小的等轴晶, 还包含了少量近球形晶。

图2 Al-3%Mg合金常规铸锭与半固态坯料的显微组织

Fig.2 Microstructures of conventional casting and semisolid billet of Al-3%Mg alloy

2.2 工艺条件对半固态Al-3%Mg合金坯料组织的影响

浇注温度对Al-3%Mg半固态合金坯料组织的细化与球化具有重要影响, 随着浇注温度降低, 合金组织进一步发生细化与球化(如图2(c)、 (d)所示)。 这是因为浇注温度降低时, 合金在冷却板表面形成的晶核会增多, 从而使合金组织细化, 同时由于温度较低, 合金在冷却模中发生凝固的时间较短, 合金枝晶状生长时间较短, 因此, 合金组织中的枝晶臂较少。 从图2(d)可观察到在680℃浇注时, 得到合金组织的二次枝晶臂几乎完全消失。 当然, 浇注温度不能太低, 实验证明, 在浇注温度低于660℃时, 合金会在冷却板表面快速冷却并形成凝固壳, 影响制备过程。 因此, 在本实验条件下, 比较合理的浇注温度范围为660~680℃。

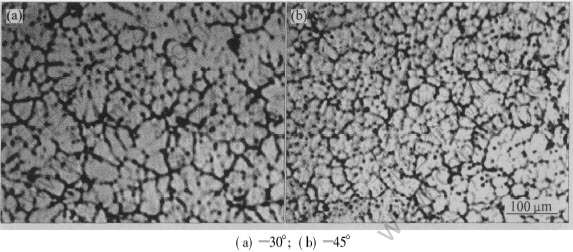

倾角α(如图1(a)所示)直接影响合金液重力加速度沿冷却板平行方向的分量, 从而影响到合金所受剪切力的大小。 因此, 在适当范围内增大倾角会提高合金所受到的剪切强度, 从而使合金组织更细小、 球化。 在45°倾角下比在30°倾角条件下制备的合金组织更细小(如图3所示)。 但是, 倾角过大, 会使合金在冷却板表面驻留时间太短, 合金液会快速流过冷却板表面, 冷却板引起的冷却作用并不明显, 合金爆发形核的孕育时间太短, 最终得到的合金组织并不理想。 综合来看, 比较合理的倾角范围应为40°~60°[12-16]。

2.3 半固态Al-3%Mg合金坯料的二次加热组织与触变性能

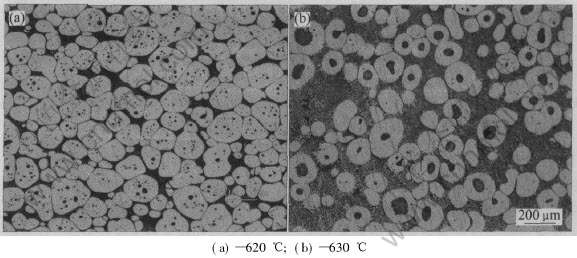

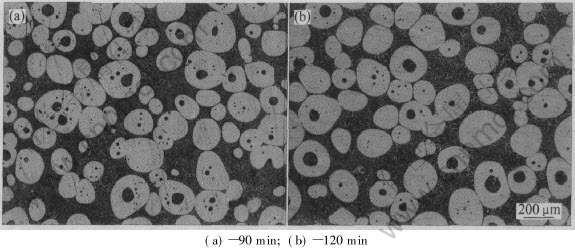

图4、 5所示为660℃浇注制备的半固态Al-3%Mg合金坯料经二次加热后的显微组织。 可以看出其组织主要由细小圆滑的近球形的初生α(Al)晶粒与晶间液相组成, 同时存在少量球形晶粒团, α(Al)固相内部存在少量液相。 保温温度与保温时间是影响二次加热后半固态合金组织的重要因素。图4所示为在保温时间为30min时, 不同保温温度下所获得的二次加热组织。 由图可见, 两种保温温度下的组织均发生不同程度的球化。 二次加热保温温度为620℃时(图4(a)), 晶粒明显球化而且α相明显长大, 晶界已明显地区分开, 部分地方已有一定量的液相出现。 在二次加热期间, 组织内部已发生部分晶界的重熔, 即部分的晶界处的共晶组织和α相溶解成液相分布在α相晶界上, 熔化的共晶组织发生溶质扩散, 使得组织内部出现了少许的液相聚集区。 α相内部的出现了泪滴状的液相。 在相同的保温时间下, 二次加热保温温度提高到630℃时, 其组织如图4(b)所示。 固相α(Al)的体积分数进一步下降, 大量液相存在且已连成一片, α相内部的液相增多。 630℃保温比620℃下保温后的固相更进一步的细化、 球化, 尺寸也更均一。 这是由于保温温度的提高, 合金内的溶质扩散速度加快, 另一方面是由于液固相界面张力的作用, 固相α(Al)更进一步球化, 使其外表面更趋光滑。 保温温度越高, 球化与液相析出的时间也越短。 在620℃保温时, 适当增加保温时间, 在元素扩散、 溶解、 表面张力的作用下, 合金组织更球化、 均匀(如图5所示)。

图3 660℃浇注时不同冷却板倾角条件下制备的半固态Al-3%Mg合金坯料的显微组织

Fig.3 Microstructures of semisolid billets of Al-3%Mg alloy prepared by cooling plate with different sloping angles at 660℃

图4 Al-3%Mg半固态合金在不同加热温度时的显微组织

Fig.4 Microstructures of Al-3%Mg semisolid alloy at

different remelting temperatures (holding time: 30min)

图5 Al-3%Mg半固态合金在620℃保温不同时间的显微组织

Fig.5 Microstructures of Al-3%Mg semisolid alloy held at 660℃ for different times

因此, 在合理的二次加热工艺条件下, 可以获得由球形固相颗粒组成、 分布均匀的半固态合金组织, 适于进行半固态触变成形。 通过实验优化, 对Al-3%Mg半固态合金坯料二次加热的最优工艺条件为: 加热温度620~630℃, 保温时间90~120min。

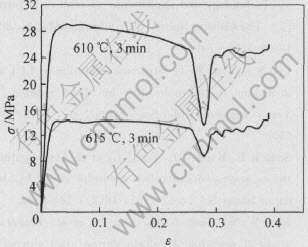

实验证明, 在保温温度为620℃时, 由于液相率太高, 置于合金中的数据电偶会滑落下来, 导致实验失败。 在610、 615℃不同保温温度下半固态坯料在半固态区压缩的真应力—真应变曲线如图6所示。 在压缩变形开始, 即应变值从0增加到约0.01左右时, 随着应变的增加, 应力是急剧增加的, 并上升到峰值, 随着应变的增加, 应力值水平维持一段时间, 应力峰值平台过后, 应力随即开始缓慢的下降, 这一阶段称为半固态合金的均匀变形阶段。 当应变达到0.28左右时, 应力值开始回升, 这并不是由于半固态合金的流变应力增加造成的, 而是由于试样的压缩量太大, 出现侧翻, 夹头与试样的接触面积迅速增加, 进而造成夹头与试样间的摩擦力的迅速增加, 改变了试样内部的应力状态, 表现为真应力回升。 因此, 在均匀变形阶段, Al-3%Mg半固态合金坯料表现出良好的触变流动, 触变成形性能良好, 随着保温温度的升高, 触变应力值显著降低。

图6 Al-3%Mg半固态坯料压缩的真应力—真应变曲线

Fig.6 True stress—true strain curves of compressing semisolid billet of Al-3%Mg alloy (ε[DD(-*2]·[DD)]=0.1s-1)

3 结论

1) 采用倾斜式冷却剪切技术可以制备具有良好组织的半固态Al-3%Mg合金坯料。

2) 浇注温度、 冷却板倾角对合金组织具有重要影响。 在本实验条件下, 制备半固态Al-3%Mg合金坯料的最优工艺条件为: 浇注温度660~680℃, 倾角40°~60°。

3) 在合理的二次加热工艺条件下, 可获得理想的适于进行触变成形的半固态合金组织。 Al-3%Mg半固态合金坯料二次加热的最优工艺条件为: 加热温度620~630℃, 保温时间90~120min。

4) 制备的半固态Al-3%Mg半固态合金坯料在均匀变形阶段表现出良好的触变性能, 随着保温温度的升高, 触变应力值显著降低。

REFERENCES

[1]Flemming M C. Behavior of metal and alloys in the semi-solid state [J]. Metal Trans A, 1991, 22: 957-969.

[2]Fan Z. Semisolid metal processing[J]. International Materials Reviews, 2002, 47(2): 49-189.

[3]Chino Y, Kobata M, Iwasaki H, et al. An investigation of compressive deformation behavior for AZ91 Mg alloy containing a small volume of liquid [J]. Acta Materialia, 2003, 51: 3309-3318.

[4]罗守靖, 田文彤, 谢水生, 等. 半固态加工技术及应用 [J]. 中国有色金属学报, 2000, 10(6): 765-769.

LUO Shou-jing, TIAN Wen-tong, XIE Shui-sheng, et al. Technology and applications of semi-solid forming [J]. The Chinese Journal of Nonferrous Metals, 2000, 10(6): 765-769.

[5]Luo S J, Tian W T. Structure evolution of LC4 alloy in making thixothropic billet by SIMA method [J]. Trans Nonferrous Met Soc China, 2001, 11(8):547-550.

[6]Song R B, Kang Y L, Sun J L, et al. Investigation of the microstructure of rolled semisolid steel [J]. Journal of Mater Sci Tech, 2002, 18(2): 281-282.

[7]Mao W M, Zhao A M, Yun D, et al. Preparation study of semisolid 60Si2Mn spring steel slurry[J]. Acta Metallurgica Sinica (English Letters), 2003, 16(6): 483-488.

[8]Chen Z H, Zhang H, Kang Z T, et al. Thixoforming of 6066 aluminum alloy by multi-layer spray deposition[J]. Trans Nonferrous Met Soc China, 2001, 11(1): 108-114.

[9]Liu C M, He N J, Li H J. Structure evolution of AlSi6.5Cu2.8Mg alloy in semisolid remelting processing[J]. J of Mate Sci, 2001, 36: 1-5.

[10]Xu X M, Zheng H X, Yuan S, et al. Recrystallization of preformed AZ91D magnesium alloys in the semisolid state[J]. Materials and Design, 2005, 26: 343-349.

[11]Kaufmann H, Mundi A, Uggowitzer P J. An update on the new rheocasting development work for Al- and Mg- alloys[J]. Die Casting Engineer, 2002, 4: 16-19.

[12]Motegi T, Yano E, Nishikawa N. New semisolid process of magnesium alloys[A]. Proceedings of the 2th Inter Conf on Light Materials for Transportation Systems, LiMAT-2001, CAAM[C]. Pusan, South Korea: CAAM, 2001. 185-190.

[13]Haga T. Semisolid strip casting using a twin roll caster with a cooling slope[J]. J of Mater Proc Tech, 2002, 130: 558-561.

[14]Haga T, Kenta T, Masaaki I. Twin roll casting aluminum alloy strips[J]. J of Mater Proc Tech, 2004, 153: 42-47.

[15]管仁国, 李俊鹏, 徐永昌, 等. 冷却剪切流变对Al-Mg合金组织的影响[J]. 轻合金加工技术, 2004, 32(11): 15-18.

GUAN Ren-guo, LI Jun-peng, XU Yong-chang, et al. Effect of rheocasting by inclined cooling and shearing on microstructures of Al-Mg-based alloy[J]. Light Alloy Fabrication Technology, 2004, 32(11): 15-18.

[16]管仁国, 李俊鹏, 石路, 等. 倾斜式冷却剪切流变制备半固态Al-Mg合金[J]. 东北大学学报(自然科学版), 2005, 26(5): 448-451.

GUAN Ren-guo, LI Jun-peng, SHI Lu, et al. Preparation of Al-Mg-based semisolid alloy by inclined cooling/shearing[J]. J Northeastern University (Natural Science), 2005, 26(5): 448-451.

基金项目: 辽宁省自然科学基金资助项目(20041006); 国家自然科学基金与宝钢联合资助项目(50274020); 教育部留学归国基金资助项目

收稿日期: 2005-09-08; 修订日期: 2005-12-09

通讯作者: 管仁国, 副教授; 电话:024-83686459, 024-83681463; E-mail: guanrenguo@126.com

(编辑陈爱华)